The Complete Guide to Wiring, Updated 6th Edition: Current with 2014-2017 Electrical Codes - Black & Decker, Cool Springs Press (2014)

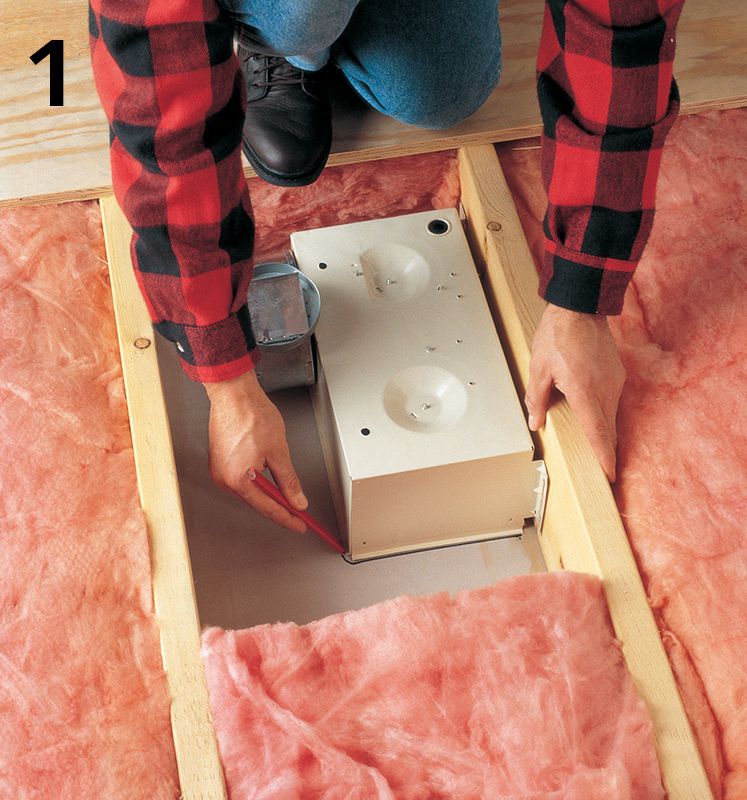

Chapter 8. Common Wiring Projects

The instructions that follow show you how to accomplish the most popular home wiring projects. Refer to pertinent sections elsewhere in the book to find background information on tools and skills needed to get the job done.

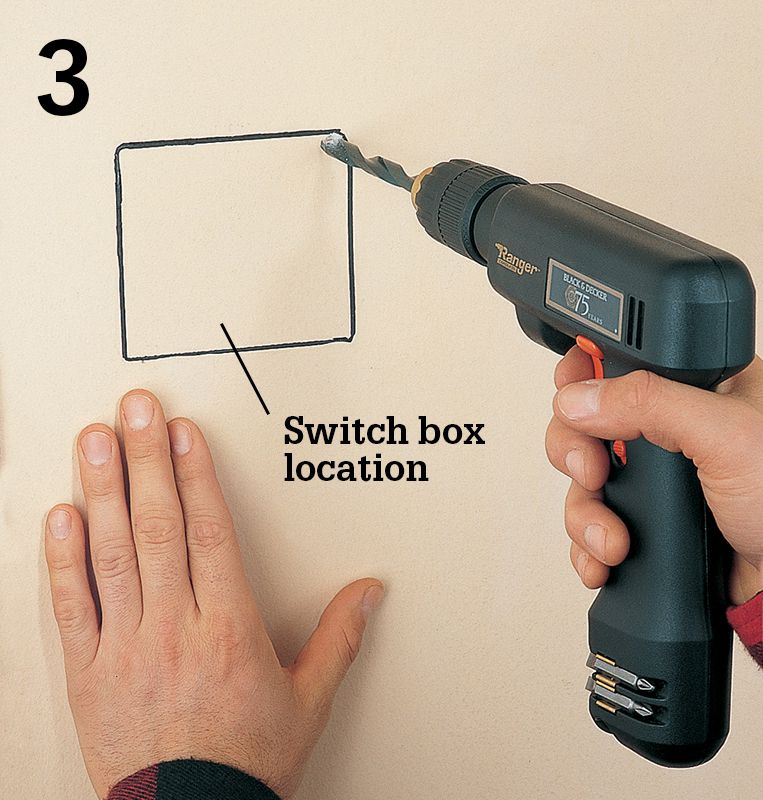

In this chapter:

![]() GFCI & AFCI Breakers

GFCI & AFCI Breakers

![]() Whole-House Surge Arrestors

Whole-House Surge Arrestors

![]() Service Panels

Service Panels

![]() Grounding & Bonding a Wiring System

Grounding & Bonding a Wiring System

![]() Subpanels

Subpanels

![]() 120/240-Volt Dryer Receptacles

120/240-Volt Dryer Receptacles

![]() 120/240-Volt Range Receptacles

120/240-Volt Range Receptacles

![]() Ceiling Lights

Ceiling Lights

![]() Recessed Ceiling Lights

Recessed Ceiling Lights

![]() Track Lights

Track Lights

![]() Undercabinet Lights

Undercabinet Lights

![]() Vanity Lights

Vanity Lights

![]() Low-Voltage Cable Lights

Low-Voltage Cable Lights

![]() Hard-Wired Smoke & CO Alarms

Hard-Wired Smoke & CO Alarms

![]() Landscape Lights

Landscape Lights

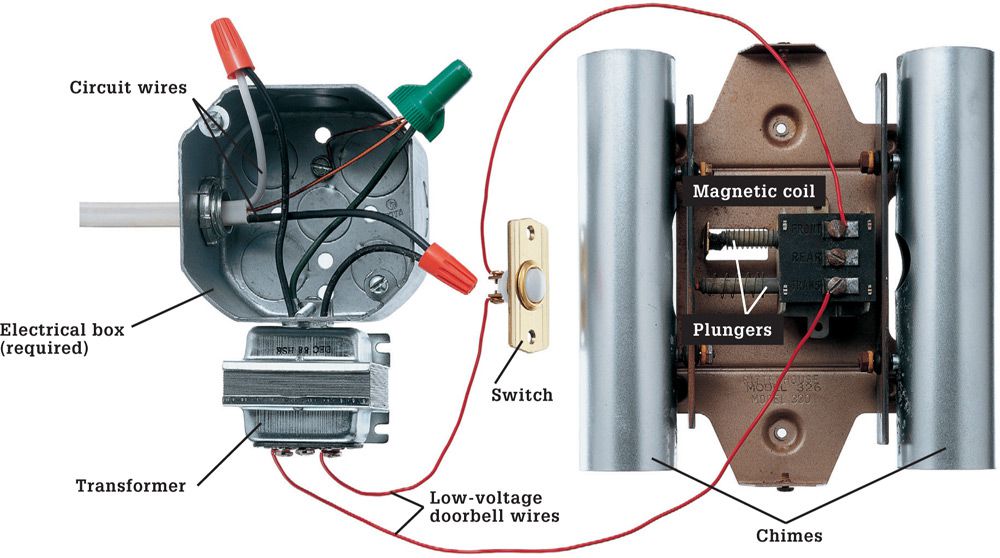

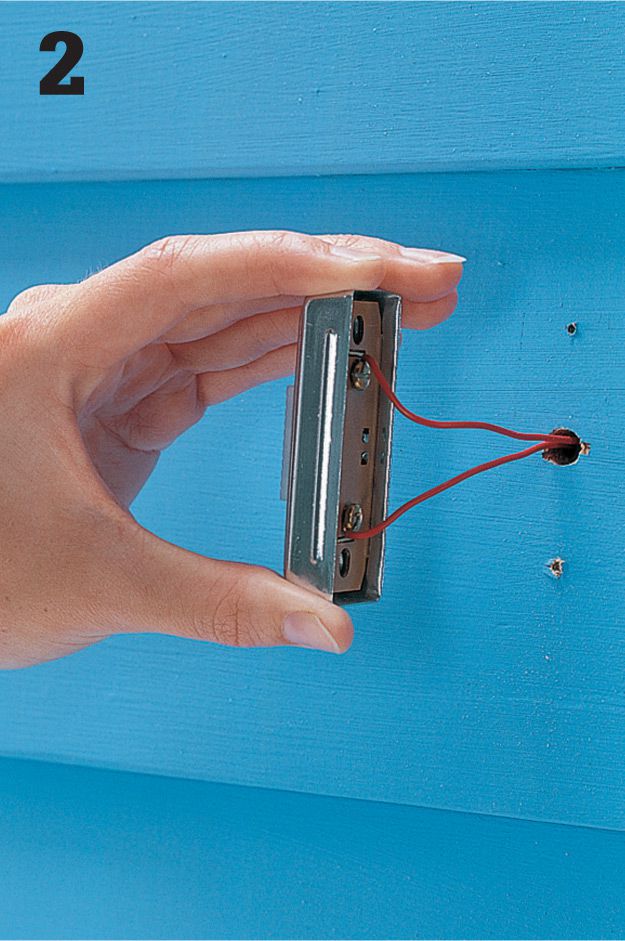

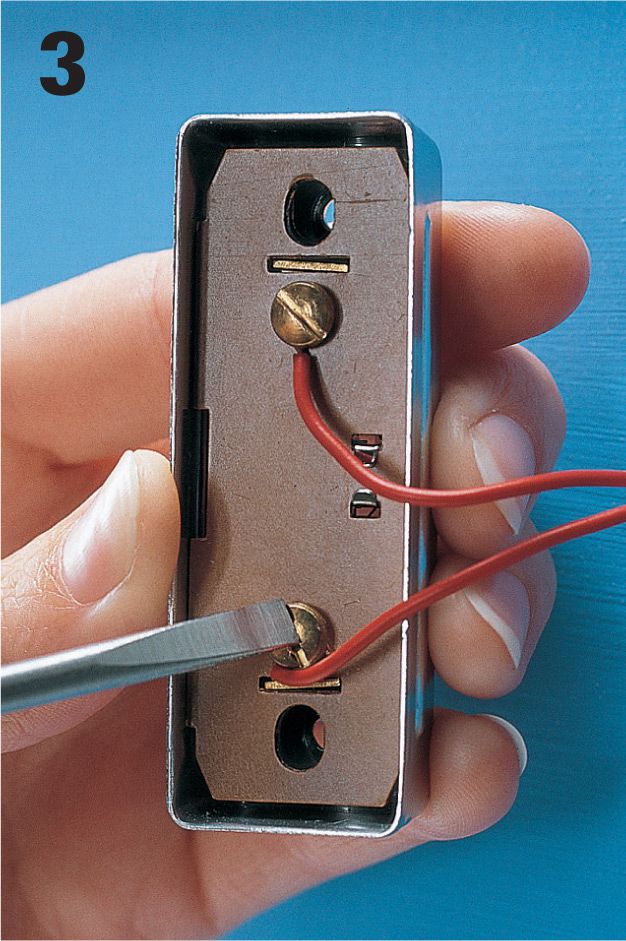

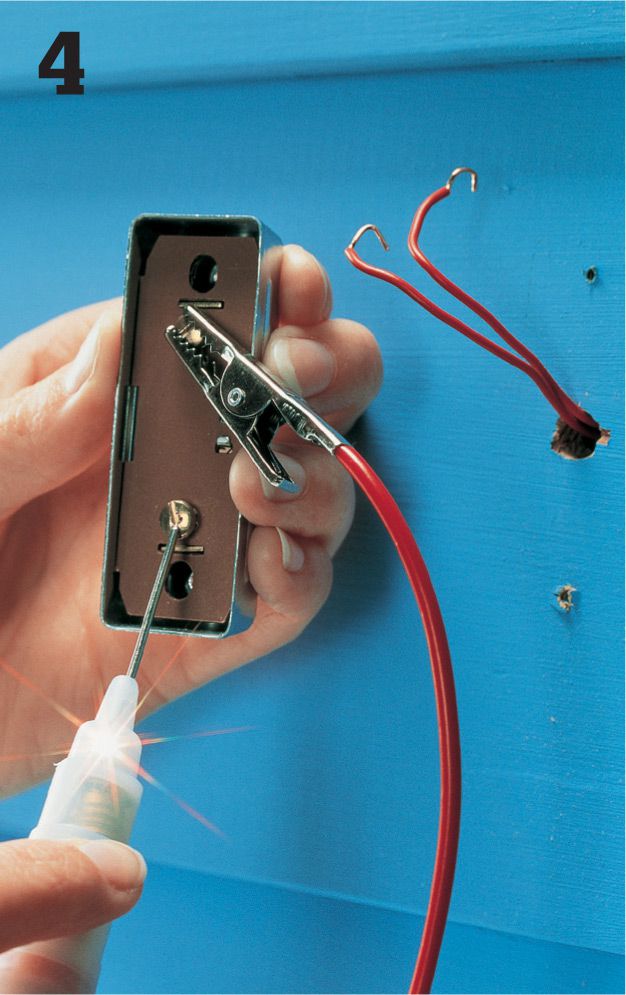

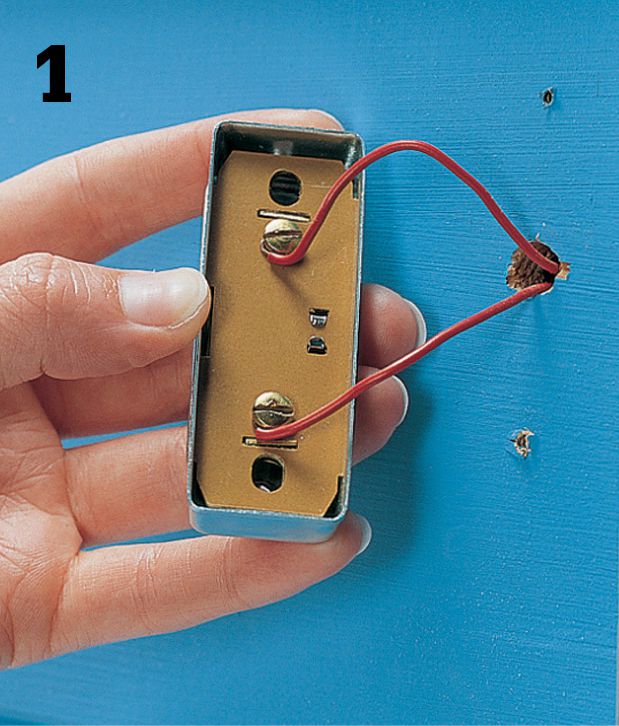

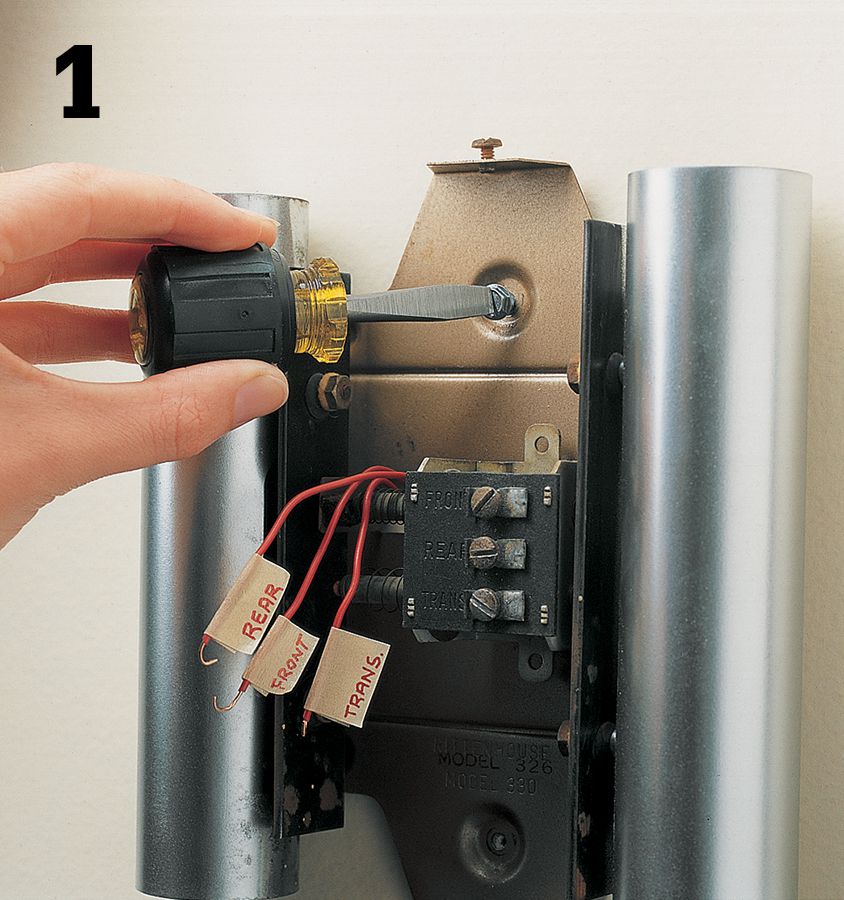

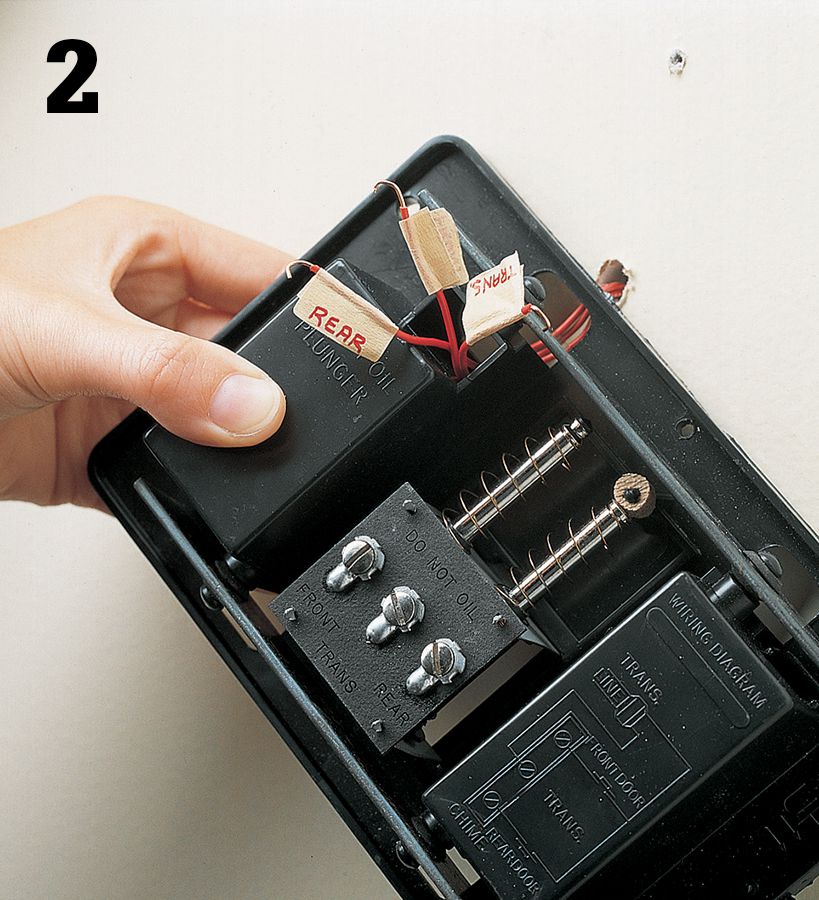

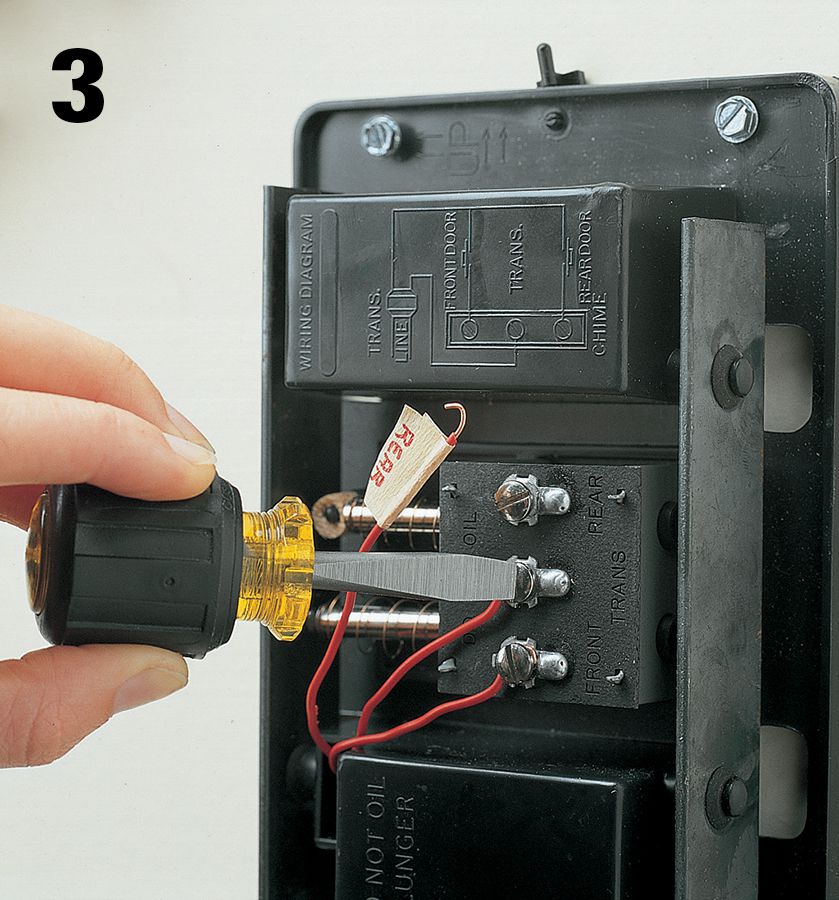

![]() Doorbells

Doorbells

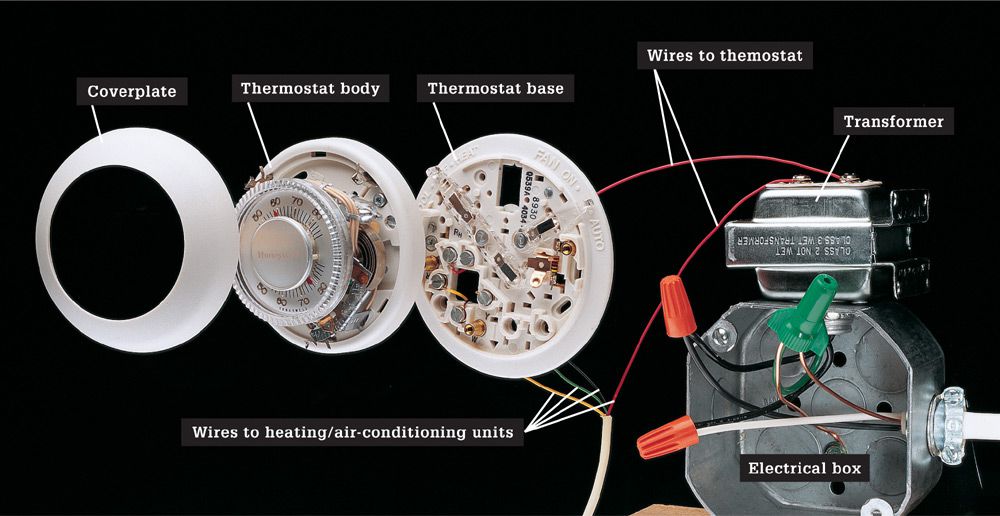

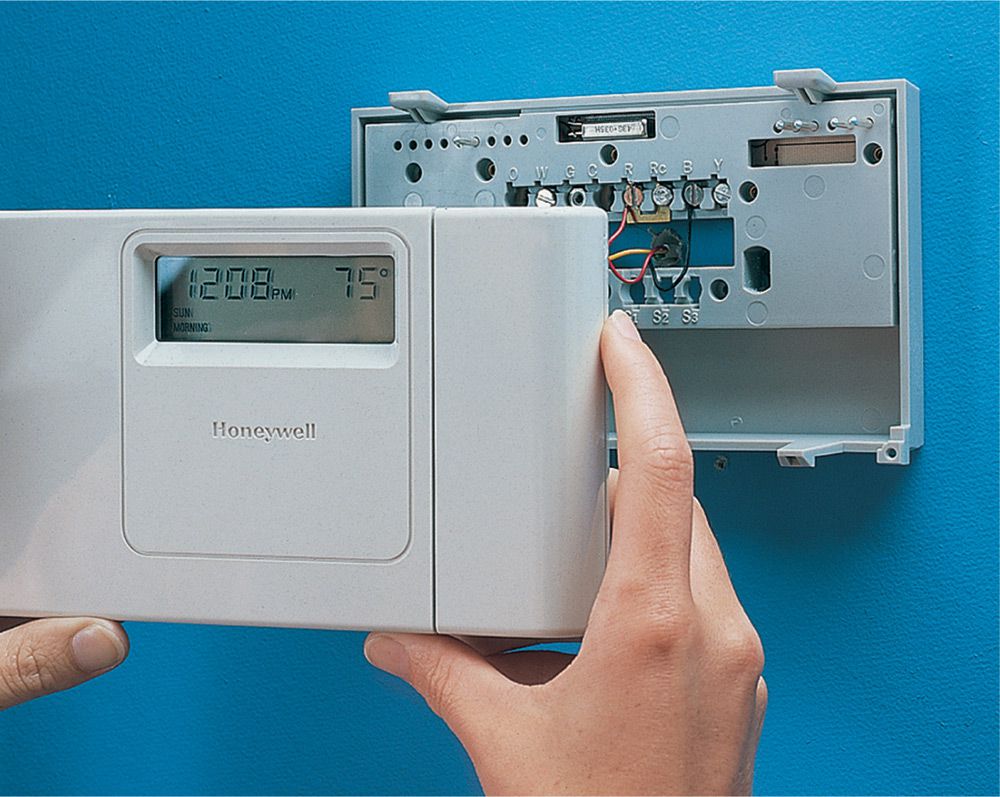

![]() Programmable Thermostats

Programmable Thermostats

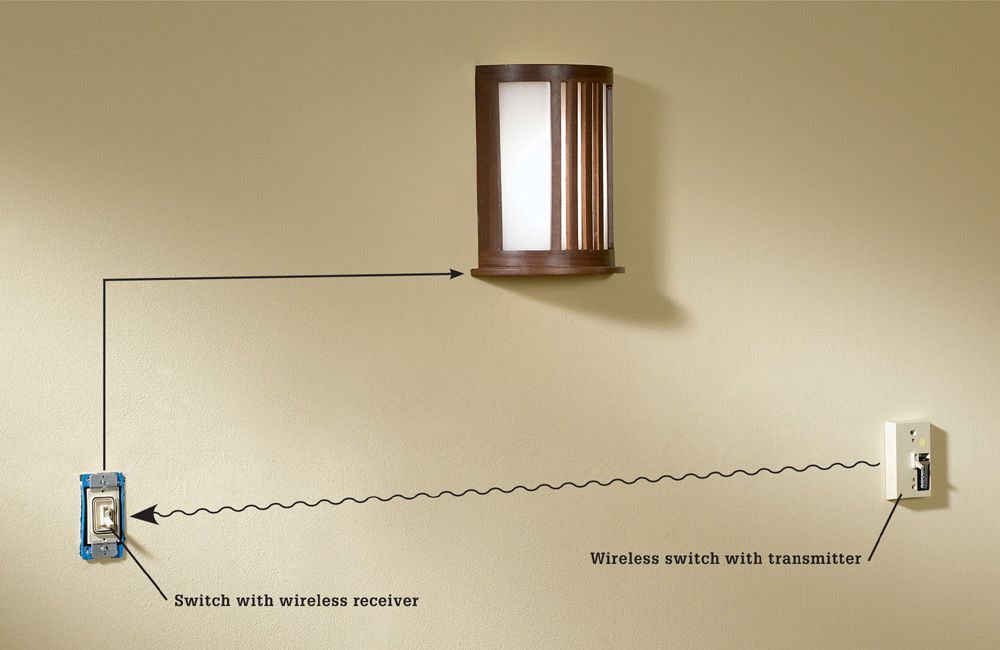

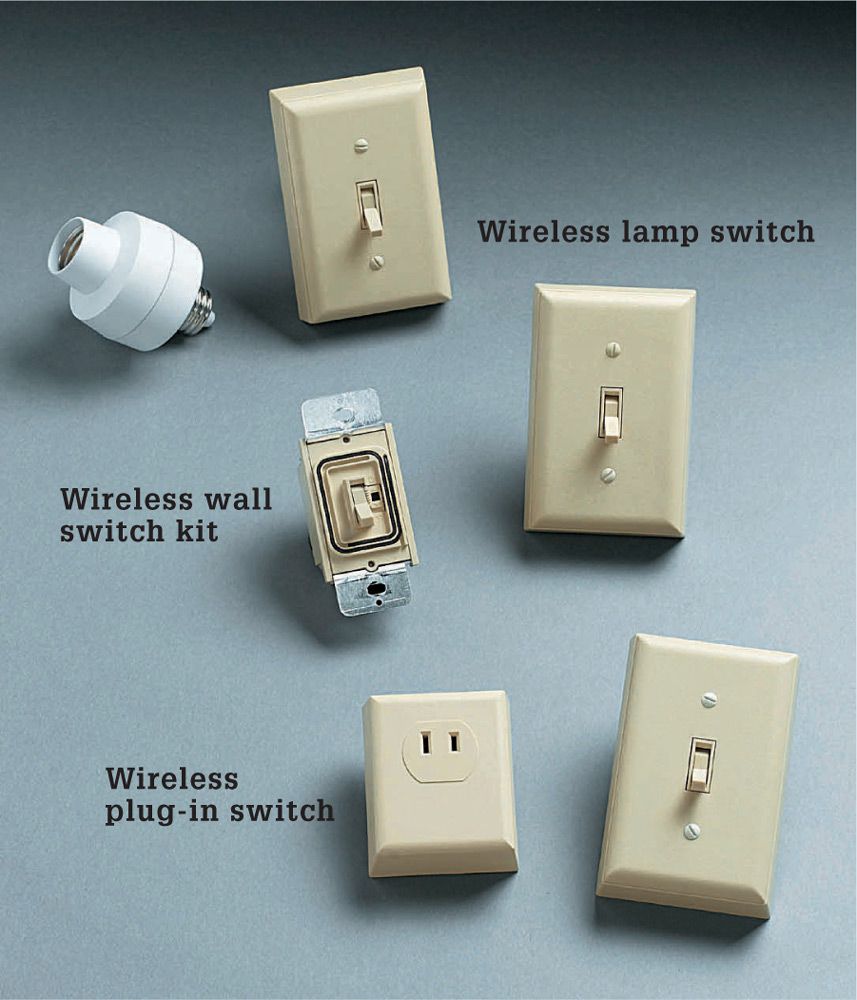

![]() Wireless Switches

Wireless Switches

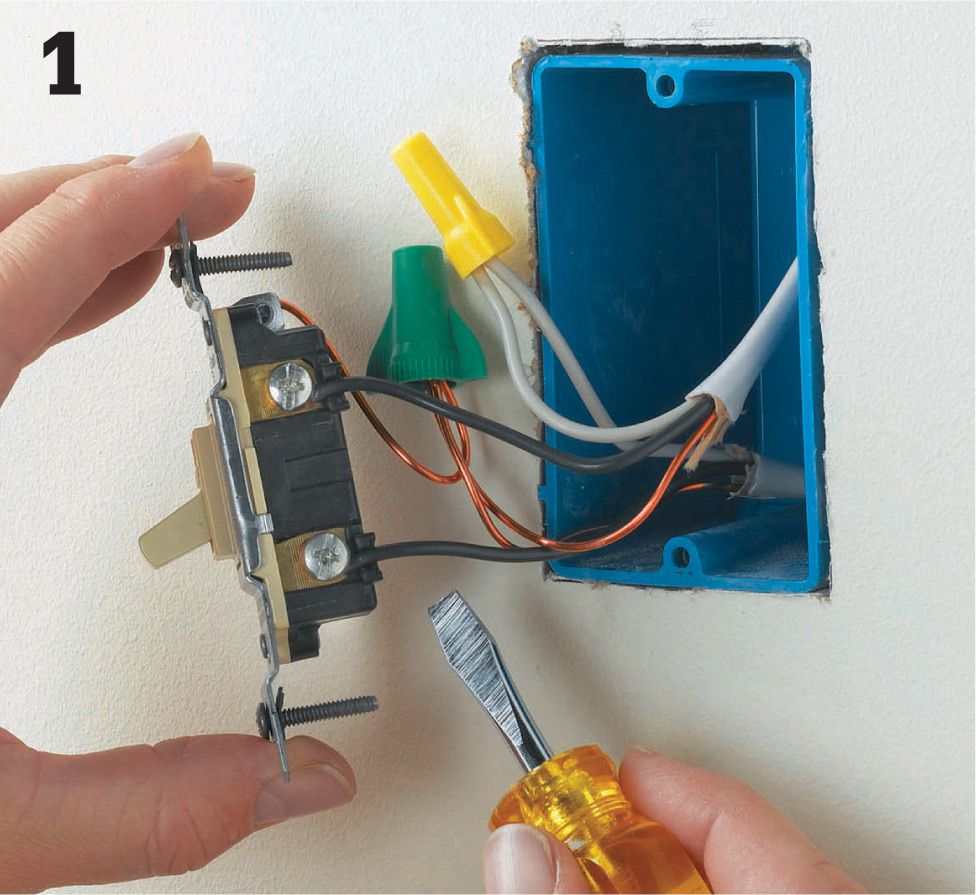

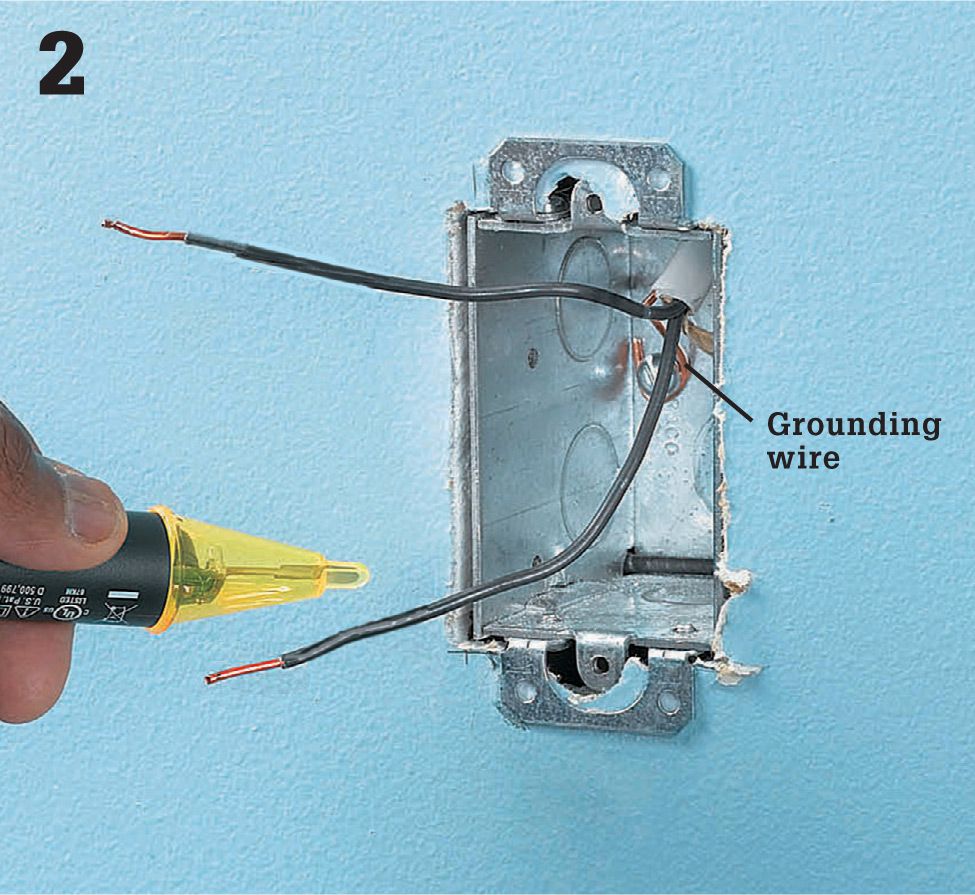

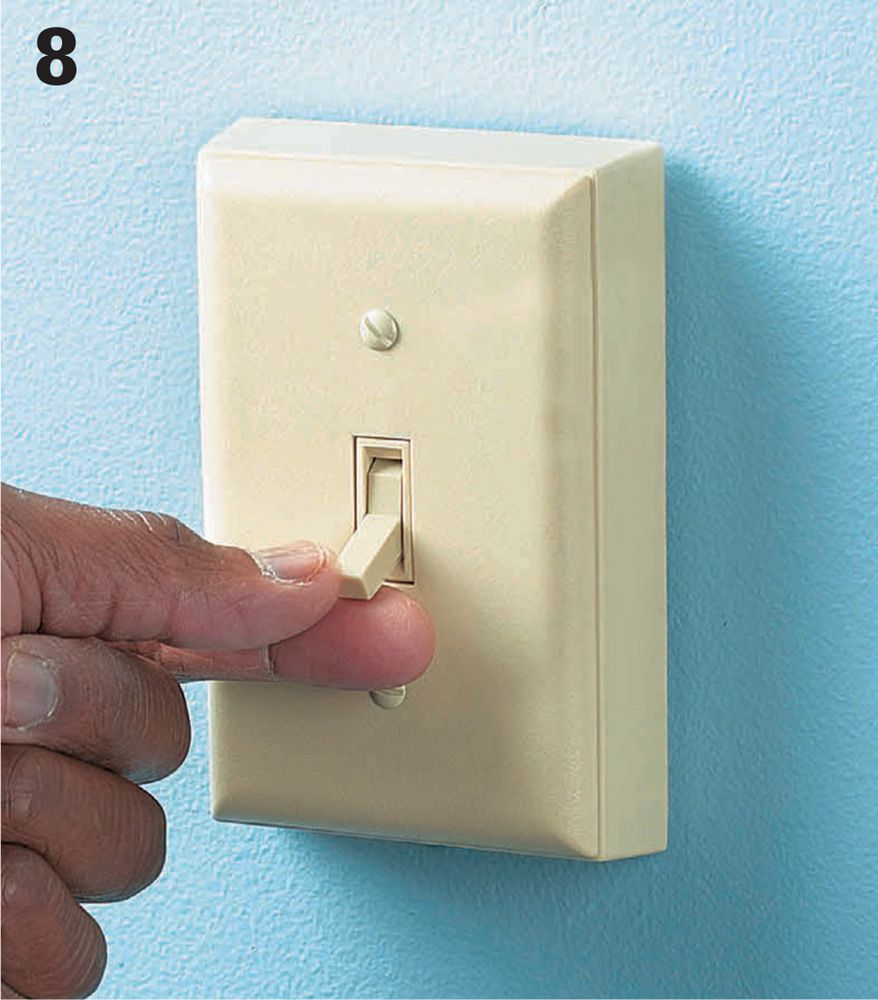

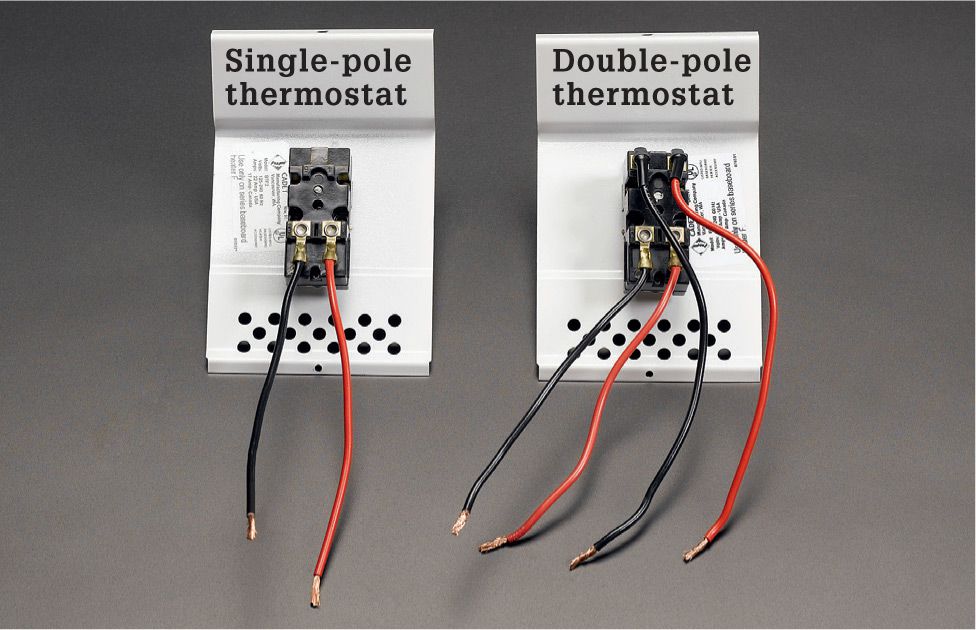

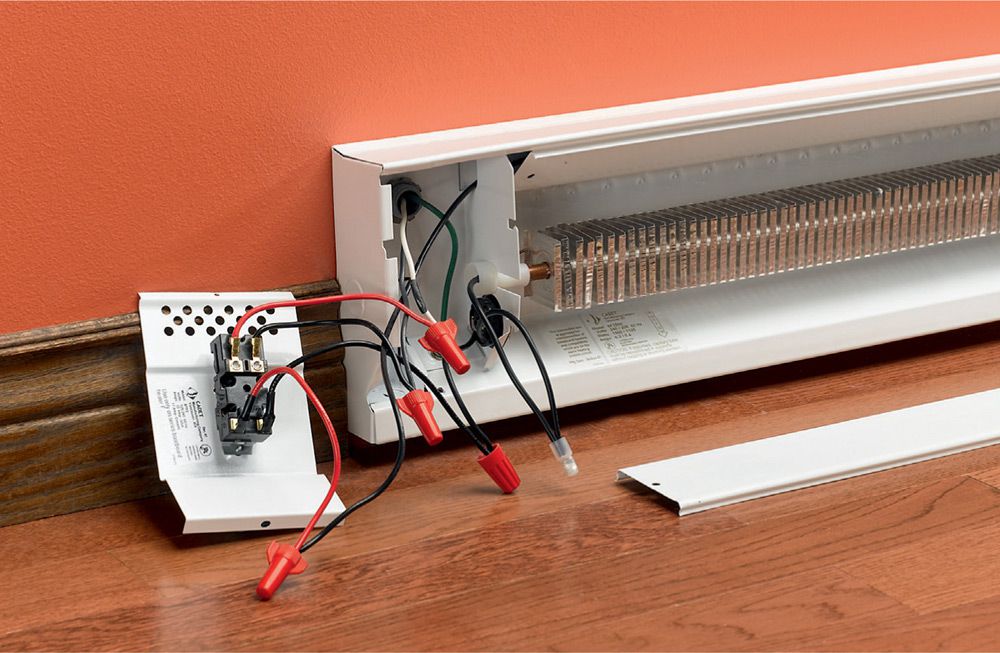

![]() Baseboard Heaters

Baseboard Heaters

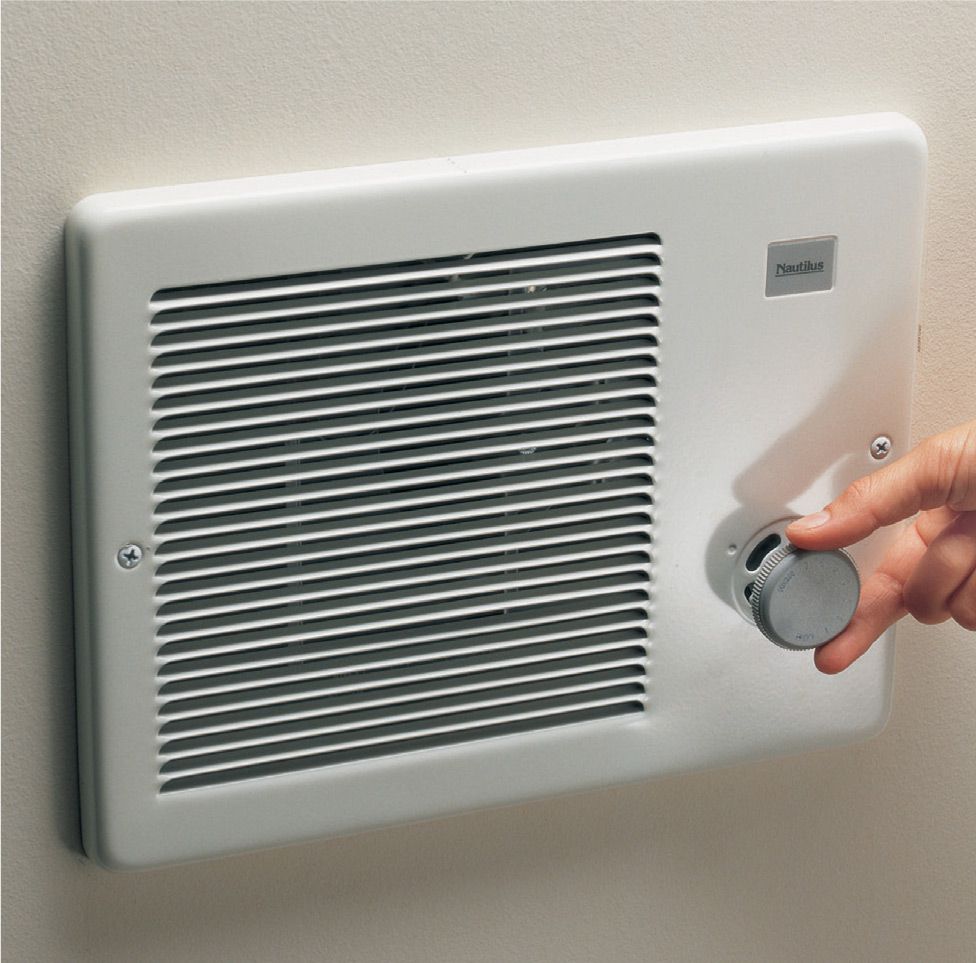

![]() Wall Heaters

Wall Heaters

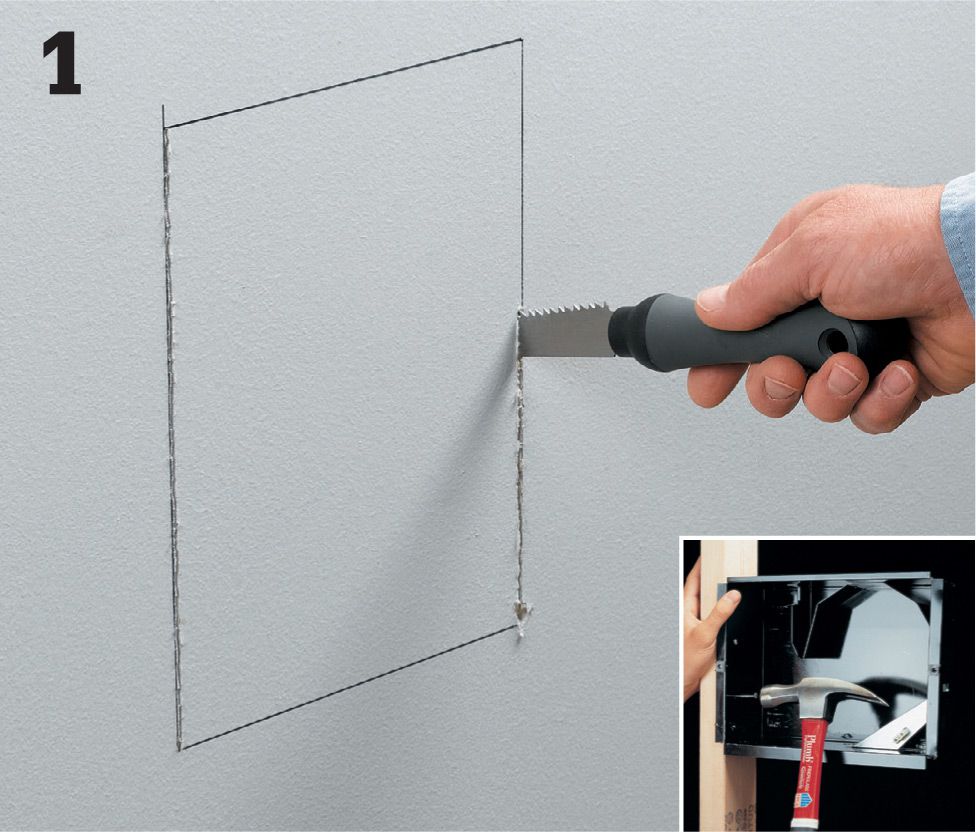

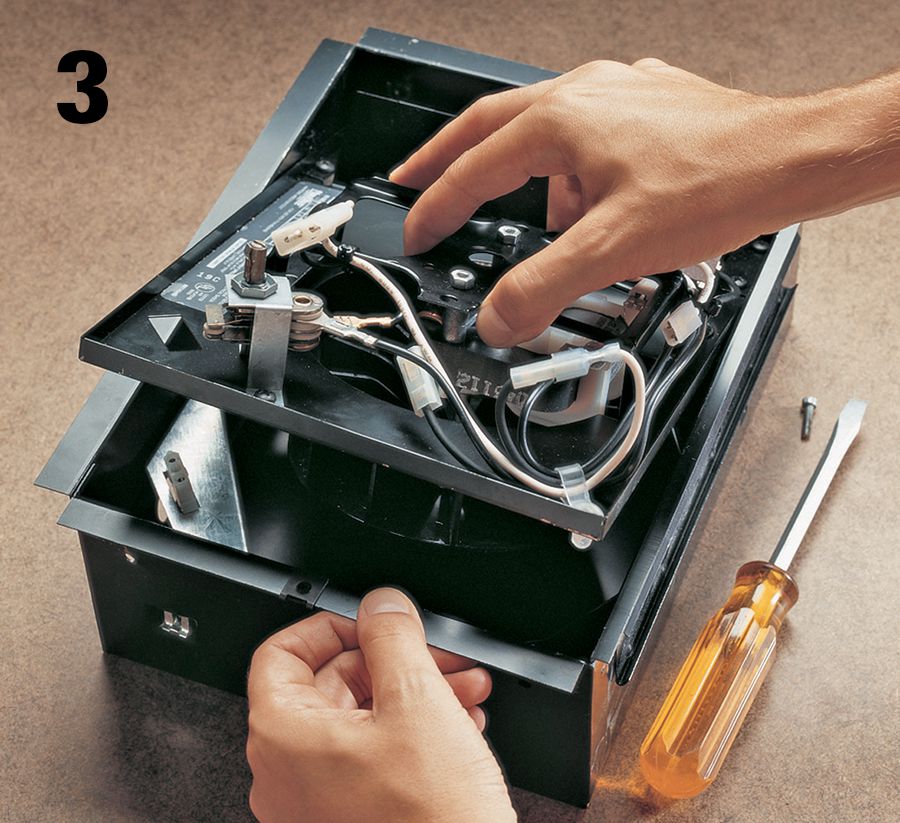

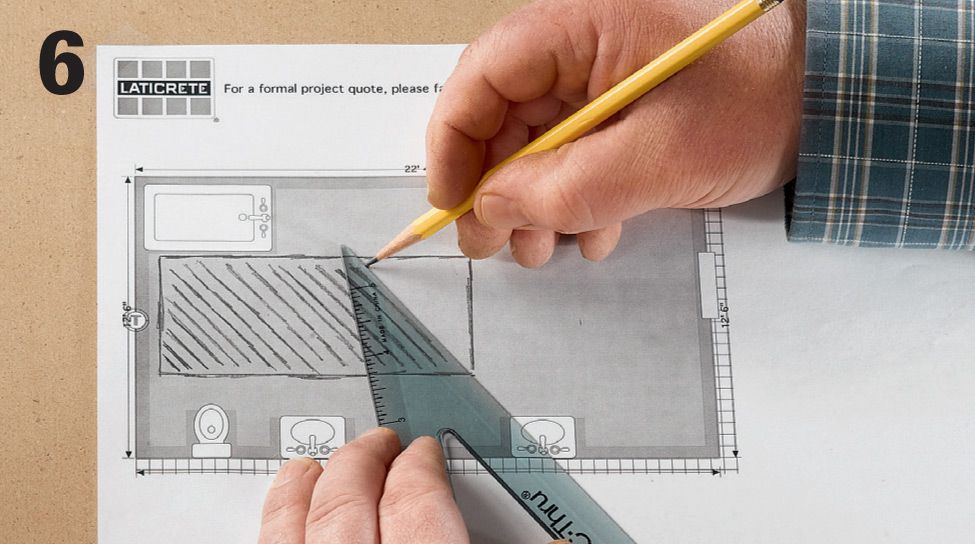

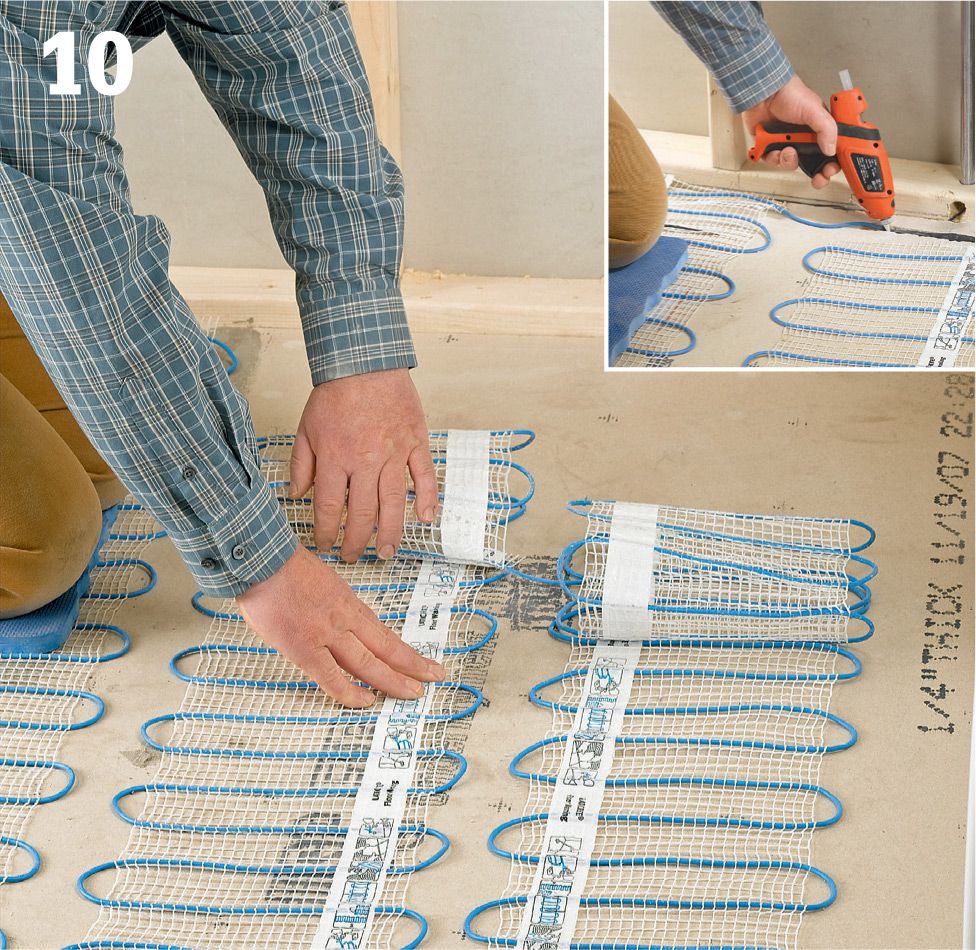

![]() Underfloor Radiant Heat Systems

Underfloor Radiant Heat Systems

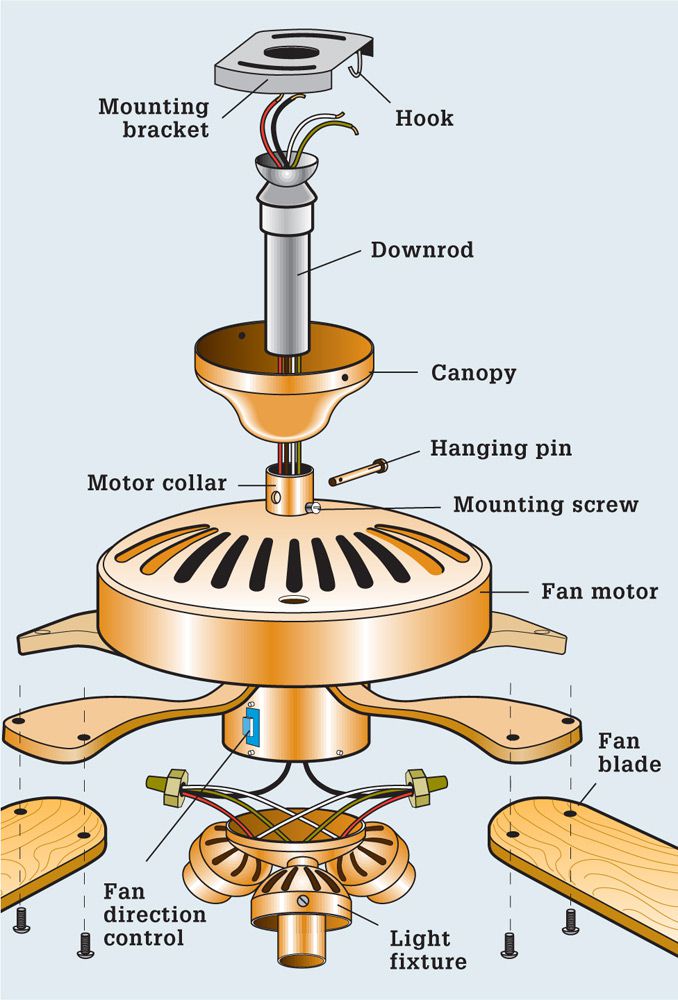

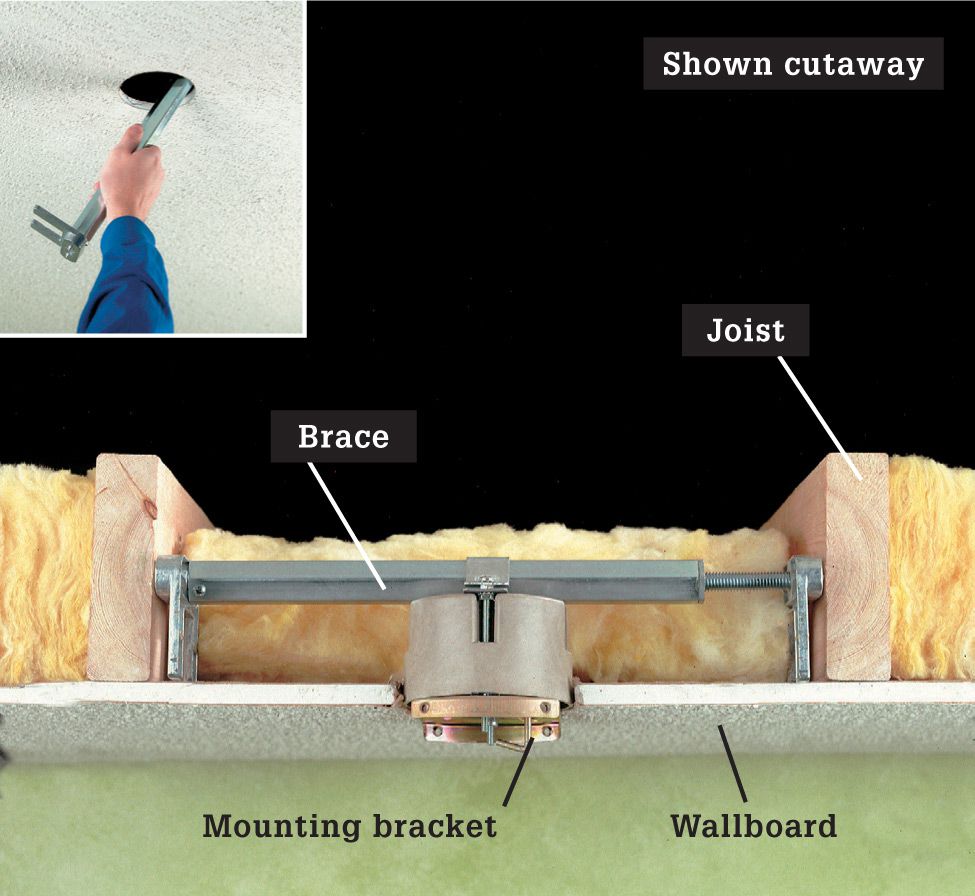

![]() Ceiling Fans

Ceiling Fans

![]() Remote-Control Ceiling Fan Retrofit

Remote-Control Ceiling Fan Retrofit

![]() Bathroom Exhaust Fans

Bathroom Exhaust Fans

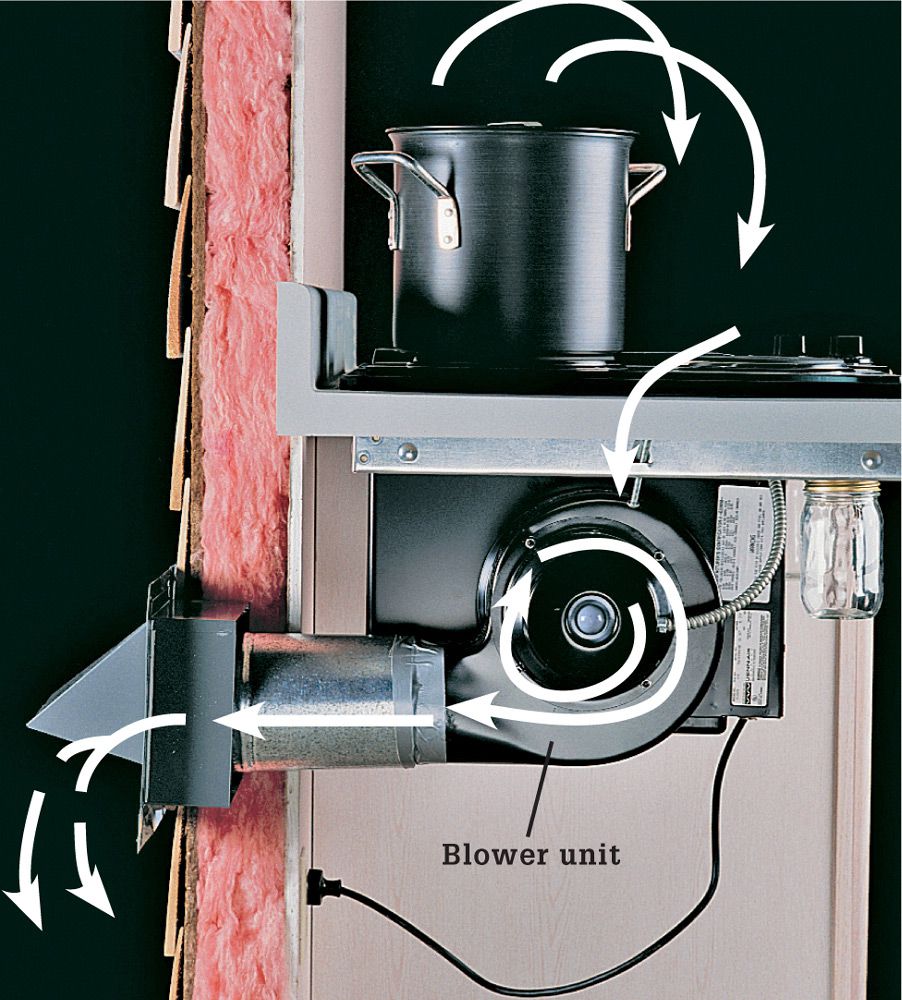

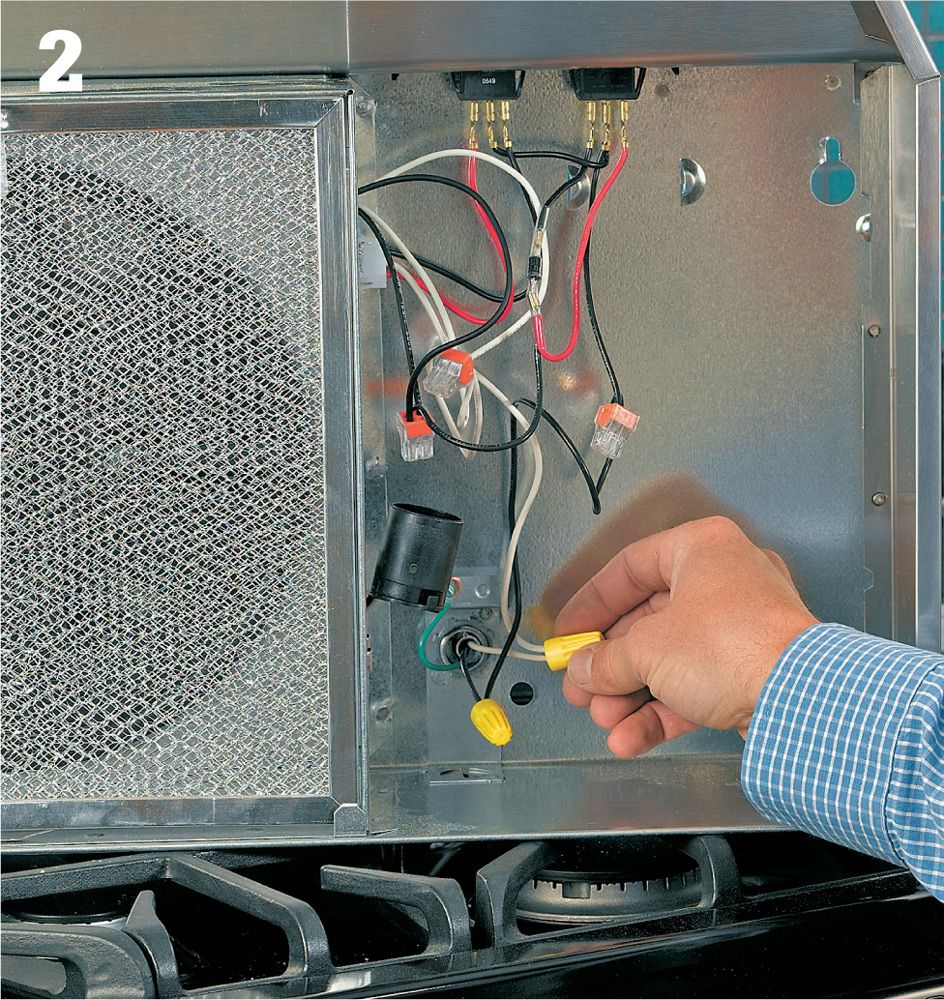

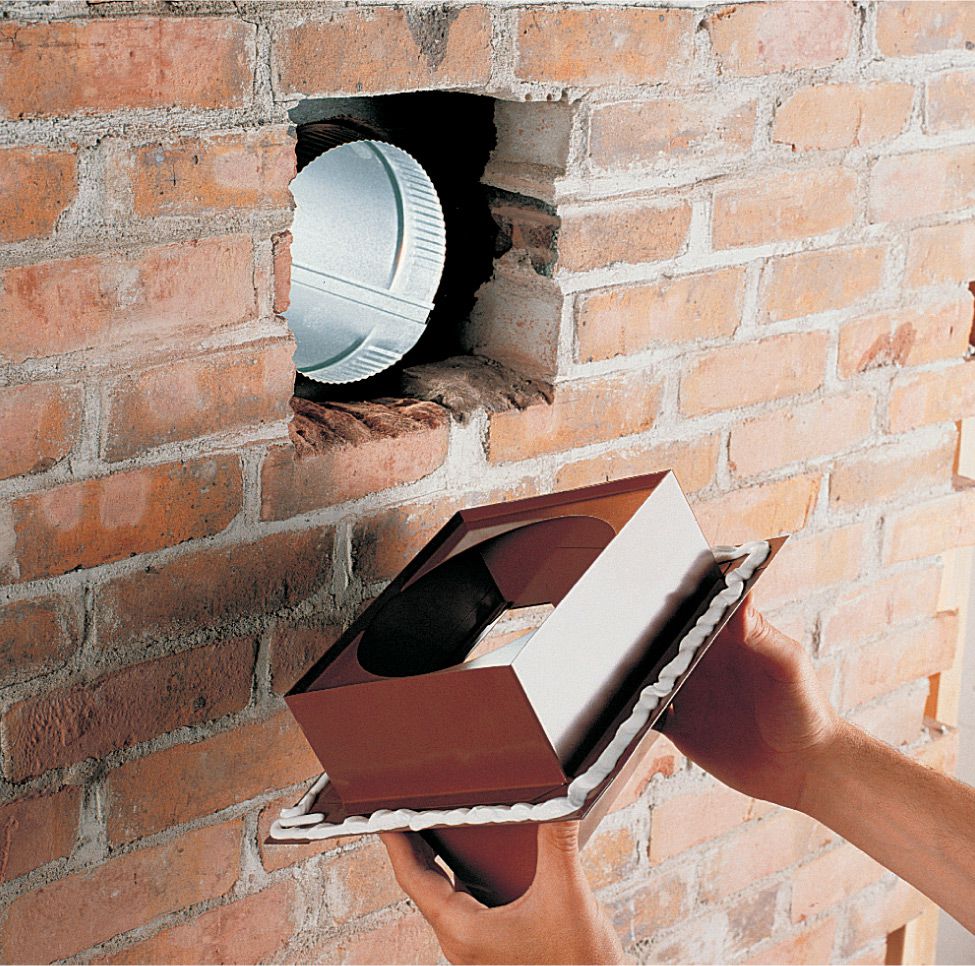

![]() Range Hoods

Range Hoods

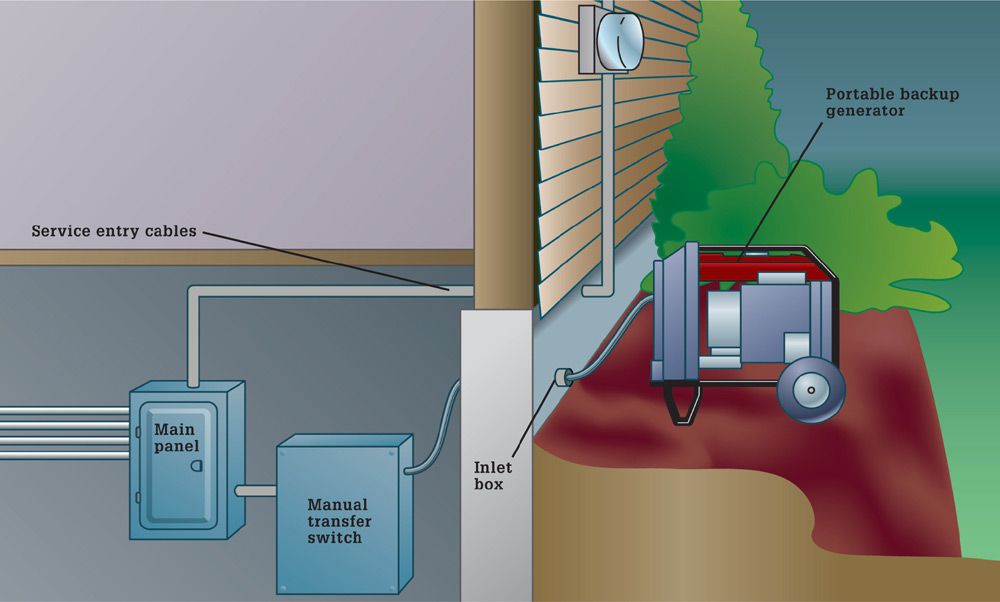

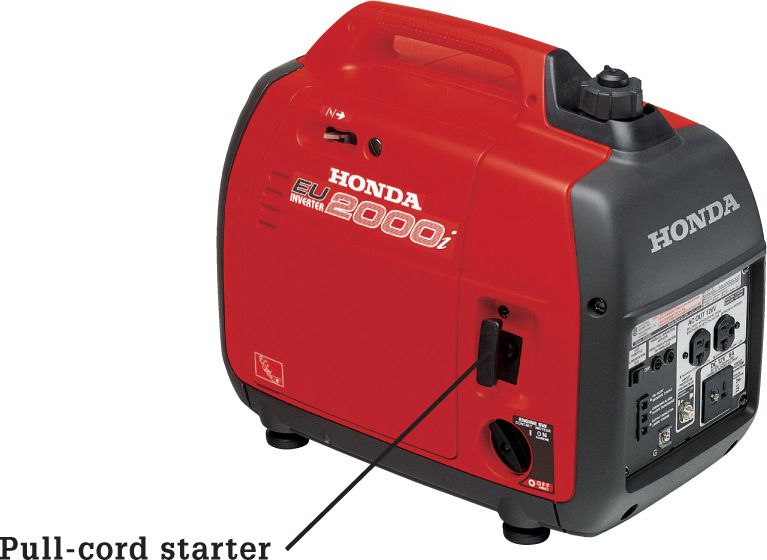

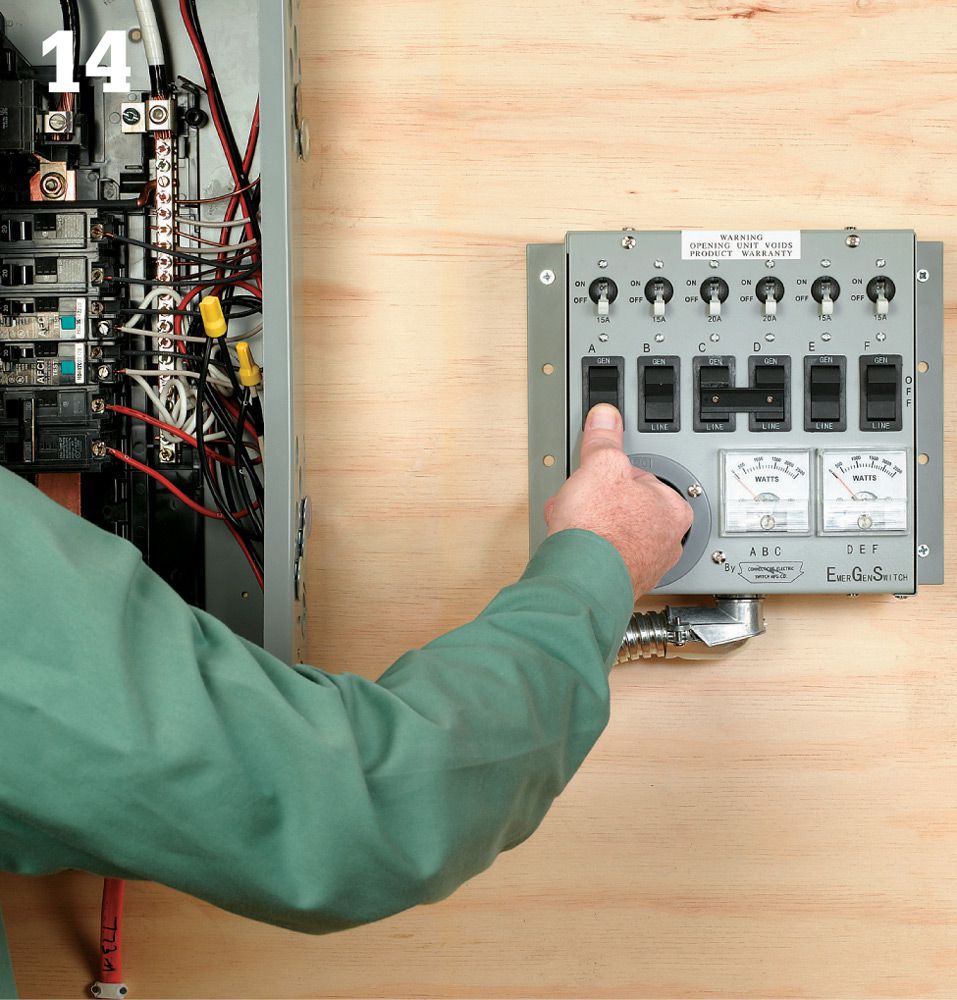

![]() Backup Power Supply

Backup Power Supply

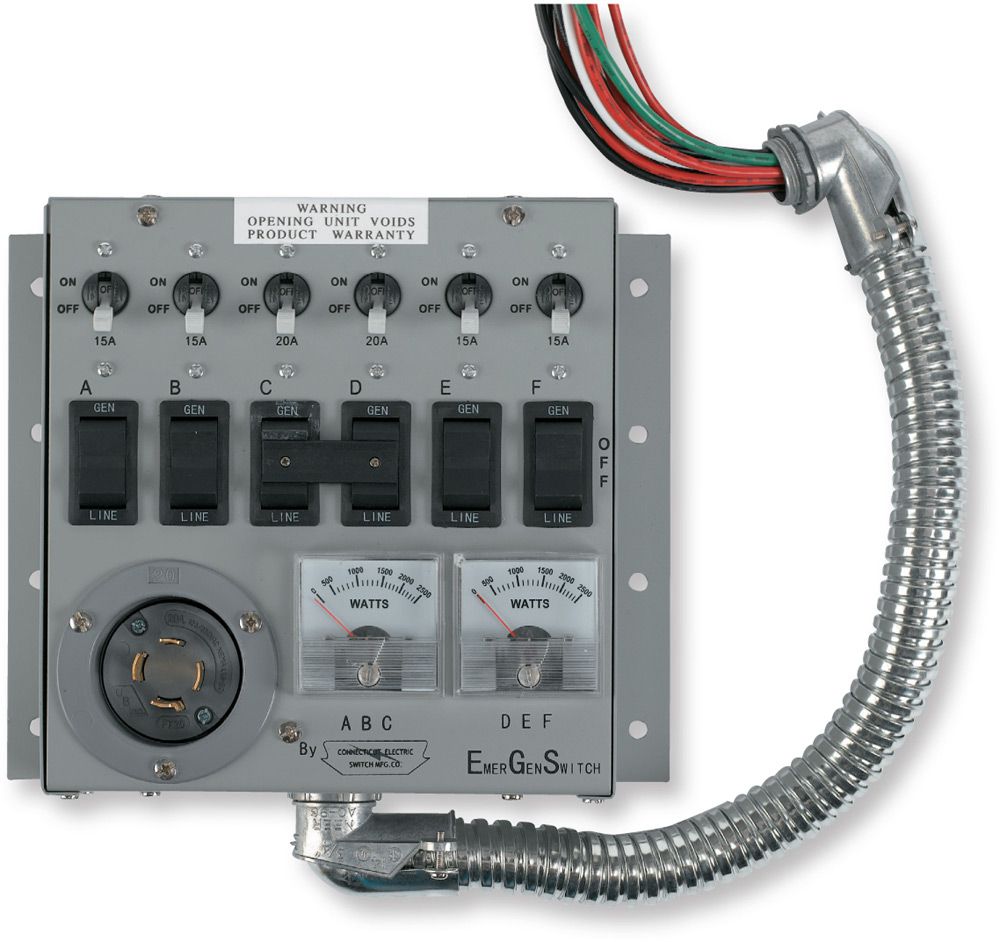

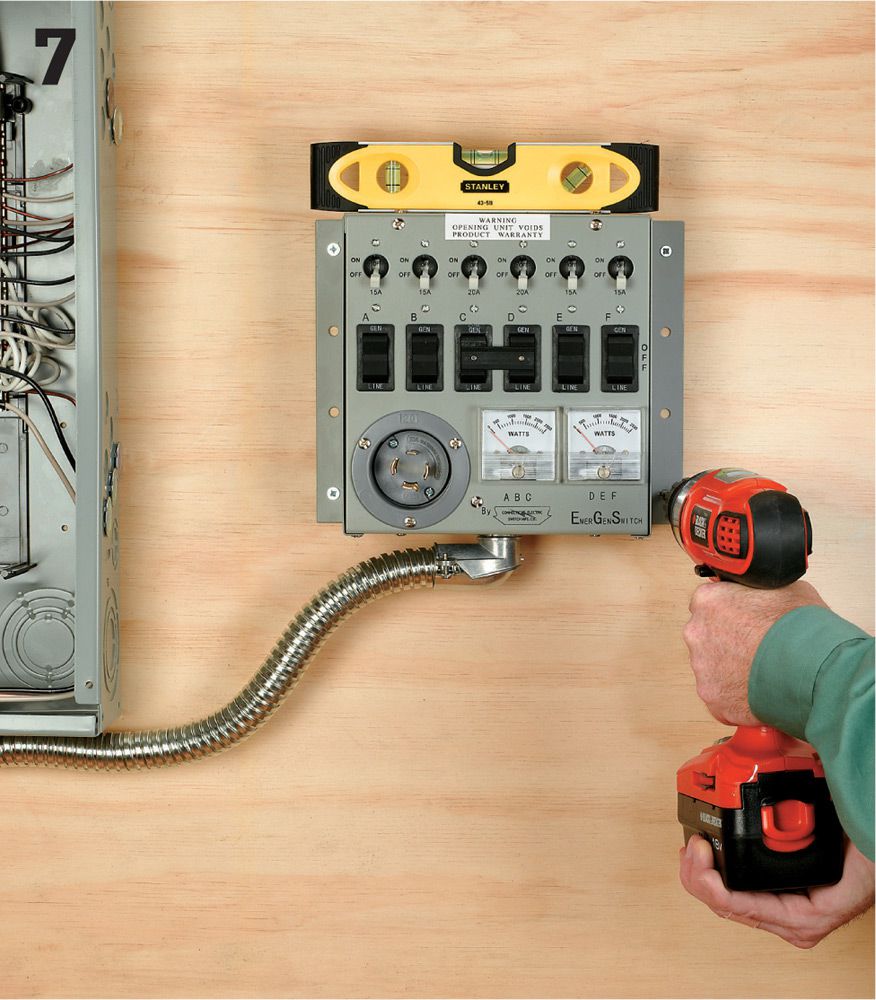

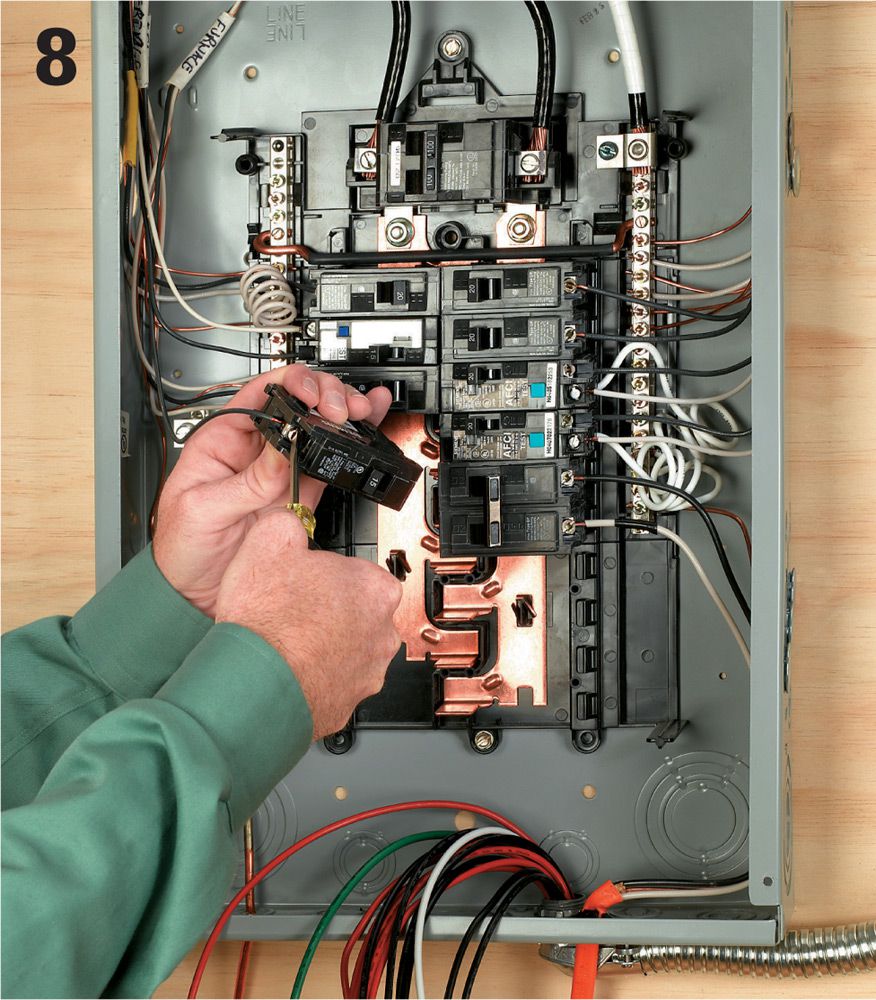

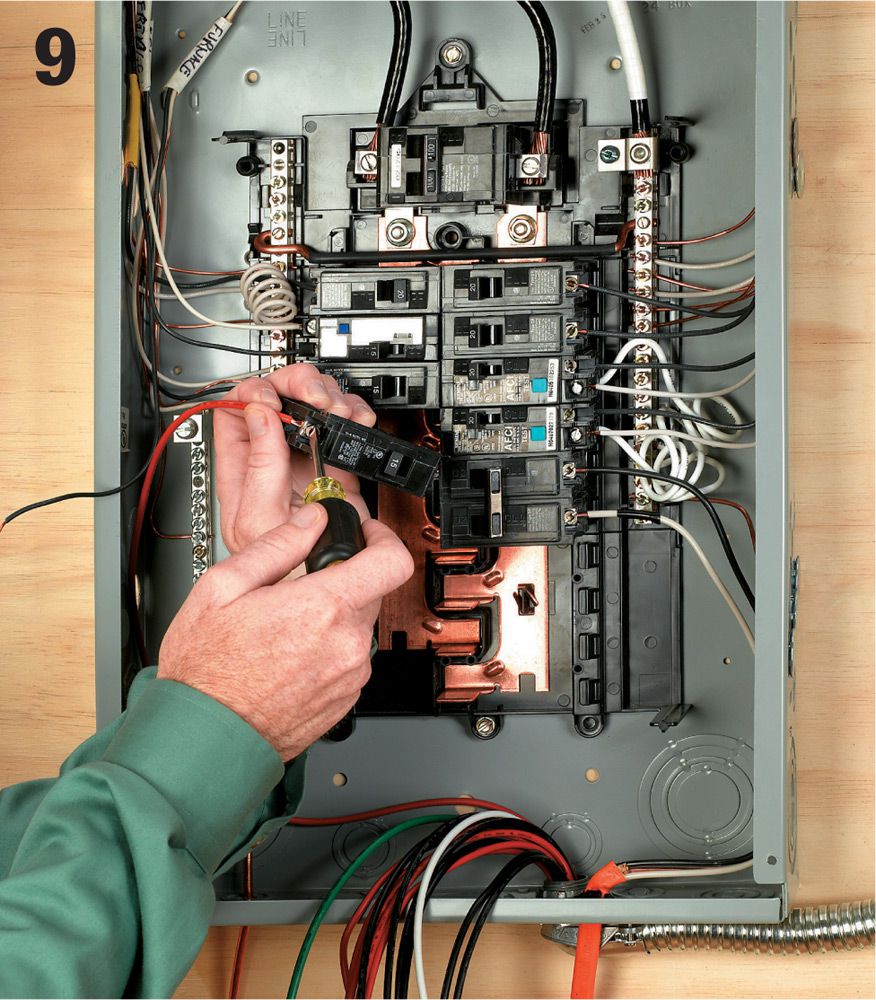

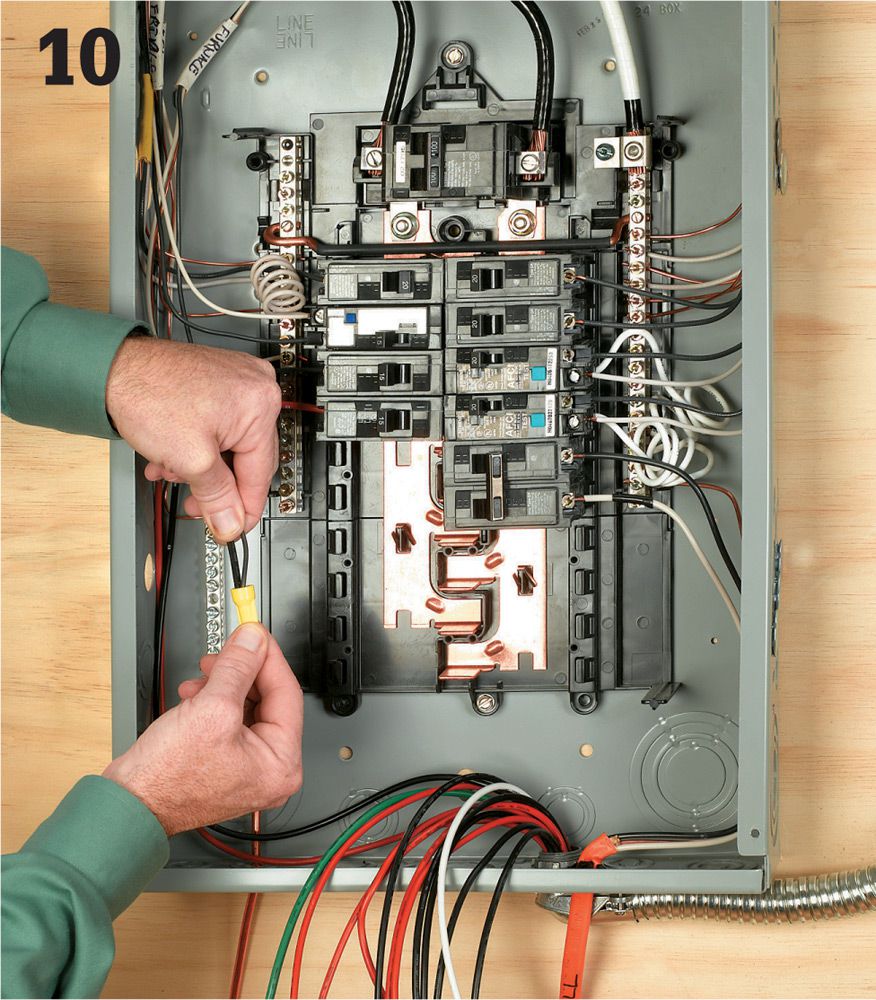

![]() Installing a Transfer Switch

Installing a Transfer Switch

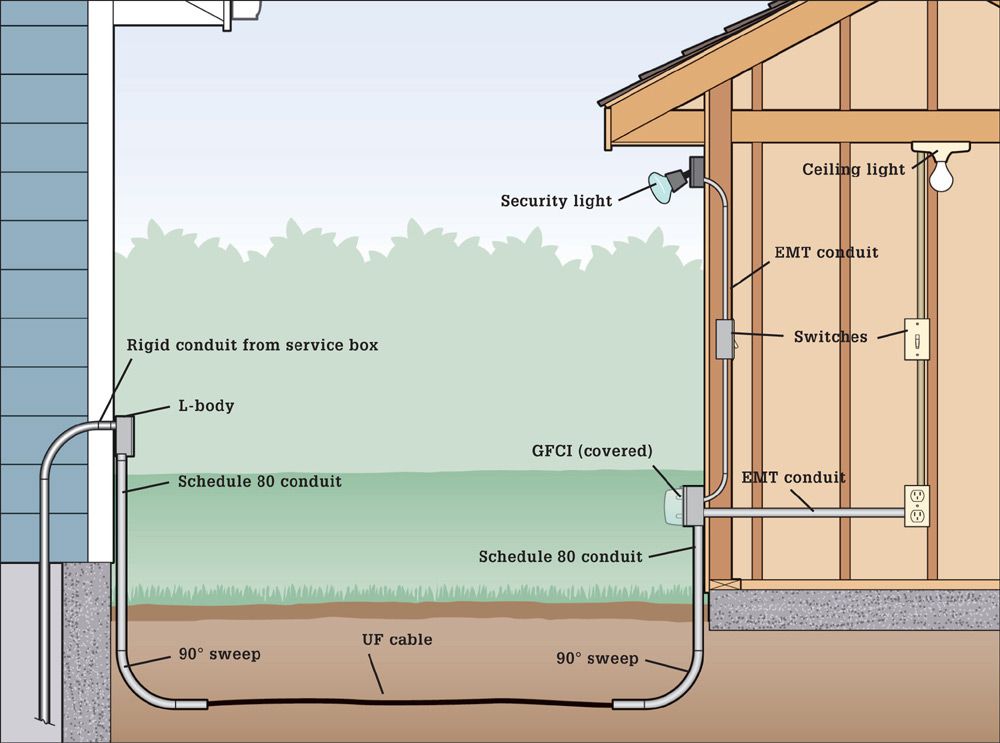

![]() Outbuildings

Outbuildings

![]() Motion-Sensing Floodlights

Motion-Sensing Floodlights

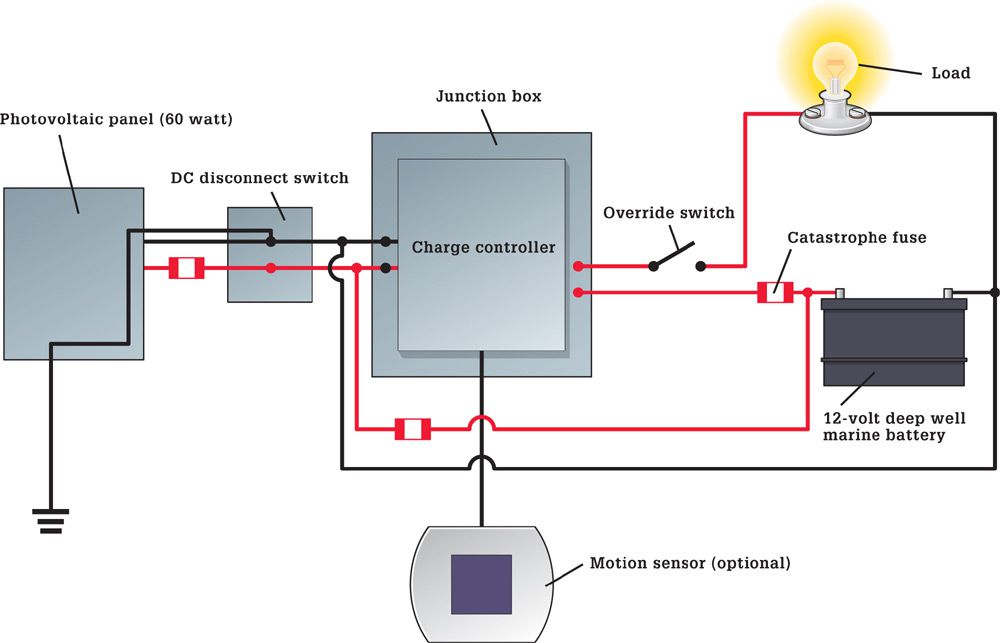

![]() Standalone Solar Lighting System

Standalone Solar Lighting System

![]() GFCI & AFCI Breakers

GFCI & AFCI Breakers

Understanding the difference between GFCI (ground-fault circuit interrupter) and AFCI (arc fault circuit interrupter) is tricky for most homeowners. Essentially it comes down to this: Arc-fault interrupters keep your house from burning down; ground-fault interrupters keep people from being electrocuted.

The National Electric Code (NEC) requires that an AFCI breaker be installed on most branch circuits that supply outlets or fixtures in newly constructed homes. The NEC also requires adding AFCI protection to these circuits when you add new circuits and modify or extend existing circuits. They’re a prudent precaution in any home, especially if it has older wiring. AFCI breakers will not interfere with the operation of GFCI receptacles, so it is safe to install an AFCI breaker on a circuit that contains GFCI receptacles.

GROUND-FAULT CIRCUIT-INTERRUPTERS

A GFCI is an important safety device that disconnects a circuit in the event of a ground fault (when current takes a path other than the neutral back to the panel).

On new construction, GFCI protection is required for receptacles in these locations: kitchen counter tops, bathrooms, garages, unfinished basements, crawlspaces, outdoors, within six feet of sinks, and in unfinished accessory buildings such as storage and work sheds. In general it is a good practice to protect all receptacle and fixture locations that could encounter damp or wet circumstances.

Tools & Materials ![]()

Insulated screwdriver

Circuit tester

Combination tool

AFCI or GFCI breaker

ARC-FAULT CIRCUIT INTERRUPTERS

AFCIs detect arcing (sparks) that can cause fires between and along damaged wires. AFCI protection is required for 15- and 20-amp, 120-volt circuits that serve living rooms, family rooms, dens, parlors, libraries, dining rooms, bedrooms, sun rooms, kitchens, laundry areas, closets, and hallways. AFCI protection is not required for circuits serving bathrooms, garages, the exterior of the home, appliances such as furnaces and air handlers.

The easiest way to provide AFCI protection for a circuit is to install an AFCI circuit breaker labeled as a “combination” device in the electrical panel. The 2014 NEC allows several alternate methods of providing AFCI protection, but you should consult an electrician before using these alternate methods. You should install combination AFCI circuit breakers when installing new circuits that require AFCI protection. You should install either combination AFCI circuit breakers or AFCI receptacles when you modify, replace, or extend an existing circuit that requires AFCI protection.

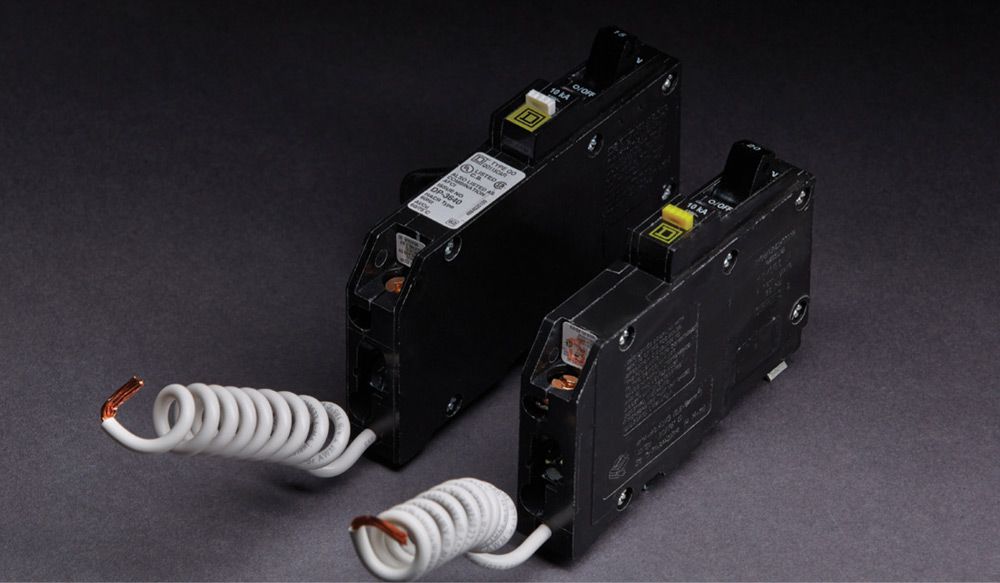

AFCI breakers are similar in appearance to GFCI breakers, but they function differently. AFCI breakers trip when they sense an arc fault. GFCI breakers trip when they sense fault between the hot wire and the ground.

An AFCI-protected receptacle

![]() How to Install an AFCI or GFCI Breaker

How to Install an AFCI or GFCI Breaker

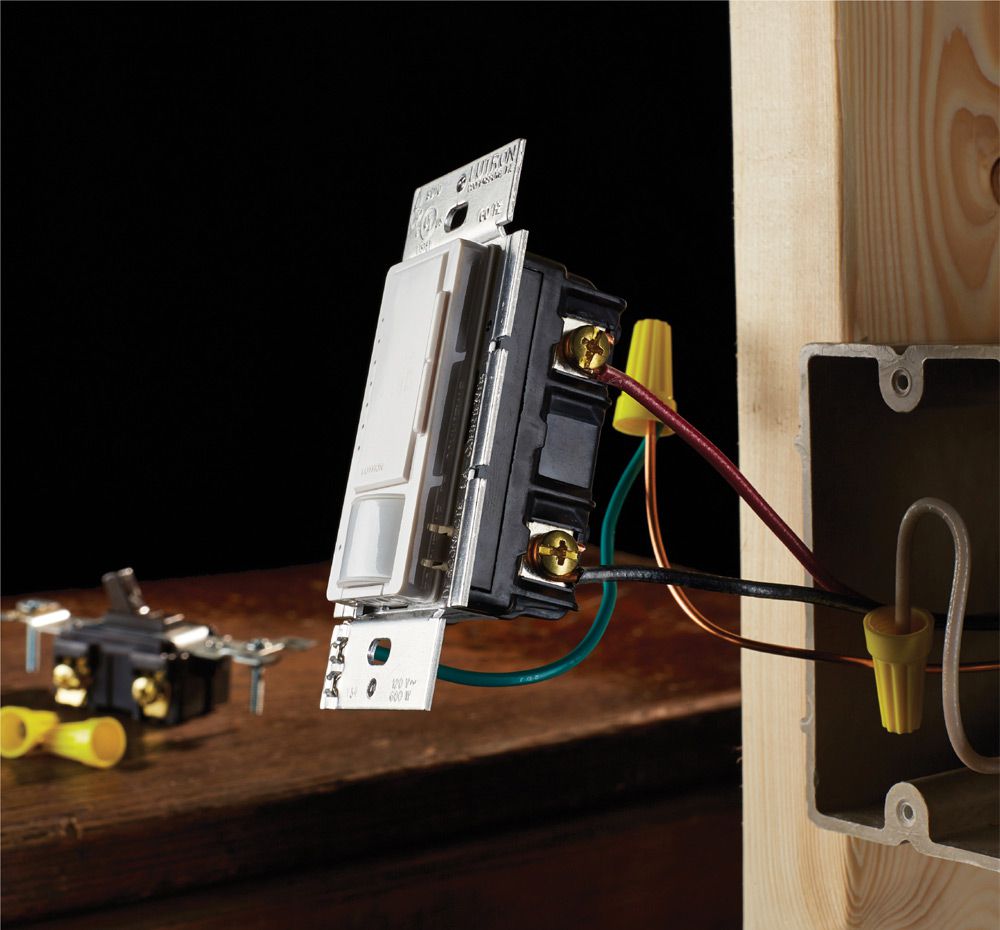

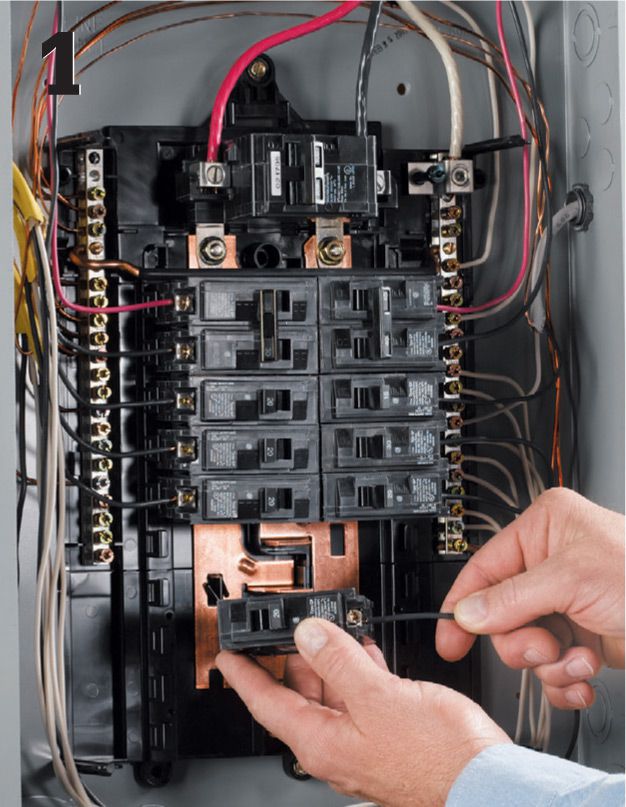

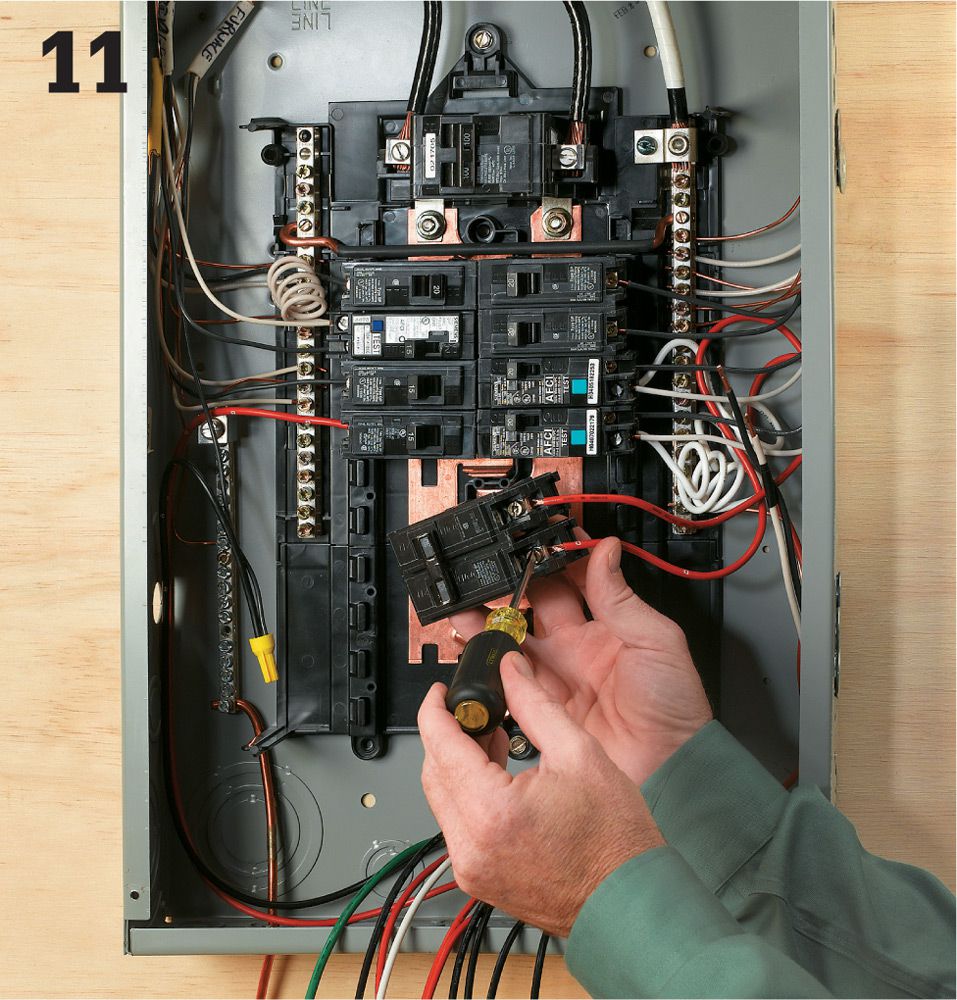

Locate the breaker for the circuit you’d like to protect. Turn off the main circuit breaker. Remove the cover from the panel, and test to ensure that power is off (see page 80). Remove the breaker you want to replace from the panel. Remove the black wire from the LOAD terminal of the breaker.

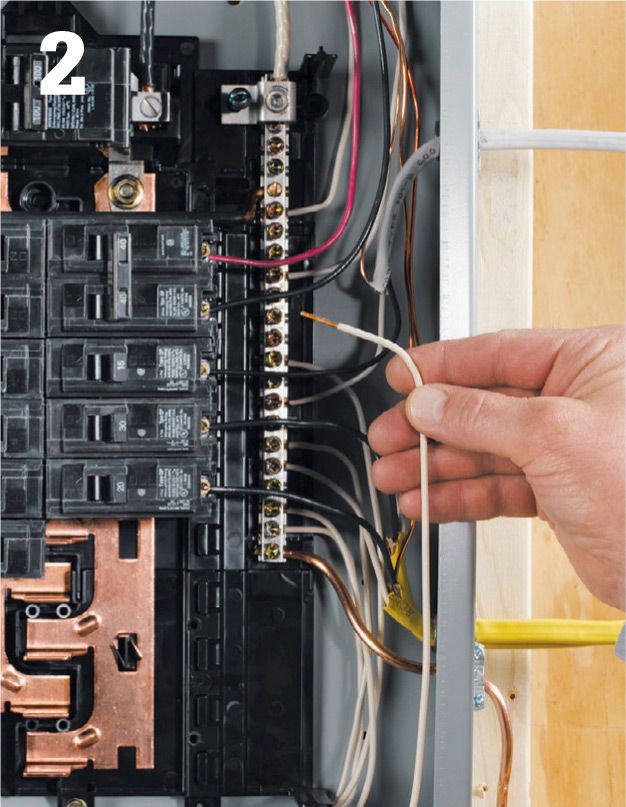

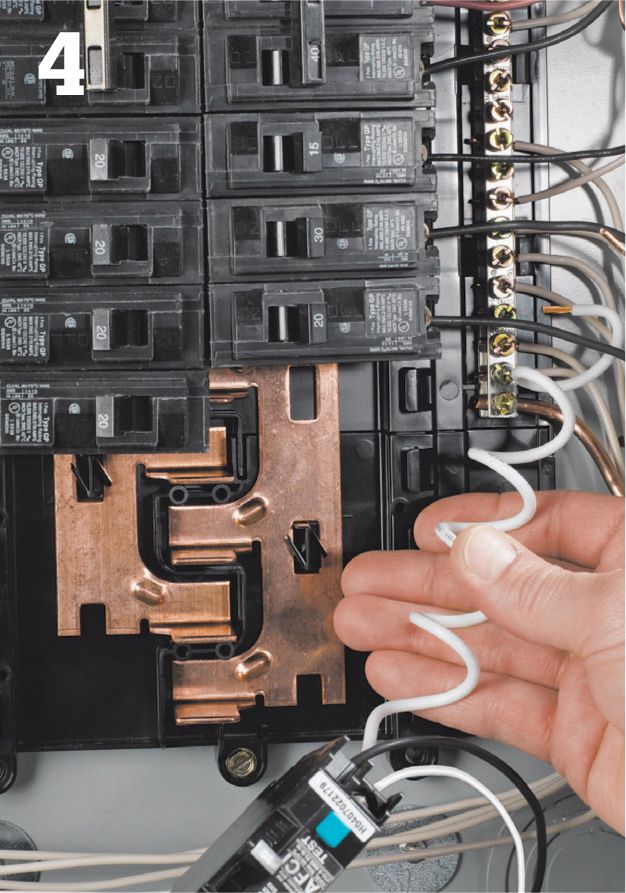

Find the white wire on the circuit you want to protect, and remove it from the neutral bus bar.

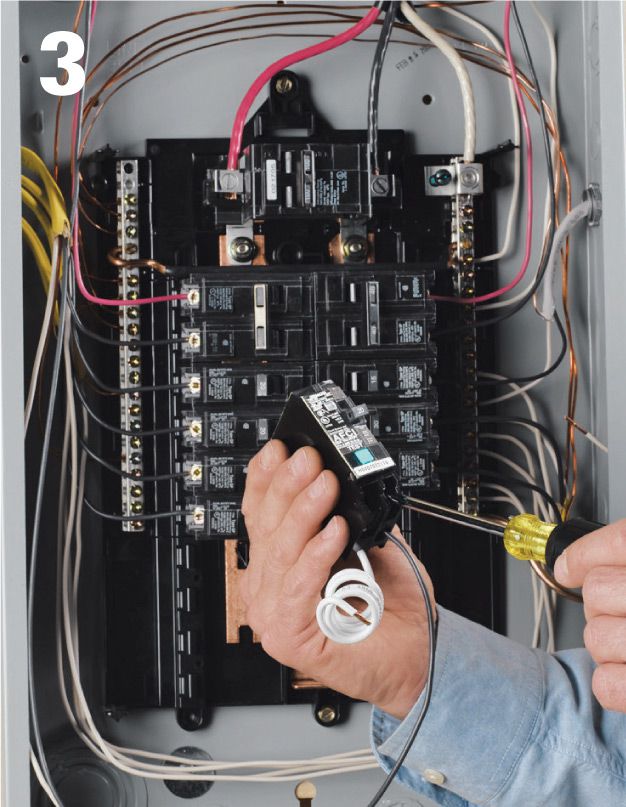

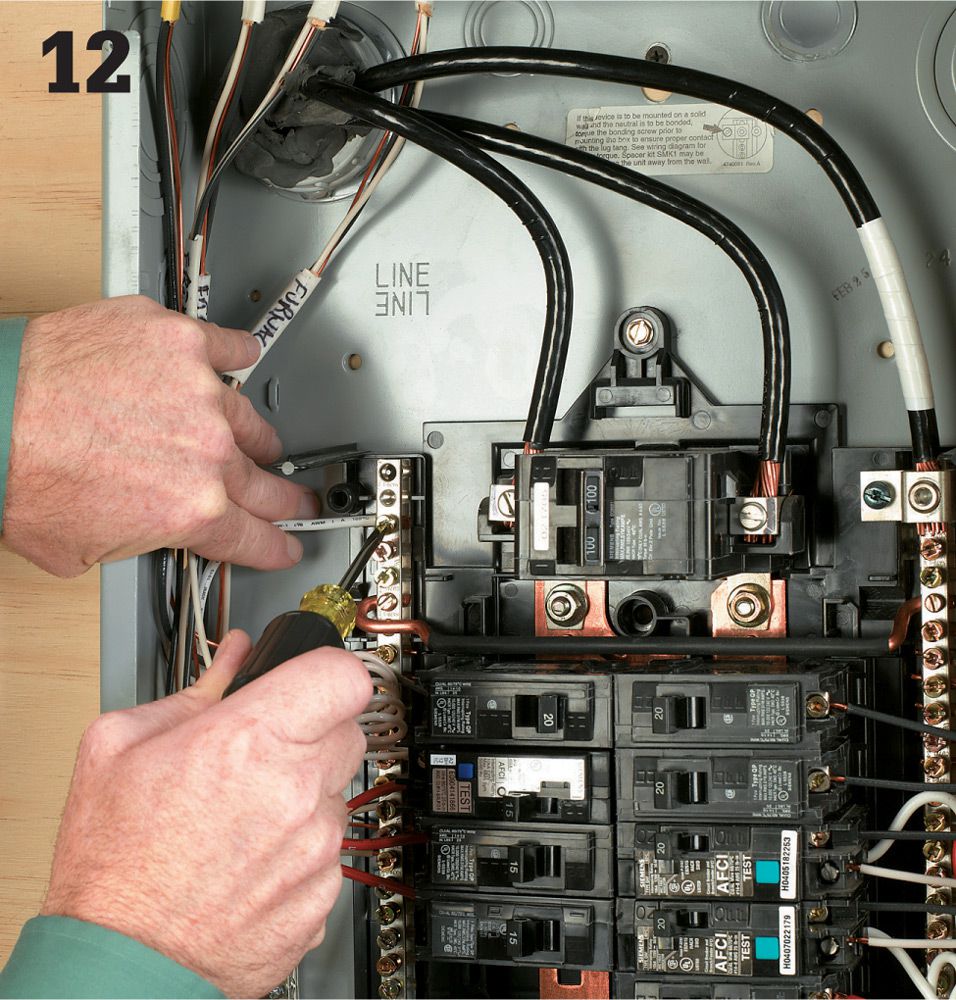

Flip the handle of the new AFCI or GFCI breaker to OFF. Loosen both of the breaker’s terminal screws. Connect the white circuit wire to the breaker terminal labeled PANEL NEUTRAL. Connect the black circuit wire to the breaker terminal labeled LOAD POWER.

Connect the new breaker’s coiled white wire to the neutral bus bar on the service panel.

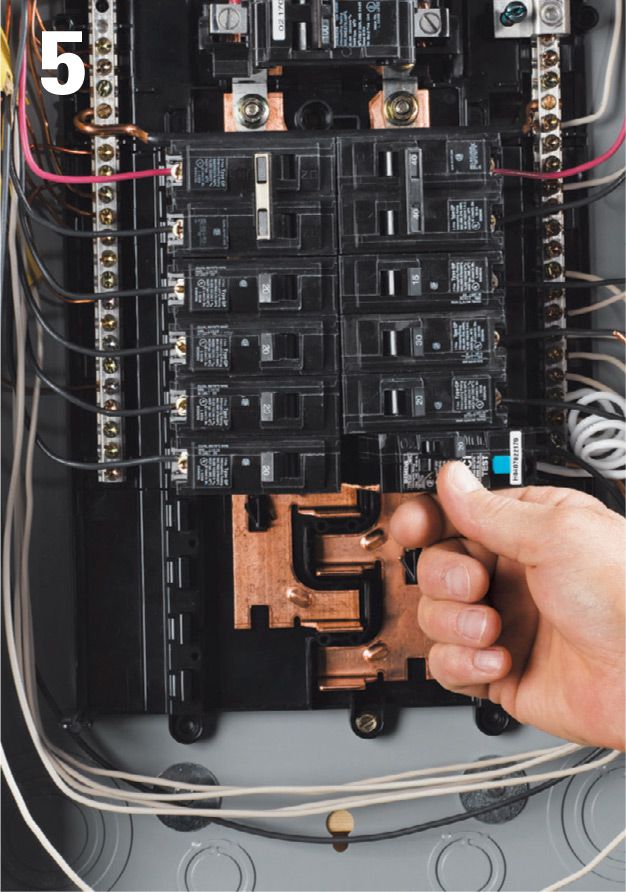

Make sure all the connections are tight. Snap the new breaker into the bus bar.

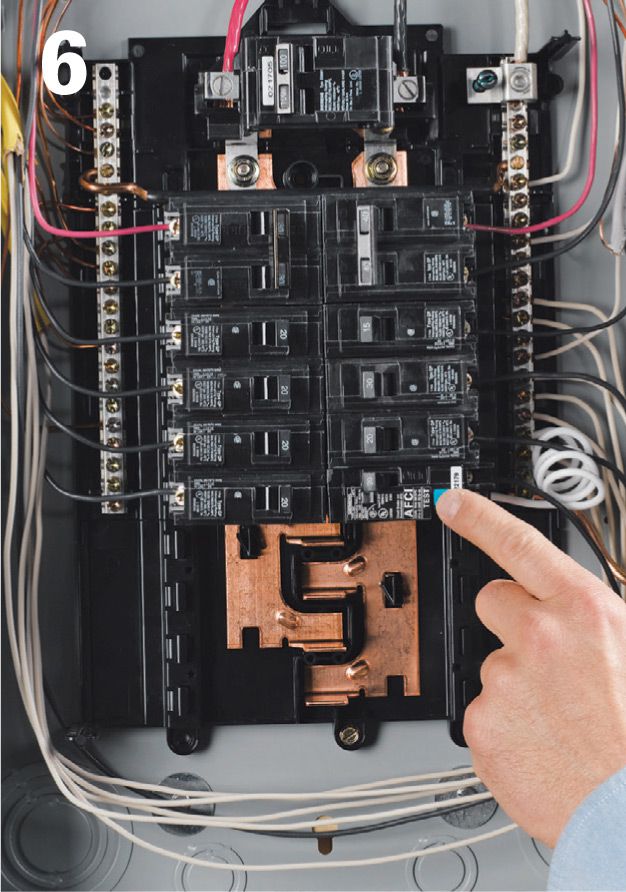

Turn the main breaker on. Turn off and unplug all fixtures and appliances on the AFCI or GFCI breaker circuit. Turn the AFCI or GFCI breaker on. Press the test button. If the breaker is wired correctly, the breaker trips open. If it doesn’t trip, check all connections or consult an electrician. Replace the panel cover.

![]() Whole-House Surge Arrestors

Whole-House Surge Arrestors

Electrical surges caused by lighting or utility malfunctions can destroy or seriously damage sensitive electronics. Many homes contain tens of thousands of dollars worth of computers and home entertainment equipment protected by no more than a $10 plug-in surge suppressor. While these devices do afford a modest level of protection, they are no match for the voltage a lightning strike will push through a system. And they offer no protection for the wiring itself. Whole-house surge arrestors provide comprehensive protection for the wiring and devices attached to it.

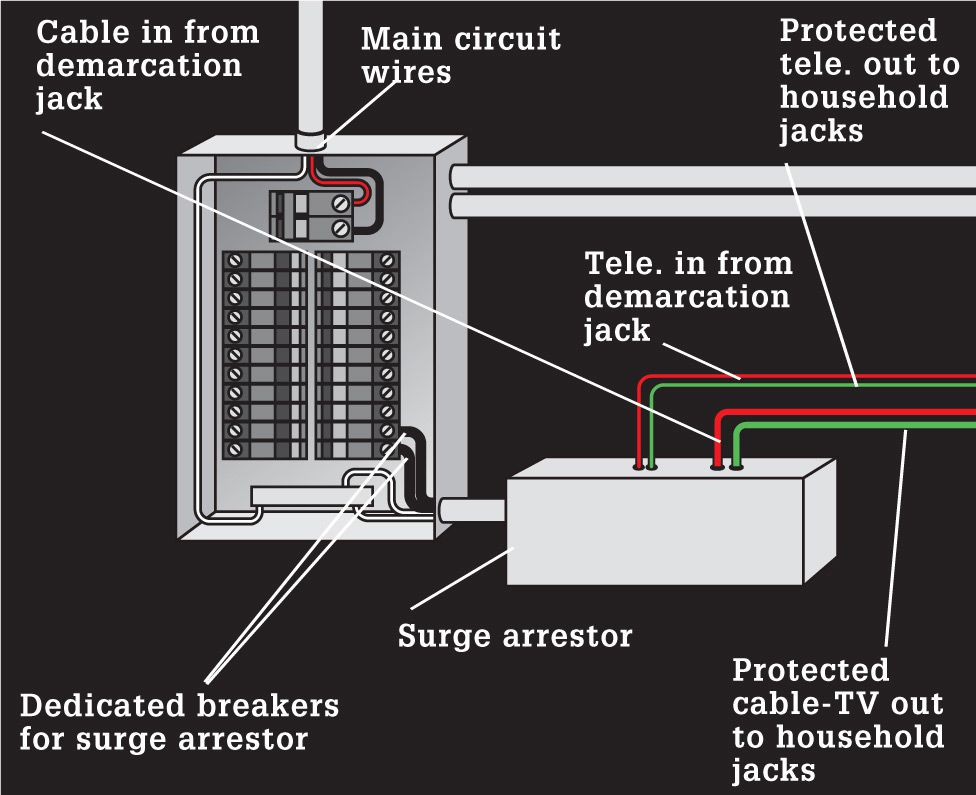

Whole-house surge arrestors are available in two basic types. One type is wired on the utility side of the panel, normally at the meter. When installed by a licensed electrician, these devices provide the highest level of protection, shielding the panel and all electrical devices in the house. The other type wires directly into the panel and protects all circuits originating at that panel. Manufacturers offer units that are housed in separate boxes (these look like a small subpanel) as well as models that are designed to replace a double-pole breaker in the panel itself. These install like standard breakers. Both types provide protection for the whole house. Freestanding models are also available with separate protection for phone, data, and cable-television lines—a wise addition if you need to protect networked computers or cable-TV receivers.

Whatever style you choose, look for models with the Underwriters Laboratories 1449 rating and indicator lights showing that the system is protected. Most manufacturers also include a warranty against defect that covers a certain amount of property damage.

Tools & Materials ![]()

Hammer

Combination tool

Screwdrivers

Cable ripper

Linesman’s pliers

Circuit tester

Crimping tools

Whole-house surge arrestor

Conduit nipple and locknuts

Two 15- or 20-amp single-pole breakers

Coaxial cable and terminators

UTP cable and terminators

A Whole-house surge arrestor is an inexpensive defense against expensive damage from high-voltage shocks caused by lightning strikes and power surges. Most models install next to the main panel.

A surge arrestor installed at the panel protects all downstream connected devices and wires.

![]() How to Install a Whole-House Surge Arrestor

How to Install a Whole-House Surge Arrestor

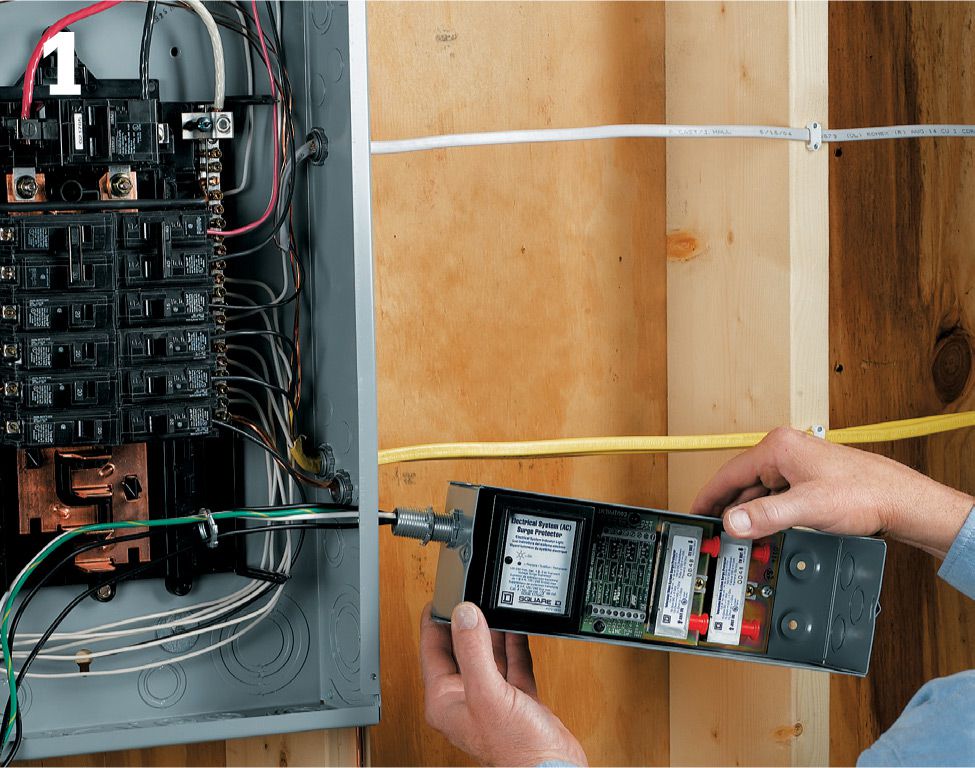

Turn off power at the main breaker. Remove the cover, and test to make sure the power is off. Mount the arrestor near the service panel following the manufacturer’s instructions. Typically the arrestor mounts on one side of the panel so its knockout lines up with a lower knockout on the panel. Remove the knockout on the panel. Install a conduit nipple on the arrestor, and thread the wires from the arrestor through the nipple and into the panel. Slip the other end of the nipple through the opening in the panel, and tighten the locknut. Secure the box to the wall with screws as directed.

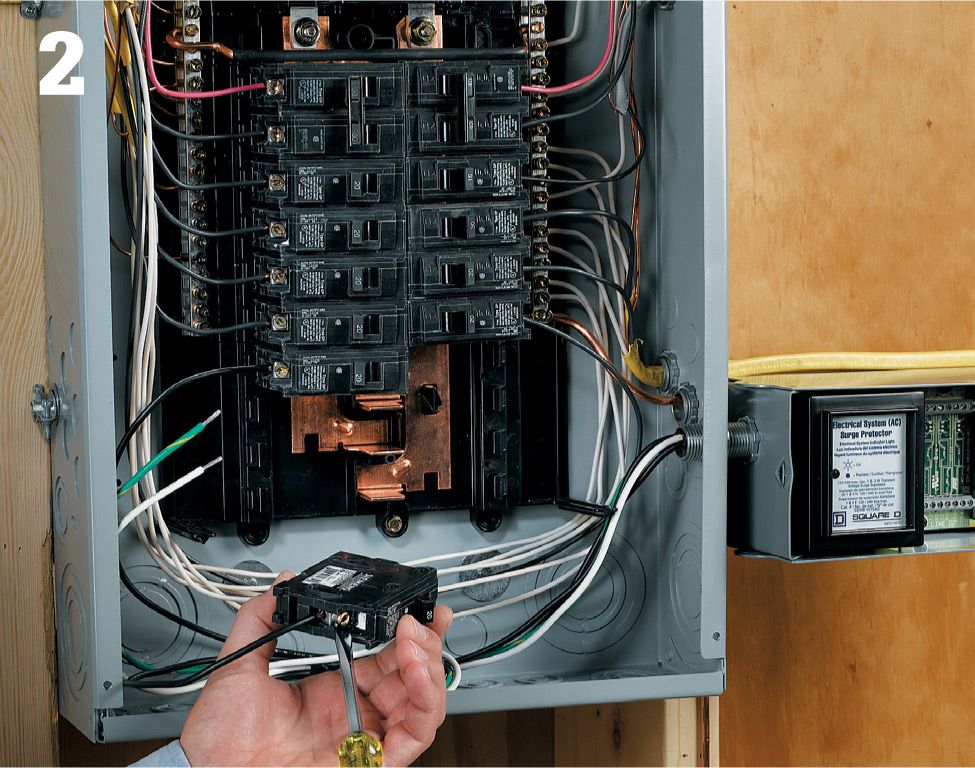

Connect the two black wires to two dedicated 15- or 20-amp breakers. Trim the wires as short as possible without making sharp bends. Connect the white neutral wire to the neutral bar and the green grounding wire to the grounding bar. Keep wire lengths as short as possible. Snap the new breakers into the bus bar. Restore the power and carefully test that the voltage between the two black arrestor leads is 240 volts. Replace the panel cover and the arrestor cover. If the arrestor has indicator lights, they should glow, showing that the system is now protected.

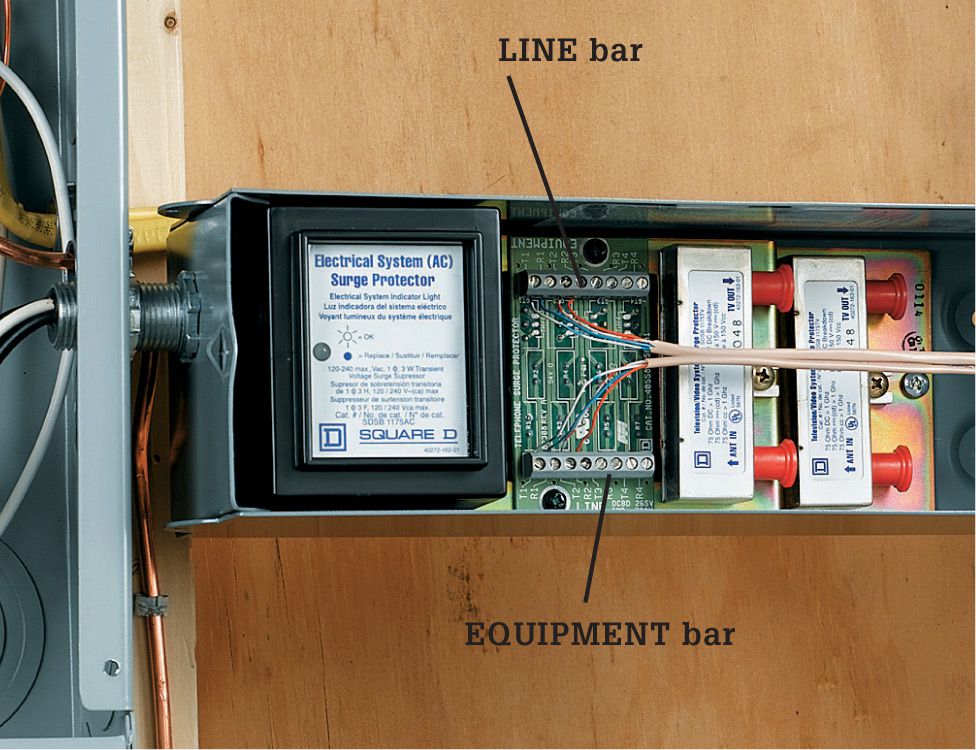

Variation: If the arrestor has separate protection for the telephone circuits, remove the cable that runs from the phone demarcation jack to the junction box. Then remove a knockout in the arrestor and route a new UTP cable from the demarcation jack to the arrestor. Strip insulation from the wires and connect them to the terminals on the LINE bar (labeled IN on some models) on the phone protection module in the arrestor. Run a UTP cable from the EQUIPMENT bar (labeled OUT on some models) to the junction box. Strip and connect the wires from this cable to the appropriate terminals in the arrestor and the junction box.

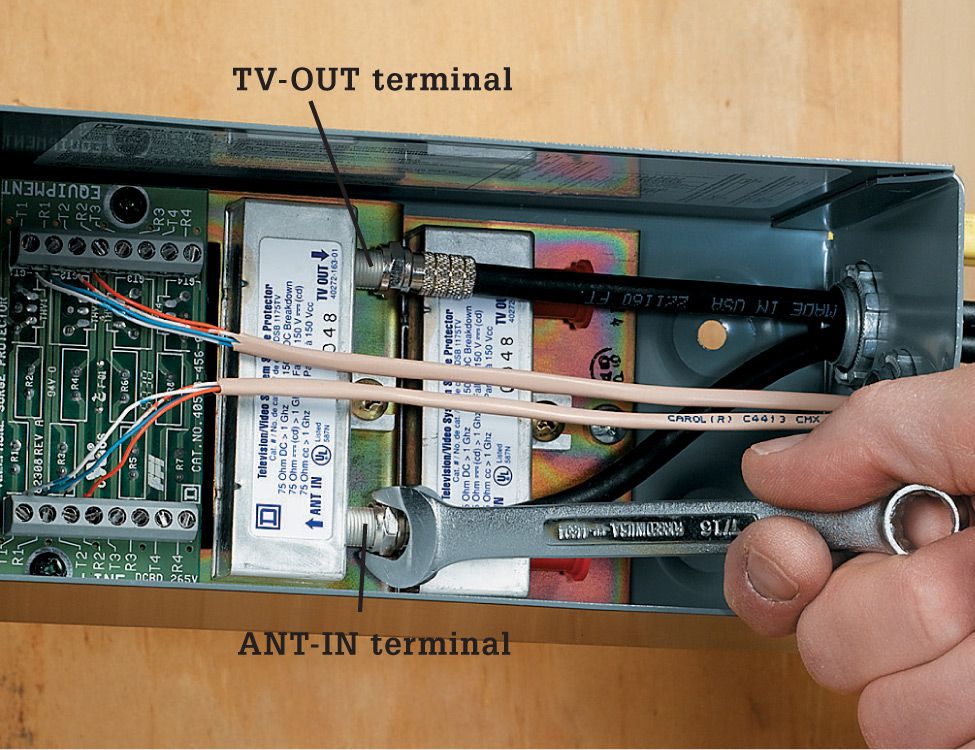

Variation: If the arrestor has separate protection for a cable television circuit, remove the appropriate knockout from the arrestor and run a coaxial cable to the arrestor from the cable-TV demarcation jack. Connect the coaxial cable to the ANT-IN terminal on the cable-TV protection module. Run another coaxial cable from the TV-OUT terminal to the cable TV junction box or the distribution panel. Do not overtighten the connections.

![]() Service Panels

Service Panels

Only a generation ago, fuse boxes were commonplace. But as our demands for power increased, homeowners replaced the 60-amp boxes with larger, safer, and more reliable circuit breaker panels. Typical new homes were built with perfectly adequate 100-amp load centers. But today, as average home size has risen to more than 2,500 sq. ft. and the number of home electronics has risen exponentially, 100 amps is often inadequate service. As a result, many homeowners have upgraded to 200-amp service, and new single-family homes often include 250 amps or even 400 amp service.

Upgrading your electrical service panel from 100 amps to 200 amps is an ambitious project that requires a lot of forethought. The first step is to obtain a permit. When you are ready to begin, you will need to have your utility company disconnect your house from electrical service at the transformer that feeds your house. When you schedule this, talk to your utility company about the size of your service drop or lateral. That may need to be upgraded too. Not only does this involve working them into your schedule, it means you will have no power during the project. You can rent a portable generator to provide a circuit or two, or you can run a couple extension cords from a friendly neighbor. But unless you are a very fast worker, plan on being without power for at least one to two days while the project is in process.

Also check with your utility company to make sure you know what equipment is theirs and what belongs to you. In most cases, the electric meter and everything on the street side belongs to the power company, and the meter base and everything on the house side is yours. Be aware that if you tamper with the sealed meter in any way, you likely will be fined. Utility companies will not re-energize your system without approval from your inspecting agency.

Upgrading a service panel is a major project. Do not hesitate to call for help at any point if you’re unsure what to do.

Tools & Materials ![]()

200-amp load center (service panel)

200-amp bypass meter base

Circuit breakers (AFCI if required by local code)

Schedule 80 or RMC conduit and fittings

Weatherhead

Service cable

Circuit wires

Plywood backer board

Screwdrivers

Drill/driver

Tape

Allen wrench

Circuit tester

Multimeter

Modern homeowners consume more power than our forebears, and it is often necessary to upgrade the electrical service to keep pace. While homeowners are not allowed to make the final electrical service connections, removing the old panel and installing the new panel and meter base yourself can save you hundreds or even thousands of dollars.

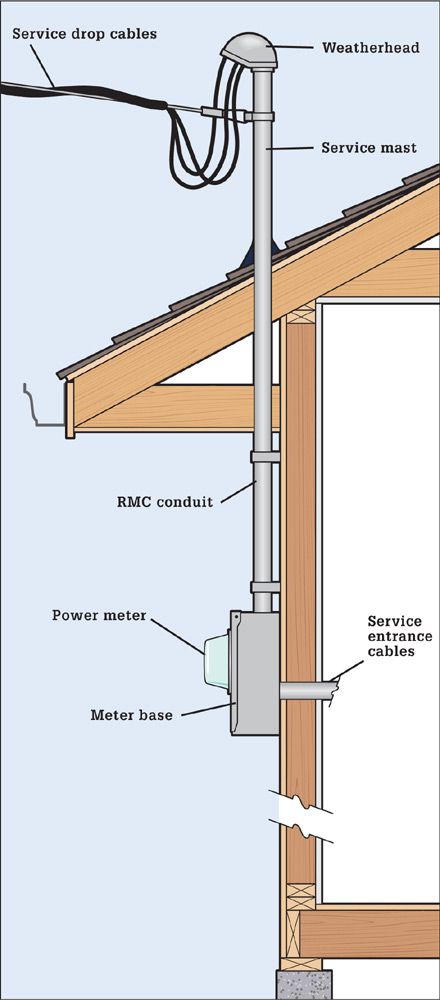

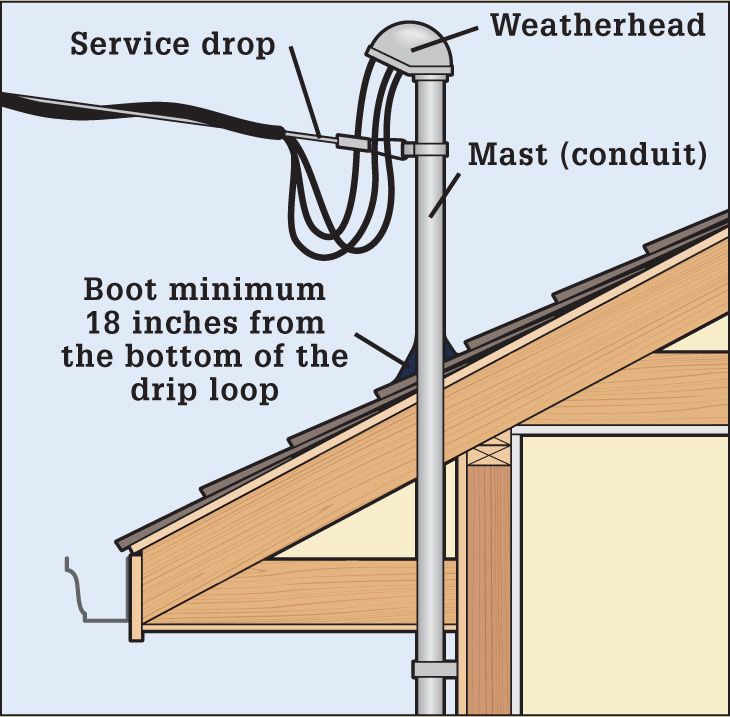

Aboveground service drop. In this common configuration, the service cables from the closest transformer (called the service drop) connect to service entrance wires near the weatherhead. This connection is called the service point and is where your property usually begins. The service entrance wires from the weatherhead are routed to a power meter that’s owned by your utility company but is housed in a base that’s considered your property. From the meter the service entrance wires enter your house through the wall and are routed to the main service panel, where they are connected to the main circuit breaker.

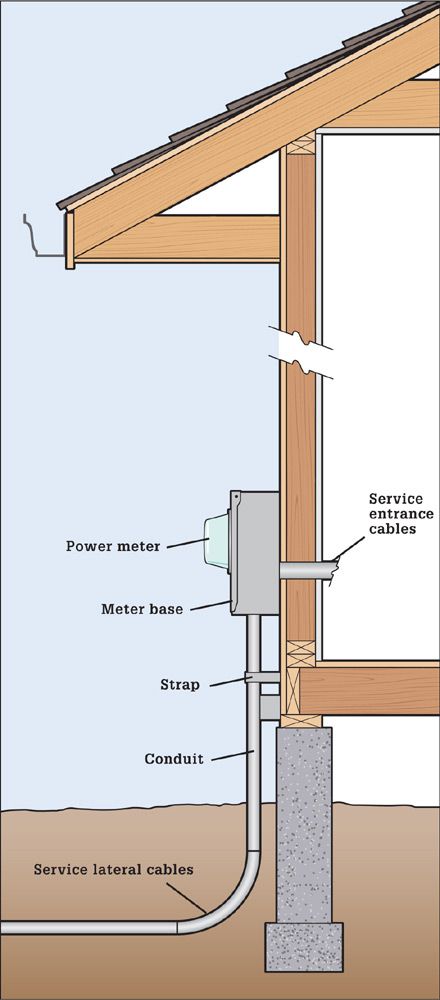

Underground service lateral. Increasingly, homebuilders are choosing to have power supplied to their new homes underground instead of an overhead service drop. Running the cables in the ground eliminates problems with power outages caused by ice accumulation or fallen trees, but it entails a completely different set of cable and conduit requirements. For the homeowner, however, the differences are minimal, because the hookups are identical once the power service reaches the meter.

Locating Your New Panel ![]()

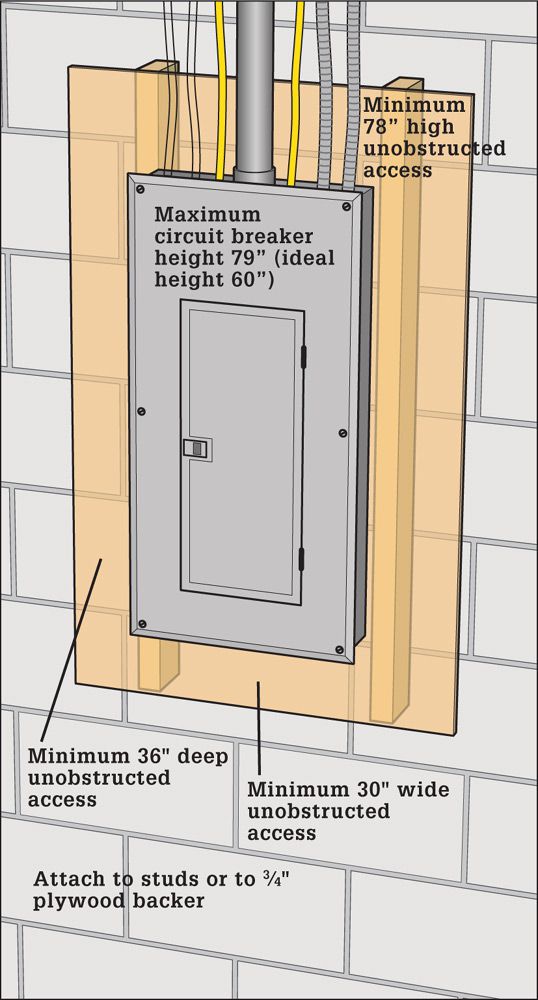

Local codes dictate where the main service panel may be placed relative to other parts of your home. Although the codes vary (and always take precedence), national codes stipulate that a service panel (or any other distribution panel) may not be located near flammable materials, in a bathroom, clothes closet or other area designated for storage, above stairway steps, or directly above a workbench or other permanent work station or appliance. The panel also can’t be located in a crawl space. If you are installing a new service entry hookup, there are many regulations regarding height of the service drop and the meter. Contact your local inspections office for specific regulations.

All the equipment you’ll need to upgrade your main panel is sold at most larger building centers. It includes (A) a new 200-amp panel; (B) a 200-amp bypass meter base (also called a socket); (C) individual circuit breakers (if your new panel is the same brand as your old one you may be able to reuse the old breakers); (D) new, THW, THHW, THWN-2. RHW, RHW-2, XHHW (2/0 copper seen here); (E) 2" dia. rigid metallic conduit; (F) weatherhead shroud for mast.

The main circuit breaker (called the service equipment) may need to be located outside next to the electric meter if your main panel is too far away from the point where the service cable enters your house. The maximum distance allowed varies widely, from as little as 3 ft. to more than 10 ft. Wiring the service cable through the shutoff has the effect of transforming your main panel into a subpanel, which will impact how the neutral and ground wires are attached (see Subpanels, pages 186 to 189).

![]() How to Replace a Main Panel

How to Replace a Main Panel

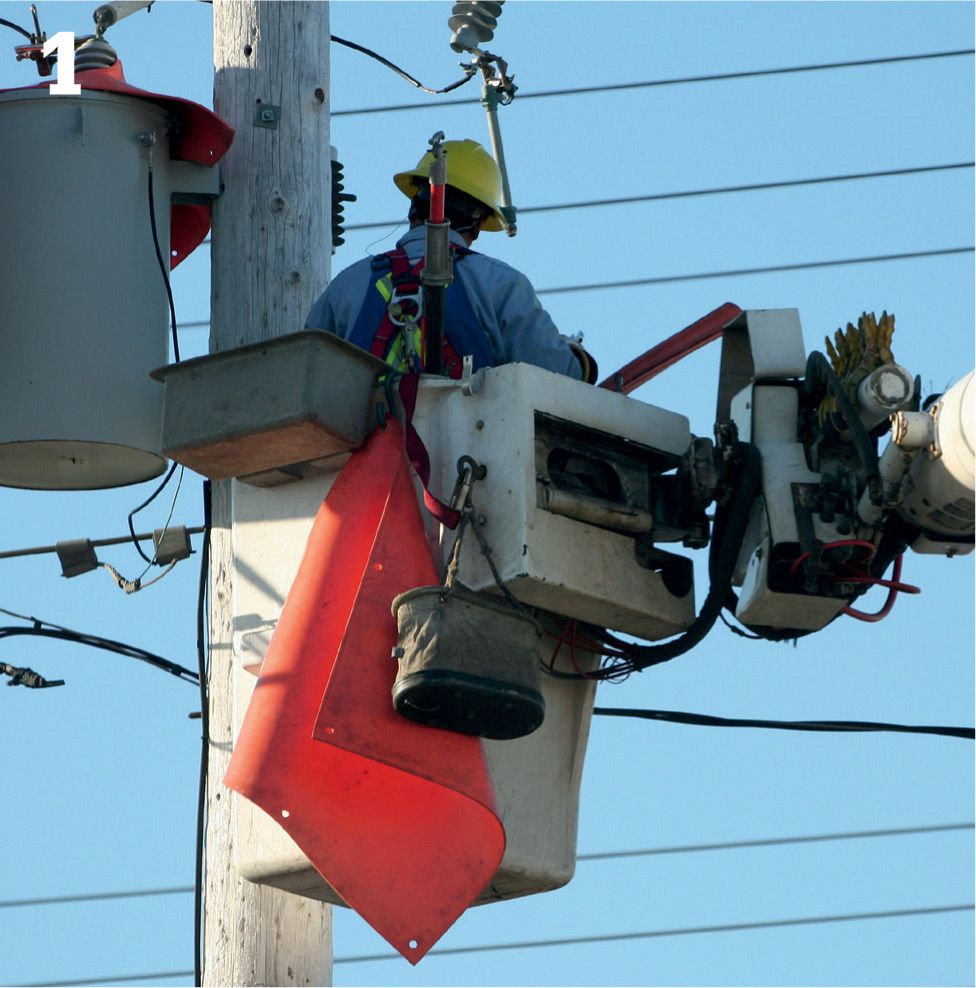

Shut off power to the house at the transformer. This must be done by a technician who is certified by your utility company. Also have the utility worker remove the old meter from the base. It is against the law for a homeowner to break the seal on the meter.

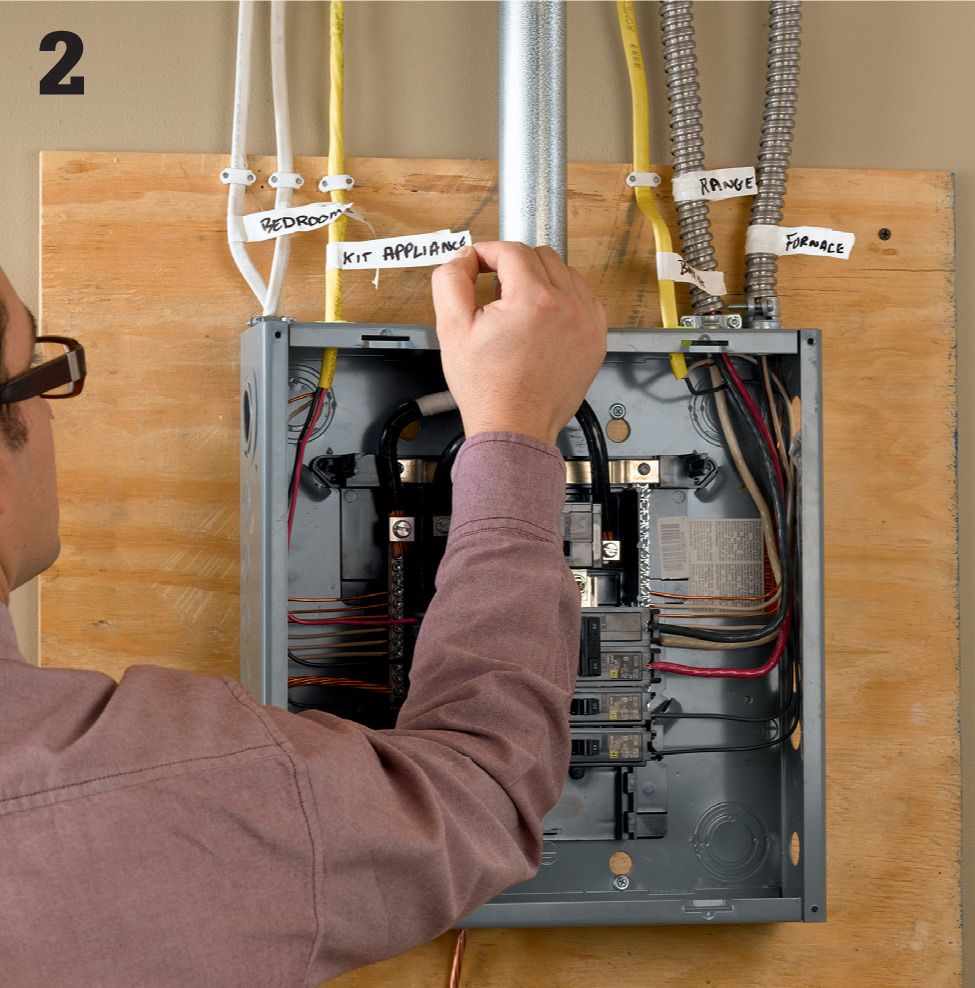

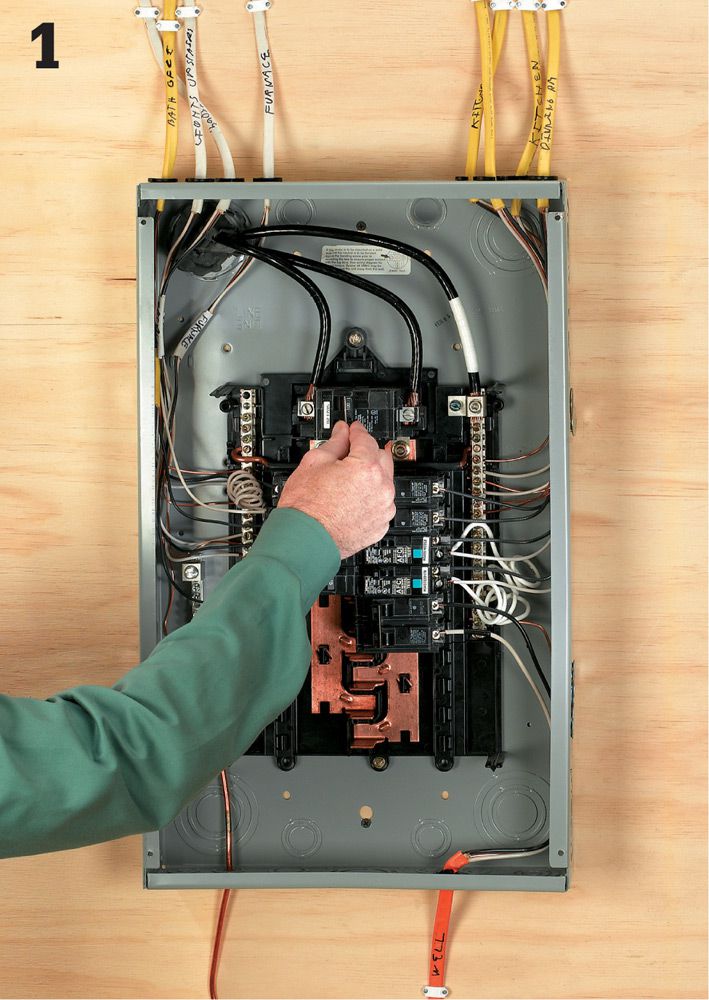

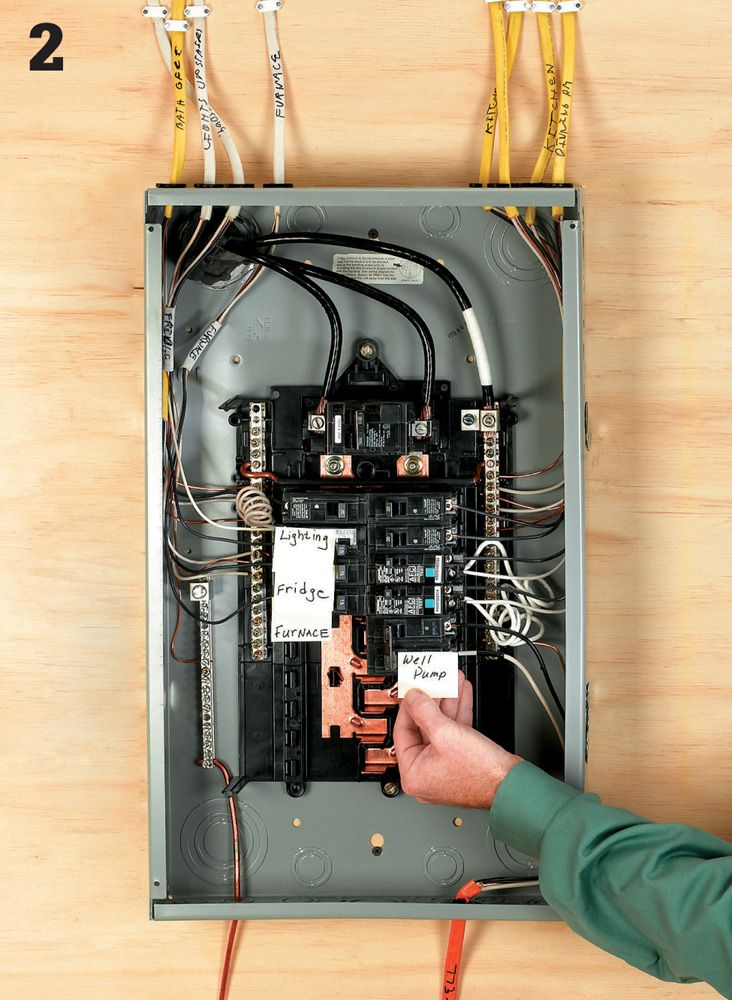

Label all incoming circuit wires before disconnecting them. Labels should be written clearly on tape that is attached to the cables outside of the existing service panel. Test the circuits before starting to make sure they are labeled correctly.

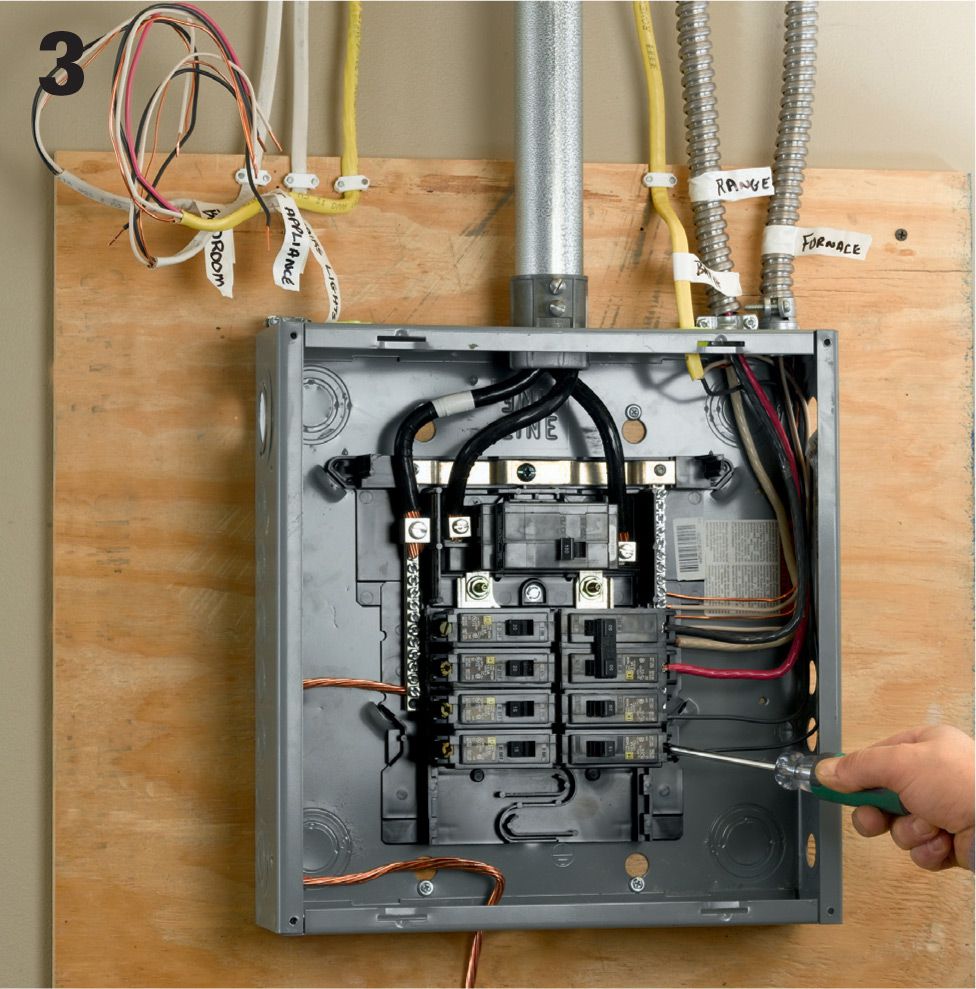

Disconnect incoming circuit wires from breakers, grounding bar, and neutral bus bar. Also disconnect cable clamps at the knockouts on the panel box. Retract all circuit wires from the service panel and coil it up neatly, with the labels clearly visible.

Unscrew the lugs securing the service entry cables at the top of the panel. For 240-volt service you will find two heavy-gauge SE cables, probably with black sheathing. Each cable carries 120 volts of electricity. A neutral service cable, usually of smaller gauge than the SE cables, will be attached to the neutral bus bar. This cable returns current to the source.

Remove the old service panel box. Boxes are rated for a maximum current capacity; and if you are upgrading, the components in the old box will be undersized for the new service levels. The new box will have a greater number of circuit slots as well.

Replace the old panel backer board with a larger board in the installation area (see sidebar, page 174). A piece of 3/4" plywood is typical. Make sure the board is well secured at wall framing members.

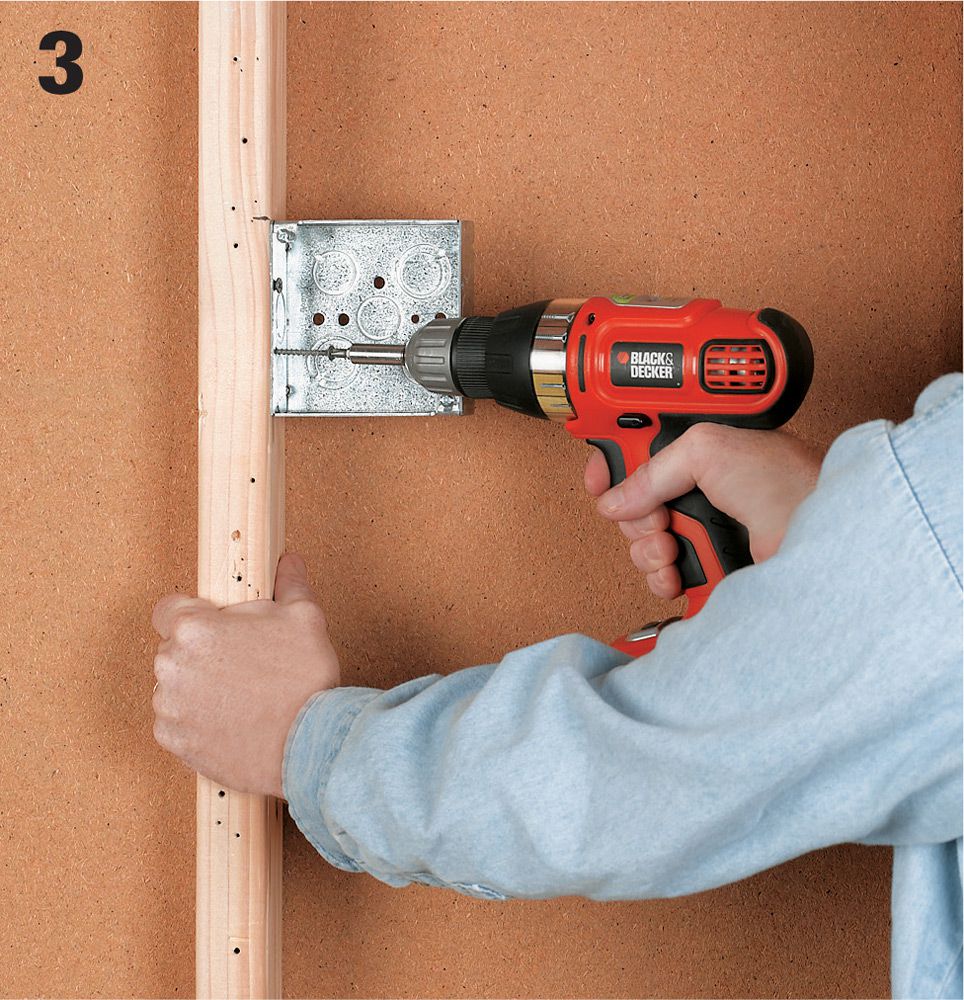

Attach the new service panel box to the backer board, making sure that at least two screws are driven through the backer and into wall studs. Drill clearance holes in the back of the box at stud locations if necessary. Use roundhead screws that do not have tapered shanks so the screwhead seats flat against the panel.

Attach properly sized cable clamps to the box at the knockout holes. Install one cable per knockout in this type of installation and plan carefully to avoid removing knockouts that you do not need to remove (if you do make a mistake, you can fill the knockout hole with a plug).

Splicing in the Box ![]()

Some wiring codes allow you to make splices inside the panel box if the circuit wire is too short. Use the correct wire cap and wind electrical tape over the conductors where they enter the cap. If your municipality does not allow splices in the panel box, you’ll have to rectify a short cable by splicing it in a junction box before it reaches the panel and then replacing the cable with a longer section for the end of the run. Make sure each circuit line has at least 12" of slack.

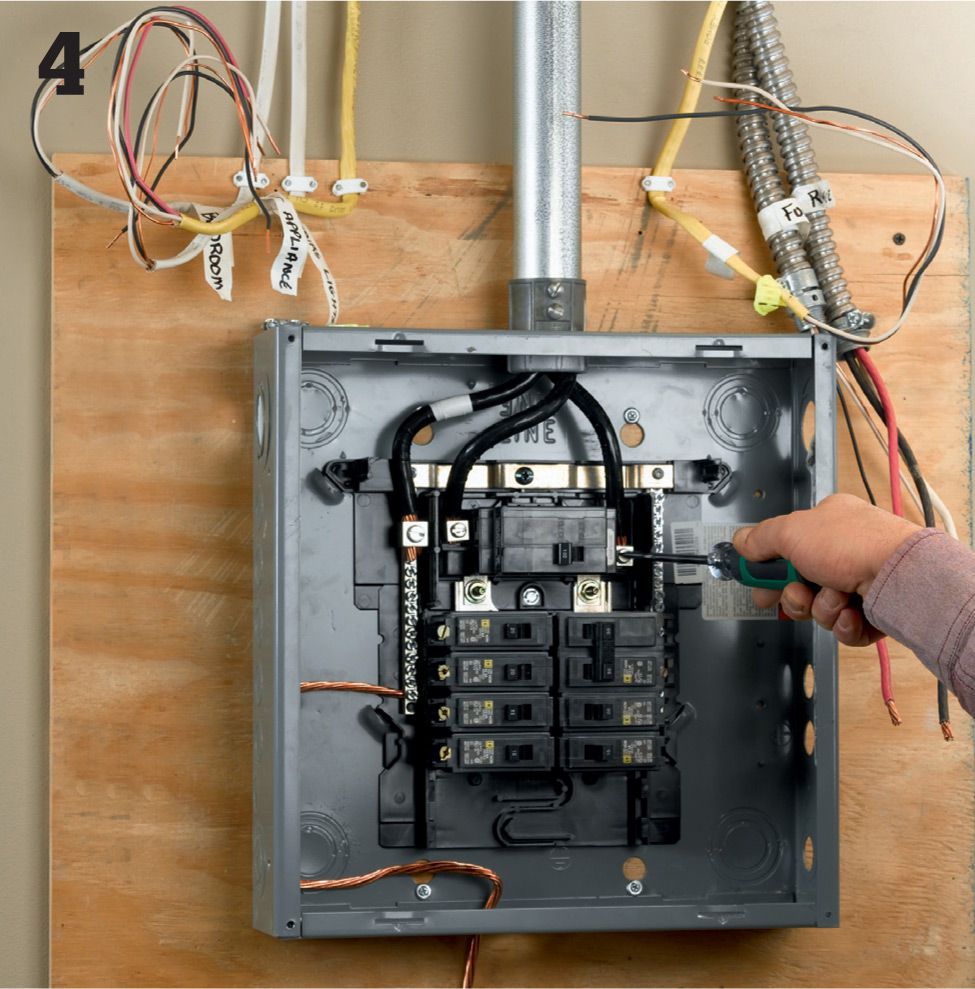

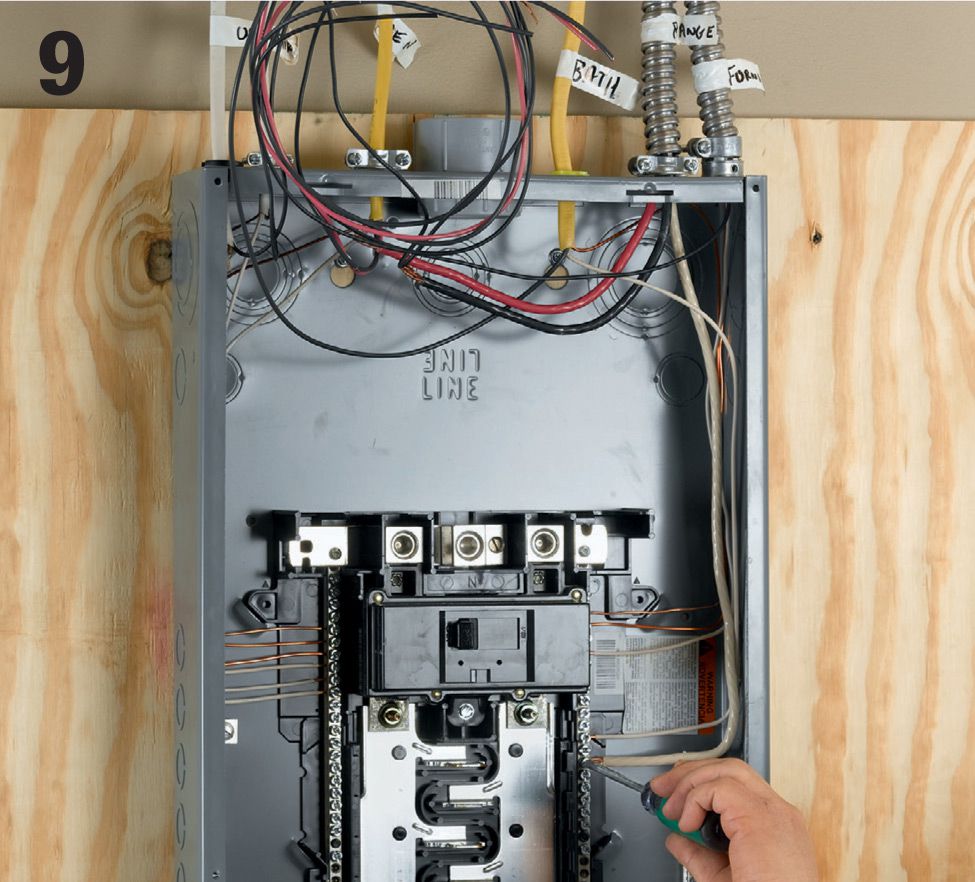

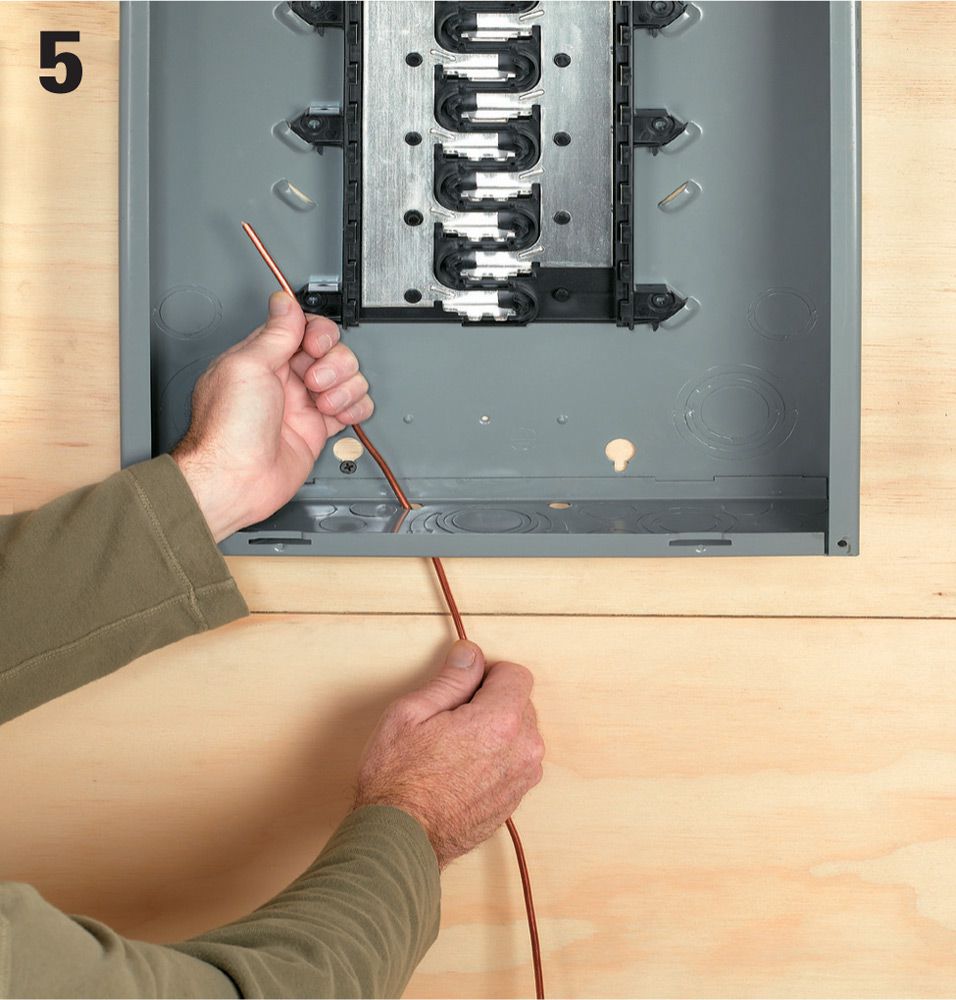

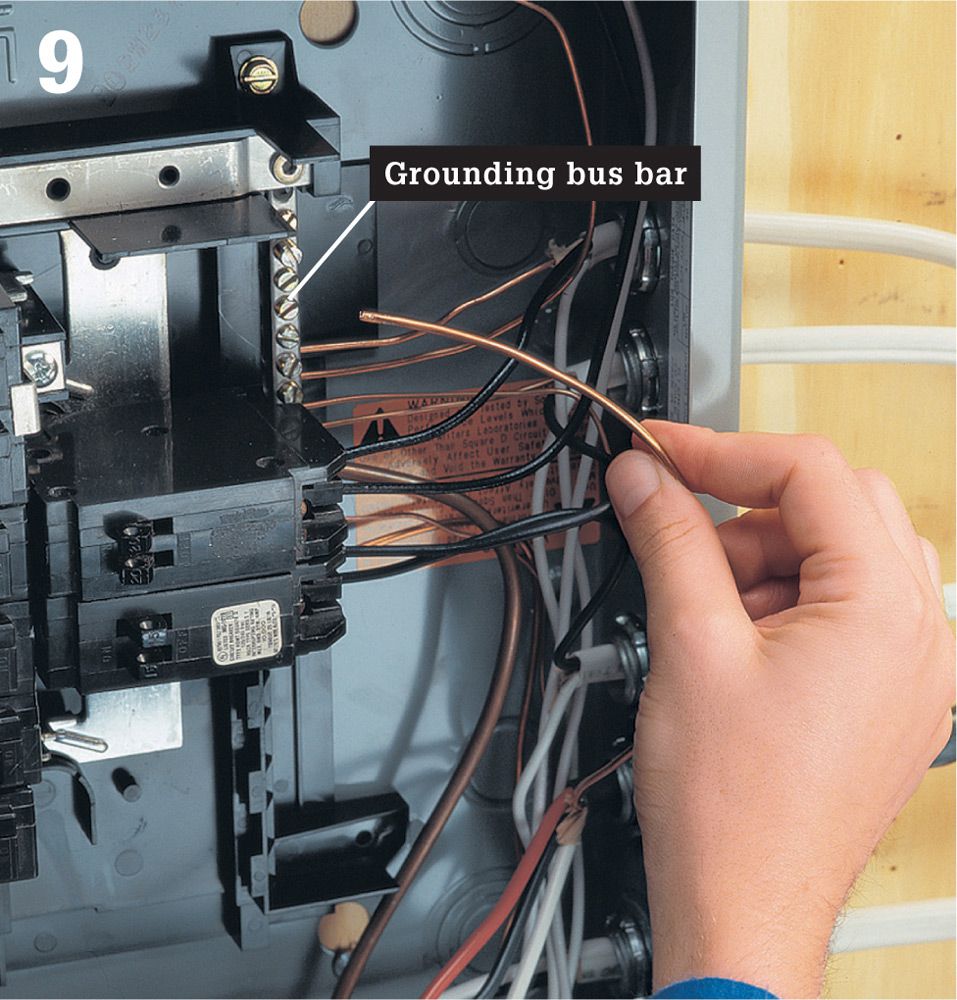

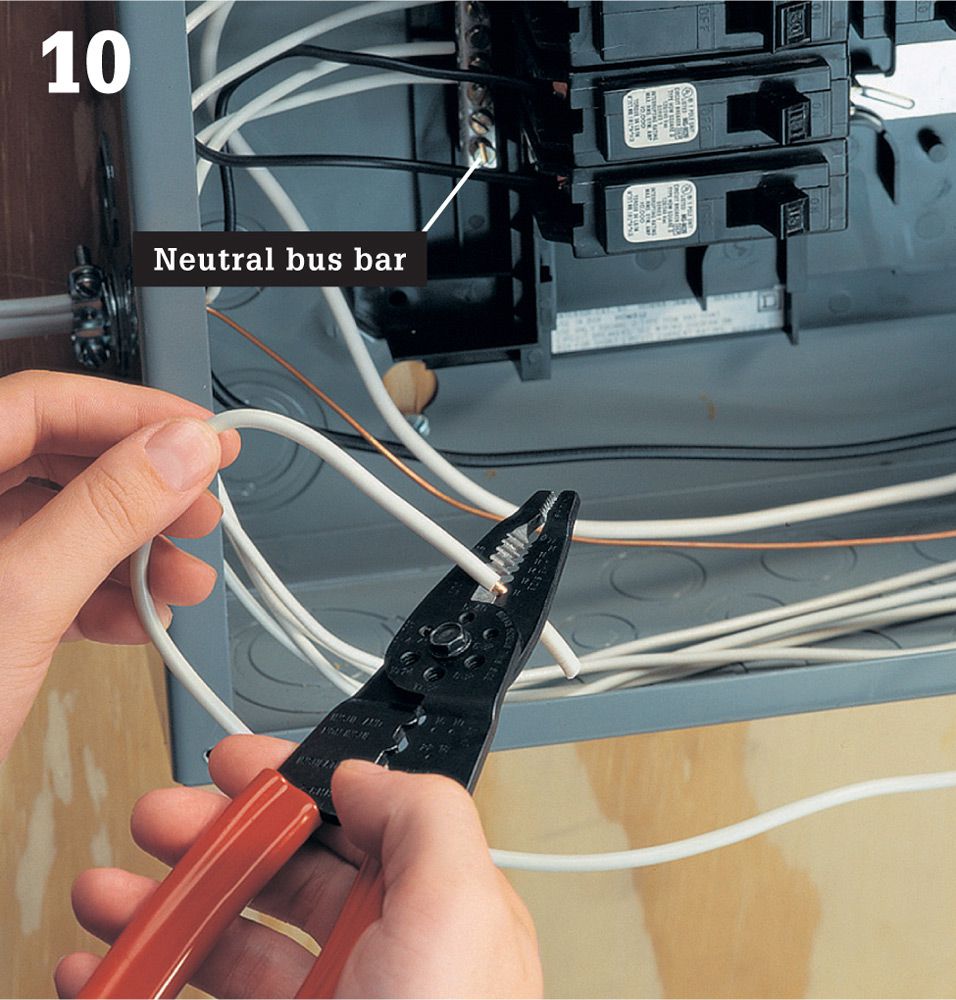

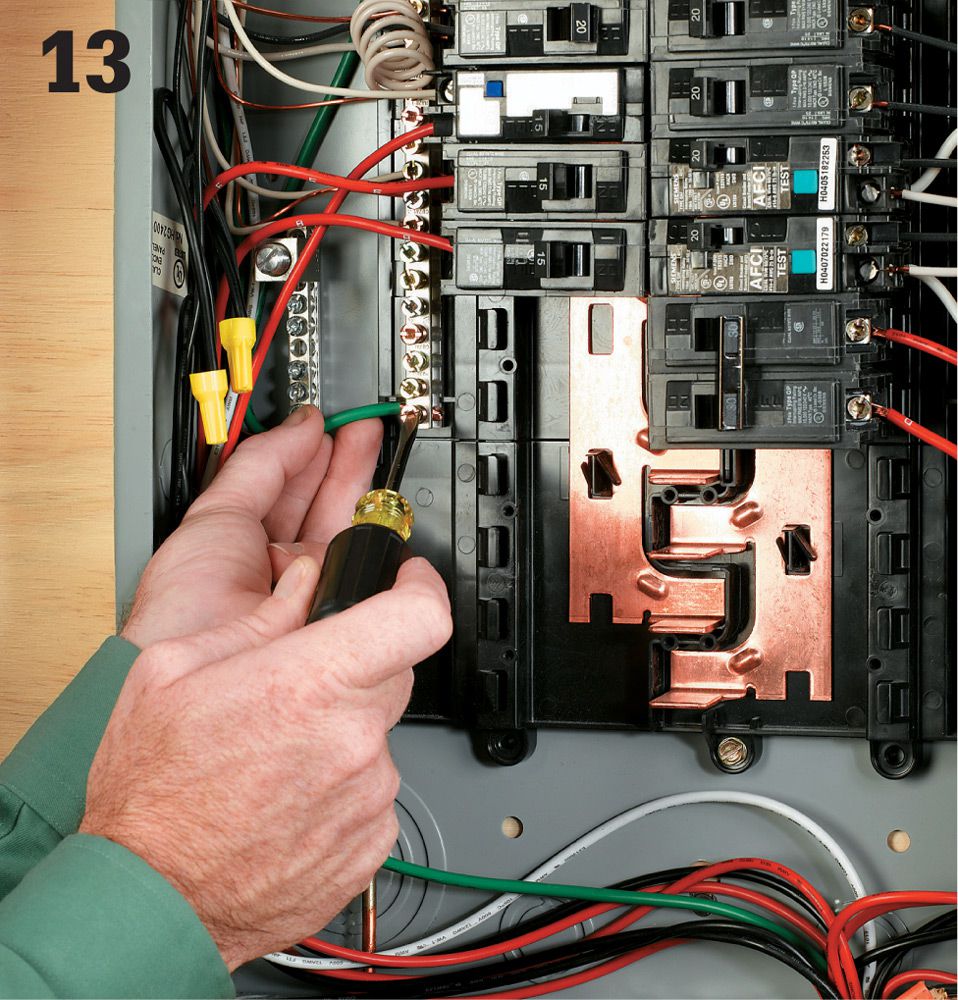

Attach the white neutral from each circuit cable to the neutral bus bar. Most panels have a preinstalled neutral bus bar, but in some cases you may need to purchase the bar separately and attach it to the panel back. The panel should also have a separate grounding bar that you also may need to purchase separately. Attach the grounds as well.

Attach the hot lead wire to the terminal on the circuit breaker, and then snap the breaker into an empty slot. When loading slots, start at the top of the panel and work your way downward. It is important that you balance the circuits as you go to equalize the amperage. For example, do not install all the 15-amp circuits on one side and all the 20-amp circuits on the other.

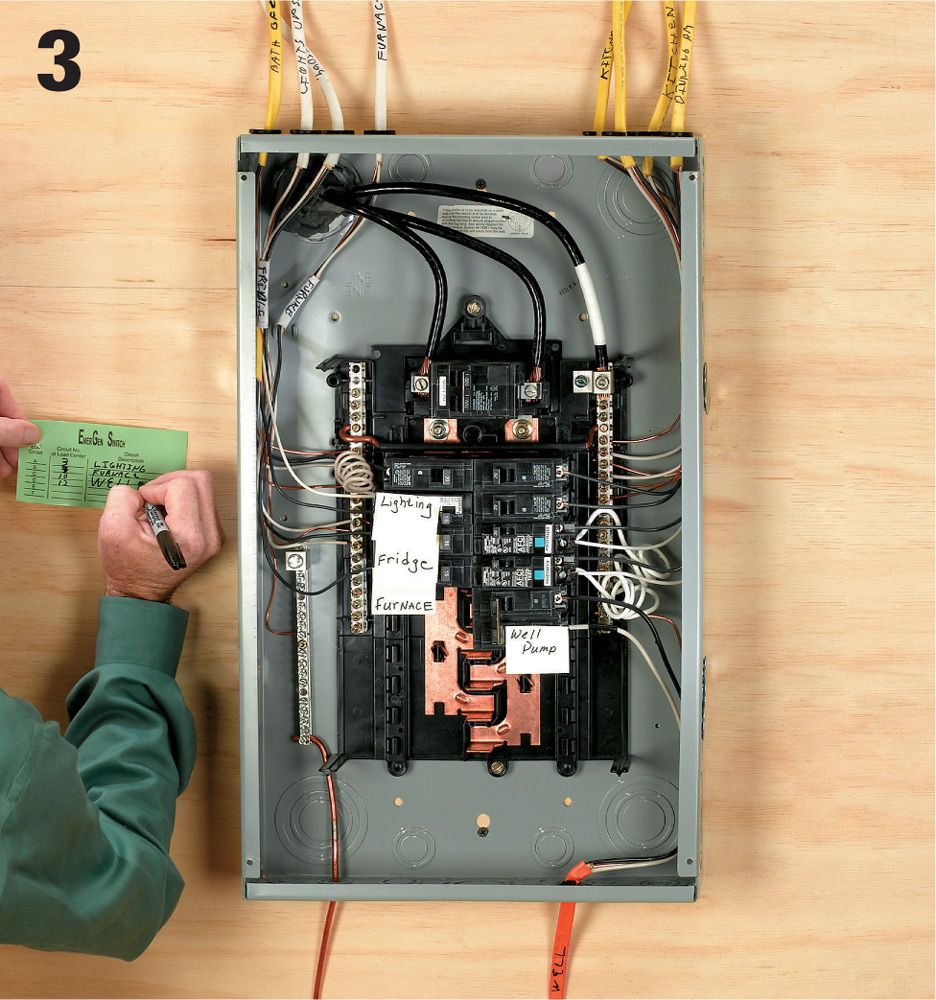

Create an accurate circuit index and affix it to the inside of the service panel door. List all loads that are on the circuit as well as the amperage. Once you have restored power to the new service panel (see step 18), test out each circuit to make sure you don’t have any surprises. With the main breakers on, shut off all individual circuit breakers, and then flip each one on by itself. Walk through your house and test every switch and receptacle to confirm the loads on that circuit.

Install grounding conductors (see pages 180 to 185). Local codes are very specific about how the grounding and bonding needs to be accomplished. For example, some require multiple rods driven at least 6 ft. apart. Discuss your grounding requirements thoroughly with your inspector or an electrician before making your plan.

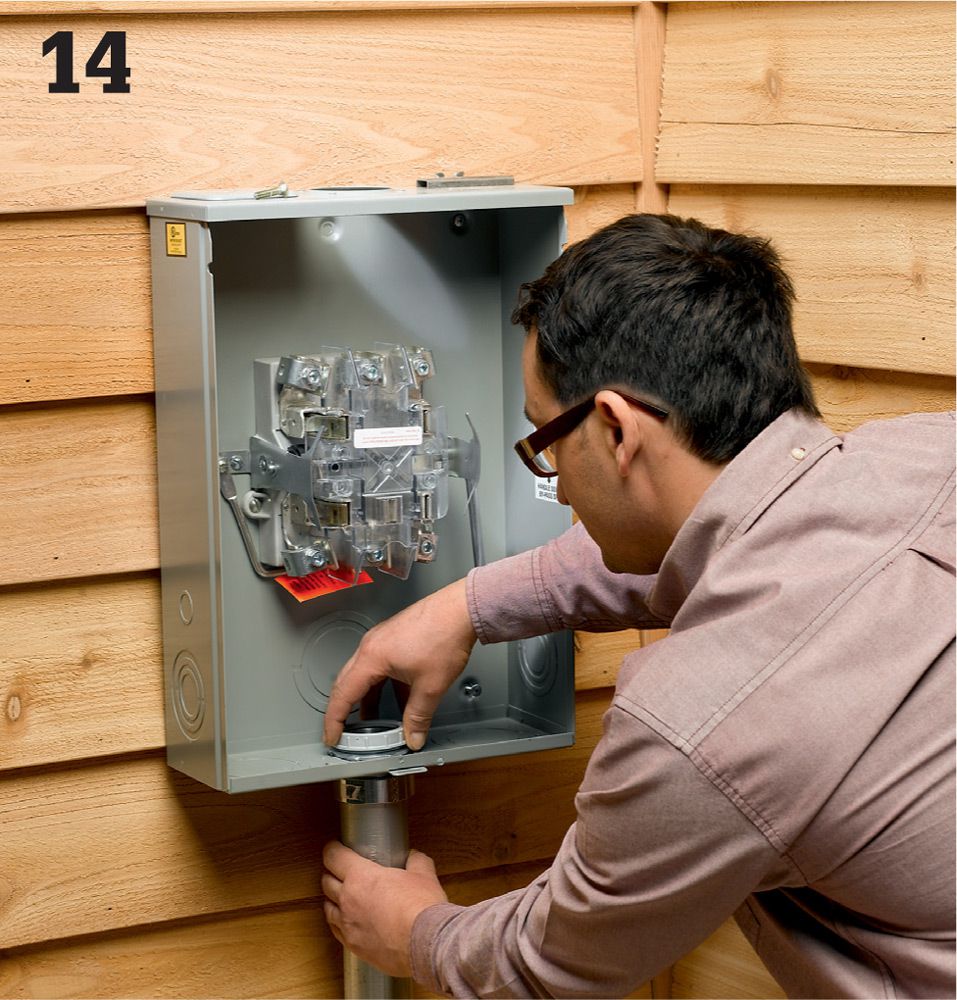

Replace the old meter base (have the utility company remove the meter when they shut off power to the house, step 1). Remove the old meter base, also called a socket, and install a new base that’s rated for the amperage of your new power service. Here, a 200-amp bypass meter base is being installed.

Update the conduit that runs from your house to the bottom of the meter base. This should be 2" rigid conduit in good repair. Attach the conduit to the base and wall with the correct fittings. Rigid metal conduit is a good option, but Schedule 80 PVC is probably the best choice for housing the service entrance wires.

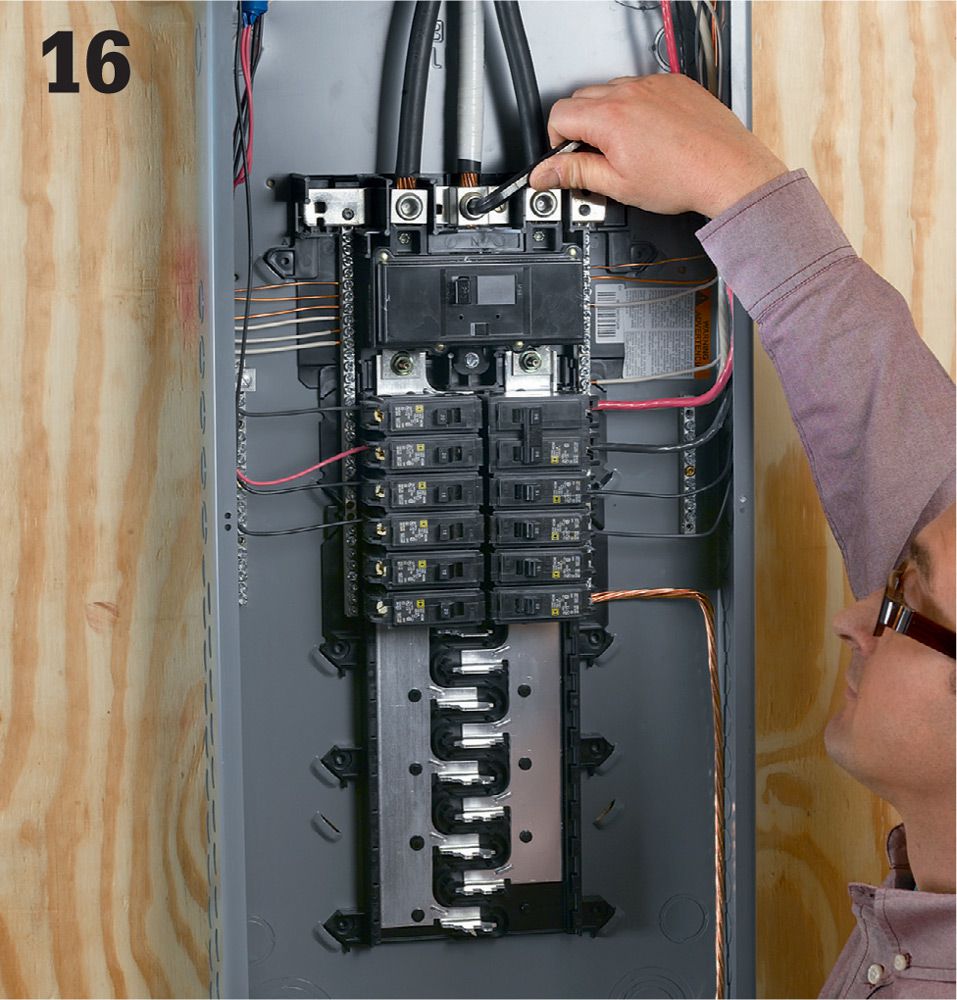

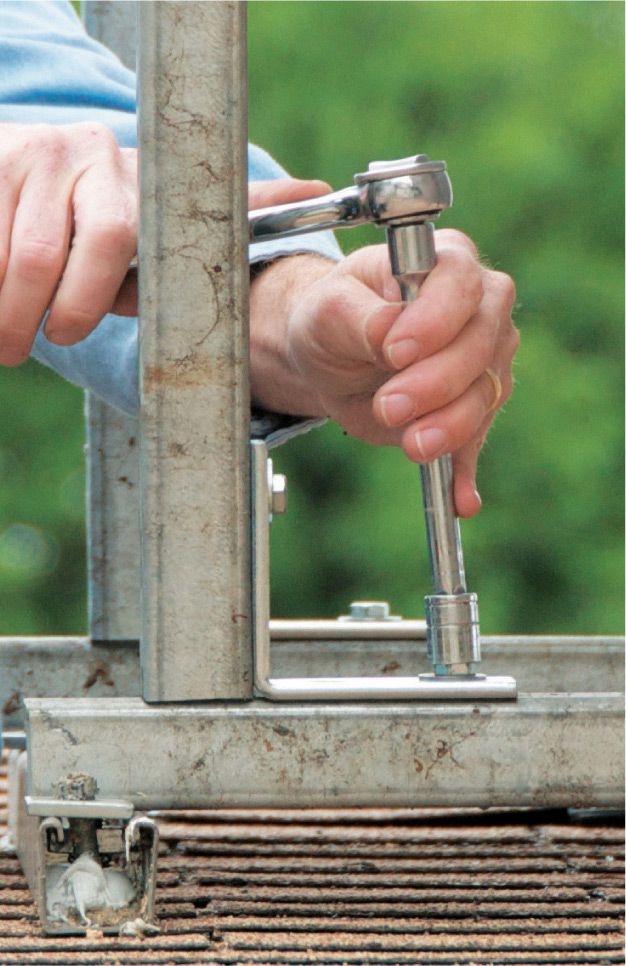

Install new service entrance wires. Each wire carries 120 volts from the meter to the service wire lugs at the top of your service panel. Code is very specific about how these connections are made. In most cases, you’ll need to tighten the terminal nuts with a specific amount of torque that requires a torque wrench to measure. Also attach the sheathed neutral wire to the neutral/grounding lug.

Attach the se wires to the lugs connected to the main breakers at the top of your service entry panel. Do not remove too much insulation on the wires—leaving the wires exposed is a safety hazard. The neutral service entry wire is attached either directly to the neutral bus bar or to a metal bridge that is connected to the neutral bonding bus bar. Install the green grounding screw provided with the panel.

Install service entrance wires from the meter to the weatherhead, where the connections to the service drop wires are made. Only an agent for your public utility company may make the hookup at the weatherhead.

Have the panel and all connections inspected and approved by your local building department, and then contact the public utility company to make the connections at the power drop. Once the connections are made, turn the main breakers on and test all circuits.

Tall Mast, Short Roof ![]()

The service drop must occur at least 10 ft. above ground level, and as much as 14 ft. in some cases. Occasionally, this means that you must run the conduit for the service mast up through the eave of your roof and seal the roof penetration with a boot.

![]() Grounding & Bonding a Wiring System

Grounding & Bonding a Wiring System

All home electrical systems must be bonded and grounded according to code standards. This entails two tasks: the metal water and gas pipes must be connected electrically to create a continuous low resistance path back to the main electrical panel; and the main electrical panel must be grounded to a grounding electrode such as a ground rod or rods driven into the earth near the foundation of your house. Although the piping system is bonded to the ground through your main electrical service panel, the panel grounding and the piping bonding are unrelated when it comes to function. The grounding wire that runs from your electrical panel to grounding electrode helps even out voltage increases that often occur because of lightning and other causes. The wires that bond your metal piping are preventative, and they only become important in the unlikely event that an electrical conductor energizes the pipe. In that case, correct bonding of the piping system will ensure that the current does not remain in the system, where it could electrocute anyone who touches a part of the system, such as a faucet handle. Bonding is done relatively efficiently at the water heater, as the gas piping and water piping generally there.

Gas pipe in older homes is usually steel or copper. The bonding connection point for these pipes can be at any accessible location, such as at the water heater or at the gas meter. Gas pipe in some new homes is a flexible material called corrugated stainless steel tubing (CSST). The bonding point for CSST must be at the first piece of steel or copper pipe where the gas service enters the home. This is because lightning can blow holes in CSST, causing a gas leak.

Tools & Materials ![]()

Hammer

Straight edge screwdriver

Drill

1/2" drill bit

A length of ground wire

Some wire staples

3 pipe ground clamps

Eye and ear protection

Work gloves

Grounding rods

5-lb. maul

Caulk

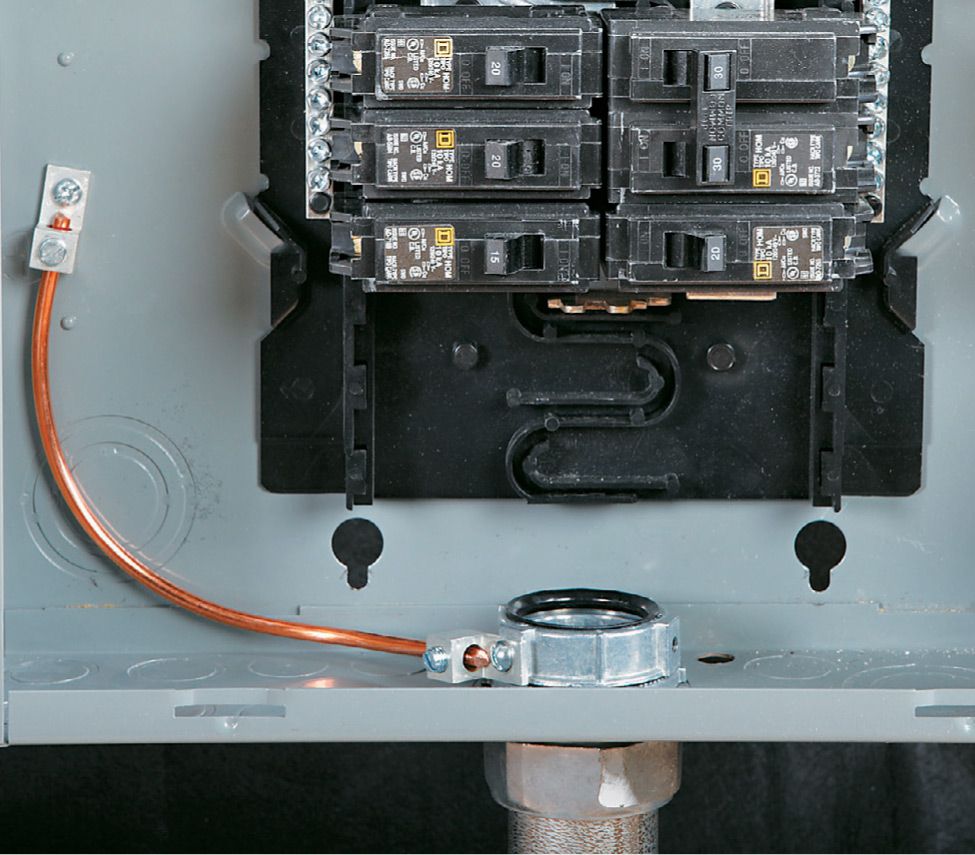

A pair of 8-ft.-long metal ground rods are driven into the earth next to your house to provide a path to ground for your home wiring system.

![]() How to Bond Metallic Piping

How to Bond Metallic Piping

Determine the amperage rating of your electrical service by looking at your main breakers. The system amperage (usually 100 or 200 amps) determines the required gauge of the bonding wire you need. #4 copper wire is sufficient for service not exceeding 200 amps. Smaller, less expensive copper wire is allowed for services between 100 and 175 amps. Check with your electrical inspector if you want to use wire smaller than #4.

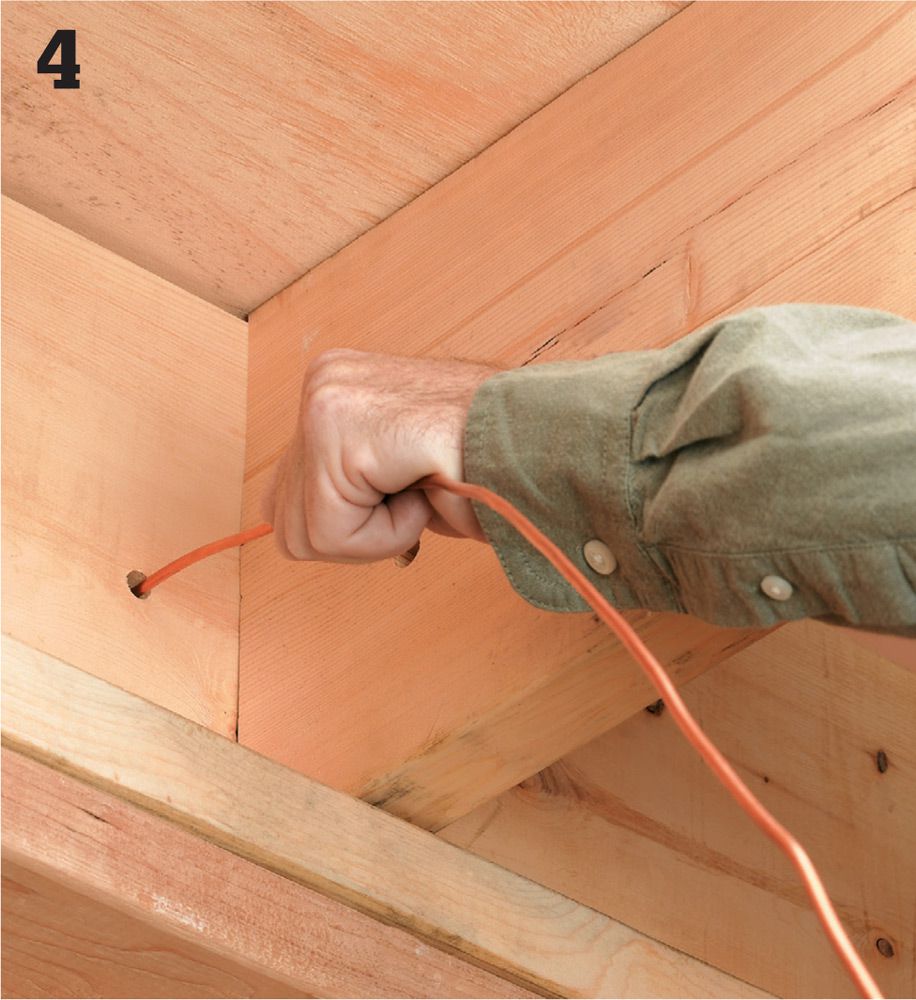

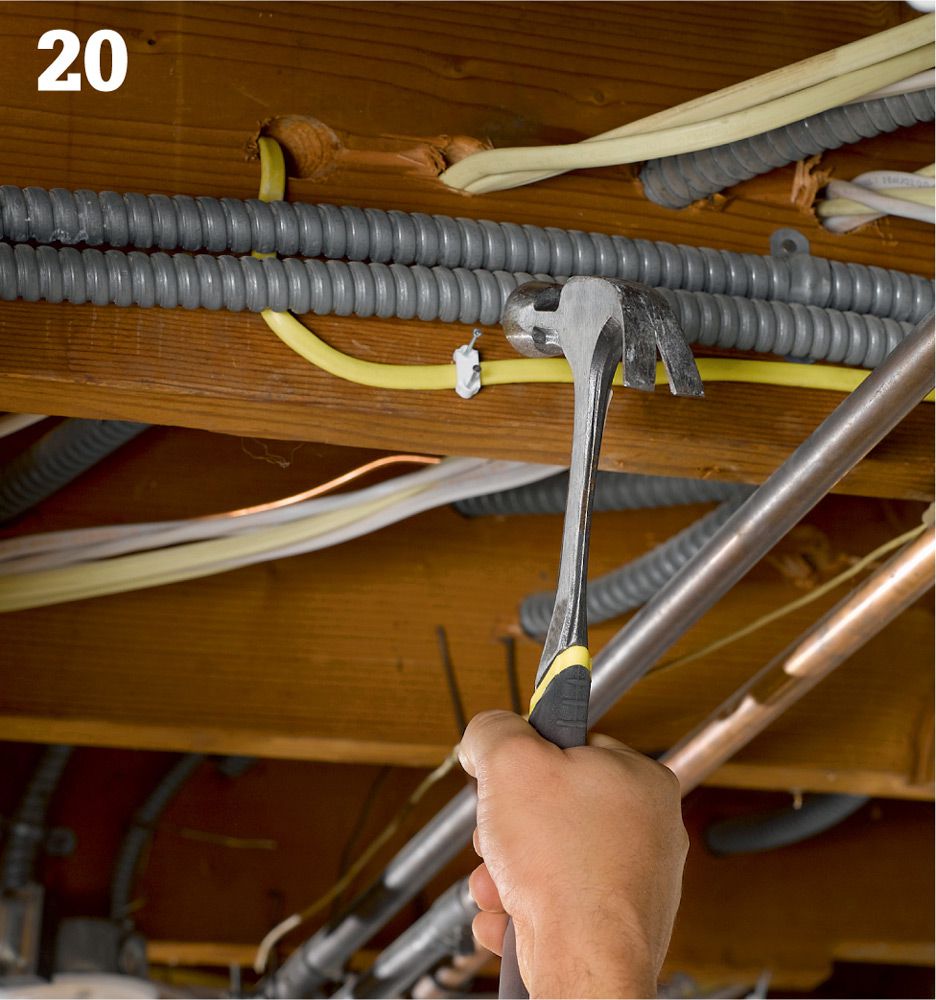

Run the bonding wire from a point near your water heater (a convenient spot if you have a gas-fueled water heater) to an exit point where the wire can be bonded to the grounding wire that leads to the exterior grounding electrodes. This is frequently done at the service panel. Run this wire as you would any other cable, leaving approximately 6 to 8 ft. of wire at the water heater. If you are running this wire through the ceiling joists, drill a 1/2" hole as close to the center as possible to not weaken the joist. Staple the wire every 2 ft. if running it parallel to the joists.

Install pipe ground clamps on each pipe (hot water supply, cold water supply, gas), roughly a foot above the water heater. Do not install clamps near a union or elbow because the tightening of the clamps could break or weaken soldered joints. Also make sure the pipes are free and clear of any paint, rust, or any other contaminant that may inhibit a good clean connection. Do not overtighten the clamps. Use clamps that are compatible with the pipe so that corrosion will not occur. Use copper or brass clamps on copper pipe. Use brass or steel clamps on steel pipe.

Route the ground wire through each clamp wire hole and then tighten the clamps onto the wire. Do not cut or splice the wire: The same wire should run through all clamps.

At the panel, turn off the main breaker. Open the cover by removing the screws, and set the cover aside. Route the ground wire through a small 3/8" hole provided towards the rear of the panel on the top or bottom. You will usually have to knock the plug out of this hole by placing a screwdriver on it from the outside and tapping with a hammer. Make sure the ground wire will not come into contact with the bus bars in the middle of the panel or any of the load terminals on the breakers.

Locate an open hole on your ground and neutral bus and insert the ground wire. These holes are large enough to accommodate up to a #4 awg wire, but it may be difficult at times. If you’re having trouble pushing the wire in, trim a little wire off the end and try with a clean cut piece. Secure the set screw at the lug. Replace the panel cover and turn the main breaker back on.

![]() Tips for Grounding the Main Service Panel

Tips for Grounding the Main Service Panel

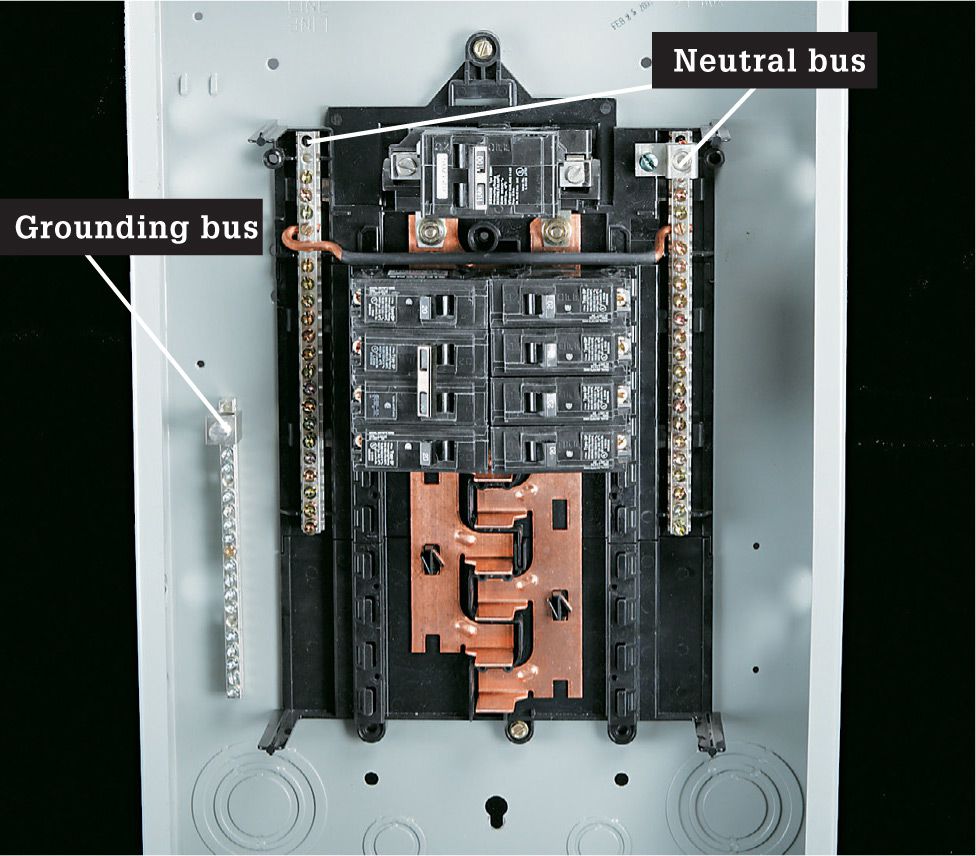

The neutral and grounding wires should not be connected to the same bus in most subpanels. The grounding bus should be bonded to the subpanel cabinet. The neutral bus should not be bonded to the subpanel cabinet.

Metallic conduit must be physically and electrically connected to panel cabinets. A bonding bushing may be required in some cases, where not all of a knockout is removed.

![]() Ground Rod installation

Ground Rod installation

The ground rod is an essential part of the grounding system. Its primary function is to create a path to ground for electrical current, such as lightning, line surges, and unintentional contact with high voltage lines. If you upgrade your electrical service you likely will need to upgrade your grounding wire and rods to meet code.

Note: Different municipalities have different requirements for grounding, so be sure to check with the AHJ (Authority Having Jurisdiction) first before attempting to do this yourself.

Call before you dig! Make sure the area where you will be installing the ground rods is free and clear from any underground utilities.

Exercise Your Breakers ![]()

Your breakers (including the main) should be “exercised” once a year to ensure proper mechanical function. Simply turn them off and then back on. A convenient time to perform the exercise is at daylight savings time, when you’ll need to reset all of your clocks anyway.

![]() How to Install a Grounding Electrode System

How to Install a Grounding Electrode System

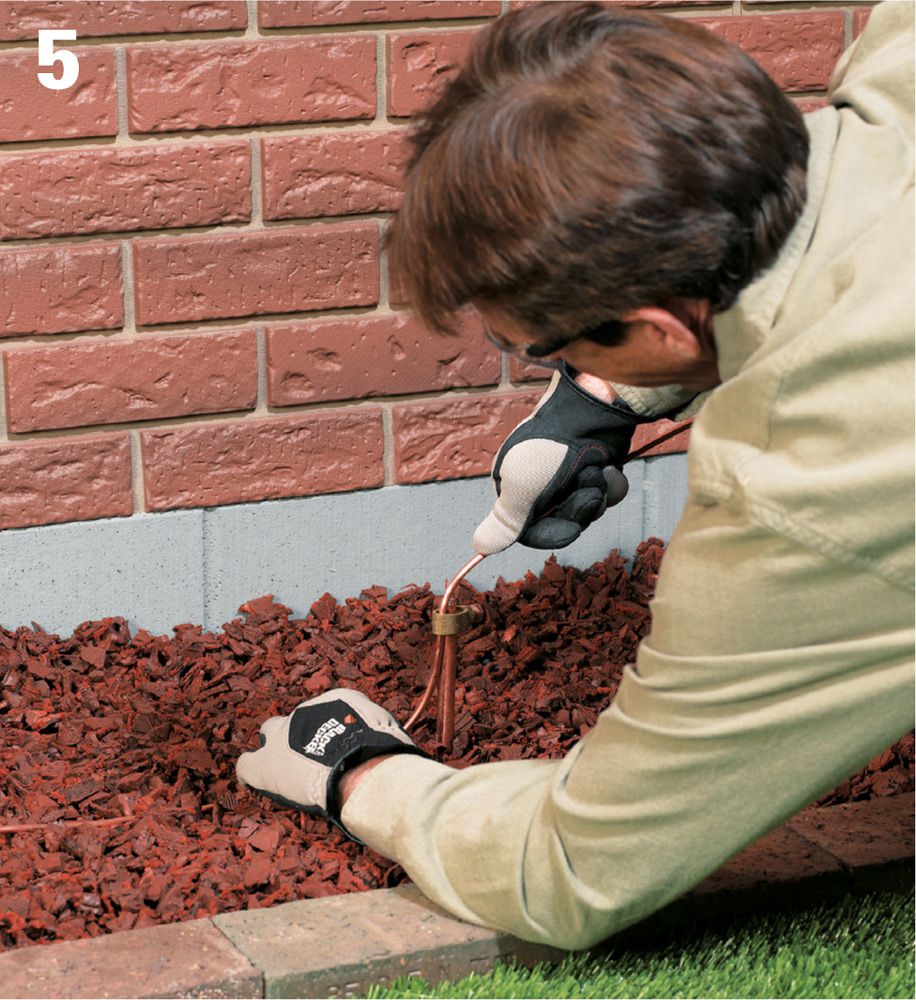

Begin by purchasing two copper-coated steel ground rods 5/8" diameter by 8' long. Grounding rods have a driving point on one end and a striking face on the other end.

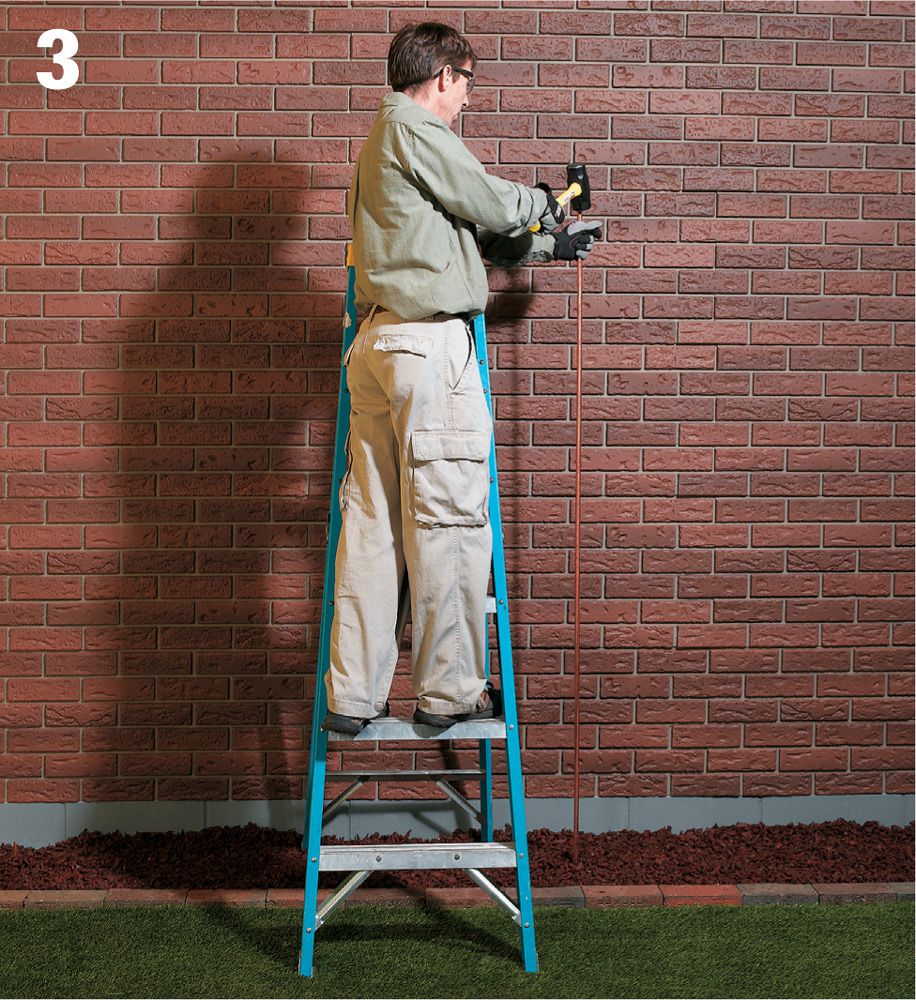

Drill a 5/16" hole in the rim joist of your house, as close as practical to the main service panel to the outside of the house above the ground level at least 6".

About a foot from the foundation of the house, pound one ground rod into the earth with a five-pound maul. If you encounter a rock or other obstruction, you can pound the ground rod at an angle as long as it does not exceed 45°. Drive until only 3" or 4" of the rod is above ground. Measure at least 6 ft. from the first ground rod and pound in another one.

Run uninsulated #4 copper wire from the ground bus in your main service panel through the hole in the rim joist and to the exterior of the house, leaving enough wire to connect the two ground rods together.

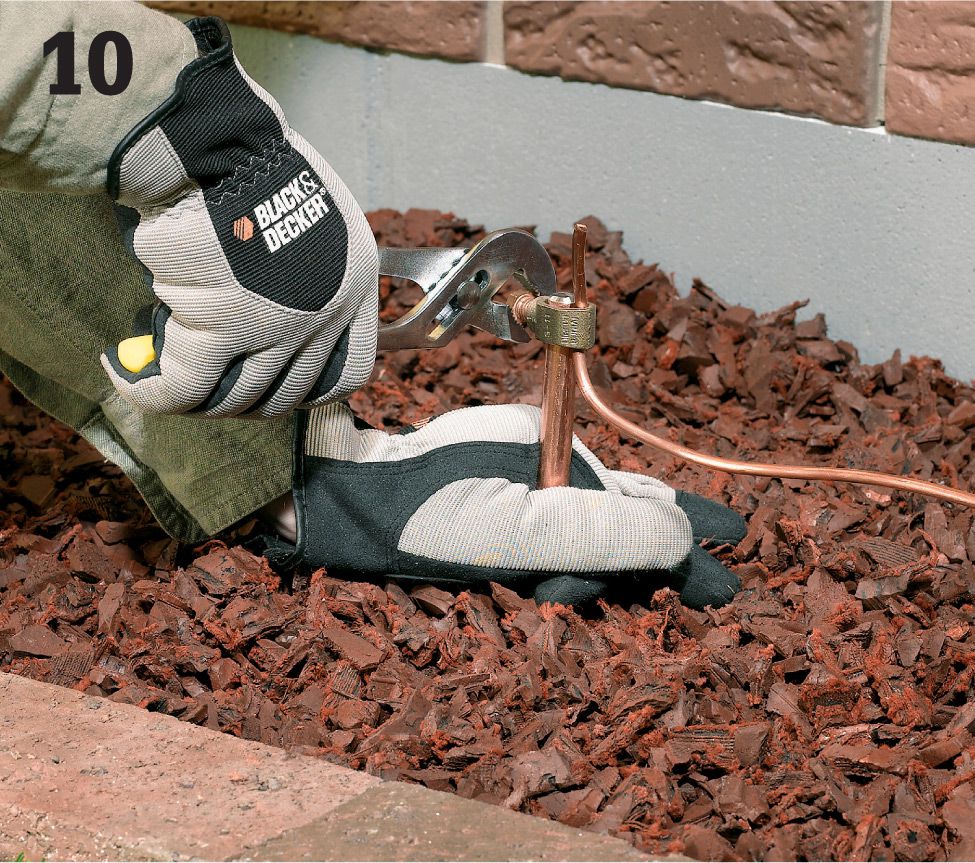

Using a brass clamp commonly referred to as an acorn, connect the wire to the first ground rod, pulling the wire taut so no slack exists. Continue pulling the wire to reach the second grounding rod, creating a continuous connection.

Connect the second ground rod with another acorn to the uncut grounding wire previously pulled through the first acorn. Trim the excess wire.

Dig out a few inches around each rod to create clearance for the five-pound maul. Creating a shallow trench beneath the grounding wire between the rods is also a good idea. Drive each rod with the maul until the top of the rod is a few inches below grade.

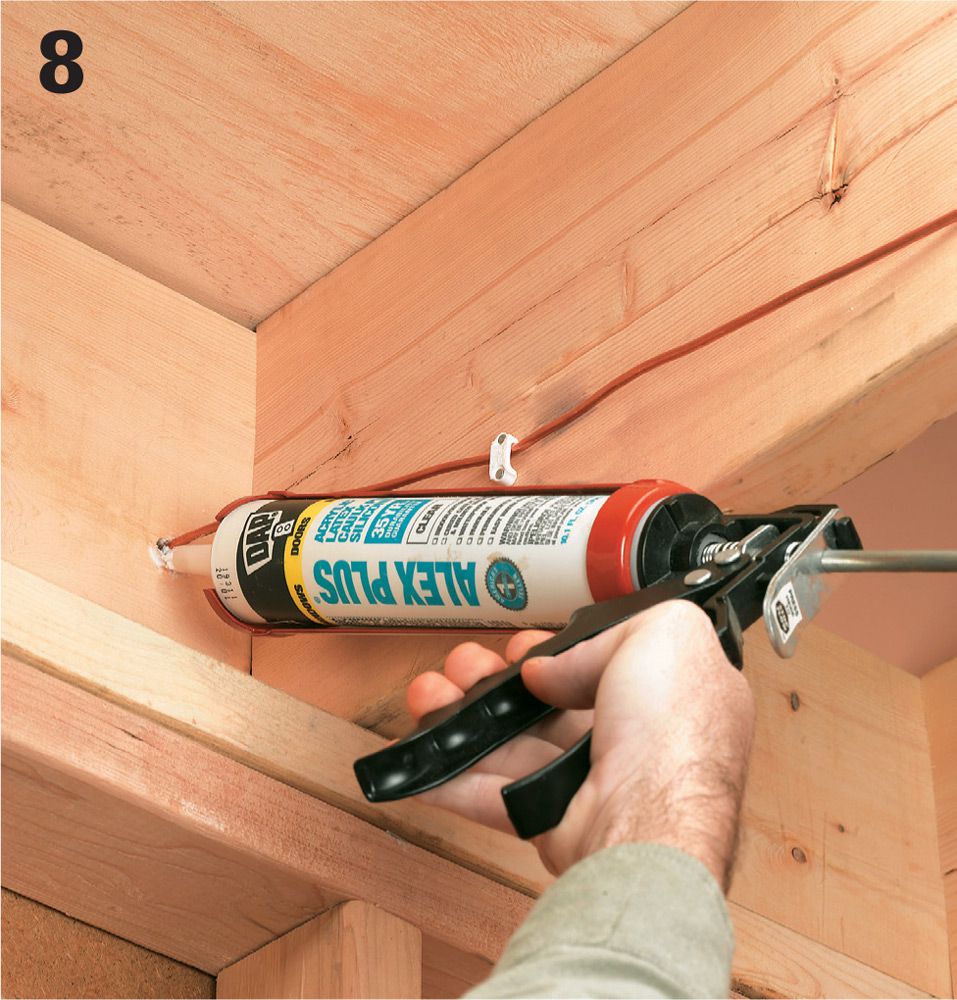

Inject caulk into the hole in the rim joist on both the interior and exterior side.

![]() Tips for Grounding

Tips for Grounding

A listed metal strap may be used to ground indoor communication wires such as telephone and cable TV if an intersystem bonding terminal is not available.

A piece of reinforcing bar encased in a concrete footing is a common grounding electrode in new construction. Called an ufer, the electrode must be No. 4 or larger rebar and at least 20 ft. long. (Shown prior to pouring concrete.)

![]() Subpanels

Subpanels

Install circuit breaker subpanels if the main circuit breaker panel does not have enough open breaker slots for the new circuits you are planning. Subpanels serve as a second distribution center for connecting circuits. They receive power from a double-pole circuit breaker you install in the main circuit breaker panel.

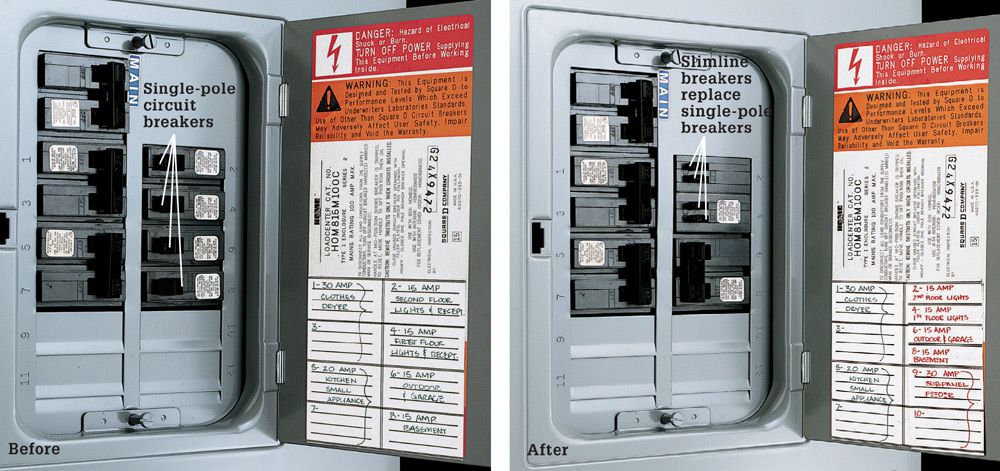

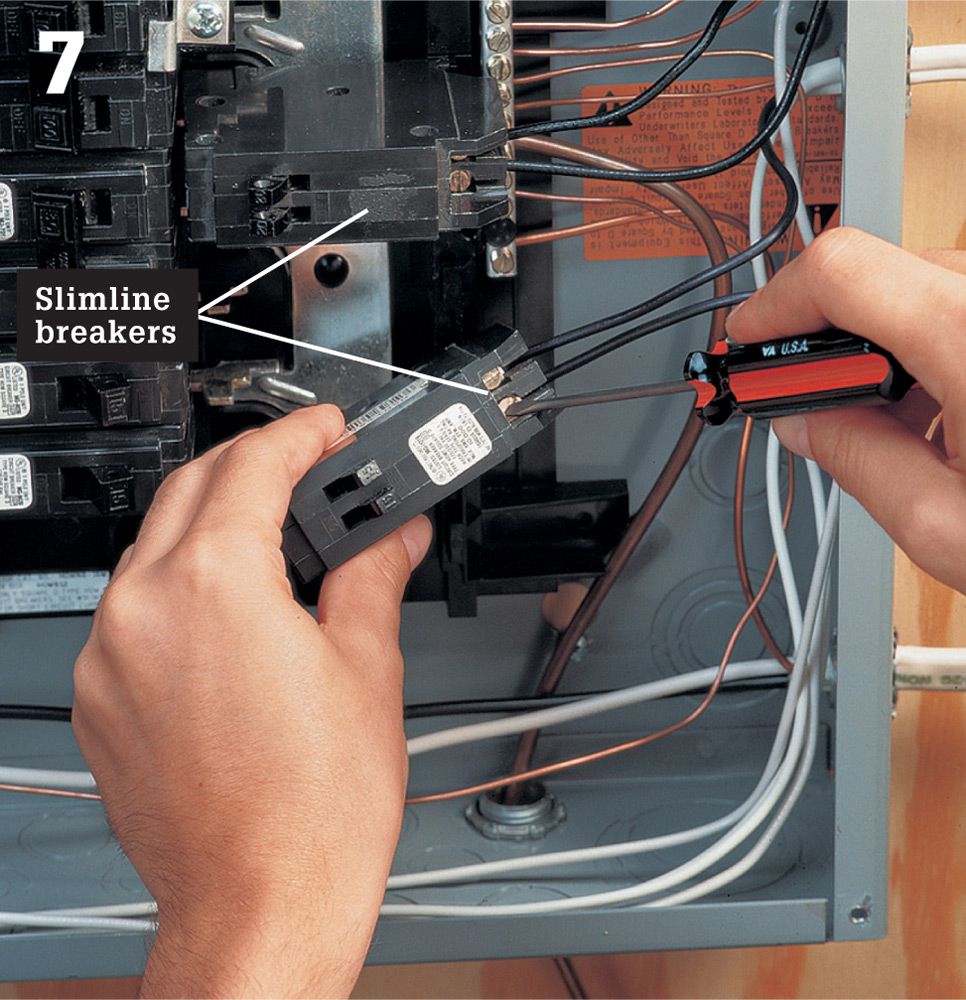

If the main service panel is so full that there is no room for the double-pole subpanel breaker, you can reconnect some of the existing 120-volt circuits to special slimline breakers (photos below).

Plan your subpanel installation carefully, making sure your electrical service supplies enough power to support the extra load of the new subpanel circuits. Assuming your main service is adequate, consider installing an oversized subpanel breaker in the main panel to provide enough extra amps to meet the needs of future wiring projects.

Also consider the physical size of the subpanel, and choose one that has enough extra slots to hold circuits you may want to install later. The smallest panels have room for up to six single-pole breakers (or three double-pole breakers), while the largest models can hold 20 single-pole breakers or more.

Subpanels often are mounted near the main circuit breaker panel. Or, for convenience, they can be installed close to the areas they serve, such as in a new room addition or a garage. In a finished room, a subpanel can be painted or housed in a decorative cabinet so it is less of a visual distraction. If it is covered, make sure the subpanel is easily accessible and clearly identified.

Tools & Materials ![]()

Hammer

Screwdriver

Circuit tester

Cable ripper

Combination tool

Screws

Cable clamps

Three-wire NM cable

Cable staples

Double-pole circuit breaker

Circuit breaker subpanel

Slimline circuit breakers

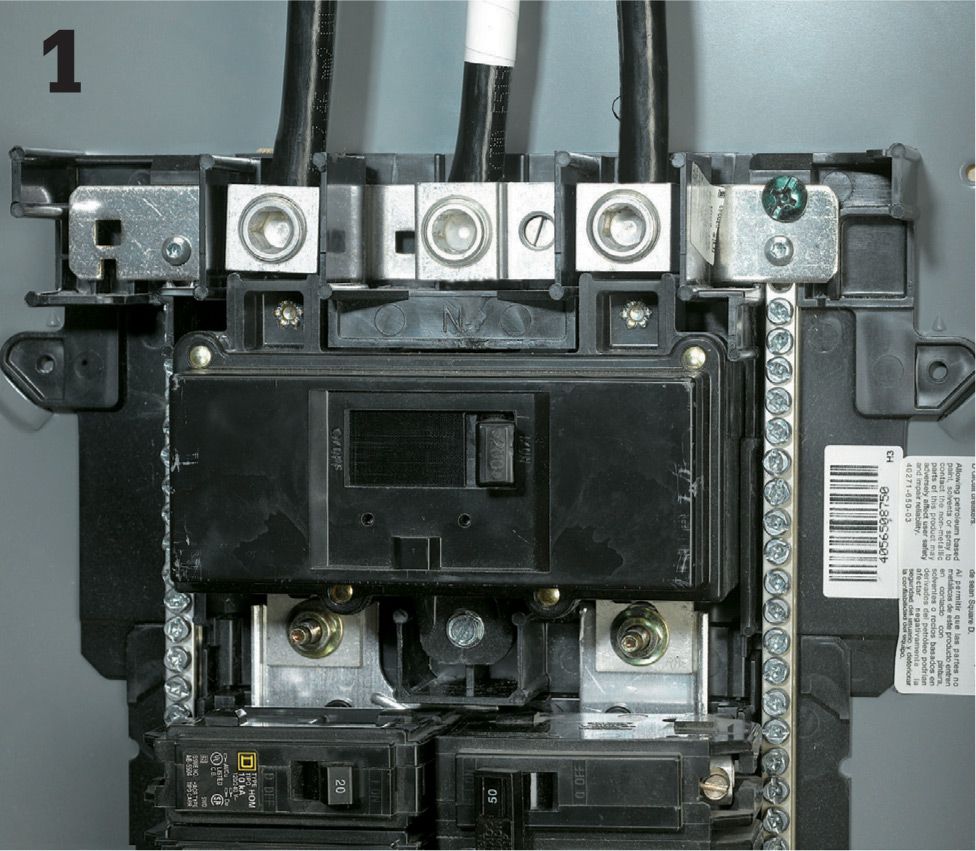

To conserve space in a service panel, you can replace single-pole breakers with slimline breakers. Slimline breakers take up half the space of standard breakers, allowing you to fit two circuits into one single slot on the service panel. In the service panel shown above, four single-pole 120-volt breakers were replaced with slimline breakers to provide the double opening needed for a 30-amp, 240-volt subpanel feeder breaker. Use slimline breakers (if your municipality allows them) with the same amp rating as the standard single-pole breakers you are removing, and make sure they are approved for use in your panel. If your municipality and panel allow slimline breakers, there may be restrictions on the quantity and location where they may be installed on the panel.

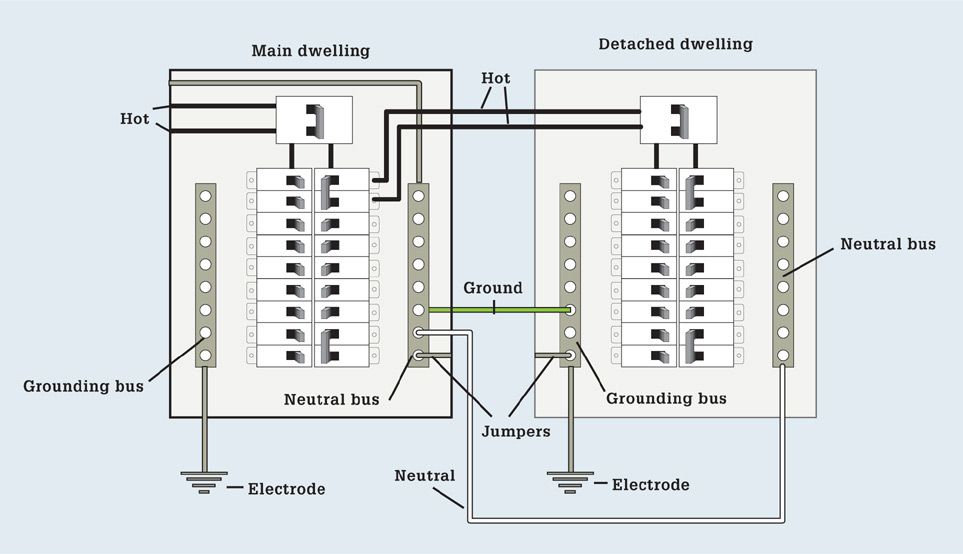

Wiring diagram for wiring a feeder from the main service panel to a subpanel in a separate building.

![]() How to Install a Subpanel

How to Install a Subpanel

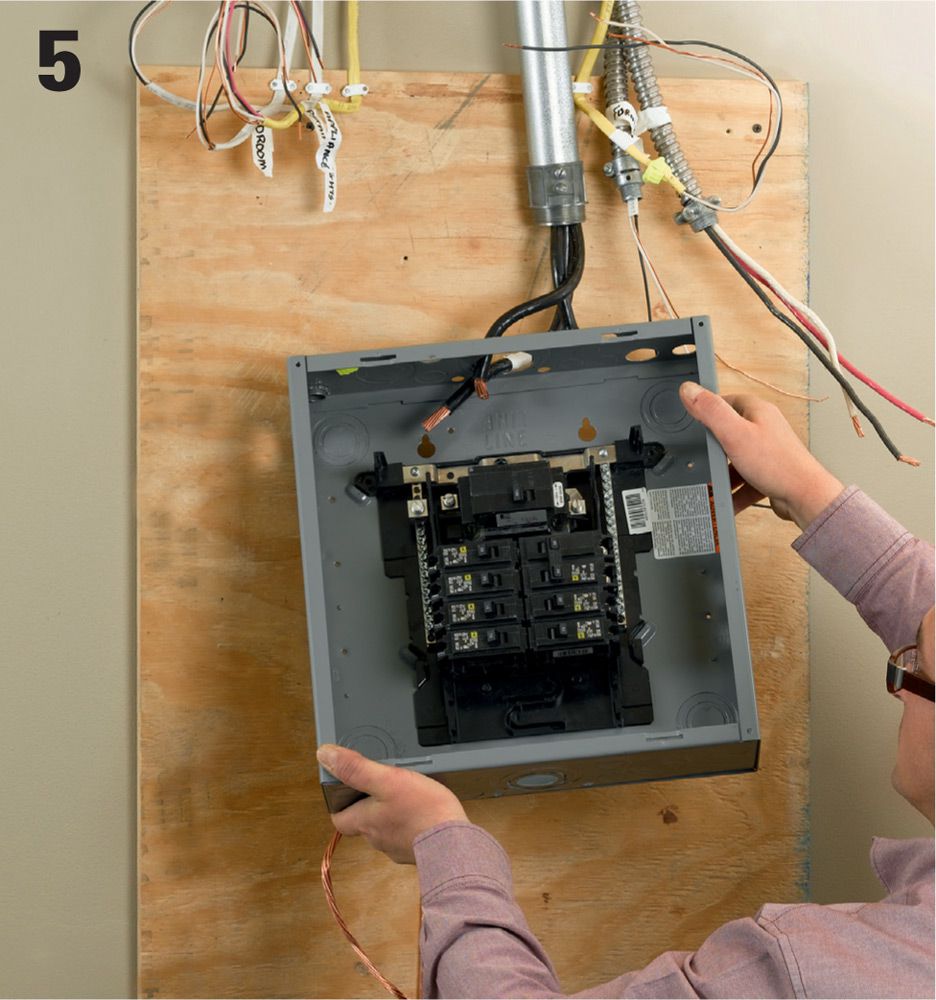

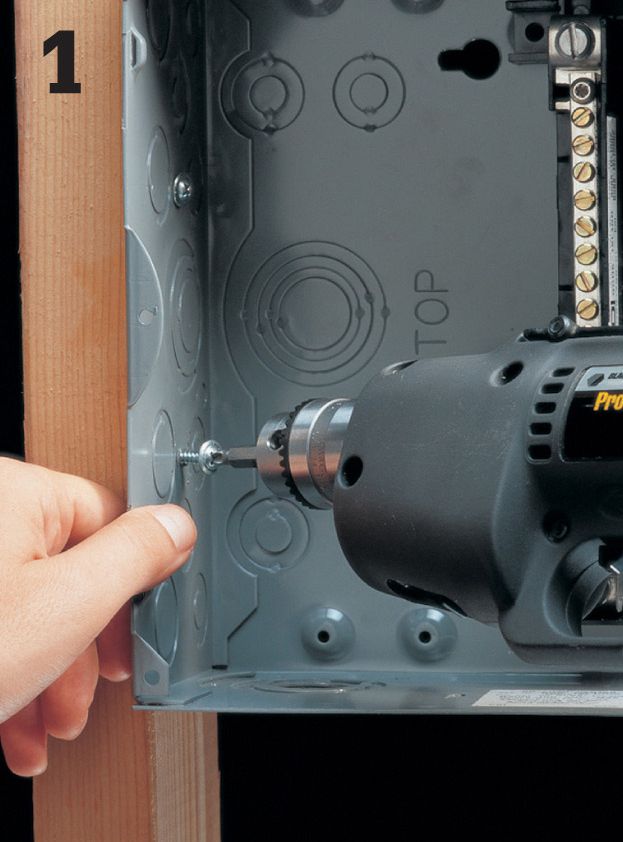

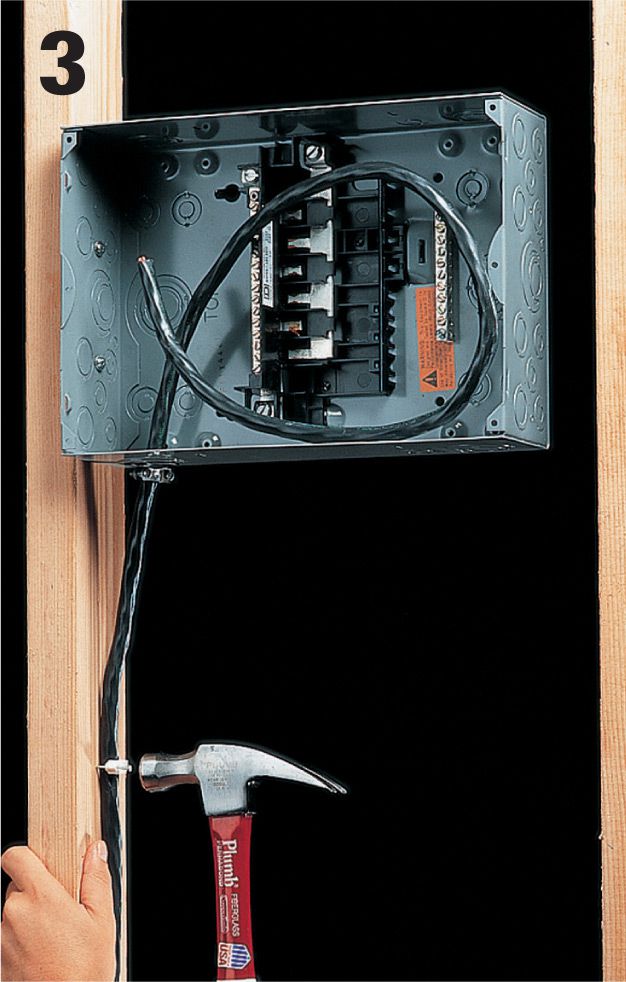

Subpanels are subject to the same installation and clearance rules as service panels. The subpanel can be mounted to the sides of studs or to plywood attached between two studs. The panel shown here extends 1/2" past the face of studs so it will be flush with the finished wall surface.

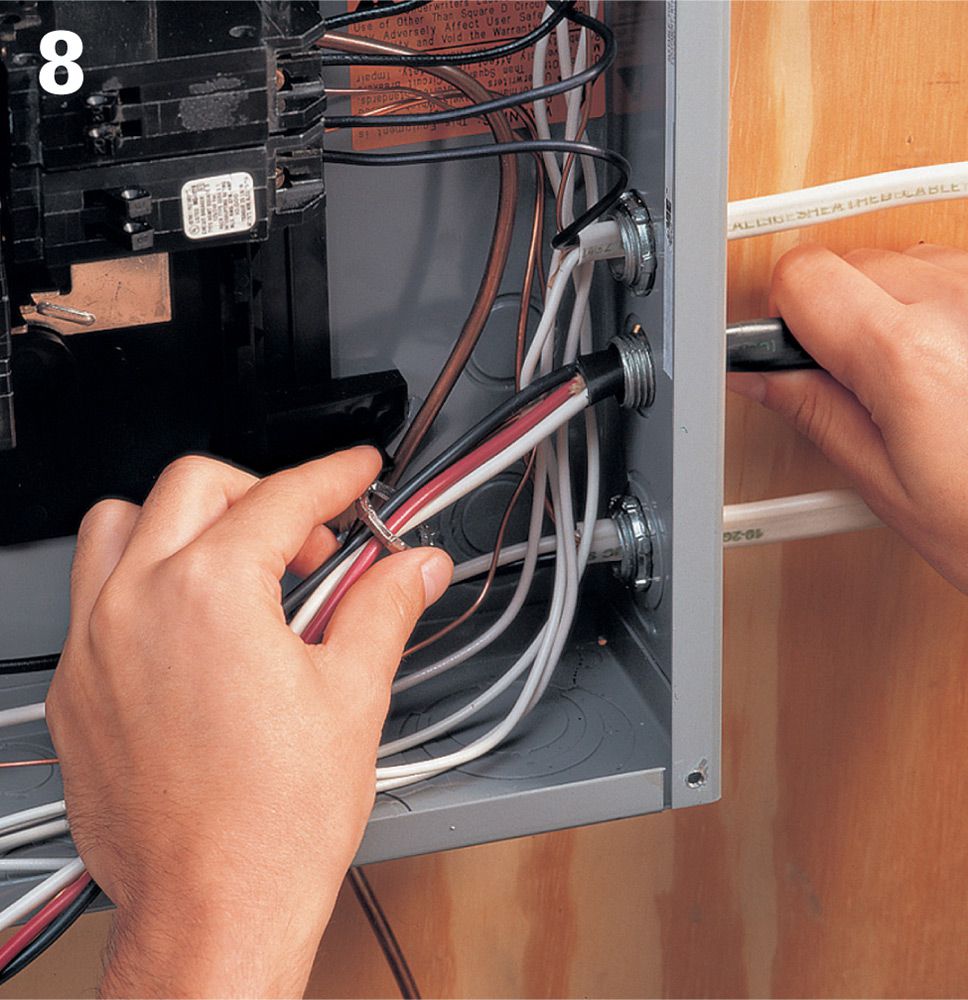

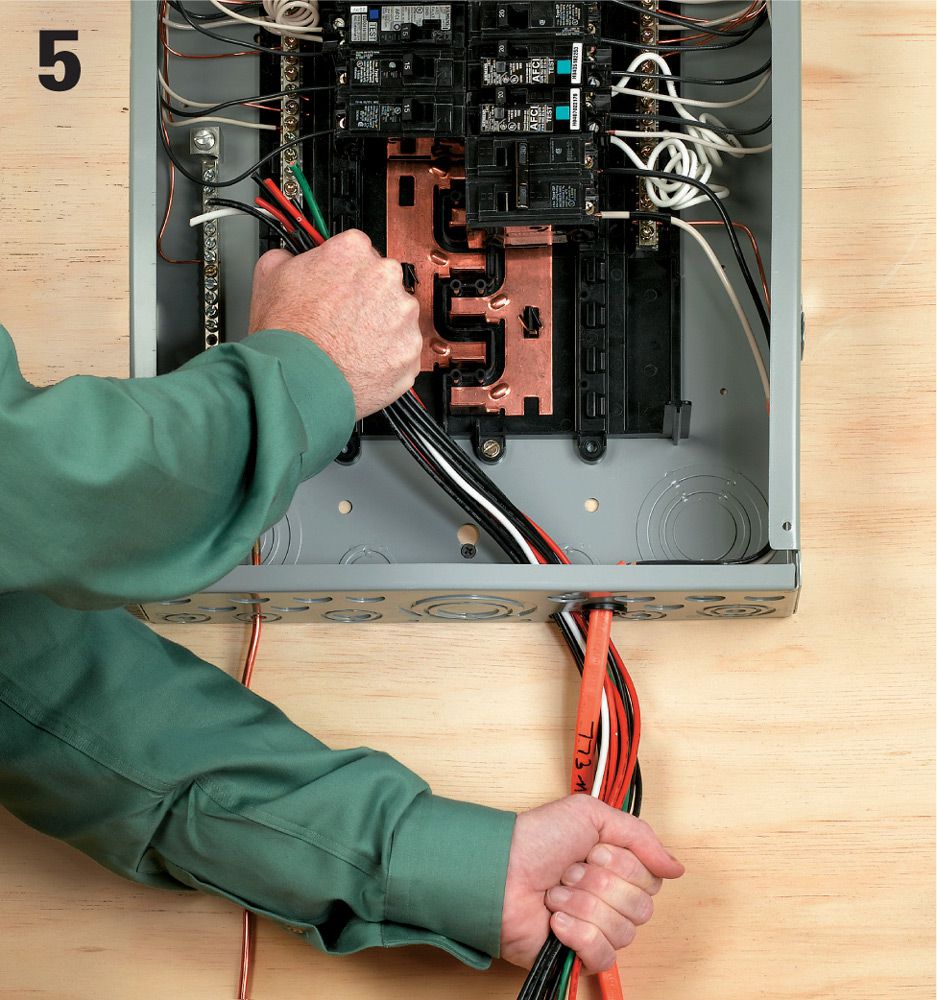

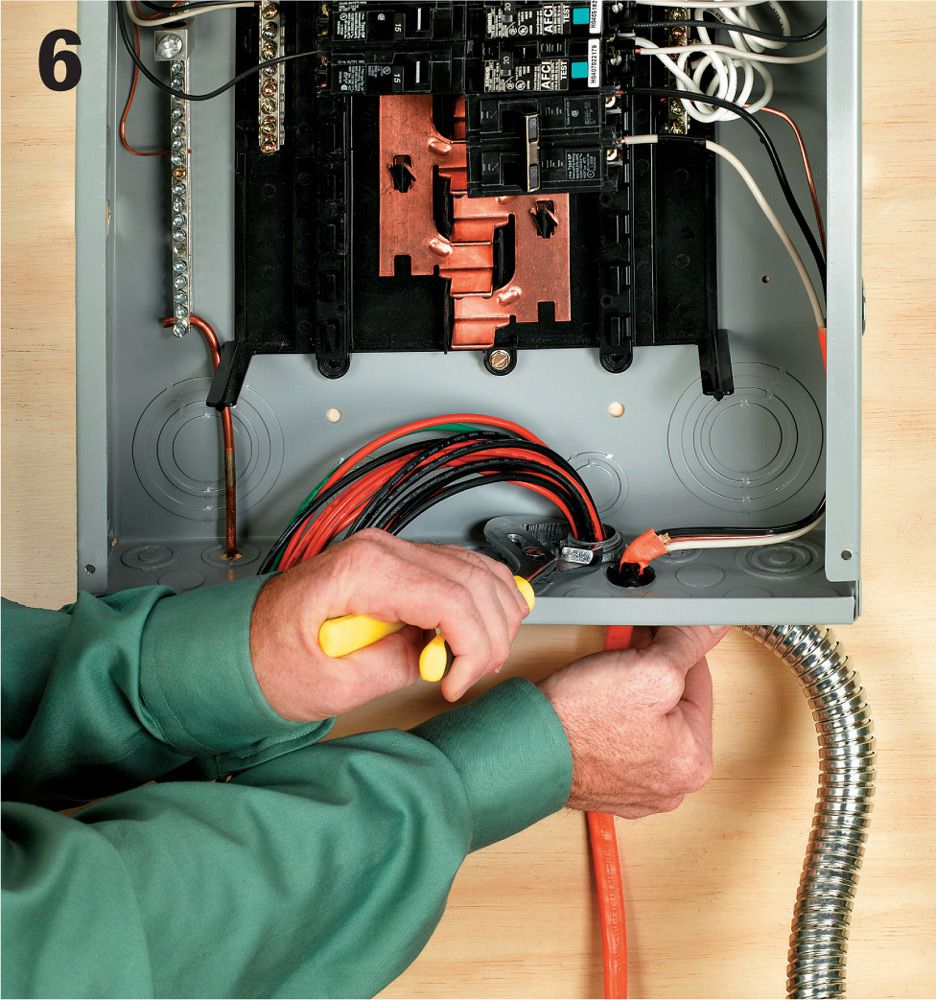

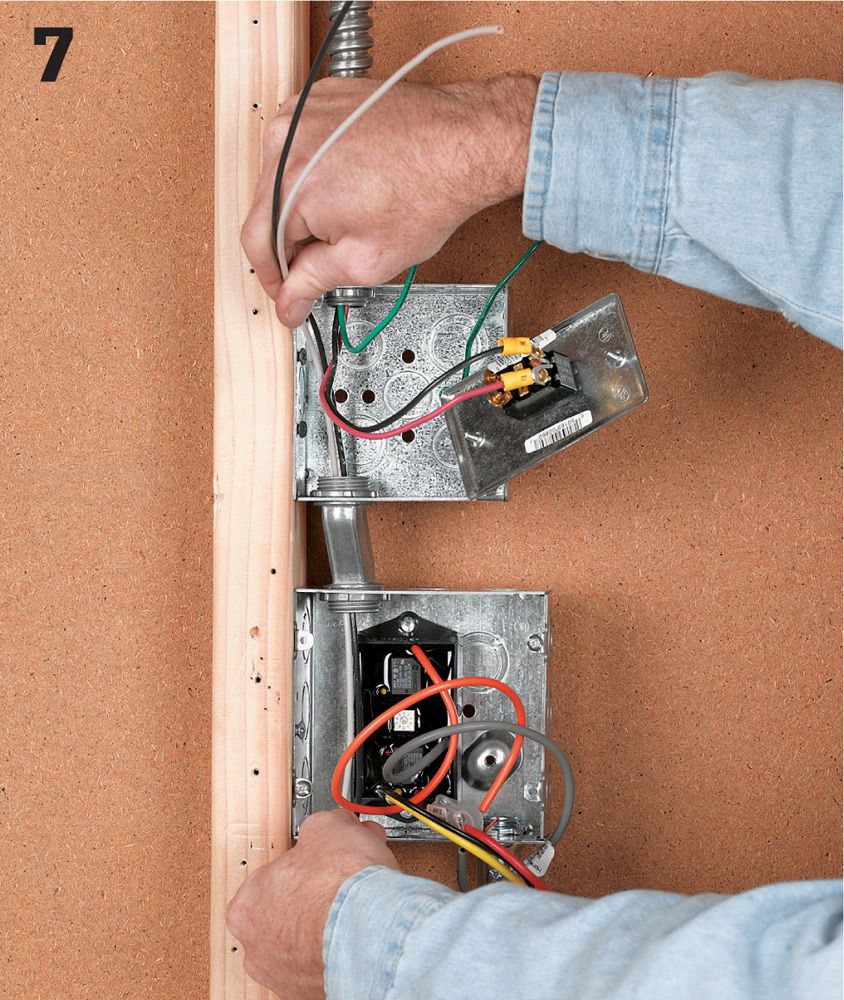

Open a knockout in the subpanel using a screwdriver and hammer. Run the feeder cable from the main circuit breaker panel to the subpanel, leaving about 2 ft. of excess cable at each end. See page 40 if you need to run the cable through finished walls.

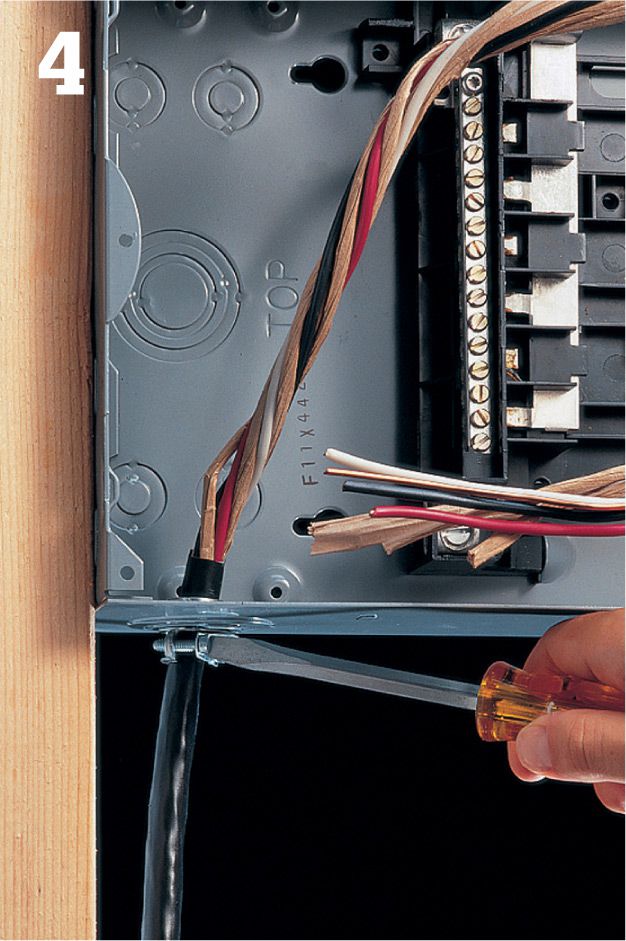

Attach a cable clamp to the knockout in the subpanel. Insert the cable into the subpanel, and then anchor it to framing members within 8" of each panel and every 54" thereafter.

Strip away outer sheathing from the feeder cable using a cable ripper. Leave at least 1/4" of sheathing extending into the subpanel. Tighten the cable clamp screws so the cable is held securely, but not so tightly that the wire sheathing is crushed.

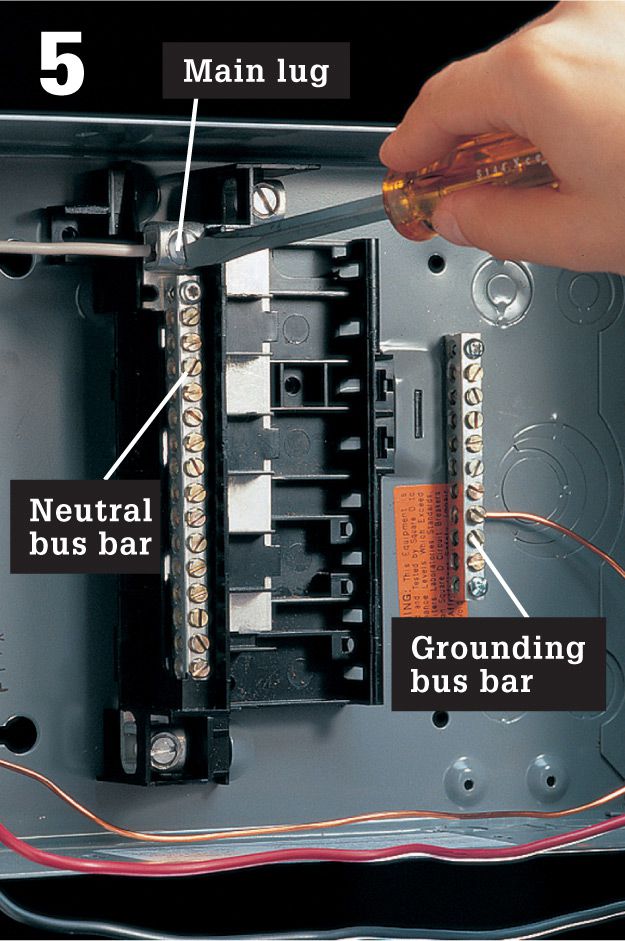

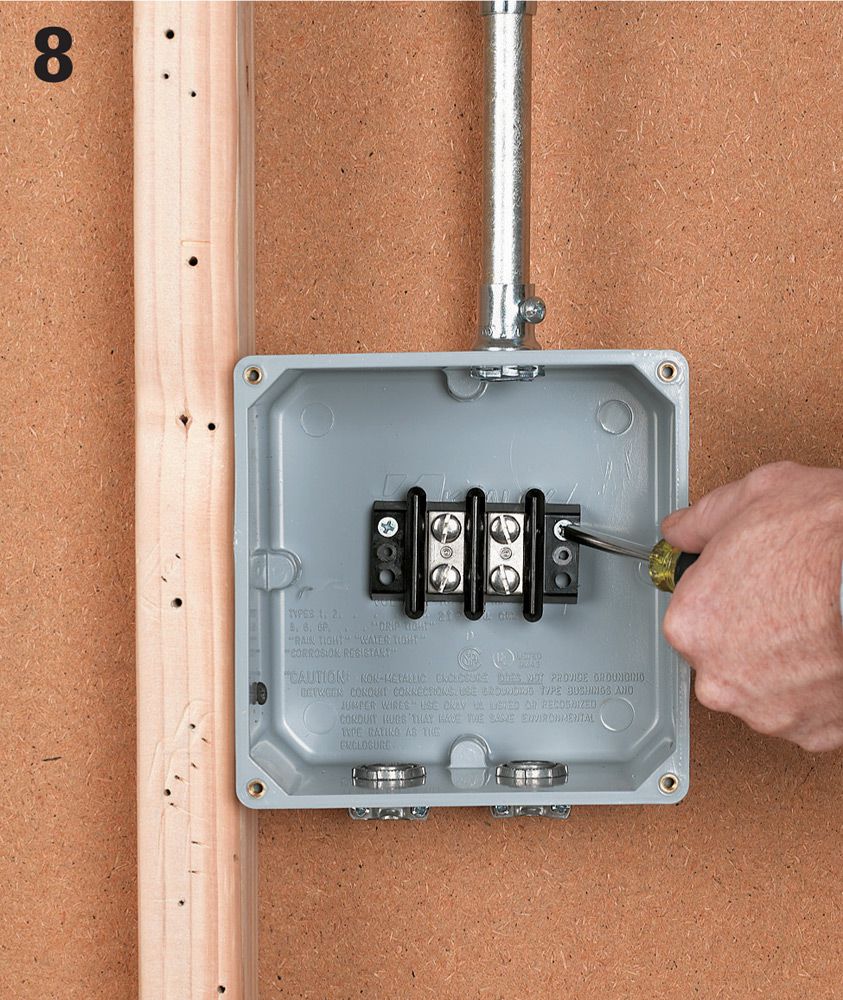

Strip 1/2" of insulation from the white neutral feeder wire, and attach it to the main lug on the subpanel neutral bus bar. Connect the grounding wire to a setscrew terminal on the grounding bus bar. Fold excess wire around the inside edge of the subpanel.

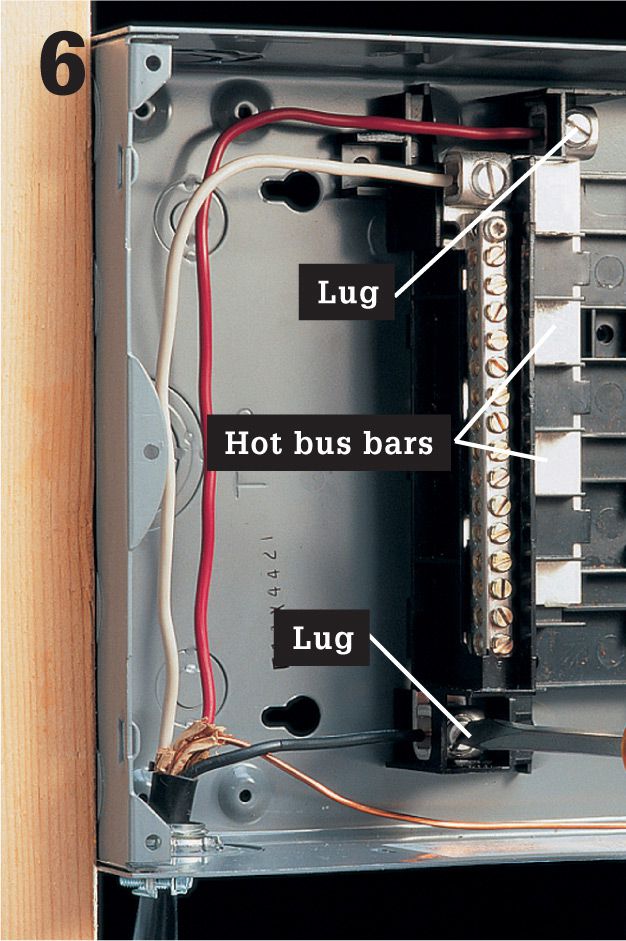

Strip away 1/2" of insulation from the red and the black feeder wires. Attach one wire to the main lug on each of the hot bus bars. Fold excess wire around the inside edge of the subpanel.

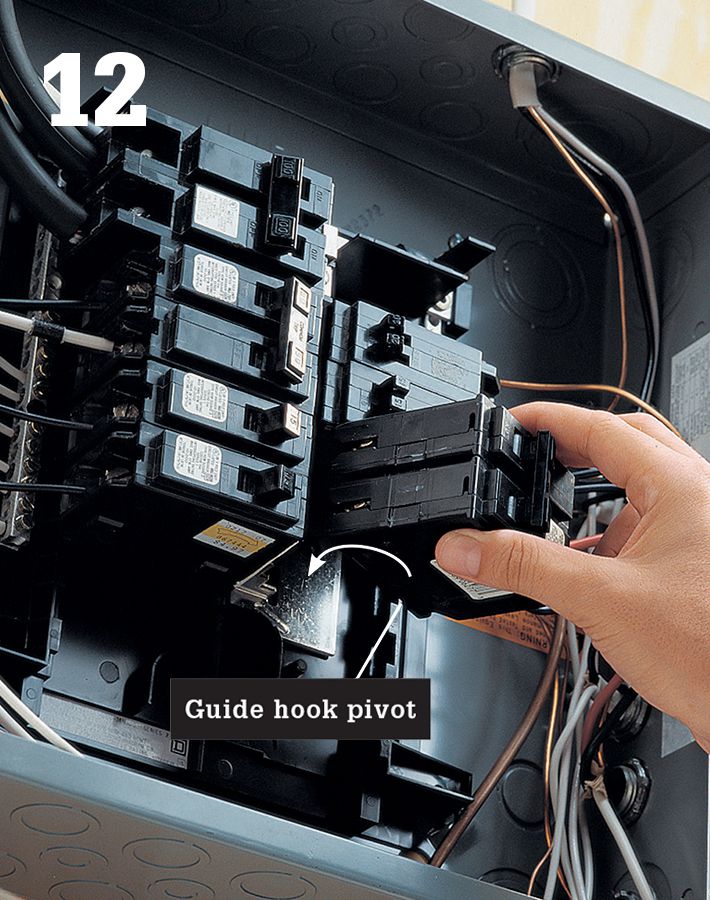

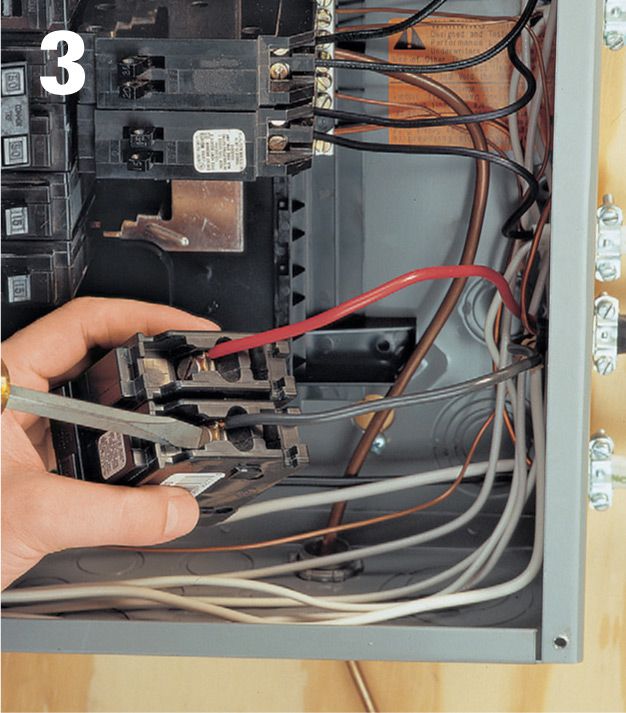

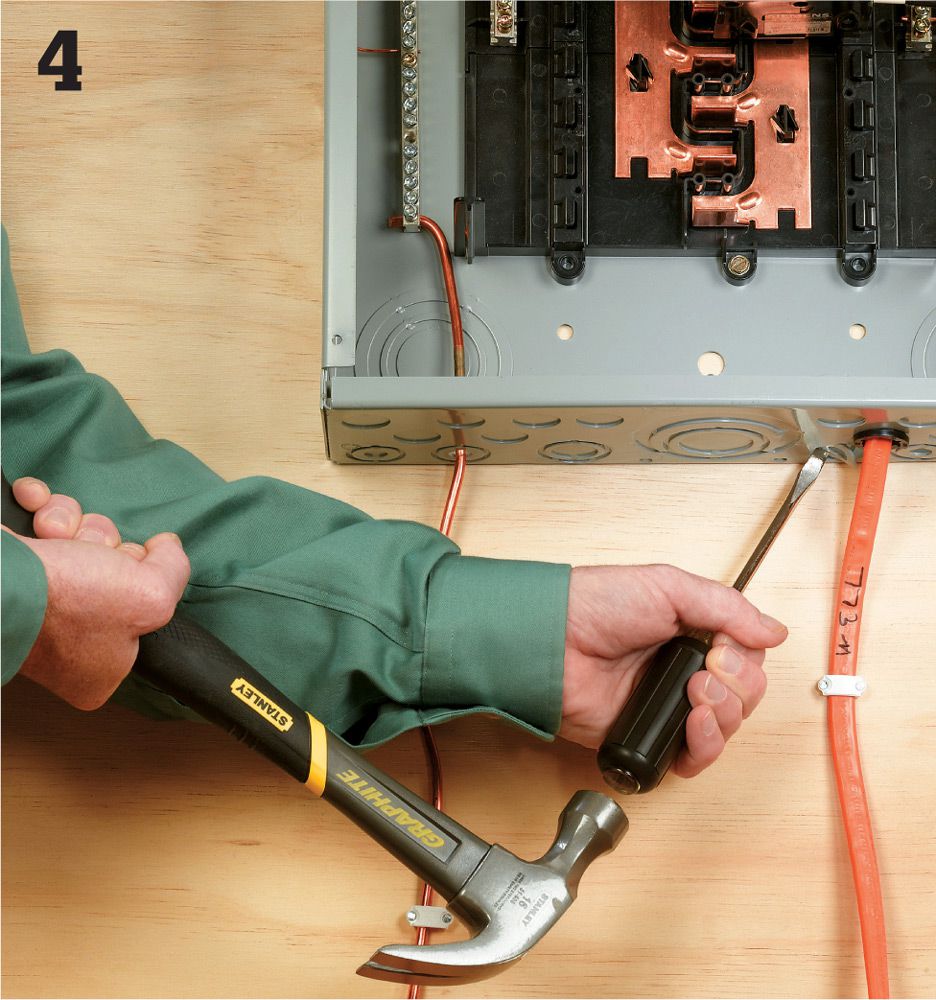

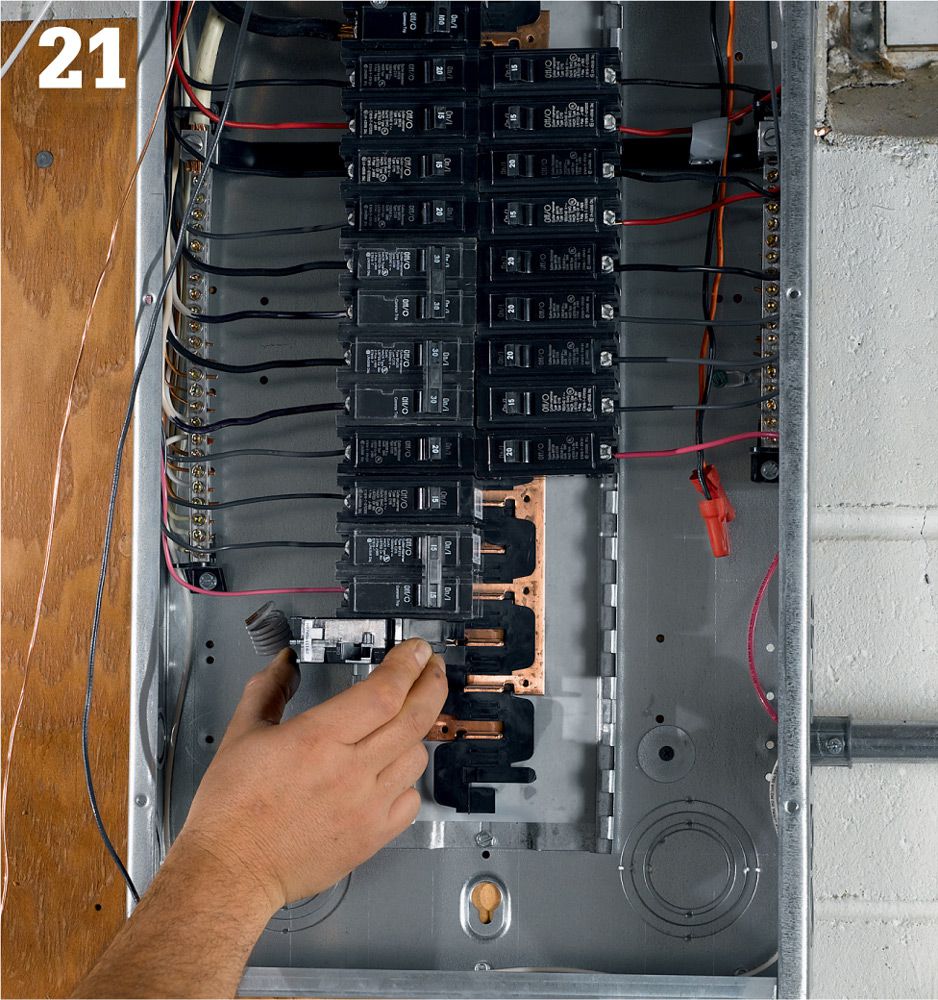

At the main circuit breaker panel, shut off the main circuit breaker, and then remove the coverplate and test for power (page 80). If necessary, make room for the double-pole feeder breaker by removing single-pole breakers and reconnecting the wires to slimline circuit breakers. Open a knockout for the feeder cable using a hammer and screwdriver. Note: some panels do not allow slimline breakers and some restrict where slimline breakers can be installed. Read the instructions on the panel cover.

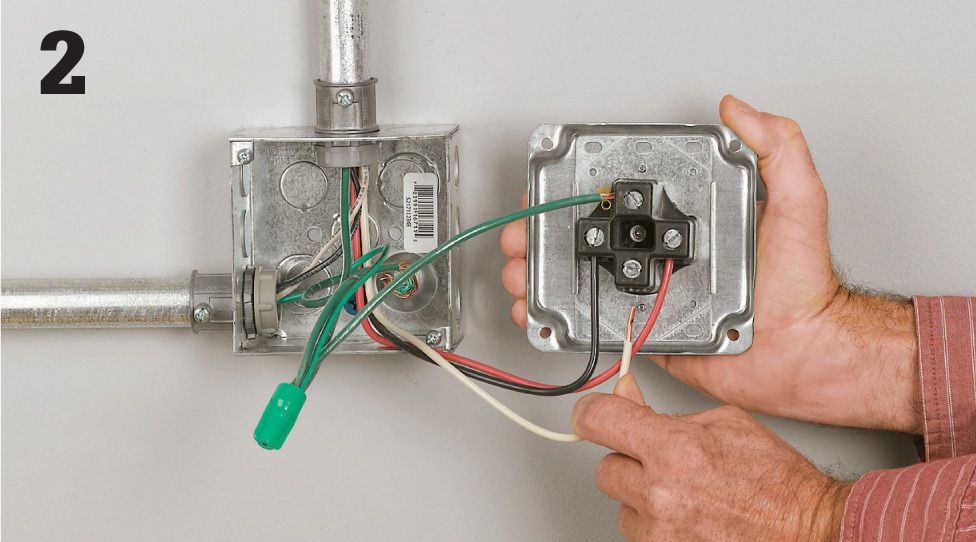

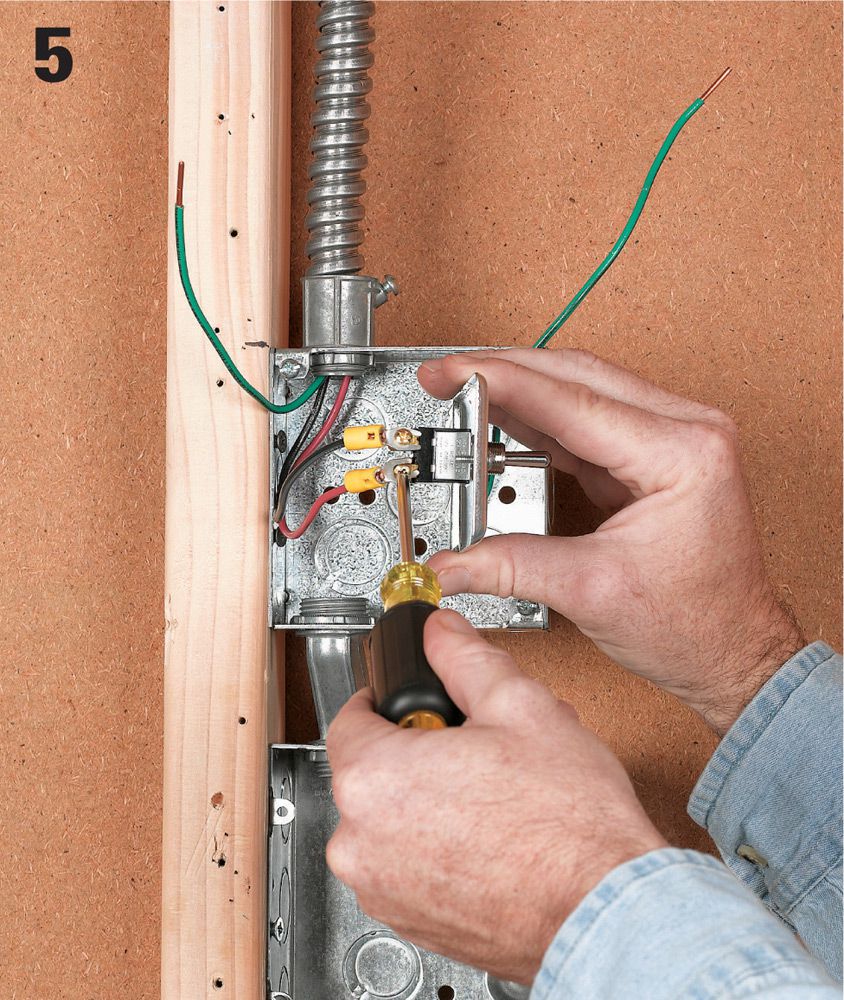

Strip away the outer sheathing from the feeder cable so that at least 1/4" of sheathing will reach into the main service panel. Attach a cable clamp to the cable, and then insert the cable into the knockout, and anchor it by threading a locknut onto the clamp. Tighten the locknut by driving a screwdriver against the lugs. Tighten the clamp screws so the cable is held securely, but not so tightly that the cable sheathing is crushed.

Bend the bare copper wire from the feeder cable around the inside edge of the main circuit breaker panel, and connect it to one of the setscrew terminals on the grounding bus bar.

Strip away 1/2" of insulation from the white feeder wire. Attach the wire to one of the setscrew terminals on the neutral bus bar. Fold excess wire around the inside edge of the service panel.

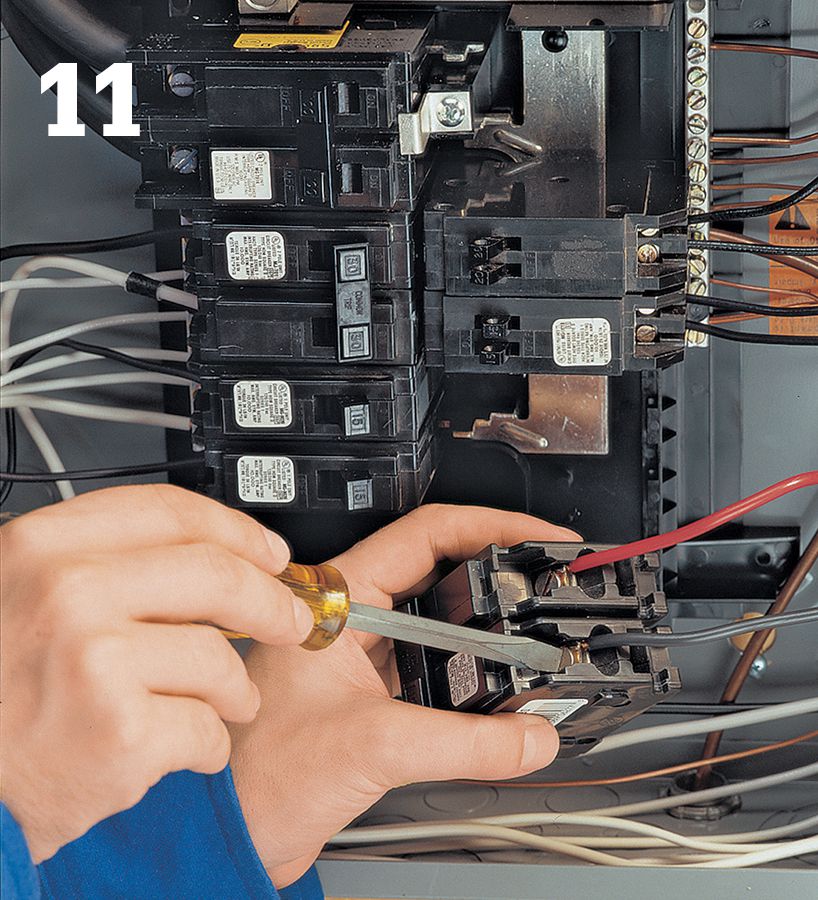

Strip 1/2" of insulation from the red and the black feeder wires. Attach one wire to each of the setscrew terminals on the double-pole feeder breaker. Note: If your subpanel arrived with a preinstalled grounding screw in the panel back, remove and discard it.

Hook the end of the feeder circuit breaker over the guide hooks on the panel, and then push the other end forward until the breaker snaps onto the hot bus bars (follow manufacturer’s directions). Fold excess wire around the inside edge of the circuit breaker panel.

If necessary, open two tabs where the double-pole feeder breaker will fit, and then reattach the cover plate. Label the feeder breaker on the circuit index. Turn the main breaker on, but leave the feeder breaker off until all subpanel circuits have been connected and inspected.

![]() 120/240-Volt Dryer Receptacles

120/240-Volt Dryer Receptacles

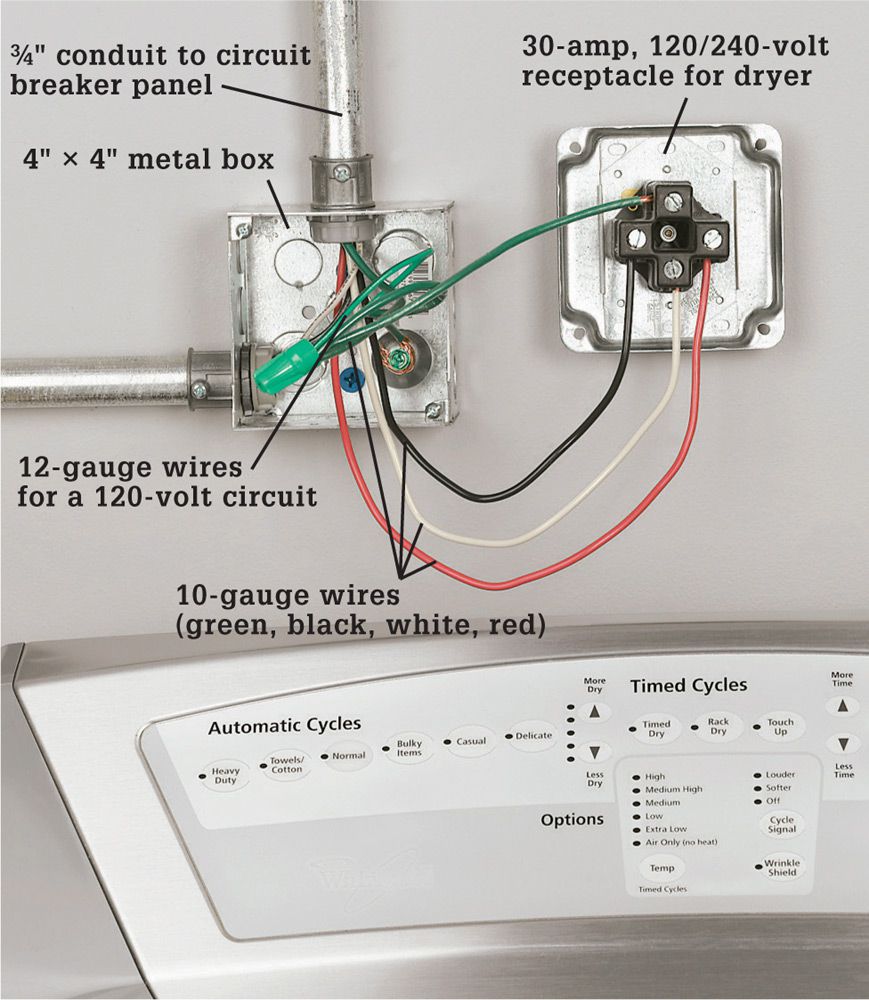

Many dryers require both 120- and 240-volt power. If you are installing this type of electric dryer, you will need to install a 30-amp, 120/240-volt receptacle that feeds from a dedicated 30-amp double-pole breaker in your service panel. Verify your dryer’s electric requirements before wiring a new receptacle.

Begin the installation by identifying a location for the dryer receptacle. Run 10/3 NM cable from the service panel to the new receptacle. If you are mounting the dryer receptacle box on an unfinished masonry wall, run the THNN wire in conduit and secure the box and conduit with masonry screws. If you are mounting the receptacle box in finished drywall, cut a hole, fish the cable through, and mount the receptacle in the wall opening.

Tools & Materials ![]()

Combination tool

Drill

Circuit tester

Hammer

Screwdriver

30-amp double-pole breaker

30-amp 120/240-volt dryer receptacle

10/3 NM cable or 10-gauge THHN/THWN

Receptacle box

Conduit (for masonry walls)

A 240-volt installation is no more complicated than wiring a single-pole breaker and outlet. The main difference is that the dryer circuit’s double-pole breaker is designed to contact both 120-volt bus bars in the service panel. Together these two 120-volt circuits serve the dryer’s heating elements with 240 volts of power. The timer, switches, and other dryer electronics utilize the circuit’s 120-volt power.

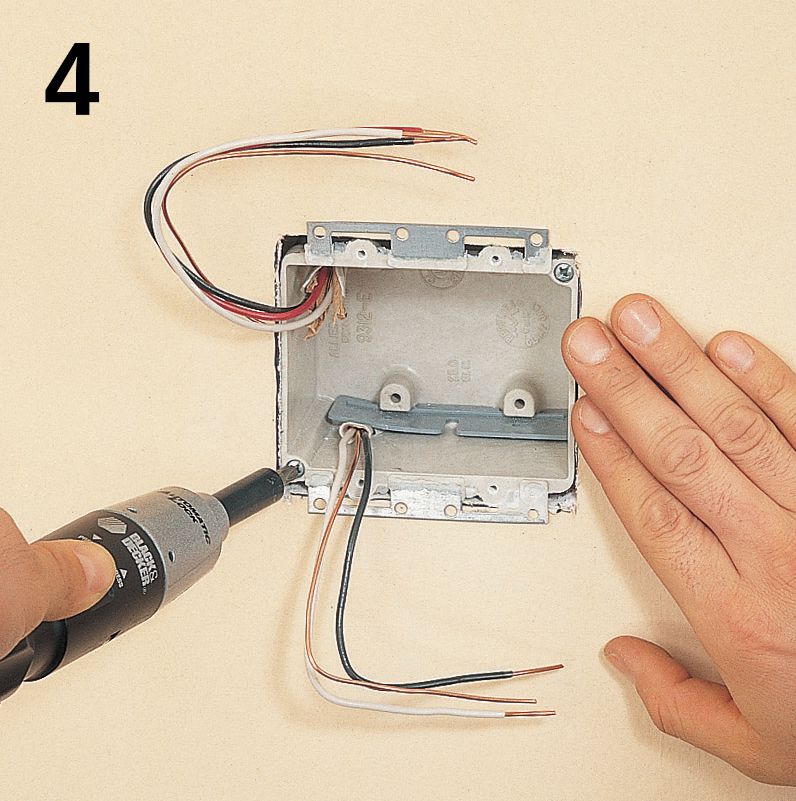

![]() How to Install a 120/240-Volt Dryer Receptacle

How to Install a 120/240-Volt Dryer Receptacle

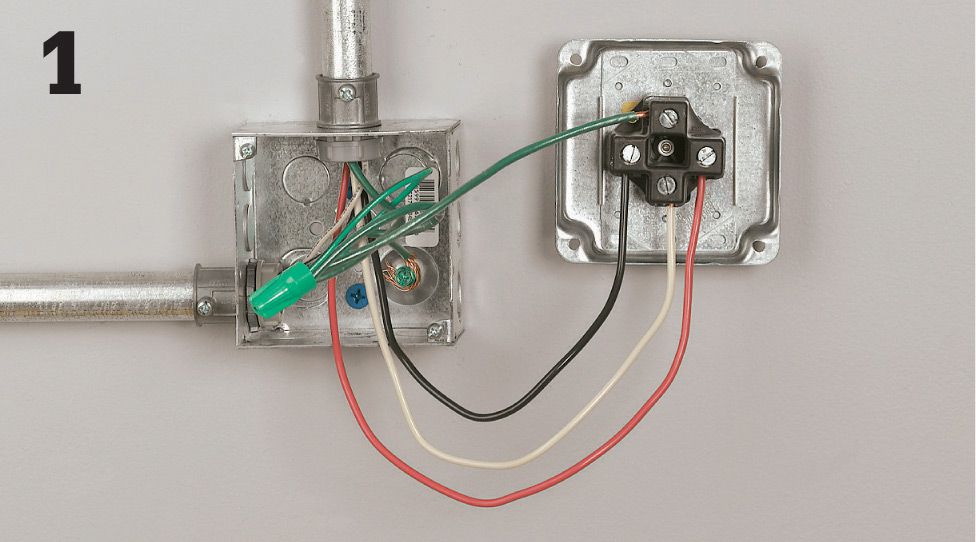

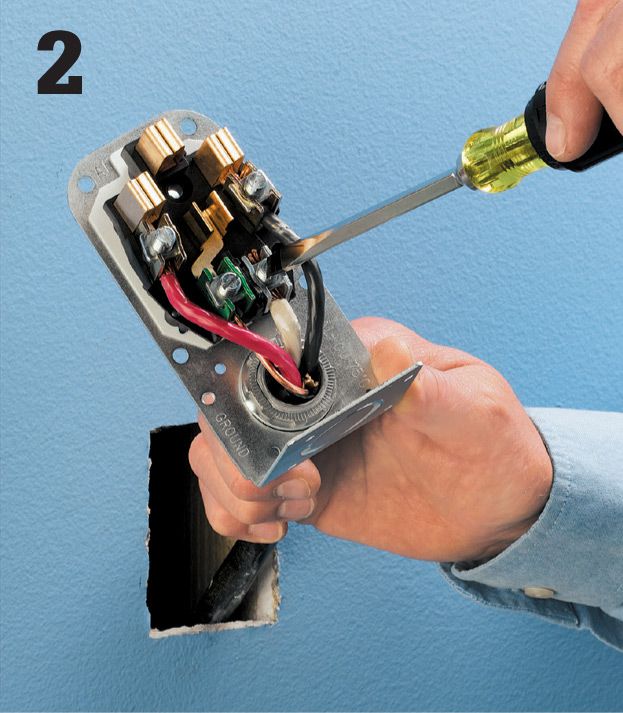

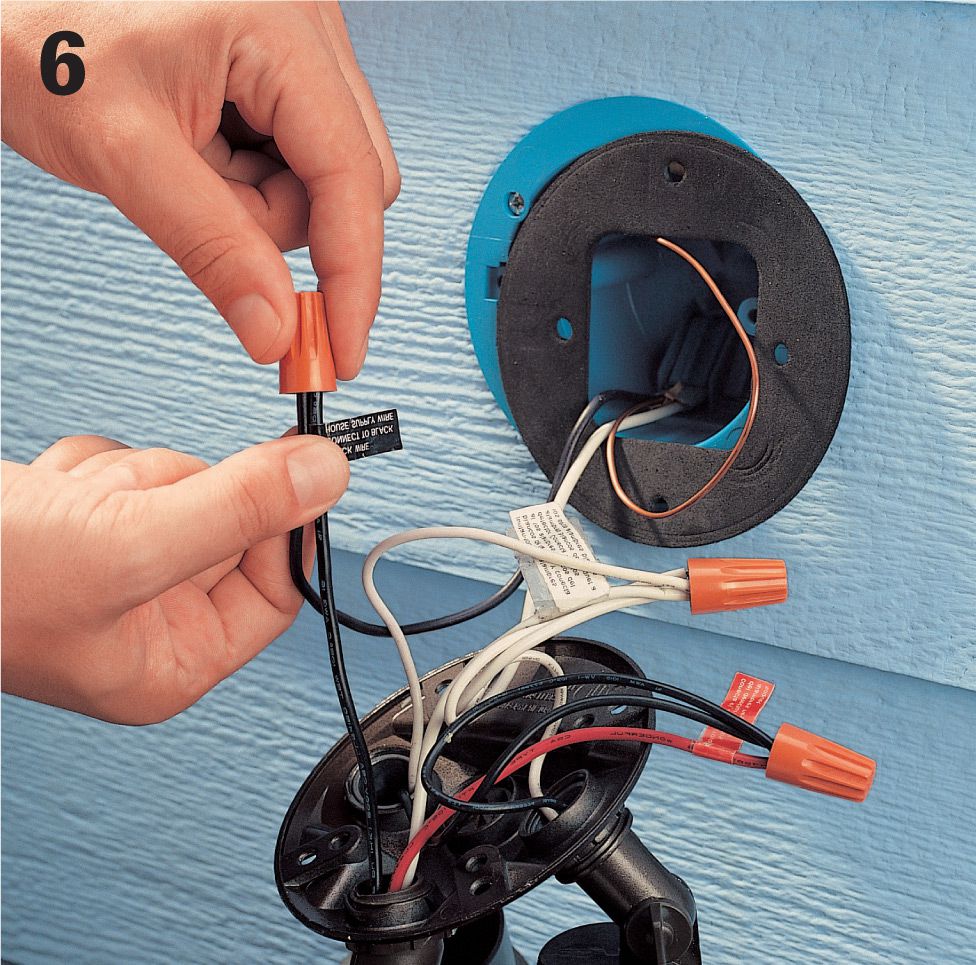

Connect the white neutral wire to the silver neutral screw terminal. Connect each of the black and the red wires to either of the brass screw terminals (the terminals are interchangeable). Connect the green ground wire to the receptacle grounding screw. Attach the cover plate.

With the service panel main breaker shut off, connect the dryer cable to a dedicated 30-amp double-pole breaker. Connect the ground wire to the panel grounding bar. Connect the white neutral wire to the neutral bar. Connect the red and the black wires to the two brass screw terminals on the breaker. Snap the breaker into the bus bar. Attach the panel cover. Turn the breakers on, and test the circuit.

![]() 120/240-Volt Range Receptacles

120/240-Volt Range Receptacles

Many electric ranges require both 120- and 240-volt power. If you are installing this type of electric range, you will need to install a 40- or 50-amp 120/240-volt receptacle that feeds from a dedicated 40- or 50-amp breaker in the service panel. Breaker amperage depends on the amount of current the range draws. Verify requirements before wiring a receptacle.

A range receptacle and breaker installation is no more complicated than wiring a single-pole breaker and outlet. The main difference is that the range circuit’s double-pole breaker is designed to contact both 120-volt bus bars in the service panel. Together these two 120-volt circuits serve the range’s heating elements with 240 volts of power. The timer, switches, and other range electronics utilize the circuit’s 120-volt power.

Modern range receptacles accept a four-prong plug configuration. The cable required is four-conductor cable, containing three insulated wires and one ground. The two hot wires might be black and red (shown below) or black and black with a red stripe. The neutral wire is generally white or gray. The grounding wire is green or bare. The size used for a kitchen range is usually 6/3 grounded NM copper cable. The receptacle itself is generally surface mounted for easier installation (shown below), though flush-mounted units are also available.

Tools & Materials ![]()

Combination tool

Circuit tester

Drill

Hammer

Screwdriver

Drywall saw

Fish tape

Surface-mounted range receptacle

6/3 grounded NM cable

40- or 50-amp double-pole circuit breaker

![]() How to Install a Kitchen Range Receptacle

How to Install a Kitchen Range Receptacle

Turn power off. Identify a location for the surface-mounted range receptacle. Cut a small hole in the wall. Fish the cable from the service panel into the wall opening. Thread the cable into a surface-mounted receptacle and clamp it. Strip insulation from the individual wires.

Wire the receptacle. Connect the bare copper ground wire to the receptacle grounding screw. Connect the white neutral wire to the silver neutral screw terminal. Connect each of the hot (black and red) wires to either of the brass screw terminals (the terminals are interchangeable). Mount the housing on the wall and attach the cover plate.

Wire the cable to a 40- or 50-amp breaker. With the main breaker off, remove the panel cover. Remove a knockout from the panel and feed the cable into the panel. Connect the ground to the grounding bar. Connect the neutral wire from the cable to the neutral bar. Connect the red and the black wires to the two brass screw terminals on the breaker. Snap it into the bus bar. Attach the panel cover. Turn the breakers on and test the circuit.

![]() Ceiling Lights

Ceiling Lights

Ceiling fixtures don’t have any moving parts, and their wiring is very simple, so, other than changing bulbs, you’re likely to get decades of trouble-free service from a fixture. This sounds like a good thing, but it also means that the fixture probably won’t fail and give you an excuse to update a room’s look with a new one. Fortunately you don’t need an excuse. Upgrading a fixture is easy and can make a dramatic impact on a room. You can substantially increase the light in a room by replacing a globe-style fixture with one with separate spot lights, or you can simply install a new fixture that matches the room’s décor. Check the weight rating of the box to which you will attach your fixture. Older boxes may not handle a heavy fixture.

Tools & Materials ![]()

Replacement light fixture

Wire stripper

Voltage sensor

Insulated screwdrivers

Wire connectors

Eye protection

If you are unsure how much weight the existing box can handle, consider changing the box. New light fixture boxes should handle fixtures up to 50 pounds. Support the fixture independently from the box if the fixture weighs more than 50 pounds.

Installing a new ceiling fixture can provide more light to a space, not to mention an aesthetic lift. It’s one of the easiest upgrades you can do.

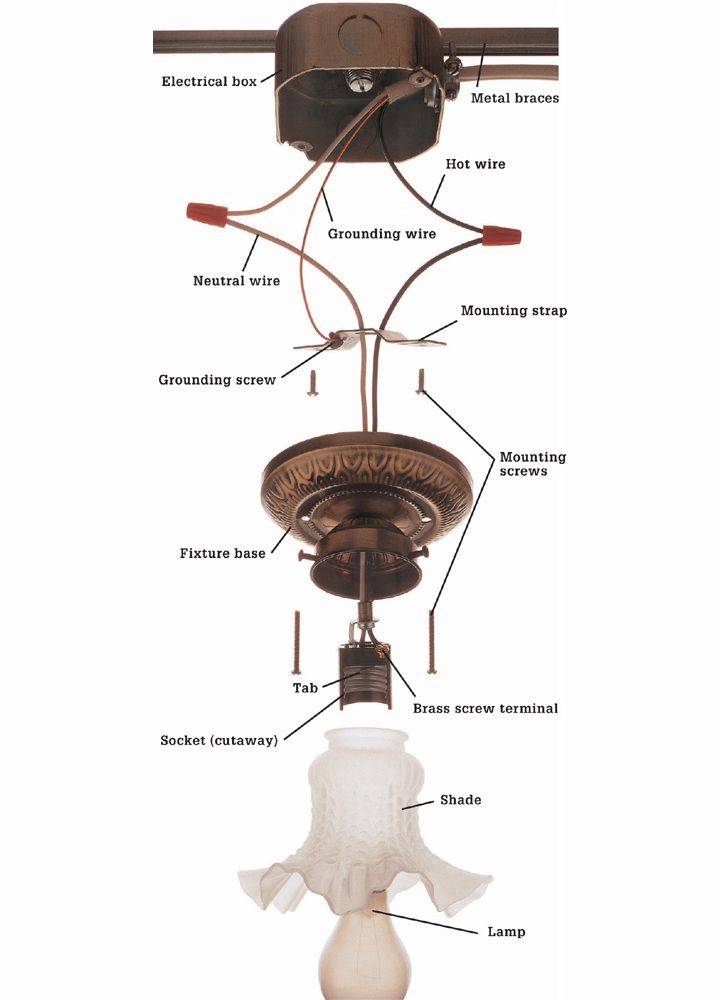

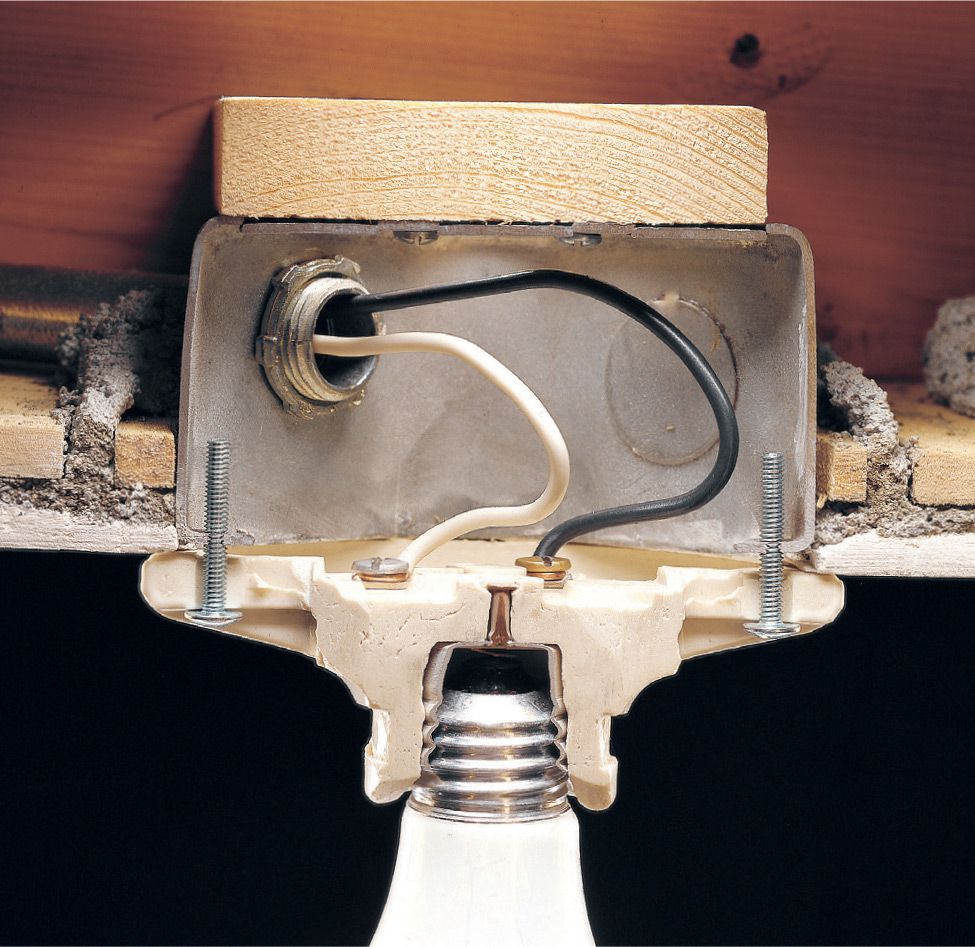

No matter what a ceiling light fixture looks like on the outside, they all attach in basically the same way. An electrical box in the ceiling is fitted with a mounting strap, which holds the fixture in place. The bare wire from the ceiling typically connects to the mounting strap. The two wires coming from the fixture connect to the black and the white wires from the ceiling.

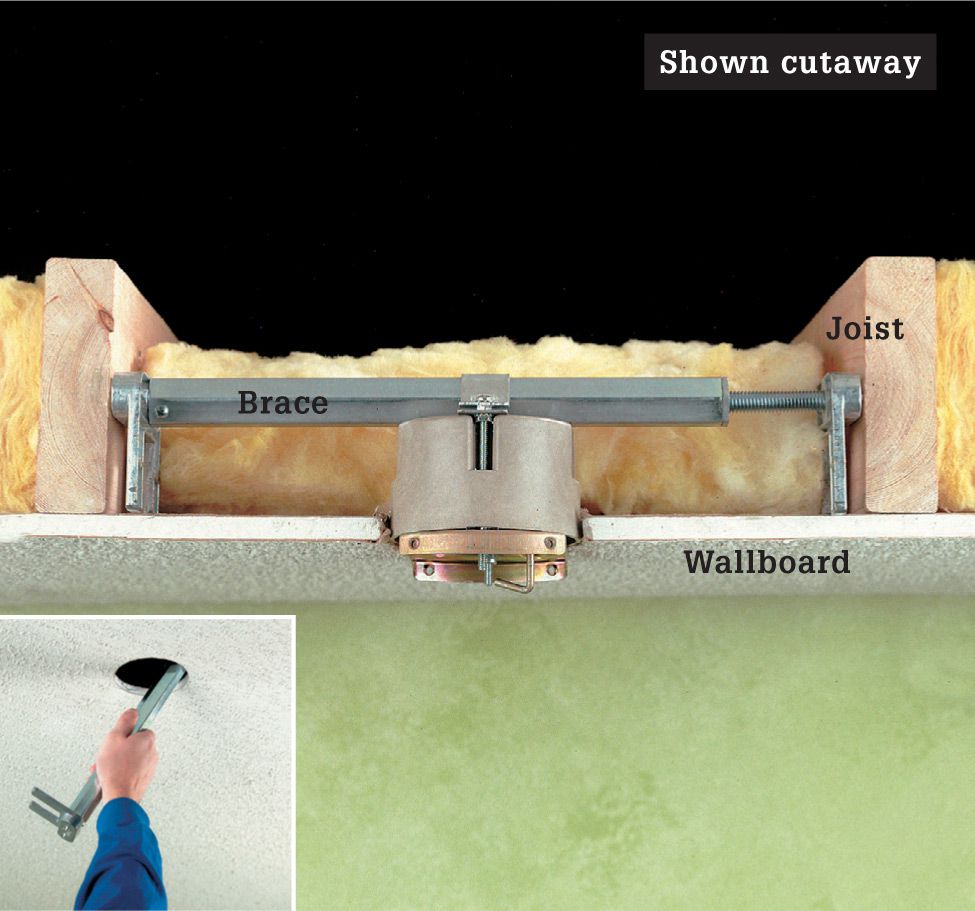

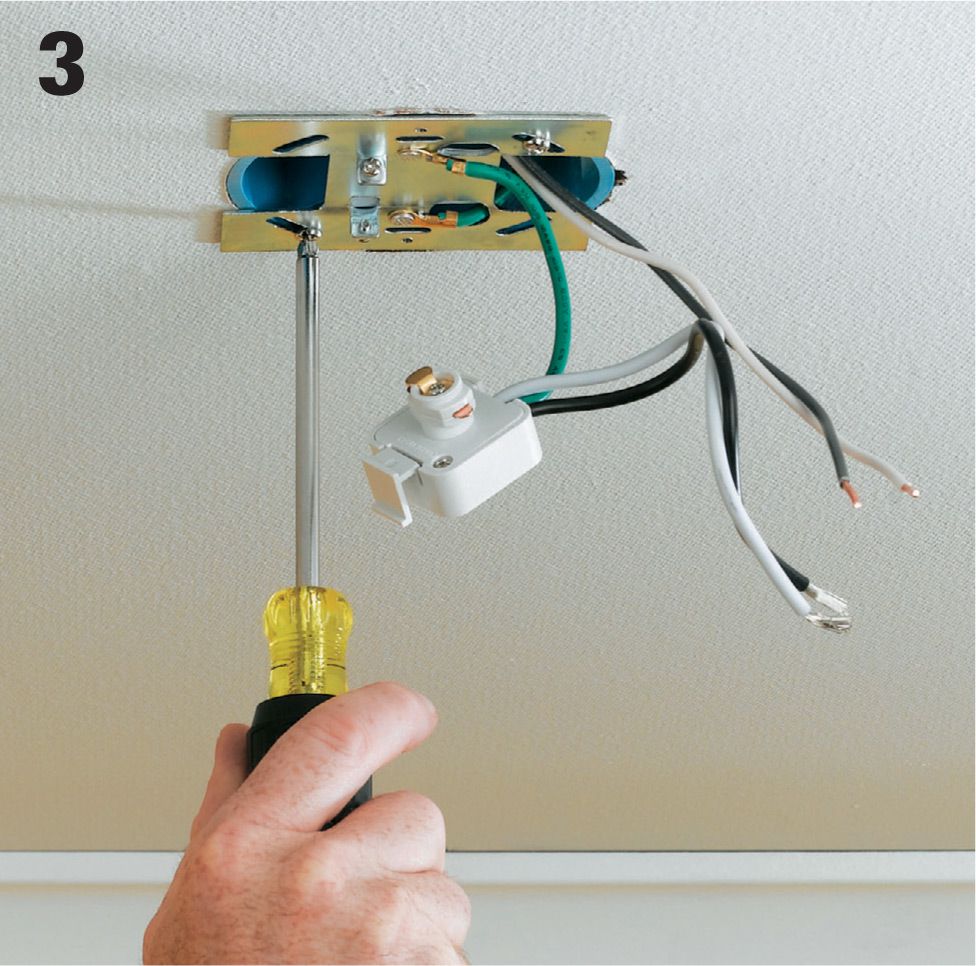

If the new fixture is much heavier than the original fixture, it will require additional bracing in the ceiling to support the electrical box and the fixture. The manufacturer’s instructions should specify the size and type of box. If the ceiling is finished and there is no access from above, you can remove the old box and use an adjustable remodeling brace appropriate for your fixture (shown). The brace fits into a small hole in the ceiling (inset). Once the bracing is in place, install a new electrical box specified for the new fixture.

Inexpensive light fixtures have screw terminals mounted directly to the backside of the fixture plate. Often, as seen here, they have no grounding terminal. Some codes do not allow this type of fixture, but even if your hometown does approve them, it is a good idea to replace them with a better quality, safer fixture that is UL-approved.

![]() How to Replace a Ceiling Light

How to Replace a Ceiling Light

Shut off power to the ceiling light, and remove the shade or diffuser. Loosen the mounting screws and carefully lower the fixture, supporting it as you work (do not let light fixtures hang by their electrical wires alone). Test with a voltage sensor to make sure no power is reaching the connections.

Remove the twist connectors from the fixture wires or unscrew the screw terminals and remove the white neutral wire and the black lead wire (inset).

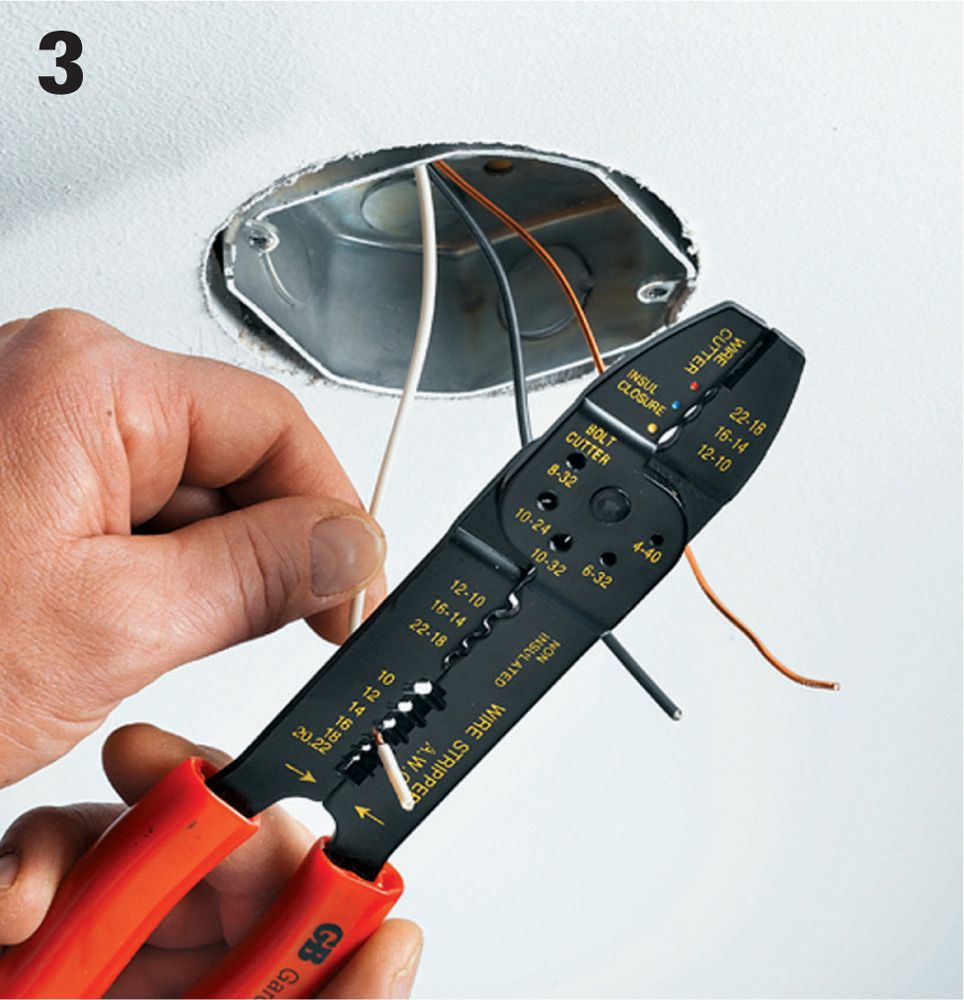

Before you install the new fixture, check the ends of the wires coming from the ceiling electrical box. They should be clean and free of nicks or scorch marks. If they’re dirty or worn, clip off the stripped portion with your combination tool. Then strip away about 3/4" of insulation from the end of each wire.

Attach a mounting strap to the ceiling fixture box if there is not one already present. Your new light may come equipped with a strap; otherwise you can find one for purchase at any hardware store.

Lift the new fixture up to the ceiling (you may want a helper for this), and attach the bare copper ground wire from the power supply cable to the grounding screw or clip on the mounting strap. Also attach the ground wire from the fixture to the screw or clip.

With the fixture supported by a ladder or a helper, join the white wire lead and the white fixture wire with a wire connector (often supplied with the fixture).

Connect the black power supply wire to the black fixture wire with a wire connector.

Position the new fixture mounting plate over the box so the mounting screw holes align. Drive the screws until the fixture is secure against the ceiling. Note: Some fixtures are supported by a threaded rod or nipple in the center that screws into a female threaded opening in the mounting strap (inset).

![]() Recessed Ceiling Lights

Recessed Ceiling Lights

Recessed lights are versatile fixtures suited for a variety of situations. Fixtures rated for outdoor use can also be installed in roof soffits and overhangs for accent and security lighting. Recessed fixtures can also be installed over showers or tubs. Be sure to use fixture cans and trims rated for bathroom use.

There are recessed lighting cans in all shapes and sizes for almost every type of ceiling or cabinet. Cans are sold for unfinished ceilings (new construction) or for finished ceilings (retrofit installation). Cans are also rated as insulation compatible or for uninsulated ceilings. Be sure to use the correct one for your ceiling to prevent creating a fire hazard. The 2012 International Residential Code requires that recessed lights installed in unconditioned spaces (such as attics) be insulation contact (IC) rated, air tight, and sealed to the drywall.

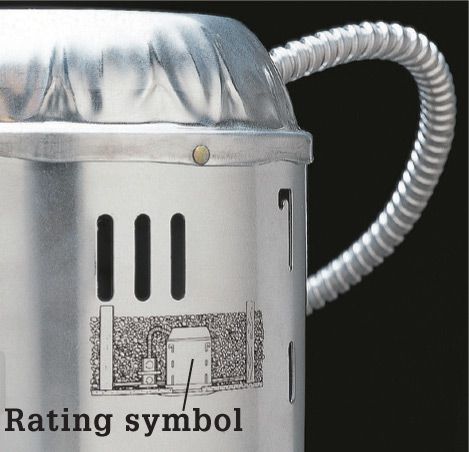

Choose the proper type of recessed light fixture for your project. There are two types of fixtures: those rated for installation within insulation (above), and those which must be kept at least 3" from insulation (below). Self-contained thermal switches shut off power if the unit gets too hot for its rating. A recessed light fixture must be installed at least 1/2" from combustible materials.

Tools & Materials ![]()

Recessed-lighting can for new construction or remodeling and trim

Circuit tester

Cable ripper

Combination tool

Pliers

Fish tape

Hack saw

Drywall saw

NM cable

Work gloves

Eye protection

Recessed ceiling lights often are installed in series to provide exacting control over the amount and direction of light. Spacing the canisters in every other ceiling joist bay is a common practice.

![]() Recessed Materials

Recessed Materials

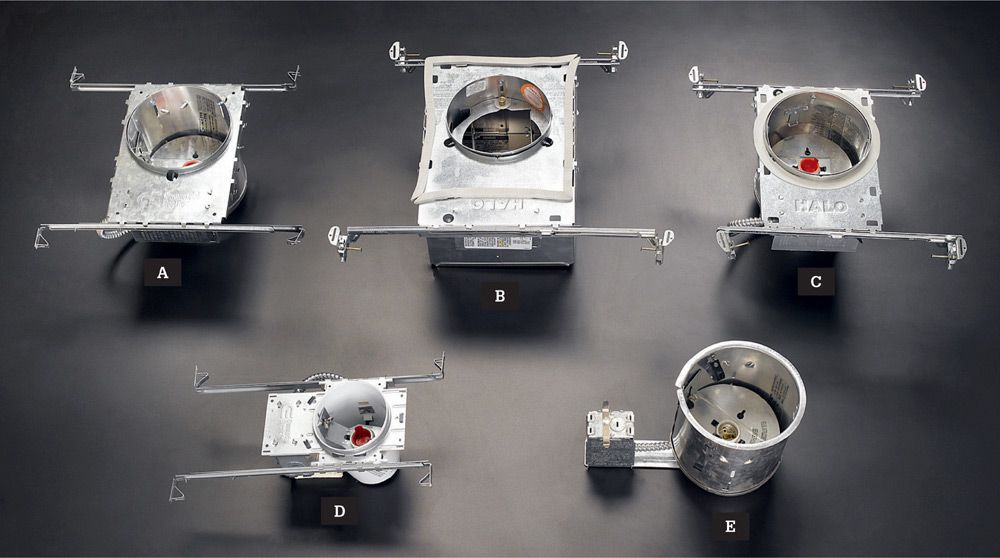

Recessed ceiling light housings come in many sizes and styles for various purposes and budgets. Some are sold with trim kits (below) included. Some common types are: new construction recessed housing (sold in economical multipacks) (A); airtight recessed housings (for heated rooms below unheated ceilings) (B); shallow recessed housings (for rooms with 2" × 6" ceiling joists) (C); small aperture recessed housing (D); recessed slope ceiling housing (for vaulted ceilings) (E).

Trim kits for recessed ceiling lights may be sold separately. Common types include: open trim with reflective baffle (A); eyeball trim (B); baffle trim (black) (C); shower light trim (D); open trim (E); baffle trim (full reflective) (F).

![]() How to Install Recessed Ceiling Lights

How to Install Recessed Ceiling Lights

Mark the location for the light canister. If you are installing multiple lights, measure out from the wall at the start and end of the run, and connect them with a chalkline snapped parallel to the wall. If the ceiling is finished with a surface (wallboard), see next page.

Install the housing for the recessed fixture. Housings for new construction (or remodeling installations where the installation area is fully accessible from either above or below) have integral hanger bars that you attach to each joist in the joist bay.

Run electric cable from the switch to each canister location. Multiple lights are generally installed in series so there is no need to make pigtail connections in the individual boxes. Make sure to leave enough extra cable at each location to feed the wire into the housing and make the connection.

Run the feeder cables into the electrical boxes attached to the canister housings. You’ll need to remove knockouts first and make sure to secure the cable with a wire staple within 8" of the entry point to the box.

Connect the feeder wires to the fixture wires inside the junction box. Twist the hot lead together with the black fixture wire, as well as the black lead to other fixtures further downline. Also connect the neutral white wires. Join the ground wires and pigtail them to the grounding screw or clip in the box. Finish the ceiling, as desired.

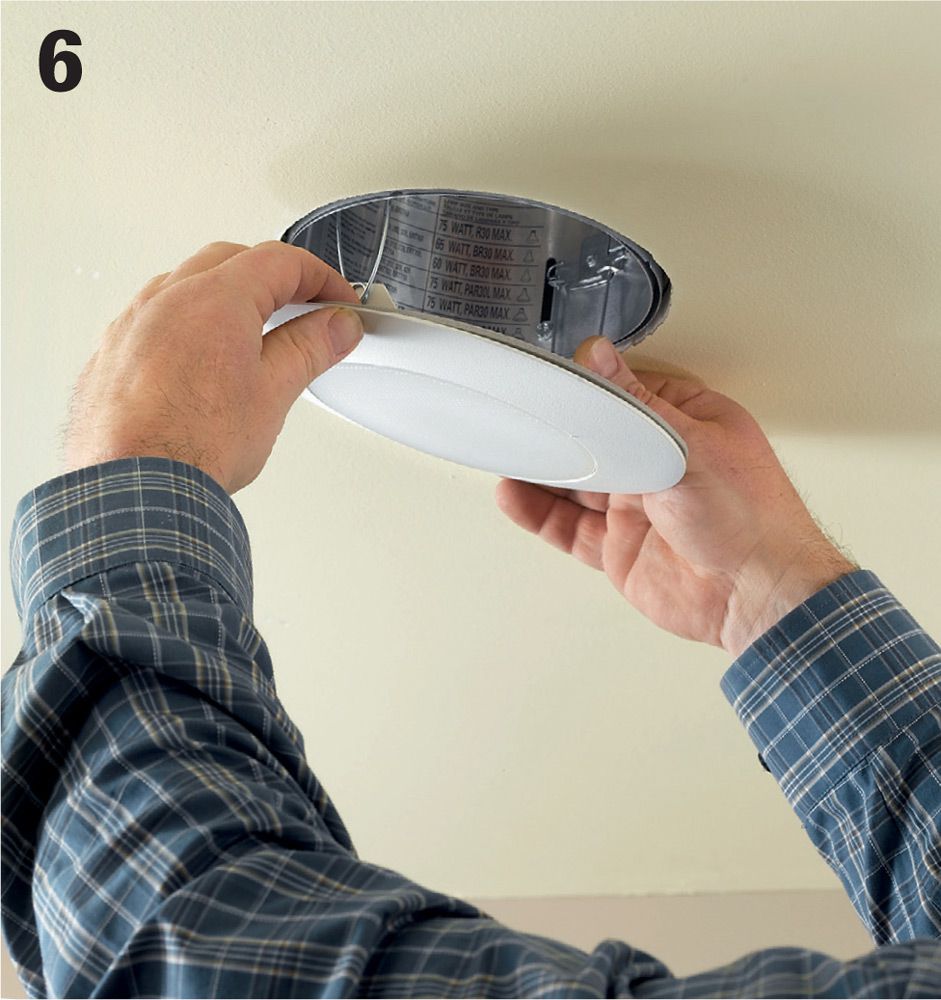

Attach your trim kit of choice. Normally these are hung with torsion spring clips from notches or hooks inside the canister. This should be done after the ceiling is installed and finished for new construction projects. With certain types of trim kits, such as eyeball trim, you’ll need to install the light bulb before the trim kit.

![]() How to Connect a Recessed Fixture Can in a Finished Ceiling

How to Connect a Recessed Fixture Can in a Finished Ceiling

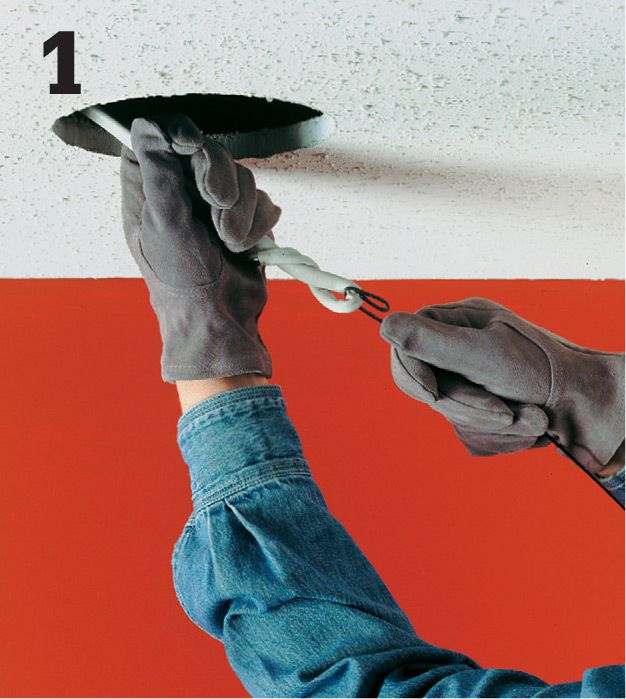

Make the hole for the can. Most fixtures will include a template for sizing the hole. Fish 14/2 cable from the switch location to the hole. Pull about 16" of cable out of the hole for making the connection.

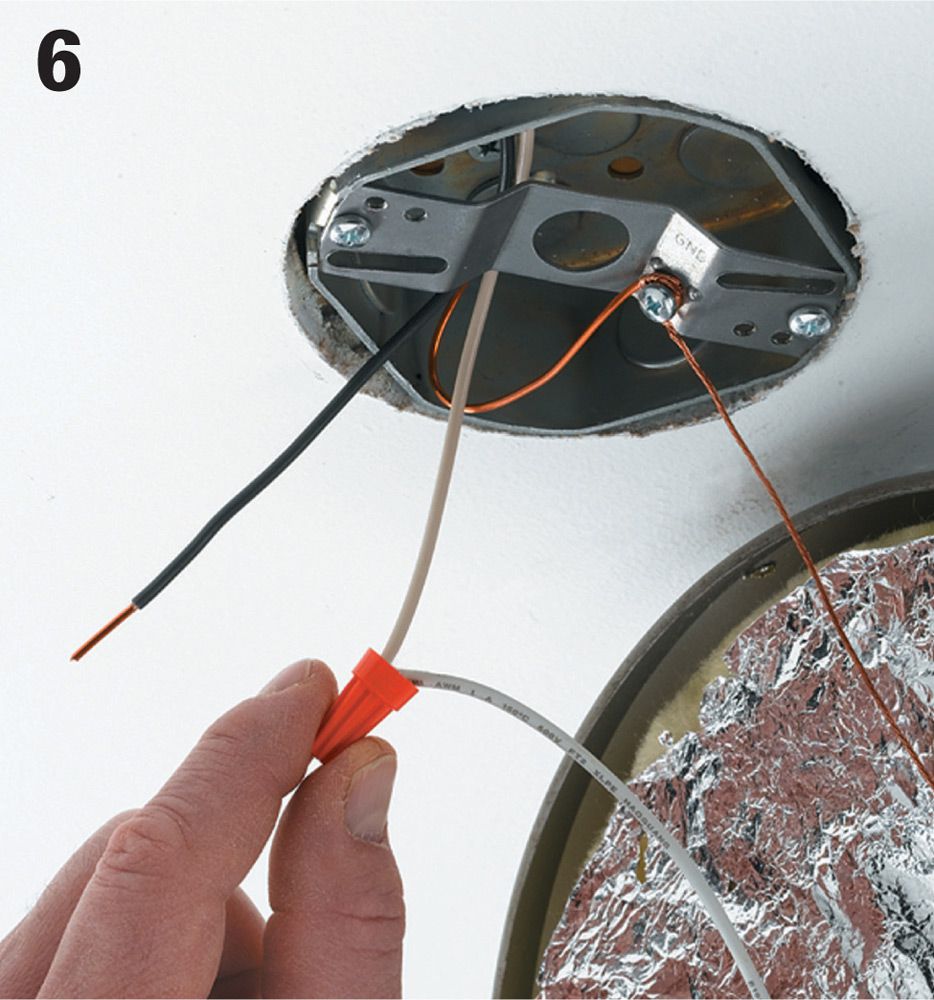

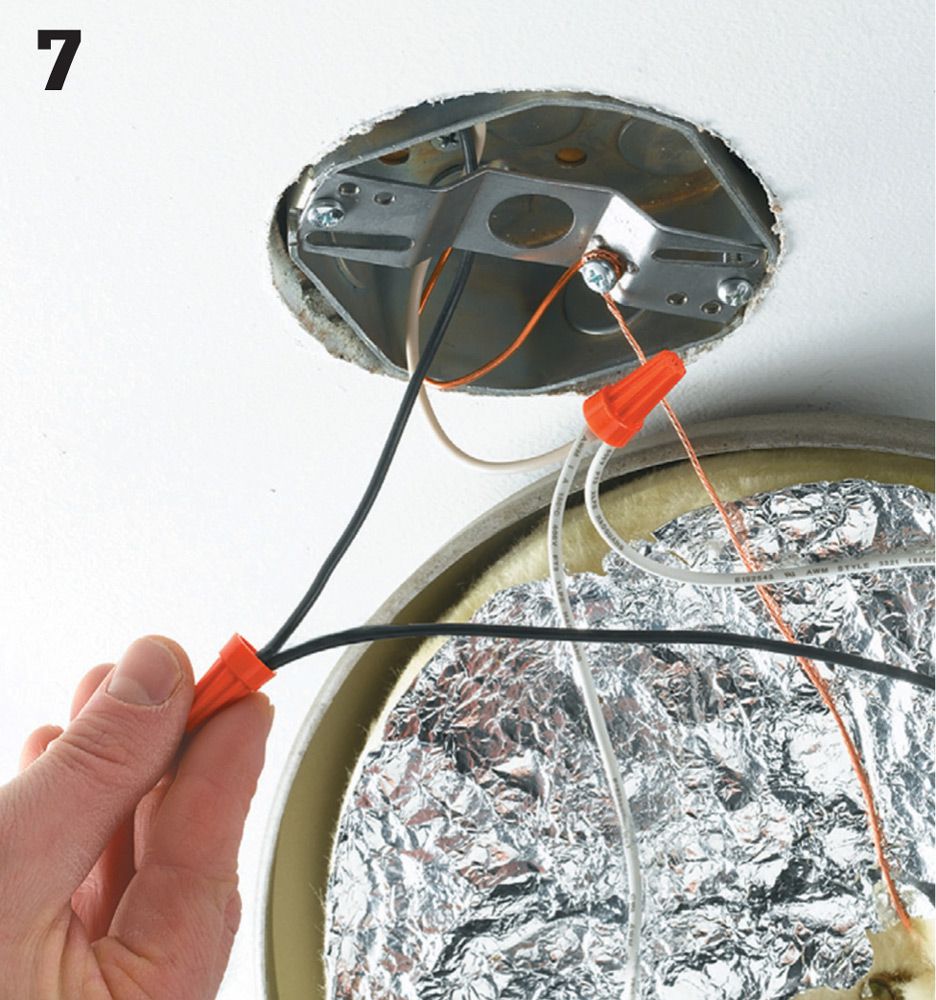

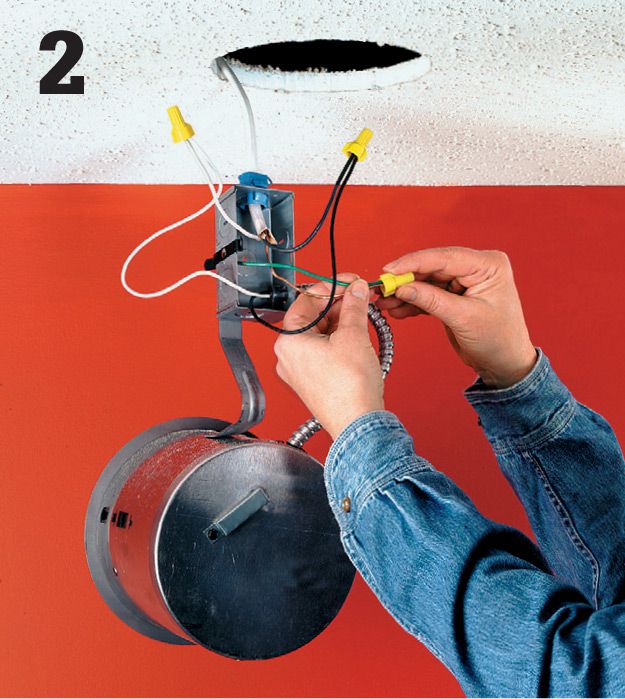

Remove a knockout from the electrical box attached to the can. Thread the cable into the box; secure it with a cable clamp. Remove sheathing insulation. Connect the black fixture wire to the black circuit wire, the white fixture wire to the white circuit wire, and then connect the ground wire to the grounding screw or grounding wire attached to the box.

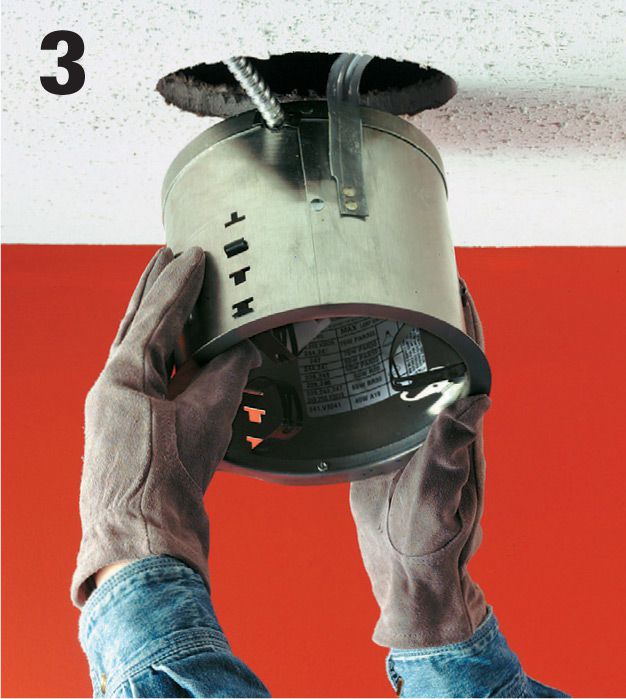

Retrofit cans secure themselves in the hole with spring-loaded clips. Install the can in the ceiling by depressing the mounting clips so the can will fit into the hole. Insert the can so that its edge is tight to the ceiling. Push the mounting clips back out so they grip the drywall and hold the fixture in place. Install the trim piece.

![]() Track Lights

Track Lights

Track lighting offers a beautiful and functional way to increase the amount of light in a room or simply to update its look. A variety of fixture and lamp options let you control the shape, color, and intensity of the light. Installing track lighting in place of an existing ceiling-mounted light fixture involves basic wiring and hand-tool skills, but the connections are even easier to make than with traditional light fixtures. Once installed, the system is very easy to upgrade or expand in the future.

Tools & Materials ![]()

Drill/driver and bits

Wire stripper

Screwdriver

Voltage sensor

Toggle bolts

Track light heads

Prewired track and fittings

Wire connector

Ceiling box

Eye protection

If you currently have a ceiling-mounted light fixture that is not meeting your lighting needs, it’s simple to replace it with a track-lighting fixture. With track lighting you can easily change the type and number of lights, their position on the track, and the direction they aim. These fixtures come in many different styles, including short 3-ft. track systems with just one or two lights up to 12-ft. systems with five or more lights.

![]() How to Install Track Lighting

How to Install Track Lighting

Disconnect the old ceiling light fixture (for remodeling projects) after shutting off power to the circuit at the main service panel. The globe or diffuser and the lamps should be removed before the fixture mounting mechanism is detached.

Test the fixture wires with a voltage sensor to make sure the circuit is dead. Support the fixture from below while you work—never allow a light fixture to hang by its electrical wires alone. Remove the wire connectors and pull the wires apart. Remove the old light fixture.

Attach the mounting strap for the new track light to the old ceiling box. If the mounting strap has a hole in the center, thread the circuit wires through the hole before screwing the strap to the box. The green or bare copper ground from the circuit should be attached to the grounding screw or clip on the strap or box.

Cut the track section to length, if necessary, using a hack saw. Deburr the cut end with a metal file. If you are installing multiple sections of track, assemble the sections with the correct connector fittings (sold separately from your kit). You can also purchase T-fittings or L-fittings (inset photo) if you wish to install tracks in either of these configurations.

Position the track section in the mounting saddle on the mounting strap and hold it temporarily in place in the location where it will be installed. The track section will have predrilled mounting holes in the back. Draw a marking point on the ceiling at each of these locations. If your track does not have predrilled mounting holes, remove it and drill a 3/16" hole in the back every 16".

Insert the bolt from a toggle bolt or molly bolt into each predrilled screw location and twist the toggle or molly back onto the free end. These types of hardware have greater holding power than anchor sleeves. Drill a 5/8" dia. access hole in the ceiling at each of the mounting hole locations you marked on the ceiling in step 5.

Insert the toggle or molly into the access hole far enough so it clears the top of the hole and the wings snap outward. Then tighten each bolt so the track is snug against the ceiling. If the mounting hole happens to fall over a ceiling joint, simply drive a wallboard screw at that hole location.

Hook up wires from the track’s power supply fitting to the circuit wires. Connect black to black and white to white. The grounding wire from the power supply fitting can either be pigtailed to the circuit ground wire and connected to the grounding screw or clip, or it can be twisted together with the circuit grounding wire at the grounding terminal. Snap the fitting into the track if you have not already done so.

Attach the protective cover that came with your kit to conceal the ceiling box and the electrical connections. Some covers simply snap in place, others require a mounting screw.

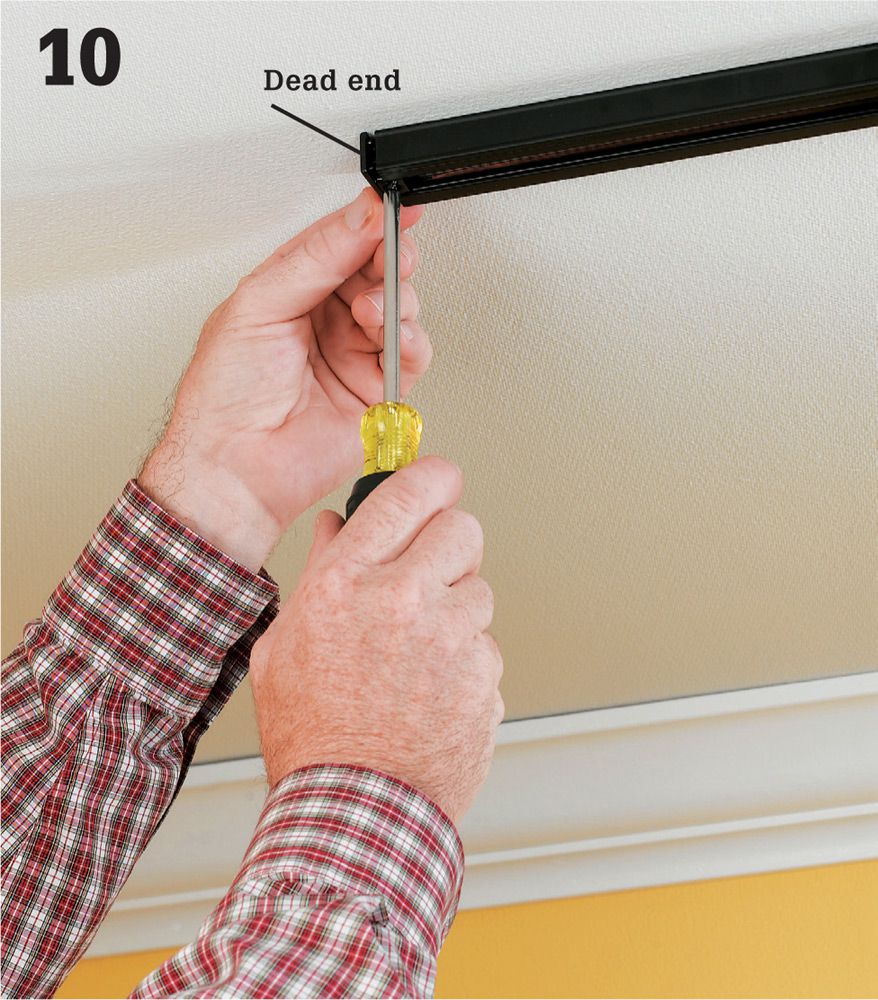

Cap the open ends of the track with a dead end cap fitting. These also may require a mounting screw. Leaving track ends open is a safety violation.

Insert the light heads into the track by slipping the stem into the track slot and then twisting it so the electrical contact points on the head press against the electrified inner rails of the track slot. Tug lightly on the head to make sure it is secure before releasing it.

Arrange the track light heads so their light falls in the manner you choose, and then depress the locking tab on each fixture to secure it in position. Restore power, and test the lights.

![]() Undercabinet Lights

Undercabinet Lights

Hardwired undercabinet lights illuminate the kitchen countertop and sink areas that fall in the shadow of ceiling lights. Most of these light fixtures, which are often called strip lights, utilize fluorescent, halogen, or xenon bulbs that emit very low levels of heat and are therefore very efficient.

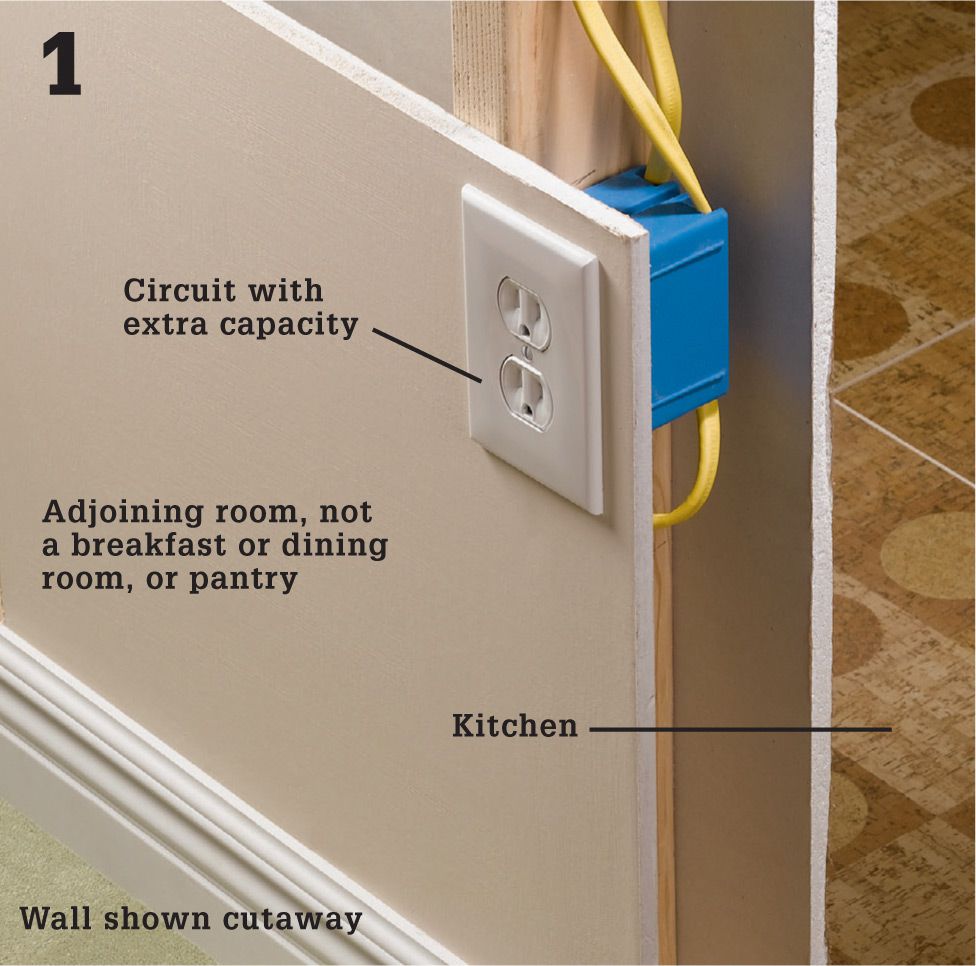

If you are doing a kitchen remodel with all-new cabinets, run the new light circuit wiring before the cabinets are installed. For a retrofit, you’ll need to find an available power source to tie into. Options for this do not include the dedicated 20-amp small-appliance receptacle circuits that are required in kitchens. The best bet is to run new circuit wire from a close-by ceiling light switch box, but this will mean cutting into the walls to run cable. Another option is to locate a receptacle that’s on the opposite side of a shared wall, preferably next to a location where a base cabinet is installed in the kitchen. This room should not be a breakfast room, dining, room, pantry, or similar area, because these rooms are also served by the small appliance receptacle circuits. By cutting an access hole in the cabinet back you can tie into the receptacle box and run cable through the wall behind the cabinets, up to the upper cabinet location, and out the wall to supply the fixture that’s mounted to the underside of the upper cabinet.

You can purchase undercabinet lights that are controlled by a wall switch, but most products have an integral on/off button so you can control lights individually.

Tools & Materials ![]()

Circuit tester

Utility knife

Wallboard saw

Hammer

Screwdriver

Drill and hole saw

Jigsaw

Wire stripper

Undercabinet lighting kit

14/2 NM cable

Wire connectors

Switch box

Switch

Eye protection

Hardboard panel adhesive

Undercabinet lights provide directed task lighting that bring sinks and countertop work surfaces out from the shadows. Hardwired lights may be controlled either by a wall switch or an onboard on/off switch located on the fixture. Note: Do not supply power for lights from the small-appliance circuit.

![]() How to Install a Hardwired Undercabinet Light

How to Install a Hardwired Undercabinet Light

Look in the adjoining room for a usable power source in the form of a receptacle that has a box located in the wall behind your base cabinets. Unlike the small-appliance circuit with outlets in your backsplash area, these typically are not dedicated circuits (which can’t be expanded). Make sure that the receptacle’s circuit has enough capacity to support another load. Shut the power to the receptacle off at the main service panel and test for power.

Cut a hole in the base cabinet back panel to get access to the wall behind it in roughly the area where you know the next-door receptacle to be. Use a keyhole saw or drywall saw and make very shallow cuts until you have positively identified the locations of the electrical box and cables. Then finish the cuts with a jigsaw.

Drill an access hole into the kitchen wall for the cable that will feed the undercabinet light. A 1/2" dia. hole should be about the right size if you are using 12-ga. or 14-ga. sheathed NM cable.

Cut a small access hole (4" × 4" or so) in the back panel of the base cabinet directly below the undercabinet light location.

Feed cable into the access hole at the light location until the end reaches the access hole below. Don’t cut the cable yet. Reach into the access hole and feel around for the free cable end, and then pull it out through the access hole once you’ve found it. Cut the cable, making sure to leave plenty of extra on both ends.

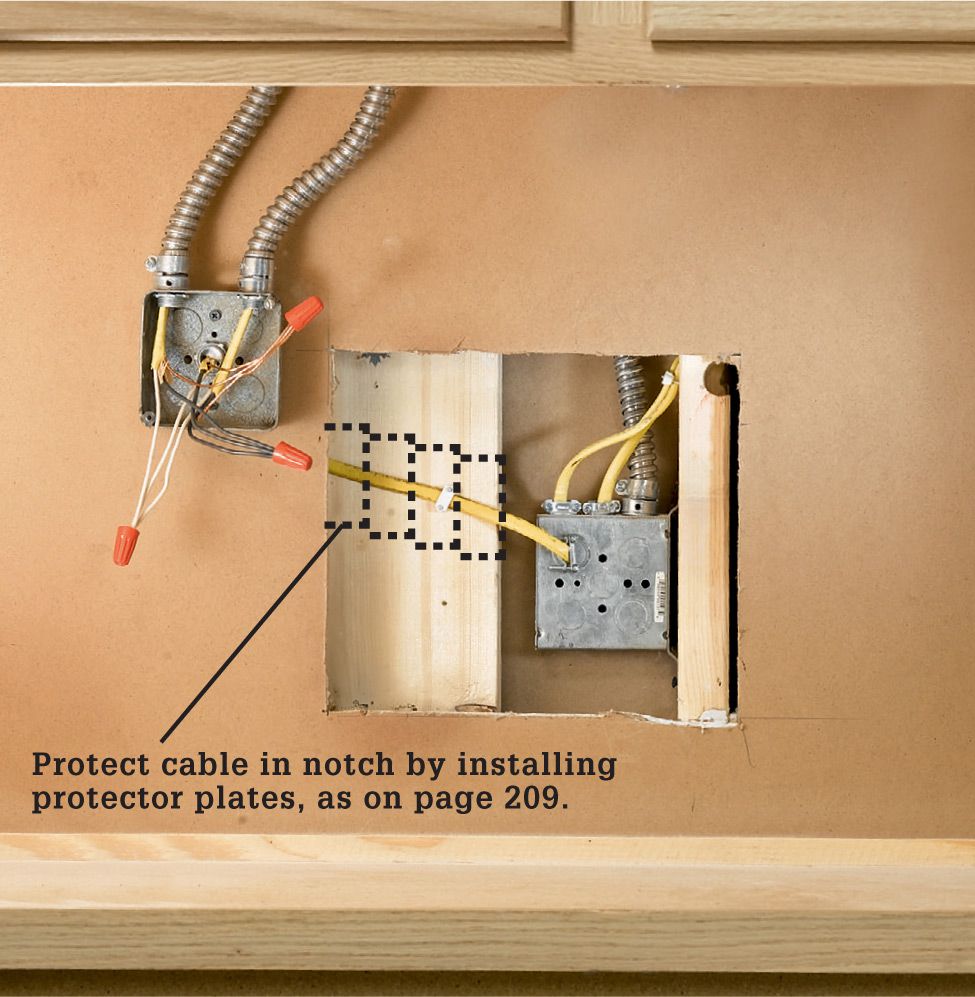

String the cable into a piece of flexible conduit that’s long enough to reach between the two access holes in the base cabinets. Attach a connector to each end of the conduit to protect the cable sheathing from the sharp edges of the cut metal. Tip: To make patching the cabinet back easier, drill a new access hole for the cable near the square access hole.

Hang the conduit with hanger straps attached to the base cabinet frame or back panel, drilling holes in the side walls of the cabinet where necessary to thread the conduit through. On back panels, use small screws to hang the straps instead of brads or nails. Support the conduit near both the entrance and the exit holes (the conduit should extend past the back panels by a couple of inches).

Variation: If you are installing more than one undercabinet light, run cable down from each installation point as you did for the first light. Mount an electrical junction box to the cabinet back near the receptacle providing the power. Run the power cables from each light through flexible conduit and make connections inside the junction box. Be sure to attach the junction box cover once the connections are made.

Remove the receptacle from the box you are tying into and insert the new circuit cable into one of the knockouts using a cable clamp. Check a wire capacity chart (see page 26) to make sure the box is big enough for the new conductors. Replace it with a larger box if necessary. Reinstall the receptacle once the connections are made.

Install the undercabinet light. Some models have a removable diffuser that allows access to the fixture wires, and these should be screwed to the upper cabinet prior to making your wiring hookups. Other models need to be connected to the circuit wires before installation. Check your manufacturer’s installations.

Connect wires inside the light fixture according to the light manufacturer’s directions. Make sure the incoming cable is stapled just before it enters the light box and that a cable clamp is used at the knockout in the box to protect the cable. Restore power, and test the light.

Cut patches of hardboard and fit them over the access holes, overlapping the edges of the cutouts. Adhere them to the cabinet backs with panel adhesive.

![]() Vanity Lights

Vanity Lights

Many bathrooms have a single fixture positioned above the vanity, but a light source in this position casts shadows on the face and makes grooming more difficult. Light fixtures on either side of the mirror is a better arrangement.

For a remodel, mark the mirror location, run cable, and position boxes before drywall installation. You can also retrofit by installing new boxes and drawing power from the existing fixture.

The light sources should be at eye level; 66" is typical. The size of your mirror and its location on the wall may affect how far apart you can place the sconces, but 36" to 40" apart is a good guideline.

Tools & Materials ![]()

Drywall saw

Drill

Combination tool

Circuit tester

Screwdrivers

Hammer

Electrical boxes and braces

Vanity light fixtures

NM cable

Wire connectors

Eye protection

Vanity lights on the sides of the mirror provide good lighting.

![]() How to Replace Vanity Lights in a Finished Bathroom

How to Replace Vanity Lights in a Finished Bathroom

Turn off the power at the service panel. Remove the old fixture from the wall, and test to make sure that the power is off. Then remove a strip of drywall from around the old fixture to the first studs beyond the approximate location of the new fixtures. Make the opening large enough that you have room to route cable from the existing fixture to the boxes.

Mark the location for the fixtures, and install new boxes. Install the boxes about 66" above the floor and 18" to 20" from the centerline of the mirror (the mounting base of some fixtures is above or below the bulb, so adjust the height of the bracing accordingly). If the correct location is on or next to a stud, you can attach the box directly to the stud; otherwise you’ll need to install blocking or use boxes with adjustable braces (shown).

Open the side knockouts on the electrical box above the vanity. Then drill 5/8" holes in the centers of any studs between the old fixture and the new ones. Run two NM cables from the new boxes for the fixtures to the box above the vanity. Protect the cable with metal protector plates. Secure the cables with cable clamps, leaving 11" of extra cable for making the connection to the new fixtures. Remove sheathing, and strip insulation from the ends of the wires.

Connect the white wires from the new cables to the white wire from the old cable, and connect the black wires from the new cables to the black wire from the old cable. Connect the ground wires. Cover all open boxes, and then replace the drywall, leaving openings for the fixture and the old box. (Cover the old box with a solid junction box cover plate.)

Install the fixture mounting braces on the boxes. Attach the fixtures by connecting the black circuit wire to the black fixture wire and connecting the white circuit wire to the white fixture wire. Connect the ground wires. Position each fixture over each box, and attach with the mounting screws. Restore power, and test the circuit.

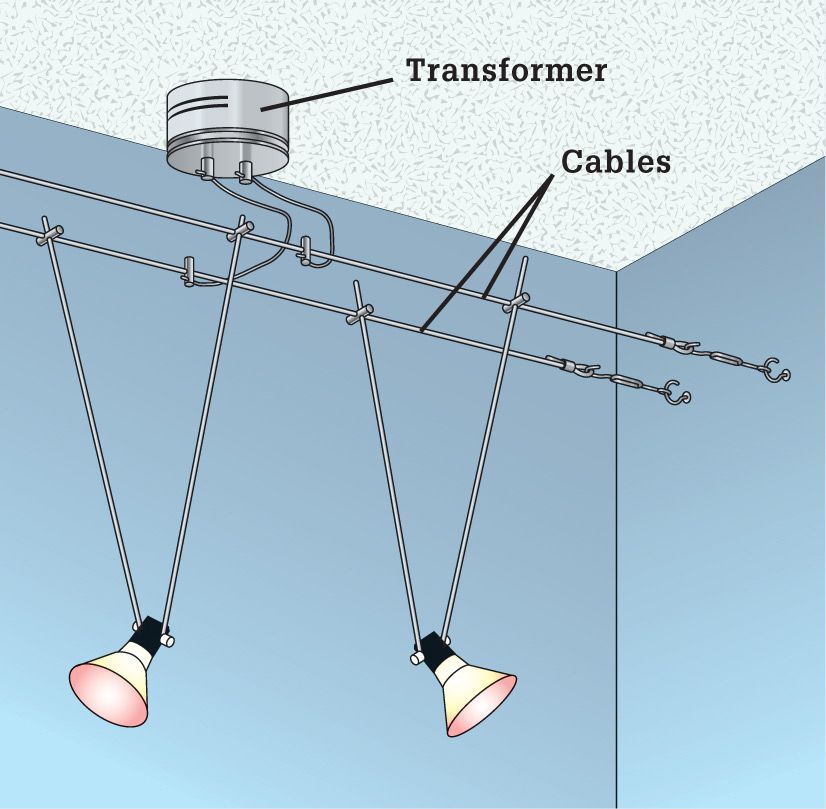

![]() Low-Voltage Cable Lights

Low-Voltage Cable Lights

This unique fixture system is a mainstay of retail and commercial lighting and is now becoming common in homes. Low-voltage cable systems use two parallel cables to suspend and provide electricity to fixtures mounted anywhere on the cables. A 12-volt transformer feeds low-voltage power to the cables.

The system’s ease of installation, flexibility, and the wide variety of individual lights available make it perfect for all kinds of spaces. Low-voltage cable light systems are ideal for retrofits and for situations where surface-mounted track is undesirable or impossible to install.

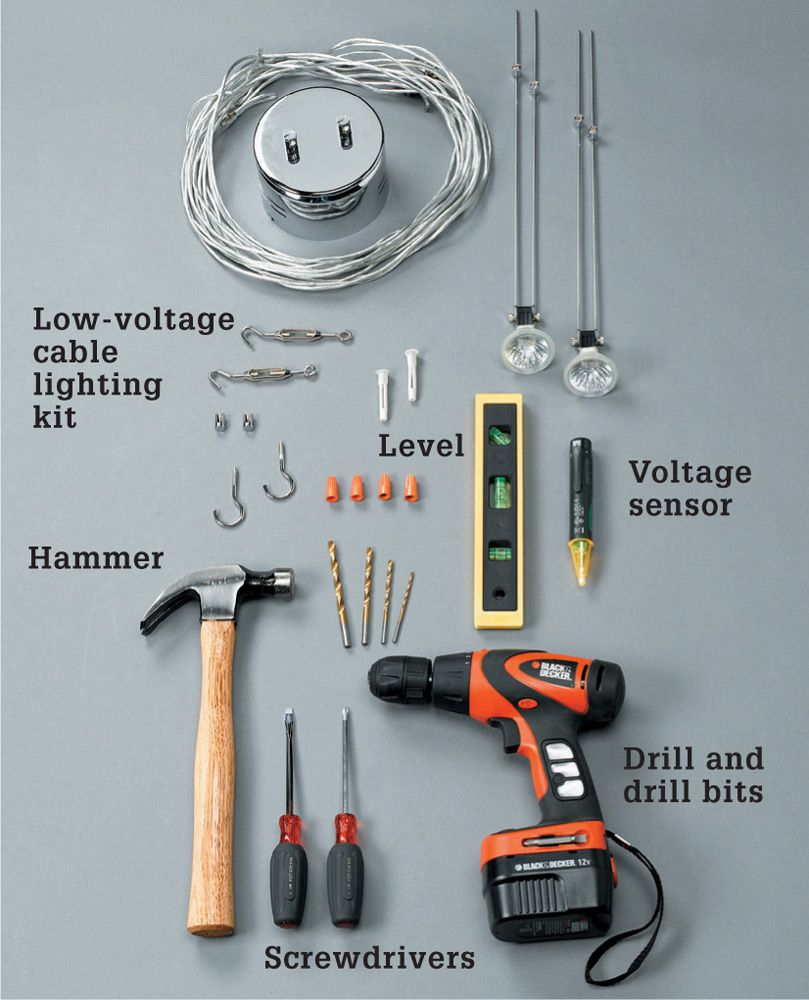

Tools & Materials ![]()

Combination tool

Screwdriver

Drill

Fish tape

Low-voltage cable light kit

Switch

Electrical boxes

NM cable

Level

Eye protection

Low-voltage Cable Lighting Kit ![]()

Low-voltage cable lights are low profile and easy to install, but they provide a surprising amount of light.

![]() How to Install Low-Voltage Landscape Lights

How to Install Low-Voltage Landscape Lights

Cable Light Kits ![]()

Low-voltage cable lights typically are sold in kits that contain the hanging lights, the low-voltage cable, and a decorative transformer that can be ceiling mounted or wall mounted.

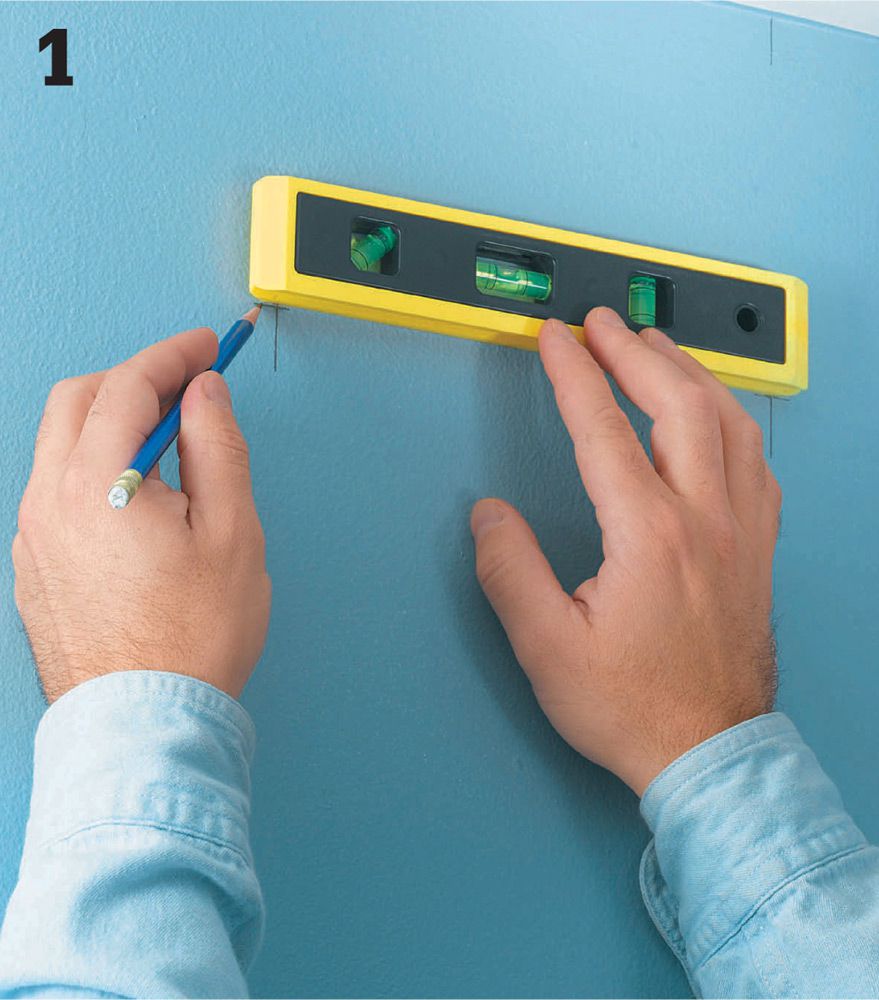

Lay out locations for the screw eyes that are used to suspend the cables, which should be in a parallel line. The path should lead the cables within a foot of the existing ceiling fixture box that you are using to provide power.

Install wall anchors at the appointed locations for the screw eyes that will suspend the cables. Plastic sleeve anchors are adequate in most cases. Drive the anchors into guide holes with a hammer.

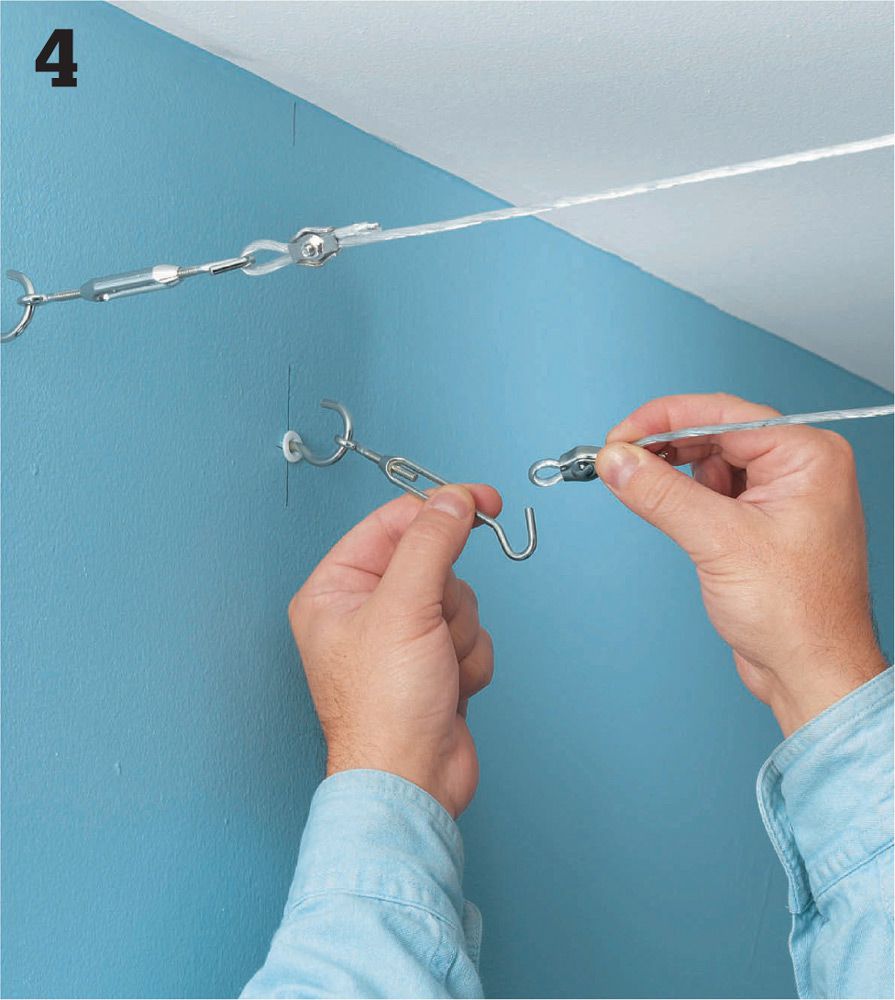

Twist the screw eyes into the wall anchor sleeves, taking care to make sure they are driven in equal amounts and are not overdriven. Install a set of screw eyes the same distance apart on each facing wall in the installation area. Cut two pieces of low-voltage cable to span between screw eyes on facing walls. Recommendations may vary — for the project shown here the cable is cut 12" shorter than the distance between the screw eyes.

Use the crimping hardware in your kit to form small loops at the ends of each cable. Slip the loops over the screw eyes on one end, and attach them to turnbuckles at the opposite ends. Slide the turnbuckles over the screw eyes and tighten them until the cables are taut.

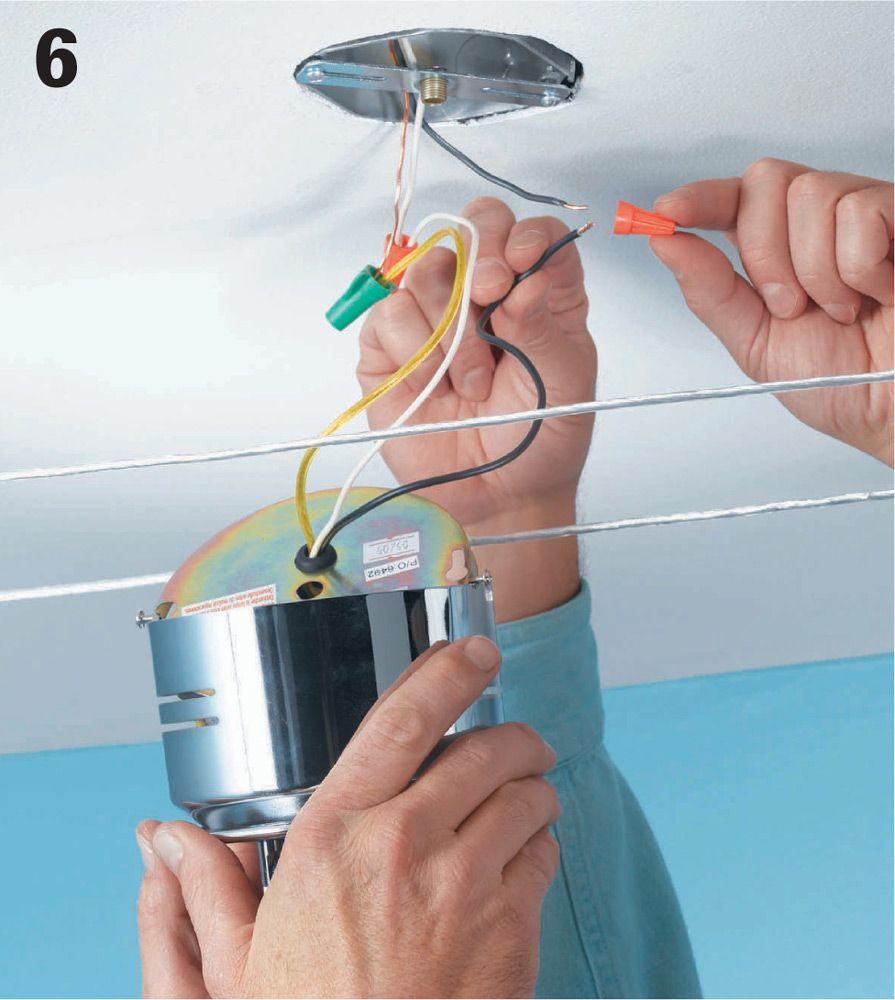

Attach the transformer crossbar to the electrical box containing the circuit leads. Shut off the power at the main service panel and test for power, and then remove the old fixture, if you have not already done so.

Make wiring connections for the transformer inside the electrical box. Make sure the transformer is supported while you join the wires. Be sure to attach the grounding wires to the grounding screw or clip in the box.

Mount the transformer onto the electrical box according to the manufacturer’s instructions. The model shown here has a separate chrome cover that is secured with a setscrew after the transformer is mounted to the crossbar.

Thread short lengths of cable into the openings on the screw terminals on the transformer. Tighten the screws until the pointed probe in each terminal pierces the cable sheathing and makes contact with the wire inside. Do the same with the other ends of the jumper cables using the provided connector hardware.

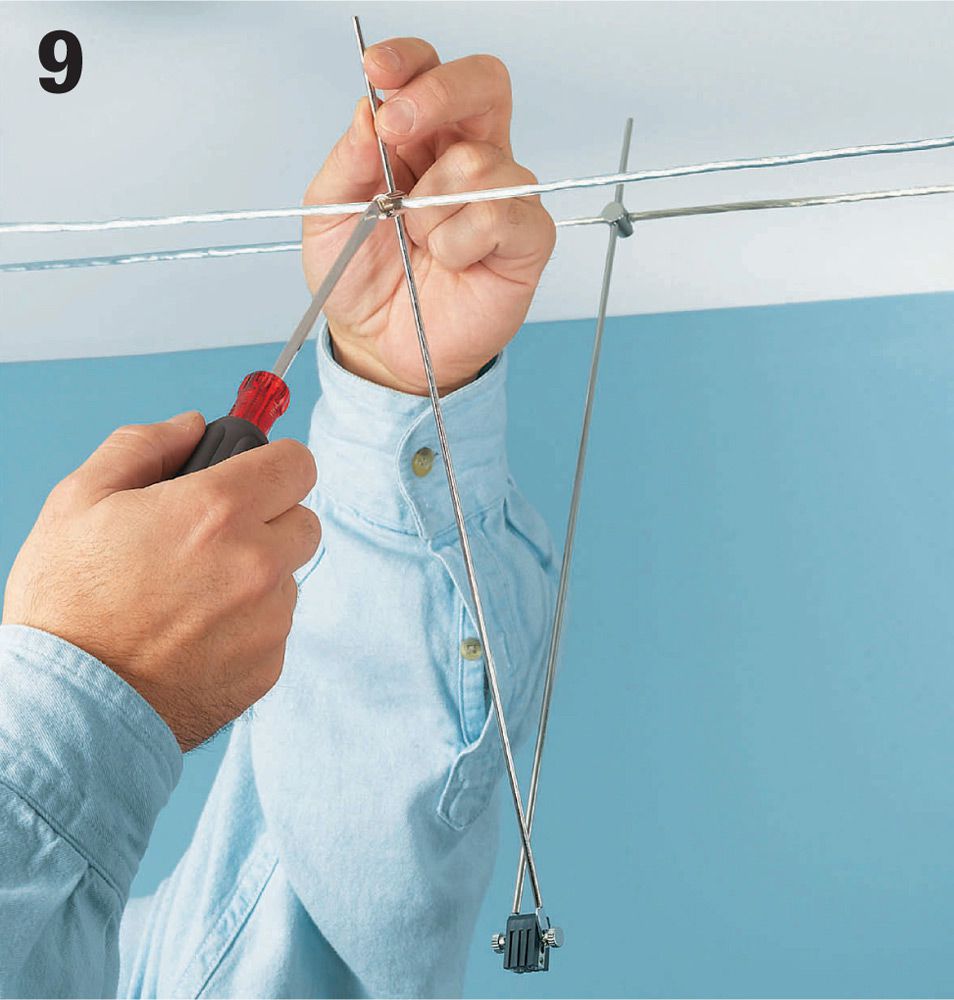

Hang the light fixture holders from the cables, tightening the screws in the hanger ends until their probes pierce the cable sheathing and make contact. It’s a good idea to hang all of the fixtures and arrange them to your liking before you begin tightening the screws and piercing the sheathing.

Insert the special low-voltage bulbs into the fixture holders and secure them as instructed (here, we are tightening a setscrew). Turn on the power and test the lights, adjusting the angles and directions of the bulbs.

Wall-Mount It ![]()

Install the transformer in a wall location if there is a more convenient power source or if you simply prefer the appearance of the wall location.

![]() Hard-Wired Smoke & CO Alarms

Hard-Wired Smoke & CO Alarms

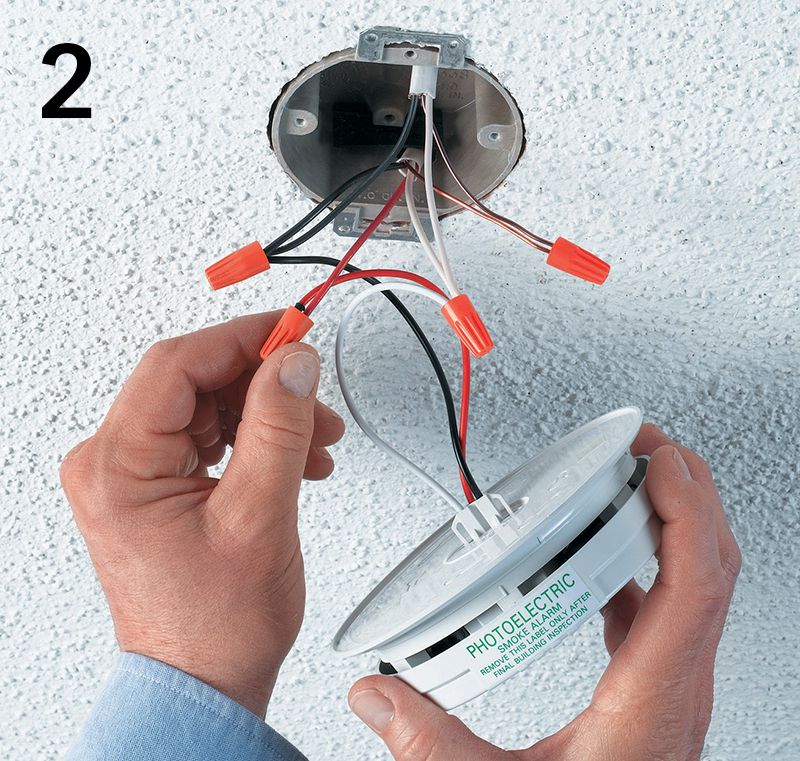

Smoke and carbon monoxide (CO) alarms are an essential safety component of any living facility. All national fire protection codes require that new homes have a hard-wired smoke alarm in every sleeping room and on every level of a residence, including basements and habitable attics.

Three types of alarms exist that can alert you to a fire. Photoelectric alarms are better at detecting fires with lots of flames. Ionization alarms are slightly better at detecting smoldering fires. Heat alarms detect high temperature created by a fire.

Many experts recommend installing photoelectric alarms instead of the more common ionization alarms, or as an alternative, installing some of each type. Heat alarms may be installed in addition to smoke alarms but may not be substituted for them.

Smoke alarms have a limited service life of about ten years. You should replace smoke alarms after ten years regardless of whether the alarm sounds when you press the test button. The test button, especially on older alarms, may only test the sounding device, not the smoke detection system.

Hard-wired alarms operate on your household electrical current but have battery backups in case of a power outage. On new homes, all smoke alarms must be wired in a series so that every alarm sounds regardless of the fire’s location. When wiring a series of alarms, be sure to use alarms of the same brand to ensure compatibility. Always check local codes before starting the job.

Tools & Materials ![]()

Screwdriver

Combination tool

Fish tape

Drywall saw

Wall or ceiling outlet boxes

Cable clamps (if boxes are not self-clamping)

Two- and three-wire 14-gauge NM cable

Alarms

Wire connectors

15-amp single-pole AFCI breaker

Eye protection

Smoke alarms installed on the ceiling should be at least 4" from the wall. Smoke alarms installed on the wall should be at least 4" and not more than 12" from the ceiling. As always, read and follow the manufacturer’s instructions.

Smoke and CO alarms are considered such important safety devices that national codes require updating these alarms to current code requirements during some types of remodeling projects. Enforcement of this requirement varies by jurisdiction, so check with your building department about their policies when adding a bedroom and before major remodeling.

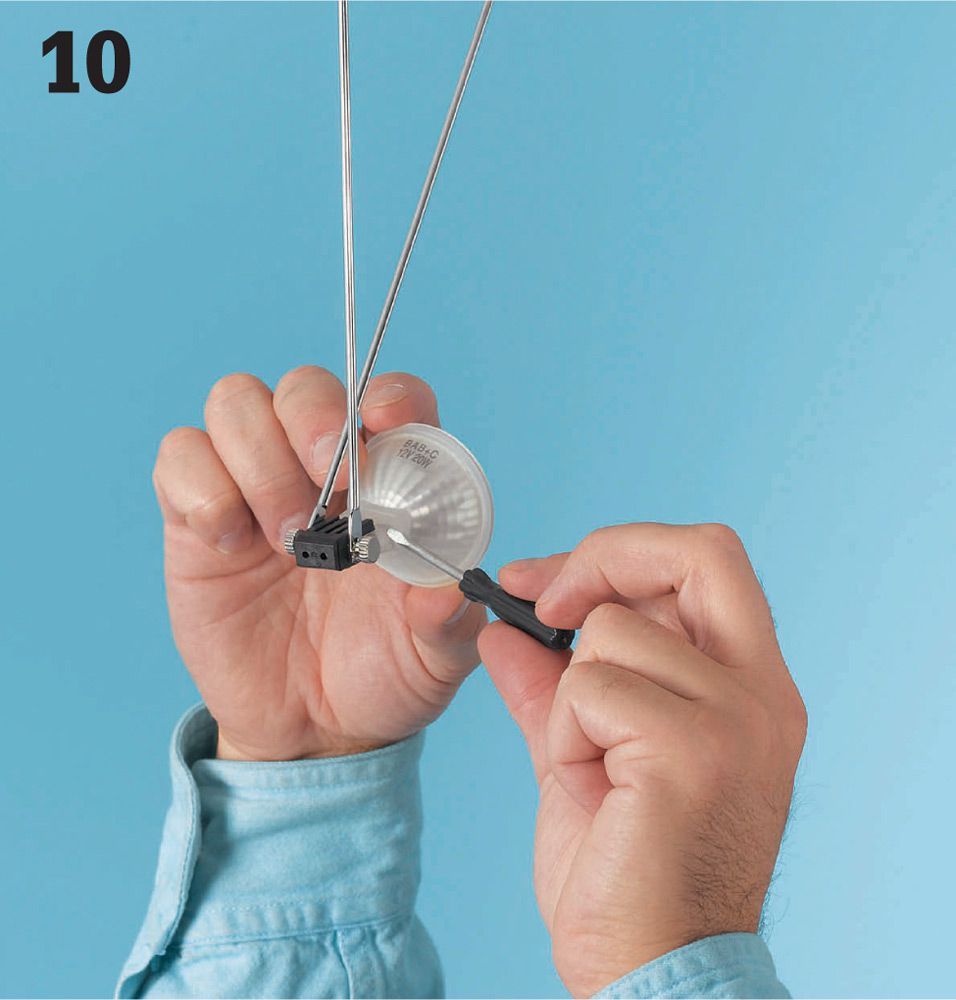

Smoke alarms and carbon monoxide (CO) alarms are required in new construction. Hard-wired CO alarms (A) are triggered by the presence of carbon monoxide gas. Smoke alarms are available in photoelectric and ionizing models. In ionizing detectors (B), a small amount of current flows in an ionization chamber. When smoke enters the chamber, it interrupts the current, triggering the alarm. Photoelectric alarms (C) rely on a beam of light, which when interrupted by smoke triggers an alarm. Heat alarms (D) sound an alarm when they detect areas of high heat in the room.

![]() How to Connect a Series of Hard-Wired Smoke Alarms

How to Connect a Series of Hard-Wired Smoke Alarms

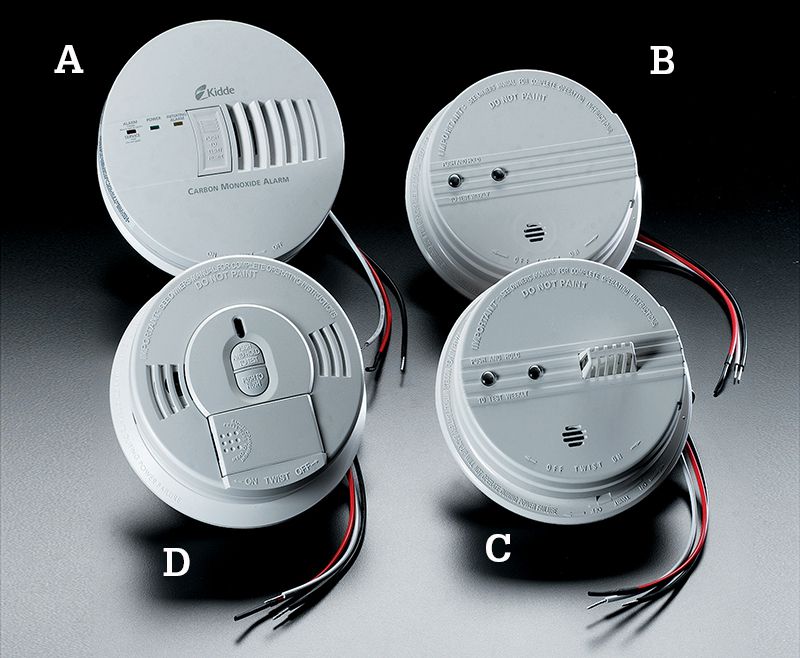

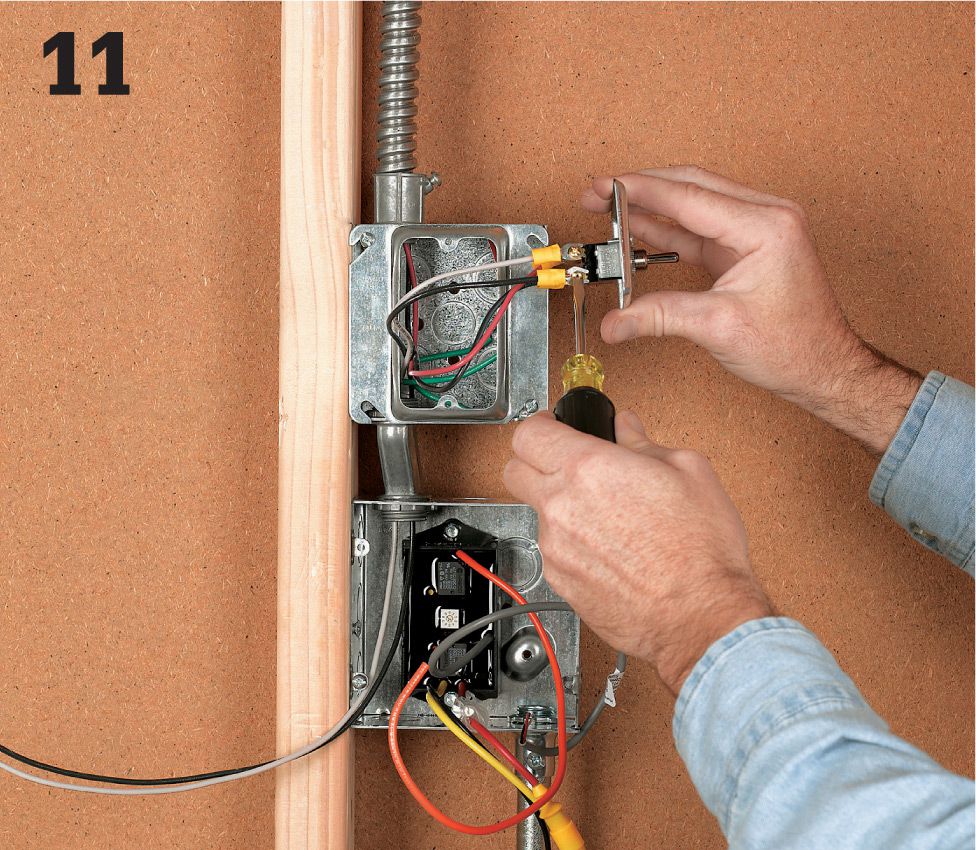

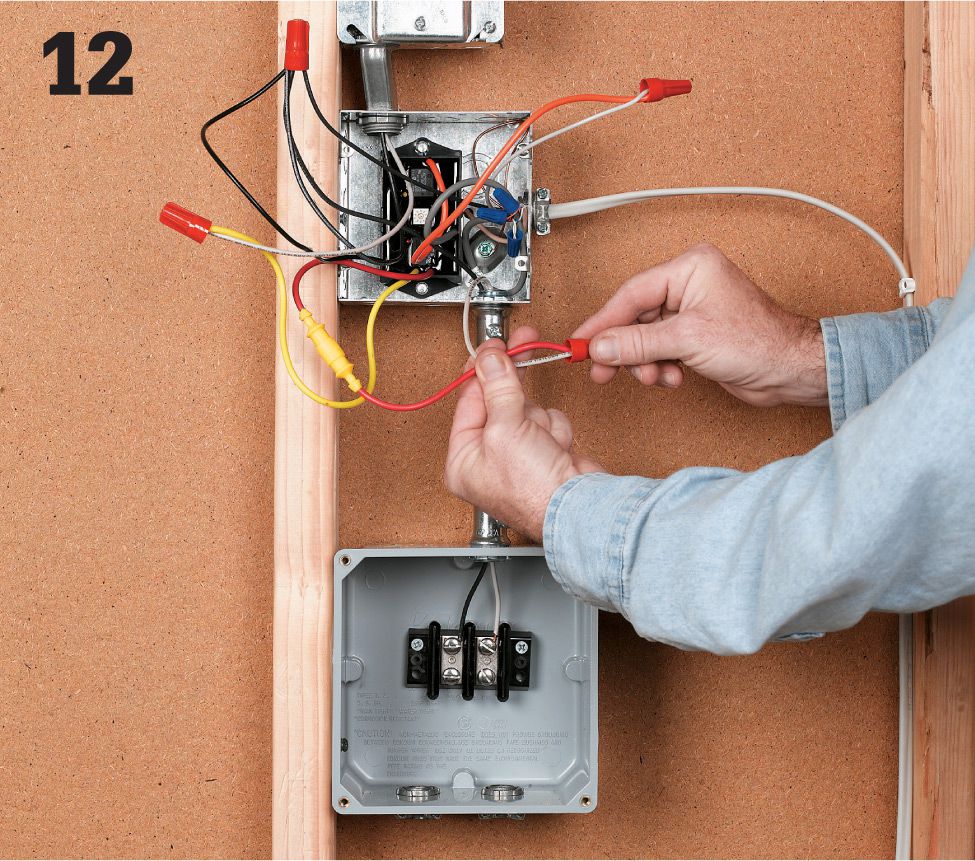

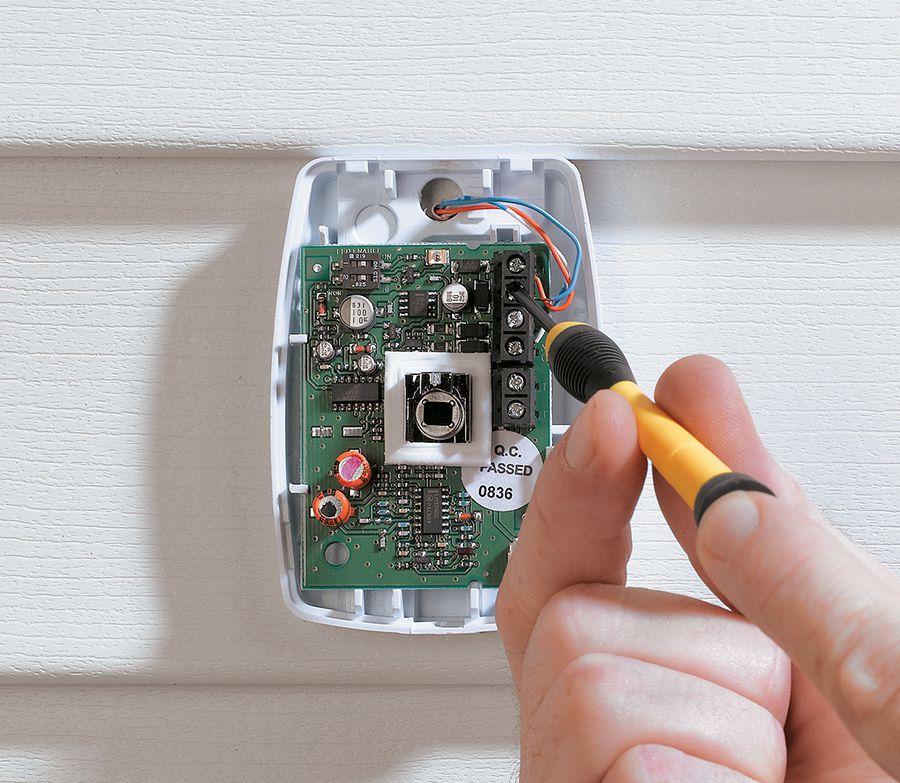

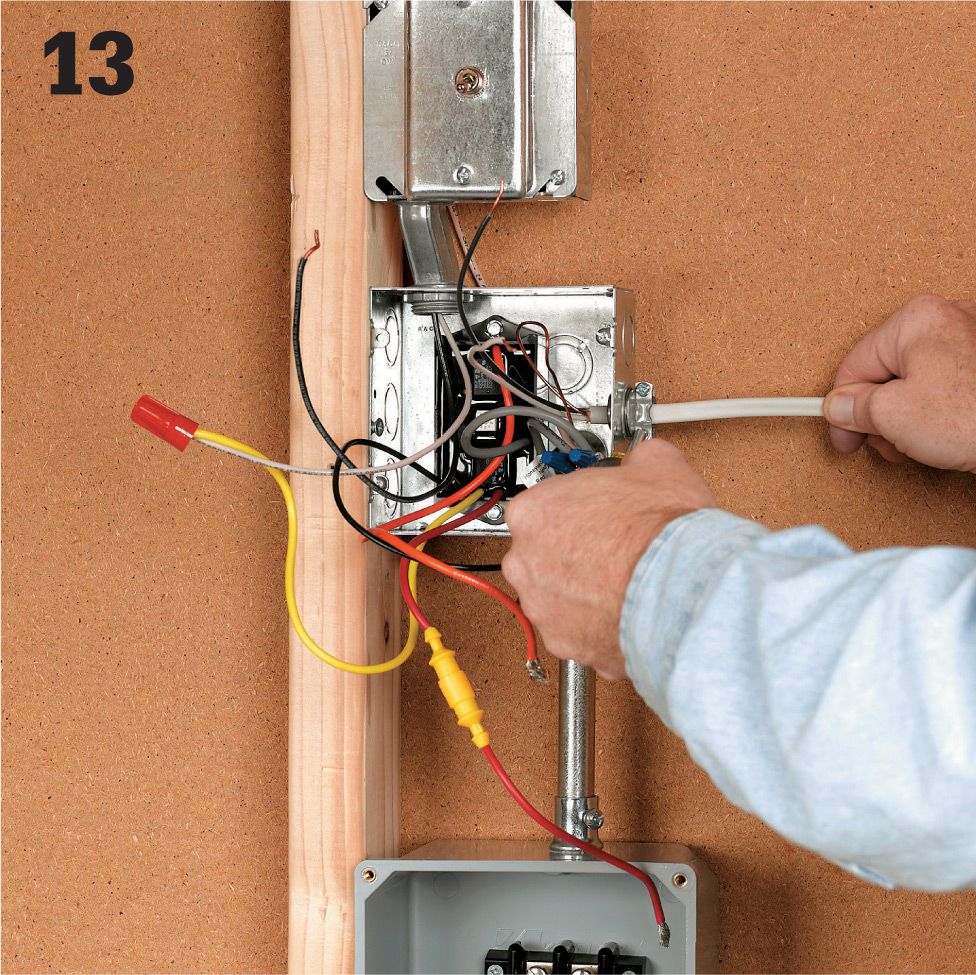

Pull 14/2 NM cable from the panel into the first ceiling electrical box in the smoke alarm series. Pull 14/3 NM cable between the remaining alarm outlet boxes. Use cable clamps to secure the cable in each outlet box. Remove sheathing, and strip insulation from wires.

Ensure power is off, and test for power. Wire the first alarm in the series. Use a wire connector to connect the ground wires. Splice the black circuit wire with the alarm’s black lead and the black wire going to the next alarm in the series. Splice the white circuit wire with the alarm’s white wire and the white (neutral) wire going to the next alarm in the series. Splice the red traveler wire with the odd-colored alarm wire (in this case, also a red wire).

Wire the remaining alarms in the series by connecting the like-colored wires in each outlet box. Always connect the red traveler wire to the odd-colored (in this case, red) alarm wire. This red traveler wire connects all the alarms together so that when one alarm sounds, all the alarms sound. If the alarm doesn’t have a grounding wire, cap the ground with a wire connector. When all alarms are wired, install and connect the new 15-amp AFCI breaker.

![]() Landscape Lights

Landscape Lights

Some landscape lighting manufacturers pitch their systems as security products. If you keep the outside of your house well lit, the reasoning goes, the thieves will turn elsewhere to find easier pickings. It’s possible that the companies are right about this. But probably the stronger arguments are for improved safety and appearance.

It can’t be surprising that adding some light to the dark makes going places safer. This idea has been around for a long time—a very long time. But the notion that you can improve the look of your house by adding some nightlights is more recent. In fact, decorating with exterior lights became widespread only in the last 25 years, when low-voltage landscape lighting showed up.

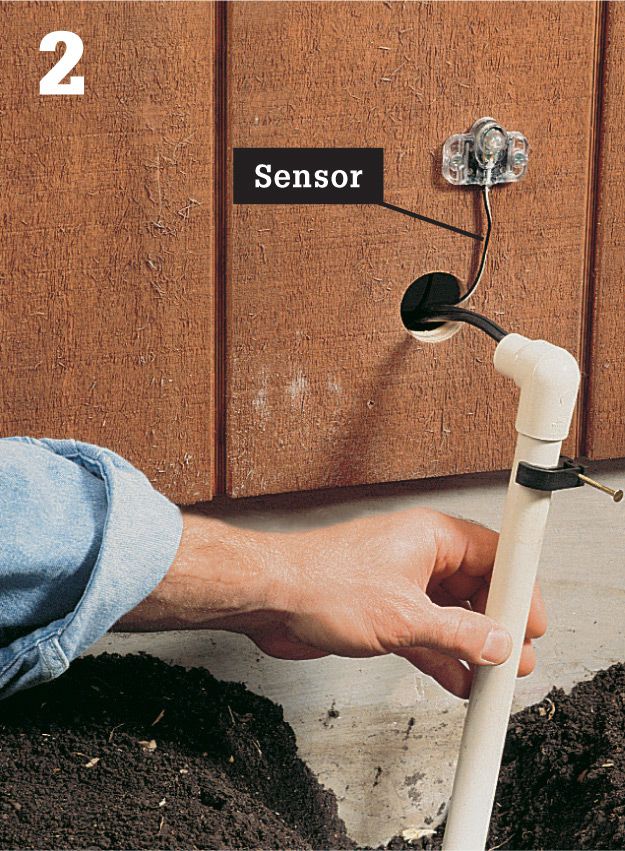

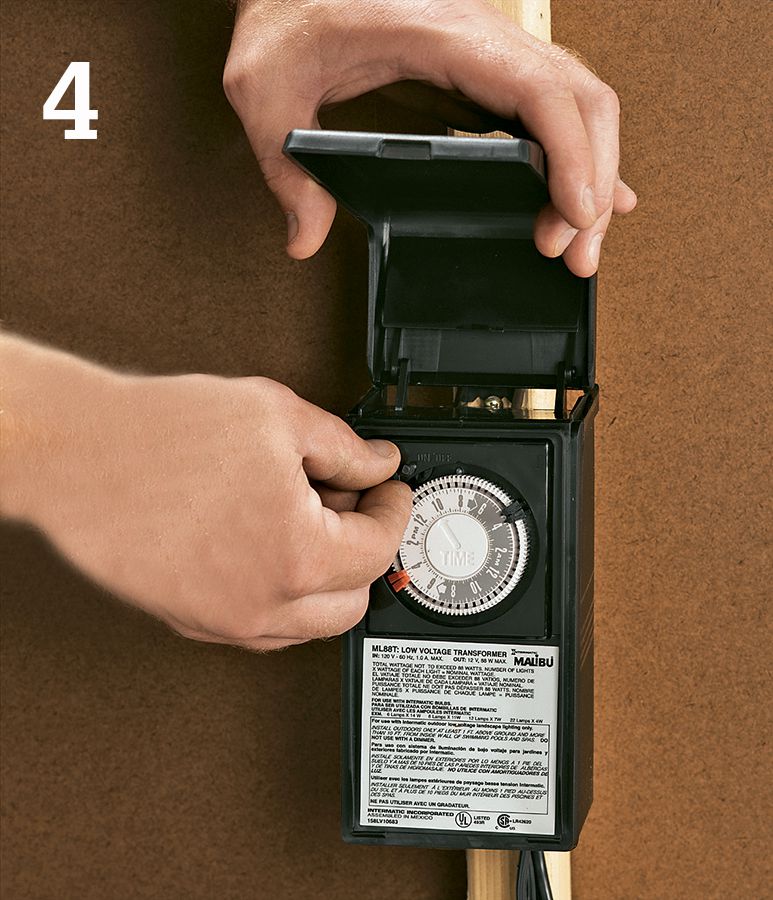

Low-voltage lights are powered by a transformer that steps 120-volt current down to a safe 12 volts. Choosing the location for the transformer is an important part of planning. You have two options: inside the house and outside the house. The outside installation is a little easier, but the inside one is a little better, especially from a security standpoint. Also take some time to review your light placement. Once you are happy with the plan, drive a small stake where you want each light to go.

Tools & Materials ![]()

Drill/driver & bits

Hammer

Screwdrivers

Hacksaw

Spade

Low-voltage fixture

Wires

Transformer

Stakes

Hacksaw

Eye protection

Low-voltage lights are safe to install and use to beautify your outdoor spaces. Unlike solar landscape lights, they are powered by good old reliable electricity, so they really can stay on all night if you wish them to.

![]() Parts of a Landscape Light System

Parts of a Landscape Light System

Landscape lighting can be ordered in kit form or as individual pieces. Kits include a few light heads, some wire, and a transformer that changes standard house current into low-voltage power. If you want half a dozen lights along the front walk, for example, then the kit is a good idea. It’s cheaper, very easy to install, and will last a long time unless the lights get run over by a lawnmower.

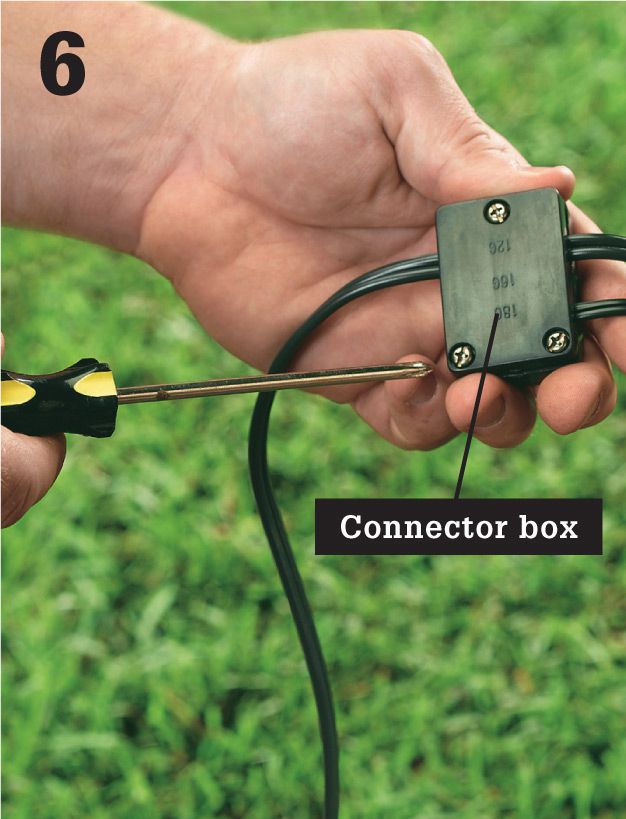

Typical low-voltage outdoor lighting systems consist of: lens cap (A), lens cap posts (B), upper reflector (C), lens (D), base/stake/cable connector assembly (contains lower reflector) (E), low-voltage cable (F), lens hood (G), 7-watt 12-volt bulbs (H), cable connector caps (I), control box containing transformer and timer (J), and light sensor (K).

![]() How To Modify Landscape Lights for Deck Installation

How To Modify Landscape Lights for Deck Installation

Specialty lights can cost a lot more than the standard plastic spike-base lamps. Because of this, many people modify the cheaper units to serve other purposes. To do this, first cut off the spike-base with a hacksaw.

To install a modified light on a deck, bore a wire-clearance hole through a deck board. Then feed the low-voltage wire through this hole, and attach the base to the deck with screws. The same technique can be used to install modified units on planters or railings.

![]() How to Install Low-Voltage Landscape Lights

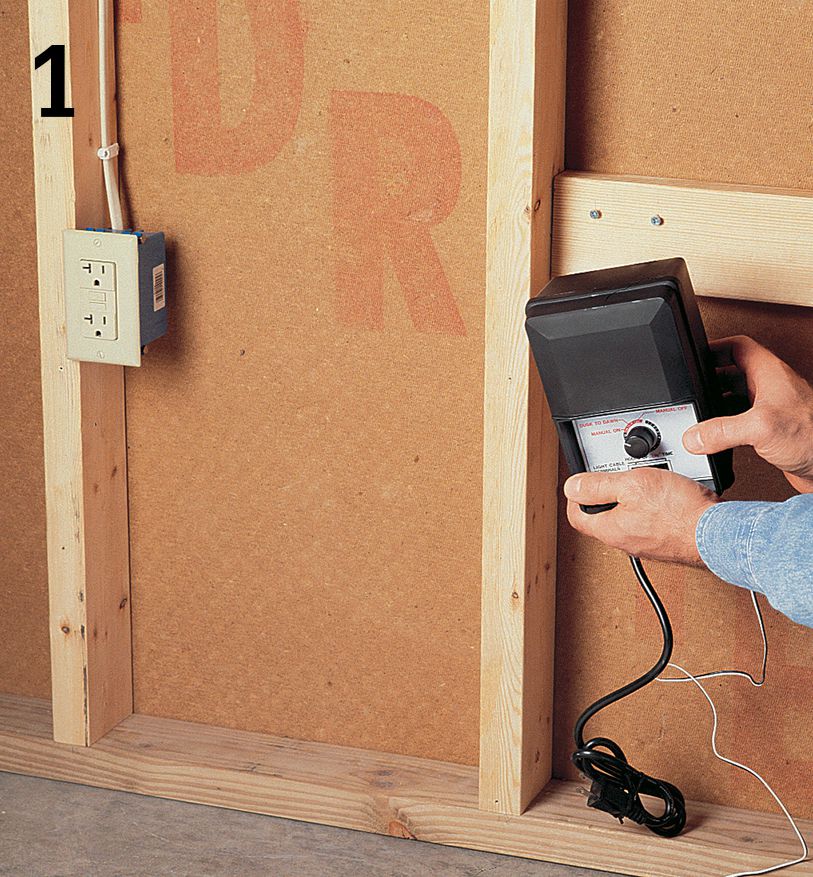

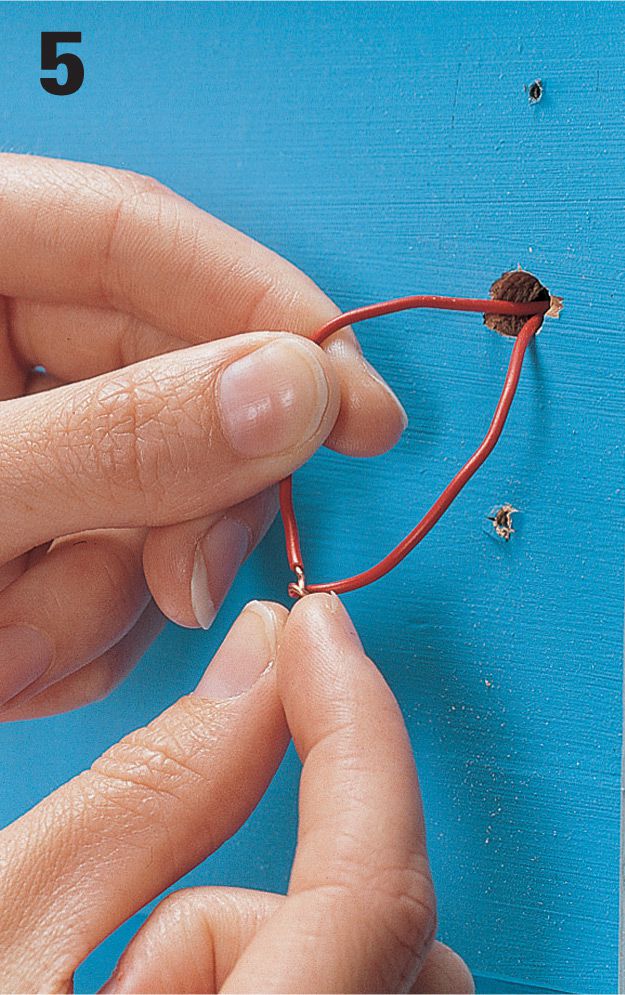

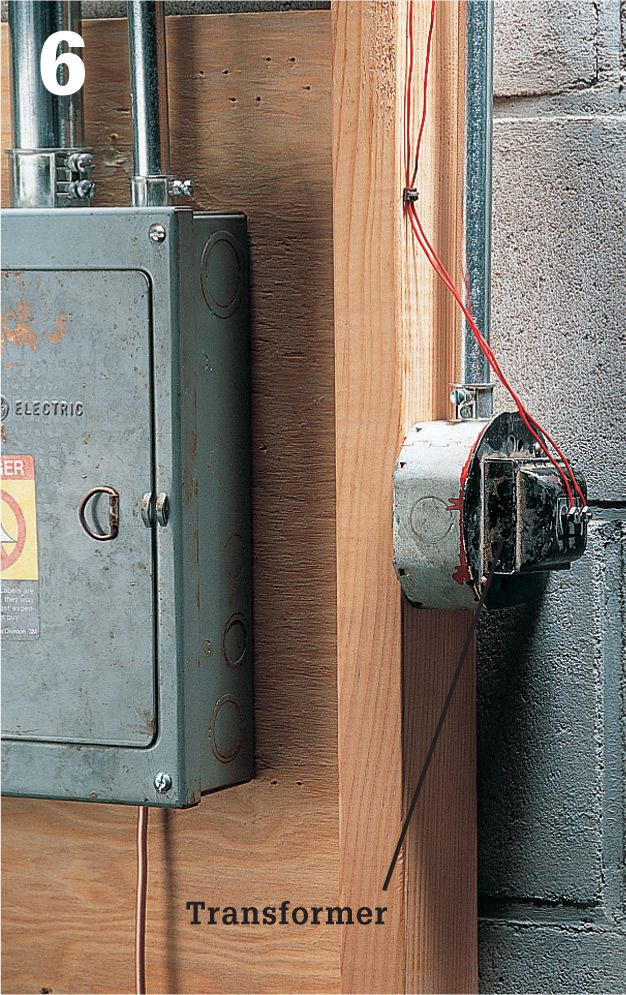

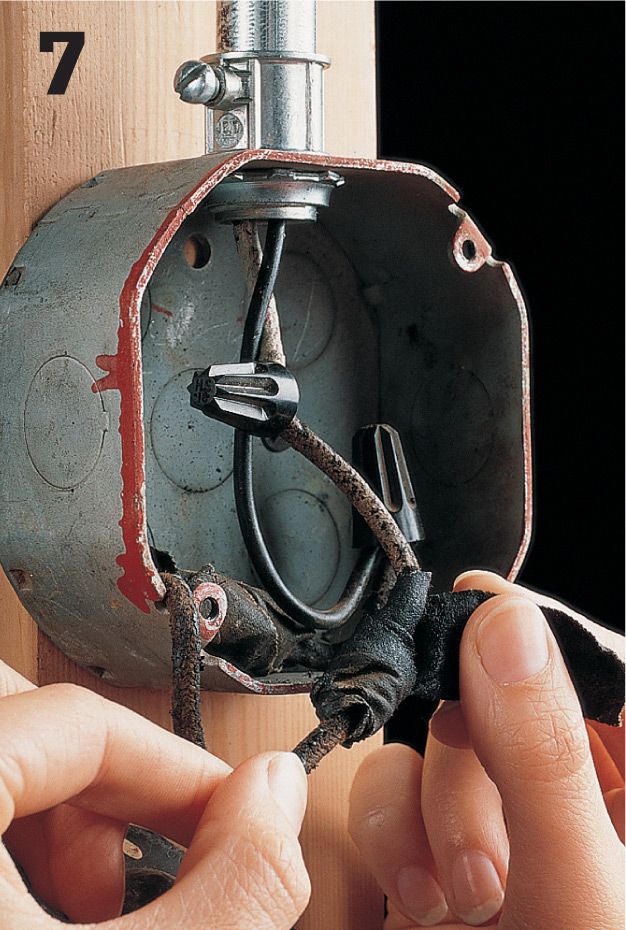

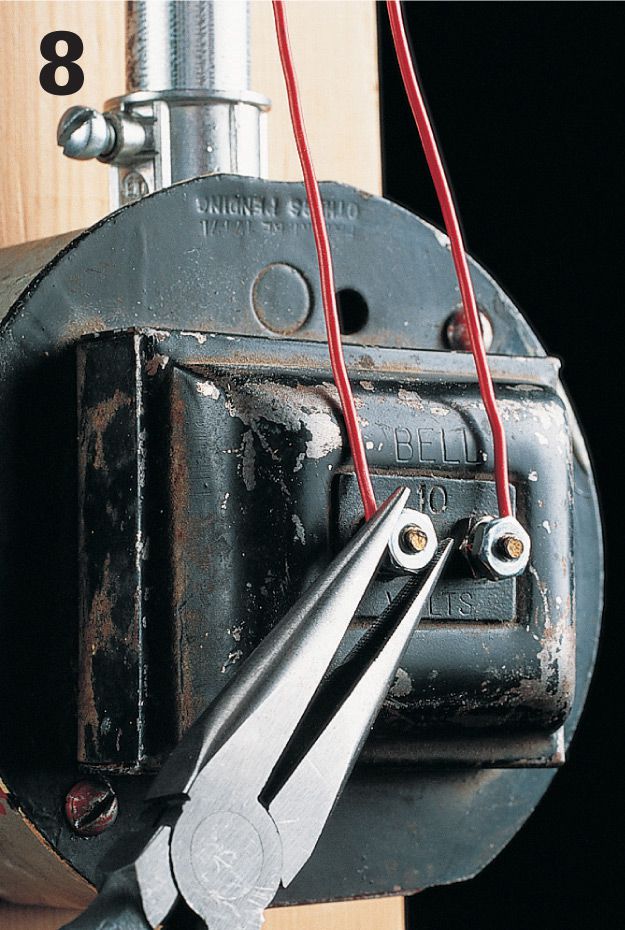

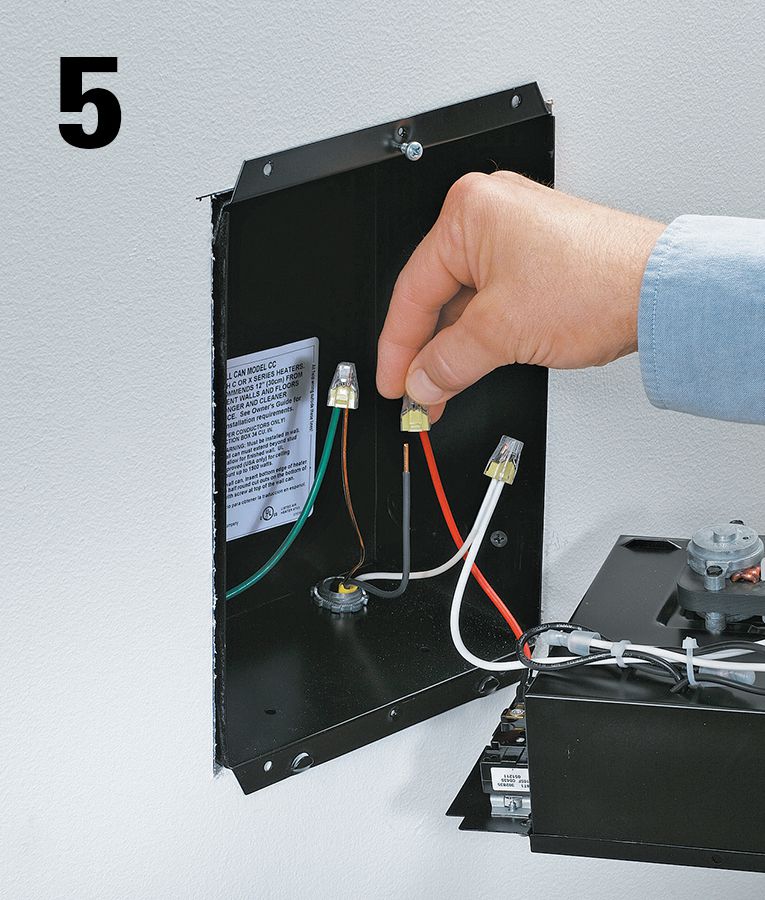

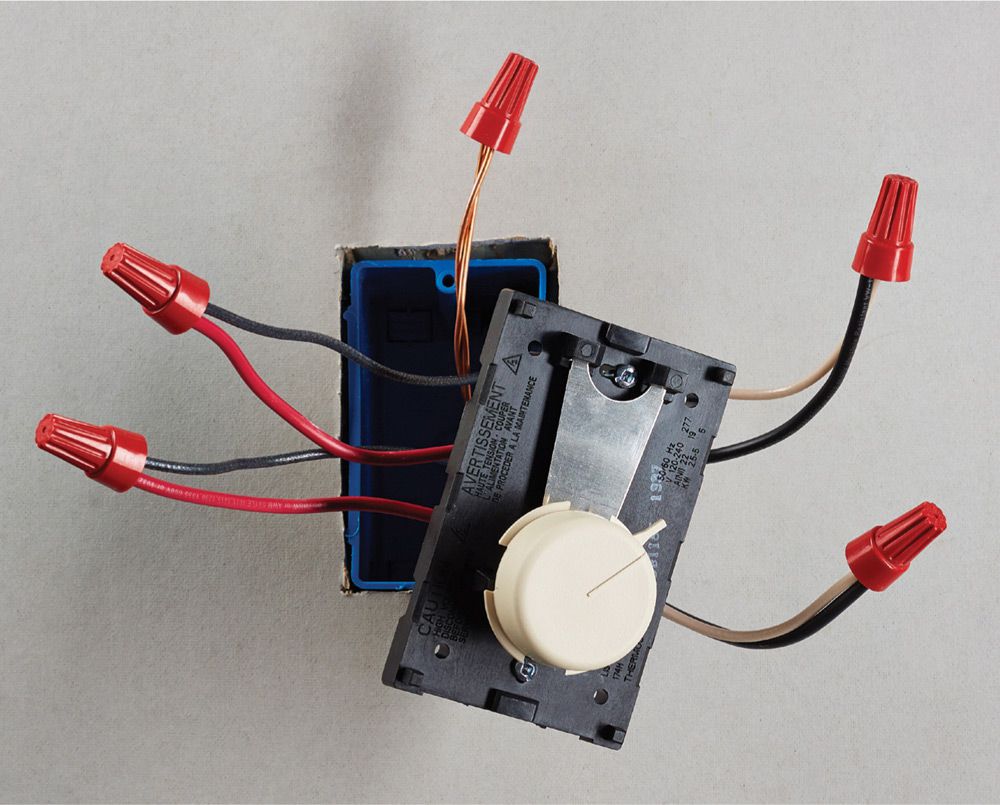

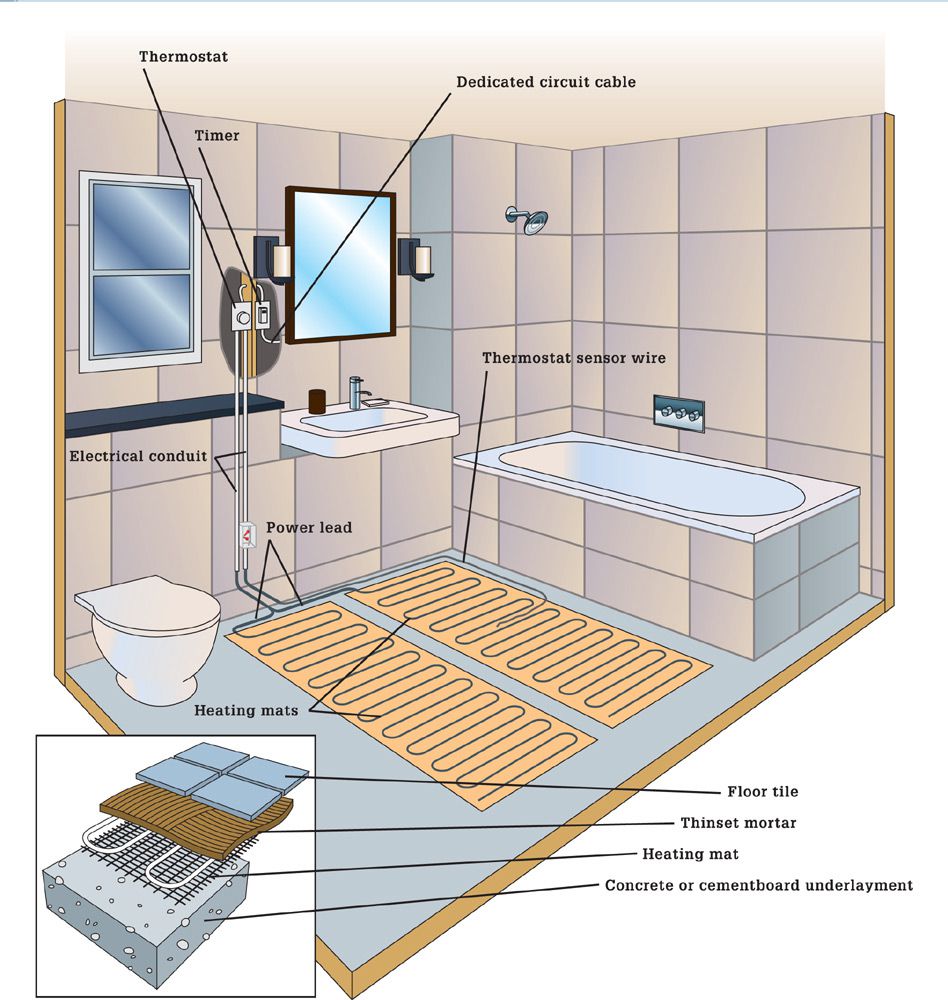

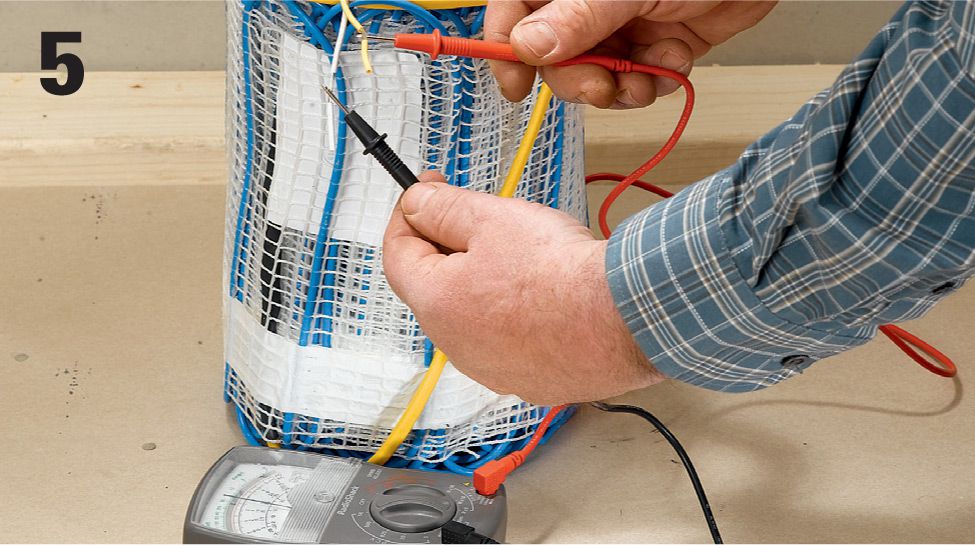

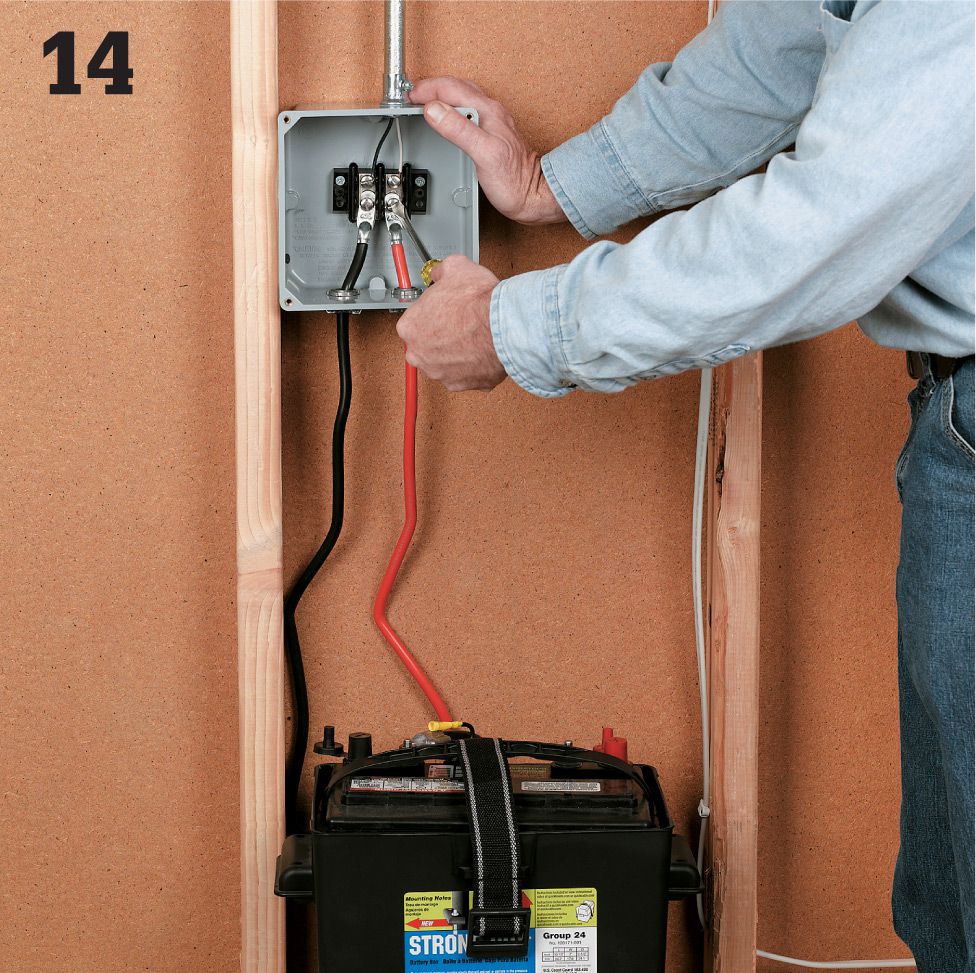

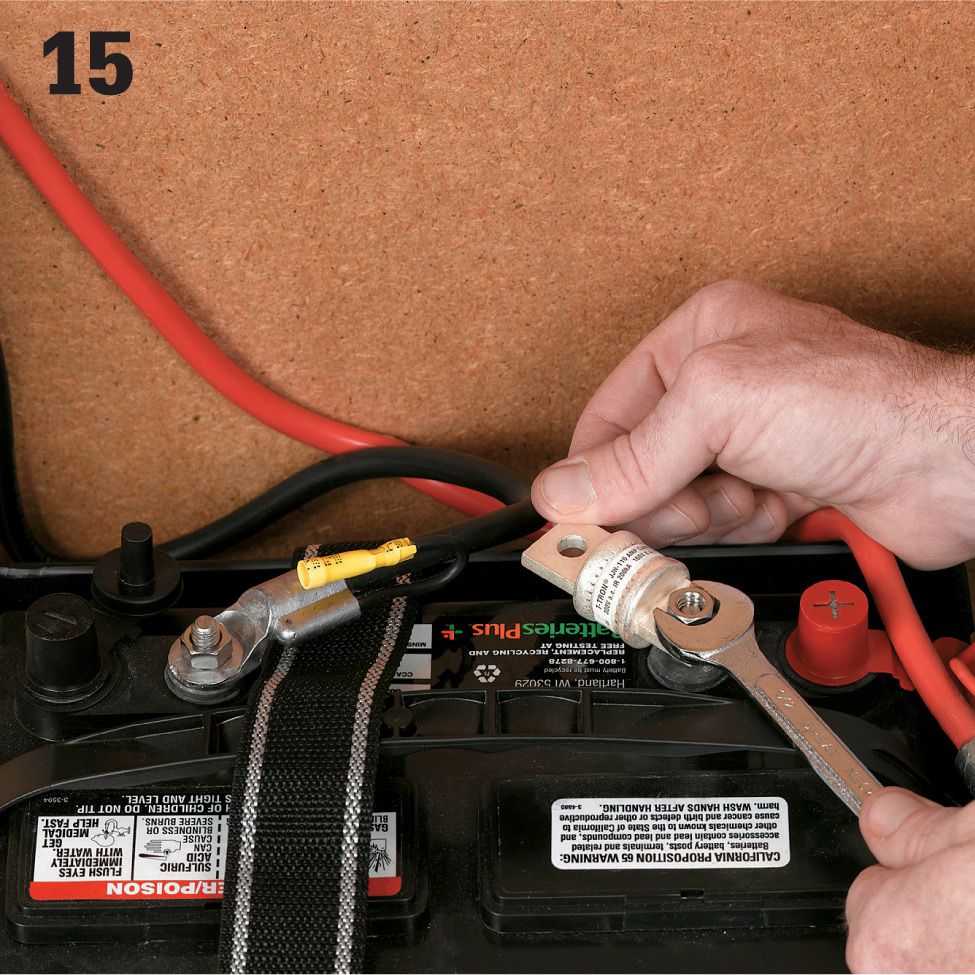

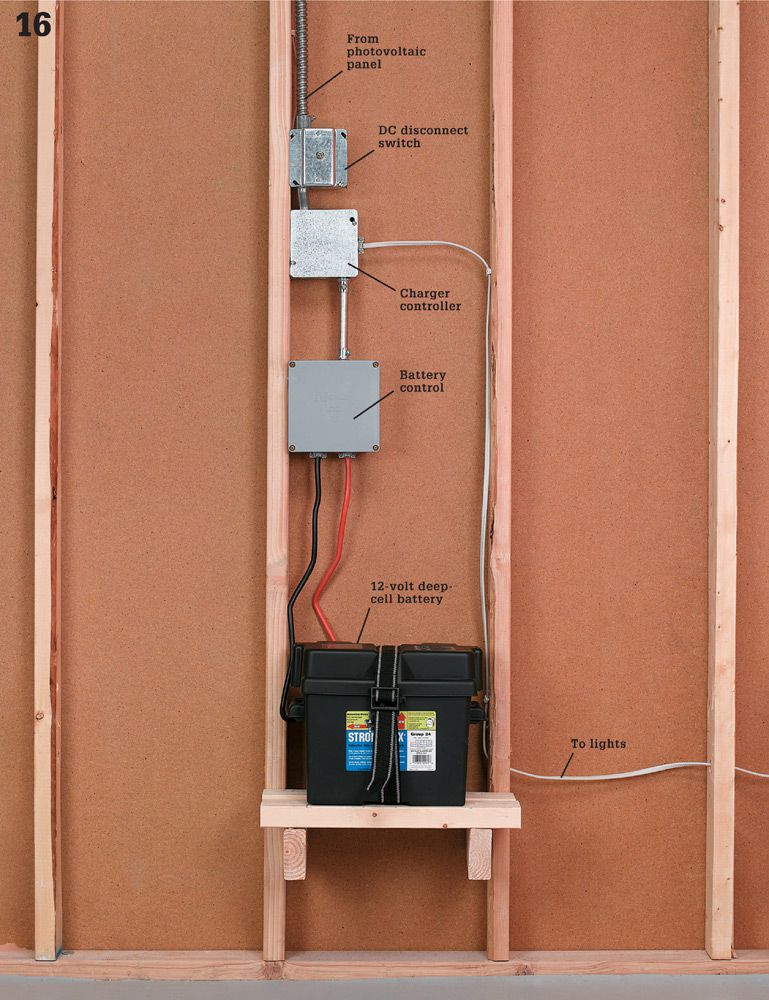

How to Install Low-Voltage Landscape Lights