50 Famous Firearms You've Got to Own: Rick Hacker's Bucket List of Guns (2015)

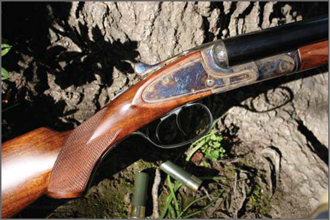

THE L.C. SMITH

By all accounts, the sidelock double-barreled shotgun belongs to the British. Indeed, “best guns” such as Purdey and Holland & Holland set the tone for the classic gentleman’s sidelock of the nineteenth and twentieth centuries. In America, names like Parker and Remington were giving the Union Jack a run for its money, but the hammerless versions were boxlocks, which became the norm. Only one firearms manufacturer emerged with the mechanical skills to produce an American hammerless sidelock, an elegant, sturdy shotgun that took the name of its creator, L.C. Smith—or “Elsie,” as this well-designed side-by-side was affectionately called.

Lyman Cornelius Smith had been in partnership with his brother, Leroy, and a neighbor, W.H. Baker, manufacturing and marketing Baker’s unique three-barreled drilling, which consisted of two side-by-side 12- or 10-gauge smoothbores over a .44-40 barrel. But this European-styled design wasn’t popular in America, and, by 1880, L.C. Smith found himself the sole proprietor of W.H. Baker & Co.

Having married into a prosperous family, money wasn’t a problem for Smith—but success was. Sales lagged. Fortunately, the entrepreneurial Smith had an inventive employee named Alexander T. Brown (who went on to develop the Dunlop tire and other automotive inventions in later years). Brown designed an exposed hammer sidelock double, which involved a sturdy “double cross-locking” rotary bolt, a strengthened barrel hinge, and hammer ears that dropped below the shooter’s line of sight when cocked. Produced in 10- and 12-gauge, the new “L.C. Smith Hammer Gun” was introduced, in 1884, with much fanfare and success.

Hacker’s 16-gauge L.C. Smith Ideal Grade was completely refurbished and brought back to life by Briley Manufacturing of Houston, Texas.

This greatly improved smoothbore was offered in a number of grades, or “Qualities,” as the company initially called them, ranging from 2 through 7 (or A to F and AA in subsequent catalogs) and priced from $55 up to $450, princely sums in the days of an average $16 weekly paycheck. For escalating Qualities and prices, you got progressively better grades of Damascus and, later, fluid steel barrels, more engraving, and better, more finely checkered wood. In 1913, the L.C. Smith grading system changed to reflect names like Field, Ideal, Olympic, Trap, Specialty, Eagle, Crown, Monogram, Premier, and De Luxe. In addition, a 12-gauge single-barreled trap gun was produced between 1917 and World War II.

A double on ducks, taken with the Italian-made L.C. Smith, which performs extremely well in the field, but doesn’t have the collectability of the original side lock.

Clearly, the L.C. Smith shotgun was geared towards sportsmen who wanted the best and were willing to pay for it. But, while the shotgun attracted well-heeled hunters, it failed to hold L.C. Smith’s attention; he had become enthralled with developing a new-fangled device called the typewriter. Thus, in 1888, Smith sold his company to a Fulton, New York, railroad builder named John Hunter, Sr. Hunter was looking for new ventures at the time and was planning to invest in a shotgun a neighbor named Harry Comstock was developing. Indeed, had Leroy Smith not learned about Hunter’s gunmaking interests, you might have been reading about the Comstock shotgun instead of those by L.C. Smith. Alas, for poor Harry, his patents and a pending partnership were scrapped once Hunter met Smith. After all, here was a quality shotgun, already established and with machinery and workers in place. Consequently, L.C. Smith went on to create what would become the famous Smith-Corona typewriter, and Hunter Arms Company was established to manufacture the equally famous L.C. Smith shotgun. And so it was under the Hunter Arms banner, which flew from 1889 until 1945, that the L.C. Smith legacy was established. This was America’s golden age of shotgunning, and we now had our very own sidelock with which to break records and bag birds.

In 1889, the Hunter Arms Company built a factory in Fulton, New York, a location that—under the leadership of John Sr. and, over the years, with his six sons—was to become revered in the annals of shotgunning. The guns were stamped “L.C. Smith” on the lockplates, while the barrels were marked, “HUNTER ARMS CO.-MAKERS-FULTON, N.Y.” In 1891, a 16-gauge was added to the line, and, in 1896, a few 8-gauges were produced; the 8-bores were discontinued one year later and today are extremely rare. In 1908, the first L.C. Smith 20-gauge made its appearance. Only one 28-gauge was made, serial No. 100, while the .410 was introduced in 1926, with a scant 2,665 of these smallbores known to exist.

In 1892, L.C. Smith became the first U.S.-made shotgun to offer automatic ejectors, especially featured, in 1895, on the company’s top-of-the-line A3 Automatic Ejector Gun. Additionally, in 1904, the company catalog touted its new Hunter One-Trigger, a non-selective system that fired the right barrel first. The Hunter One-Trigger could be ordered in any of three fixed positions: forward, middle of the trigger guard, or to the rear. It was extremely fast, yet was guaranteed against doubling. Later, in 1935, a selective single trigger was offered.

Every L.C. Smith exuded quality, from the “workhorse” blued and case hardened 00 Field Grade to the elaborately engraved and checkered A3 Monogram. Internally, all guns exhibited the same excellent workmanship. Barrels were imported rough-bored, then reamed and polished at the factory. Initially there were varying grades of Damascus, ranging from English Stub Twist to the finest qualities and patterns. Later, only the best steel tubes were used, escalating in quality from Armour Steel on the Field Grade to Nitro and Royal Steel on the higher grades. Each tube was hand straightened, and the pairs of tubes were brazed together, rather than soldered. All internal parts were mirror-polished and hand fitted. Higher grades had internal parts damascened, like a fine pocketwatch. Stocks were American, English, or French walnut, shaped at the factory and hand rubbed with linseed oil; the higher the grade, the more coats the stock received. The completed guns were then test fired for patterning perfection at the company’s indoor range.

Unfortunately, the reoccurring gremlins of financial woes and mismanagement plagued this family-owned operation and, in 1917, the Hunter Arms Company filed for bankruptcy. The reins were quickly picked up by a small cadre of Fulton businessmen who didn’t want to lose L.C. Smith, which was the town’s claim to fame. Nonetheless, in 1920, the company was sold to the Simmons family of Massachusetts, who, unfortunately, also did a less than stellar job of management. On one occasion, Hunter Arms was contracted to make a bolt-action shotgun for Sears Roebuck & Company, but a miscalculation of costs resulted in financial catastrophe. Then, in 1939, the company was put up for sale, but World War II halted negotiations. After continuing shotgun making for both civilians and the government, Hunter Arms again went into bankruptcy.

This time to its rescue rode the Marlin Firearms Company, which, on November 20, 1945, purchased the assets. The plant was reopened as the L.C. Smith Gun Company—the first time “Smith” was included as part of the company name. It was a perfect match, as Marlin, led by Frank Kenna, was also family owned. Unfortunately, after only five years, in which a total of 57,929 guns were made, a floor in the factory collapsed, putting L.C. Smith out of business.

In 1967, Frank Kenna, Jr., who’d become president of Marlin in 1959, resurrected L.C. Smith as a limited production gun. This time it was made in Marlin’s New Haven, Connecticut, factory. Offered only in 12-gauge, it differed from the original in that it featured a ventilated rib. But the demands of producing a labor-intensive sidelock, plus competition from imports and the popularity of pumps and semi-automatics doomed the “Elsie.” A scant 2,539 Marlin-made L.C. Smiths were all that remained of this classic double, before production was finally halted, in 1971.

Interestingly, Marlin resurrected the L.C. Smith once again, but this time it was in name only. The new side-by-side was, in reality, a boxlock made in Italy, one that featured false sideplates to make it look like a sidelock. It was offered in 12- and 20-gauge, and there was an Italian-made L.C. Smith over-and-under as well. Both were made for Marlin by the well-known firm of Fausti Stefano, cataloged only from 2005 through 2009. I took one of the new 12 bore side-by-sides on a Canadian goose hunt and found that the gun, with its single selective trigger and screw-in chokes, performed admirably. But though it was well made, I was bothered by the false sideplates over a boxlock action. Why not just call it as it is—a boxlock—rather than trying to make it look like something it isn’t—a sidelock? Still, unlike my original 16-gauge L C. Smith Ideal Grade, I wasn’t afraid to get this one wet and muddy. You can still find those Fausti-made guns in used condition and fairly affordable but, of course, they have no collector’s value. Personally, I would much rather have an original, as made by the Hunter family, or a post-war gun made by Marlin.

It is interesting to note that L.C. Smith, the man who gave his name to this legendary American sidelock, was involved with it only for a brief four-year period. Yet his namesake shotgun continues to endure as both a highly desirable hunting companion and a collectable, while the typewriter he invented has become obsolete.