Edison and the Electric Chair: A Story of Light and Death - Mark Essig (2005)

Chapter 5. "Down to the Last Penny"

SHORTLY AFTER Edison's demonstration of incandescent lighting on New Year's Eve 1879, an English expert published his view of the matter in the Saturday Review. "What a happy man Mr. Edison must be! Three times within the short space of eighteen months he has had the glory of finally and triumphantly solving a problem of world-wide interest. It is true that each time the problem has been the same, and that it comes up again after each solution, fresh, smiling, and unsolved, ready to receive its next death-blow. But… there is no reason why he should not for the next twenty years completely solve the problem of the electric light twice a year without in any way interfering with its interest or novelty." After crying wolf so many times, Edison deserved the mockery, but the doubts that greeted his announcement were quite genuine. Many engineers considered an inexpensive electric light to be a mathematical impossibility, something like a perpetual motion machine. One called Edison "a fraud, a willful deceiver of the public" who was interested only in booming his stock price. The humor magazine Puck offered a backhanded defense: "Edison is not a humbug. He is a man of a type common enough in this country—a smart, persevering, sanguine, ignorant, show-off American. He can do a great deal and he thinks he can do everything."1

The criticism infuriated Edison, but before reporters he maintained his genial public persona. Early in 1880 he announced plans to build his first commercial lighting station in New York, the city where he had made his fortune in telegraphy, where his investors had their offices, and where an aggressive and influential press would carry news of his achievements around the world.

Some experts believed that in the future every house would have its own small electrical generator, but Edison always imagined his system as similar to that of gas lighting, in which many homes and offices were served by one central plant. Lighting gas was produced by distilling coal, then trapping the resultant gas, purifying it, and storing it in vast reservoir tanks. Big main lines carried the gas from the reservoirs under the streets, with smaller pipes branching off into homes and businesses and terminating in lighting fixtures. By turning a key on the fixture, customers opened a valve and released gas, which they then lit with a match. Similarly, Edison imagined that large electrical generators in a central station would produce current, which would then be carried under the streets through copper wires and into homes and offices.2

When first introduced in American cities in the 1840s and 1850s, gaslight marked a big improvement over the reeking whale-oil lamps and tallow candles commonly in use. When the electric lamp came along, its advantages over gaslight seemed similarly obvious: Electric lamps produced less heat and no smoke, soot, or poisonous fumes. Gas lighting, though, had habit and tradition on its side, as well as the power of wealthy gas lighting companies. Cheap coal drove gas production costs down, while the gas companies—thanks to cozy relationships with city aldermen—enjoyed government-protected monopolies. By the early 1880s more than 70 percent of the consumer price of gas represented pure profit for the corporations, which meant that they would make money even if they slashed prices to compete with electric light. Gas company executives used political clout and bribery to try to keep Edison from getting a franchise for his system; they failed only because the Edison Electric investors were equally powerful. The biggest obstacle to incandescent lighting, however, was not political manipulation but economics. Gaslight was cheap, and electricity was not. Edison closely studied the costs of gas lighting and tried to eliminate all waste from his system. "Everything must be got down to the last penny," he said.3

Edison used a high-resistance filament for his bulb because it would give more light with less current, and he built the most efficient generator to date. In 1880 he made a breakthrough in circuit design that reduced the use of copper, one of the single biggest costs of an electric lighting system. Edison initially had planned to use what was known as a tree circuit to carry electricity from the central station to the lamps. All conductors of electricity offered some resistance to the current that flowed through them, which caused a portion of the electrical energy to be converted into heat and therefore wasted. Because of this lost energy, voltage dropped at the farther reaches of the circuit, and the lamps most distant from the generator were dimmer than those closest to it. To correct for this, the conductors in a tree circuit were thicker (and therefore had a lower resistance) near the generator, then tapered like tree branches as they got farther away. The initial thickness of the conductors prevented losses due to resistance, thereby keeping the lights shining with equal brightness throughout the circuit.

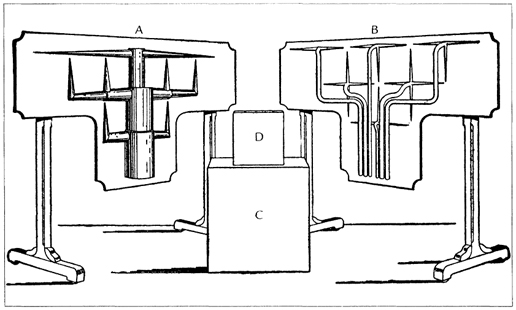

This worked well on a small scale, but a large system like the one planned for New York would have required the conductors to be as thick as tree trunks near the generators, and the copper costs would have been prohibitive. To skirt this problem, Edison designed a new circuit known as the feeder-and-main (see figure 2). Rather than having one thick, tapering conductor leading from the generator to serve all of the lamps, as in the tree circuit, a number of conductors (feeders) 51 branched off from the generator and carried current to local circuits (mains) that served homes and offices. The mains, in other words, were laid near the buildings to be illuminated, at some distance from the central station, while the feeders were longer, connecting directly to the station. The voltage drop (roughly from 120 volts to no) was localized in the feeders, so a steady pressure of about no volts was maintained in the local circuits, where the lamps were located. The cost of copper for the feeder-and-main was about one-eighth that of the tree system. When asked why no one had thought of this design before, the great British physicist Lord Kelvin replied, "The only answer I can think of is that no one else is Edison."4

Figure 2: Compared to the older tree system (A), Edison's new feeder-and-main circuit design (B) required far less copper, one of the most expensive elements of an electric lighting system. The two cubes represent the amount of copper needed to light the same number of lamps using the tree system (C) and the feeder-and-main (D).

Even with the feeder-and-main circuit, the system required so much copper that the only way to make it pay was to build it in an area of high population density, so that many customers could be served with relatively few feet of feeders and mains. Lower Manhattan, the site of 52 Edison's chosen district, fit the bill perfectly. Edison sent a small army of canvassers into the fifty-one-square-block area to ask residents how many gas jets they had, how much gas they used at various times of the year, what their gas bills were, and whether they would be willing to try electric light. The canvassers found about 1,500 customers using 18,043 gas jets. Promised free wiring and prices comparable to those of gas, almost all of the customers agreed to try electricity.5

AS HE WORKED TOWARD the big dream of a Manhattan system, Edison was distracted by another project. Henry Villard, a major stockholder in the Edison Electric Light Company, also headed the Oregon Railway and Navigation Company. Impressed by Edison's New Year's demonstration, Villard decided that the incandescent light should be installed in the Oregon company's new steamship, the SS Columbia. Although reluctant to be distracted from his central station work, Edison decided that the Columbia offered a priceless opportunity to showcase his invention. The ship docked in Manhattan, and Edison's men set to work.

The Columbia's lighting system—the first commercial installation of incandescent lamps—was rather crude. Rough cotton dipped in paraffin served as insulation for the wires, which were tacked to the woodwork with iron staples; when wires crossed over metal, a sleeve of soft rubber was slipped over them. Edison's men developed the first lamp sockets, wooden devices with two metal strips inside that pressed against two strips at the base of the bulb. (In the laboratory, the lamp's lead-in wires had been wound around terminal screws, a method too complex for general use.) No one had yet conceived of the screw socket, so the bulbs sat rather loosely in their sockets. The Columbia project inspired the invention of the first "safety catch," or fuse, a strip of soft metal that melted and broke the circuit if the line overheated, thus preventing fires and allowing the insurance underwriters to sleep easier. The last items to be installed were the bulbs themselves. The filaments were so fragile that Edison's men wrapped them in cotton batting, placed them in baskets, and carried them by hand through the streets of New York, careful to avoid jostling by passersby.

If a passenger in a stateroom wanted the lamps turned on or off, he called a steward, who unlocked a box outside the room to turn the switch. Few passengers complained about this inconvenience, though, because electric lights were such an improvement over oil lamps, which quickly fouled the air of the small staterooms. The Columbia reached San Francisco on July 26,1880, and Californians flocked to see the spectacle of the new incandescent lamps. They were a bit disappointed, because about half the bulbs had expired en route, their brittle filaments fractured by the ship pitching in rough seas. A shipment of improved bulbs—cushioned in paper and packed in barrels—was rushed overland to fill the Columbia's empty sockets.6

Edison and his men had been fiddling with filaments to lengthen bulb life even before the steamship project arose. Manufacturing the lamps seemed to be a hit-or-miss affair: A few lamps lasted as long as 500 hours, while apparently identical ones expired after just a few minutes. Starting in January 1880, dozens of materials—horsehair, fish line, teak, vulcanized rubber, cork, celluloid, grass fibers, linen twine, tar paper, wrapping paper, parchment, rattan, California redwood, corn silk, flour paste, leather, sassafras, cinnamon bark, eucalyptus, turnip, ginger, and macaroni—made their way into the carbonizing furnace and thence into evacuated bulbs. A carbonized thread of spider silk displayed a beautiful light pink phosphorescence but expired quickly.

By late spring of 1880 Edison and his men had a fairly good idea of what they were looking for: raw plant materials with dense, long, uniform fibers, which tended to hold their shape after carbonization. Rejecting jute and hemp, Edison finally settled on bamboo. Not quite satisfied with the quality of available specimens, Edison ransacked New York for new varieties of bamboo, then dispatched explorers to Japan and the Amazon. Another explorer, John Segredor, slogged through the Florida swamps. "What renders this job interesting is the strong probability of getting bitten by a snake," Segredor wrote to Edison. He traveled on to Cuba, where Edison sent him $150 for expenses. Two weeks later the explorer was dead of yellow fever. Sent news of the death, Edison drafted a response: "Bury him my expense with funds his possession." Reconsidering, he crossed that out and wired simply, "Bury him my expense." Edison located a source of high-quality bamboo in Japan.7

When the lamp experiments started in 1878, Edison employed about two dozen men, but by 1880 his staff had ballooned to sixty-five. With many different projects proceeding simultaneously—lamps, generators, insulators, conductors—Edison's role became that of director of research, but he took the lead role in every project. Although the staff had more than doubled in size, the atmosphere stayed largely the same. The boss still worked superhuman hours, and his men were expected to work whenever the boss did, day or night. Few seemed to mind. "The strangest thing to me is the $12.00 I get each Saturday," Francis Upton told his father, "for my labor does not seem like work, but like study and I enjoy it."8

The black sheep of Menlo Park's happy family was the glassblower Ludwig Boehm, whose arrogance made him the target of pranks. To escape harassment, Boehm moved out of his Menlo Park boardinghouse and into the attic room of the glassblowing shed, but it proved an unsafe retreat. Late at night the boys used one of Menlo Park's lesser-known inventions, an enormous ratcheting rattle mounted in a soapbox and turned by a crankshaft. It was known as "the corpse-reviver." They pressed it against the wall outside Boehm's bedroom, turned the crank, and produced a sound like a dynamite explosion, knocking Boehm clear out of bed.9

Boehm complained to Edison, who never bothered to solve the problem, though later he probably wished he had. Boehm quit in October 1880 and found work with a new Edison rival, the Manhattan-based United States Electric Lighting Company.

U.S. Electric was founded in 1878 to exploit the lighting patents of Hiram Maxim. Late in 1880 U.S. Electric installed 150 incandescent lamps at the Mercantile Safe Deposit Company in Manhattan. The lamps were round, not pear shaped like Edison's, and the filament was shaped not like a horseshoe but like a capital M. They nonetheless looked familiar, and there was a good reason for this. Earlier in 1880, Maxim had appeared in Menlo Park. In a display of courteousness that he later regretted, Edison spent an entire day showing him around and explaining the lamp-making process. Maxim then went back to his own lab at U.S. Electric, copied Edison's design, and went into business. The hiring of Ludwig Boehm helped U.S. Electric perfect bulb production.10

Newspaper reporters, uninterested in the niceties of patent law, offered high praise to Maxim's work in New York. It had been nearly a year since Edison had unveiled his lamp and promised to install lights in New York, yet he remained in Menlo Park, tinkering with his system. People were growing impatient. Maxim's "name will be remembered long after that of his boastful rival is forgotten," Illustrated Scientific News claimed, and others agreed. "The present stir over the Maxim incandescent light has a better basis than the Edison excitement a year ago," a newspaper reported. Edison "is no more called the 'magician of Menlo Park.'"11

Edison professed not to worry about what he was called or what his electric light rivals were up to. "I put the lights on the Columbia, but what good did it do? It put me back six weeks in the work I am doing here," Edison explained. "I could have done six months ago what Maxim has done, had I desired to make a show." In Menlo Park and on the Columbia, Edison had already installed lighting plants similar to Maxim's in New York. He was working on something big—not a handful of small dynamos running a few hundred lamps but a major system able to power entire city blocks.12

IN PREPARATION FOR the Manhattan system, Edison built a model in Menlo Park. He plotted a grid of imaginary streets in the fields around the laboratory and had his men put up white pine lampposts at fifty-foot intervals. At the top of each pole was a lamp, covered with a fishbowl-shaped globe to protect it from the elements. The 56 posts leaned crookedly, but Edison gave them little thought, because the real work was going on underground. Laborers attacked the earth with plow and shovels, digging trenches and then laying long, shallow wooden boxes into them. Workers laid copper wires into the boxes, then poured tar over the wires. The job was completed by July 1880, and the conductors seemed to work well enough. When it rained, however, the wet ground became a better conductor, and electricity leaked everywhere. The lamps on the poles barely flickered.

Edison sent one of his men into the library to read up on insulation. The state of the art was not advanced, so the Edison workers made it up as they went along. For the next two months the men boiled up batches of noxious compounds, driving everyone else out of the laboratory. Finally, they settled on a mixture of paraffin, beeswax, linseed oil, and Trinidad asphalt. The trenches were dug up and the conductors laid again with the new insulation. The work was delayed by box turtles that, investigating the new smell in the neighborhood, got stuck in the tar and had to be rescued. The system was finally ready for another full test on Tuesday, November 2, which also happened to be the day of a presidential election. Edison, a staunch Republican, gave orders that the lights should be lit only if James Garfield won. He did, and the long rows of lamps glittered atop their poles until after midnight.13

With this successful test, Edison was ready to tackle New York. On December 17, some of the same investors who two years before had formed the Edison Electric Light Company—most notably, the investment bankers of Drexel, Morgan & Company—incorporated a new firm, the Edison Illuminating Company of New York, to finance a Manhattan central station.

Republican though he was, Edison knew that building his system in New York meant fraternizing with New York's Tammany Hall Democrats, so he invited New York's Board of Aldermen out to Menlo Park. On December 21, the politicians chartered a private car on the Pennsylvania Railroad and arrived at Menlo Park about half past five. As the aldermen approached the station, they saw the model light system, parallel strings of stars against the backdrop of a moonless night. After detraining, the aldermen strolled up a brightly lit plank walkway to Edison's office, where the inventor greeted them, his hands still grimy from a laboratory project he had abandoned a moment before.

He walked the politicians to the laboratory, where he explained the details of the system, then led them to his library and showed them a big wall map of his proposed lighting district, an area of fifty-one square blocks bounded by the East River and Spruce, Nassau, and Wall Streets. He would build a central station with steam engines and generators, lay conductors under the streets, and r un wires into homes and businesses.

The group returned to the laboratory. The tools of the inventing trade had been cleared away, and in their place appeared a long table laid with a feast catered by Delmonico's: roasted and boned turkey, duck, chicken salad, and ham. Champagne, wine, and brandy flowed freely. Edison mixed his wine with liberal doses of cold water before letting it cross his lips. The aldermen drank less cautiously, and by the time they stumbled out to the train at eleven they were promising Edison he would have his permit to dig up the streets of New York and lay his conductors.14

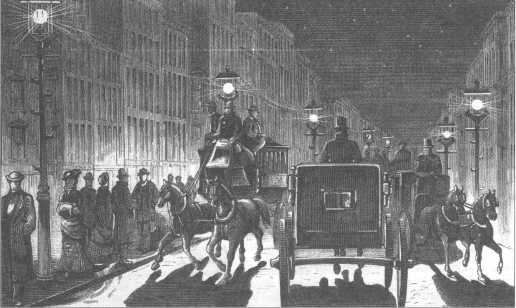

AS EDISON REFINED his system in Menlo Park, the Cleveland electrical pioneer Charles Brush was introducing powerful arc lights to American cities from coast to coast. A chemist by training, Brush began following electrical progress in Europe in the early 1870s, and by the end of the decade he had designed his own generator and arc lamp and founded the Brush Electric Company. In 1879 San Francisco became the first city to adopt the Brush system for street lighting, and Boston and Philadelphia followed suit. On December 21,1880, the same day that the aldermen visited Menlo Park, Brush installed twenty-two lamps on ornamental cast-iron posts along Broadway in New York, from the bottom of Union Square up to Madison Square. The New York Star reported that the lamps "made the gaslights look sickly in comparison." The arc lamps were so bright that just twenty-two of them displaced 500 gas streetlights.15

Brush installed dozens of lights in textile mills and steel plants, while for other customers the appeal of the lamps lay in their novelty. Brush sold one of his first lamps to a Cincinnati dentist, who installed it on his balcony to attract patients. Many small-town Americans saw their first arc lamps inside the bigtop of P. T. Barnum's traveling circus. John Wanamaker bought twenty lights to dazzle customers at his new department store in Philadelphia, and for a time Coney Island's arc lights were more popular than the rides. By the end of 1880, Brush had installed more than 5,000 lamps.16

Charles Brush's arc lamps lit up Broadway in Manhattan in December 1880.

Before the late 1870s, Americans experienced electricity in only a few ways: as pulses zipping through telegraph wires or as surprising shocks administered by doctors or carnival showmen. When arc lamps appeared—slender wires carrying enough energy to produce blinding light—they heightened the sense of mystery surrounding this unknown force. Whenever arc lamps appeared in a city, people gathered to experience this latest manifestation of electricity's powers.

Brush arc lamps arrived in Buffalo, New York, on the night of July 13,1881. After noticing a strange glow in the sky that night, many city residents walked across the Michigan Street bridge into an industrial area known as the Island, at the edge of Lake Erie. As they turned left onto Ganson Street, the Island's main thoroughfare, they saw an iron pole, twenty feet high, topped by a blazing white light. Two wires ran from that post to another, a few hundred feet beyond, and beyond that was still another pole—twelve in all, stretching alongside the wooden plank roadway for more than a mile. A small sun rested atop each pole, buzzing and sputtering and throwing a hard, silvery glare on the industrial landscape of planing mills, grain elevators, and dry docks. By the time a group of reporters and leading citizens arrived, their carriages could barely force a passage through the crowd of thousands who milled about in the road, blinking and shielding their eyes.17

When the lights were shut off late that night, the people strolled back across the bridge and made their way home, but word spread around town, and each night more people crossed over to the Island to bask in the glare. The Brush company, eager for good publicity, allowed visitors to enter the rough wood-frame building that held the steam engines and dynamos. After inspecting the machinery, some of the visitors—up to a dozen or so at a time—joined hands in a semicircle, with the person at each end grasping the iron railing surrounding the generators. A small amount of electricity leaked from the dynamos to the iron railing, causing a gentle tingle of electricity to pass through their bodies. It was a descendant of the Leyden jar experiment tried on Parisian monks more than ioo years before, a practice kept alive by traveling showmen with batteries and induction coils. The people of Buffalo found that the old trick worked just as well with this new producer of electric current, the dynamo.18

About nine o'clock on the night of August 7, a man named Lemuel Smith entered the lighting works with three friends. They joined hands, touched the railing, and laughed as they felt the mild current pass through their bodies. Smith and his friends left the plant and repaired to a saloon, where they drank a lot of beer; Smith then returned, alone, to the lighting works. When he reached over and tried to touch one of the dynamos, G. W. Chaffee, the plant's manager, ordered him away, and a police officer sent Smith tumbling out the door. He returned, and again the officer pitched him out. Thinking he had solved the problem, the officer took a stroll down Ganson Street. Smith, who had been lurking around the corner, once more entered the plant. This time Chaffee had his back turned.

Smith leaned over the railing and grasped one of the poles of the generator with his right hand, hoping to feel the tingle again. He felt nothing. He reached with his left hand and took hold of the other pole—thus completing a circuit and sending an enormous surge of electricity through his body. Smith gave one convulsive gasp and collapsed across the railing. Bystanders dragged him away from the machine and laid him on his back on the rough wooden floorboards. He was dead.19

According to the Buffalo Morning Express, "It was a lightning death, and a painless one."20