Armored Champion: The Top Tanks of World War II (2015)

CHAPTER 1

What Makes a Great Tank?

WHAT WAS THE BEST TANK OF WORLD WAR II? This book argues that there was no single “best tank of World War II.” While the Tiger may have been the best tank in the summer of 1943, it was merely an engineer’s dream in 1941. Instead, this book takes snapshots in time to examine the best tanks at critical points during World War II. The approach that I have taken is not merely to provide opinions. Instead, I have supplied extensive documentation from archives, government studies, and a wide selection of published sources. Much of this has never been published in English before. Even if readers do not agree with my judgments, I hope that this book will provide them with ample data to draw their own conclusions.

What makes a tank great? The most obvious is the holy trinity of tank design: armor, firepower, and mobility. Nevertheless, evaluating these features depends on the date. A tank protected with 45mm armor was invulnerable in 1941, but it was doomed to quick defeat by 1945. A tank armed with a 76mm gun was a world-beater in 1941, but by 1945 was a pop-gun in a tank-versus-tank duel.

Besides the holy trinity, other factors are equally vital: crew training, tactics, affordability, and dependability. The T-34 tank was clearly the best tank on the 1941 battlefield in purely technical terms. But it was a dismal failure on the battlefield due to poor crew training, poor unit organization, and wretched employment. The Panther tank was a fearsome adversary in the summer of 1944, but by the winter of 1944-45 it had lost its edge because of inexperienced crews and crippling technical deterioration.

If we were only measuring the technical aspects of tank designs, it would be very easy to come up with a nice and simple technical comparison chart and pick the winner by straightforward numerical evaluation. But war, like all human endeavors, is complicated by a variety of factors that are not easily subject to numerical evaluation. Purely mathematical evaluations contain a false disguise of objectivity. A table of clean little numbers seems utterly scientific and fair, but inevitably contains bias and distortion.

Any comparative table is based on value judgments that arbitrarily skew the assessment in one direction or another. From our current perspective, we think of tanks in the modern framework of “main battle tanks.” Contemporary armies employ a single, versatile type of tank that can serve in all tactical roles, whether it is tank-versus-tank fighting, fast exploitation, or close combat infantry fire support. But in 1939, most armies saw the need for multiple types of tanks, each tailored for specific tactical requirements. Most armies had a trio of types: a light tank or tankette for reconnaissance, an infantry tank to support rifle troops in close combat, and a cavalry tank for the fast exploitation mission. The qualities that make a great infantry tank, such as thick armor and good high-explosive firepower, are not as relevant in the cavalry tank role where speed and antitank firepower are more valuable. So it becomes very difficult to create a comparative table to determine the “best tank” since the criteria being used are likely to favor one tactical role with the risk of deprecating the combat values of another tank type. This is especially true in the 1939-42 period when most armies had hybrid tank fleets. By 1945, armies were moving in the direction of main battle tanks with the bulk of their fleets based on a single type, but there were still separate categories for light and heavy tanks roughly corresponding to the old scout and infantry tanks.

Cost is also a significant factor in war. Some armies would prefer to have a large but inexpensive tank fleet; others prefer to have a smaller number of better-quality tanks. In a tank-versus-tank fight, the better expensive tank may dominate, but from the broader perspective, a larger number of mediocre tanks may provide the critical edge on the battlefield.

With these factors in mind, three assessments of tank effectiveness can be made. In this book, I am calling them “Tanker’s Choice,” “Battlefield Dynamics,” and “Commander’s Choice.” As I will explain in a moment, “Battlefield Dynamics” is a very important criteria, but almost impossible to quantify. So, I will offer a “Tanker’s Choice” and “Commander’s Choice” for Top Tank of a given era. I do not pretend that my choices are the only plausible ones. Judgments such as these are subjective, and in some cases I have deliberately selected a more provocative choice. Readers can make their own judgments, and it is my hope that this book will provide the data and historical context to improve the choices.

TANKER’S CHOICE

Tanker’s Choice is the most basic assessment, focusing on the holy trinity of protection, firepower, and mobility. A tank crew would obviously choose a tank with the best features in these three categories. Tank crews really don’t care if the tank is horribly expensive; they aren’t paying for it. They simply want the best tank. Tanker’s Choice is often threat-driven. This evaluation is closely tied to the capabilities of the main threat against its survivability.

Several armies conducted operational research during World War II and in the years after to try to quantify technical effectiveness. After World War II, the British Army Operational Research Group (AORG) attempted to calculate the technical effectiveness of tanks in tank-versus-tank engagements using both theoretical parameters and data collected from the 1944-45 campaigns. Effectiveness was defined as “the reciprocal of the number of tanks required per enemy tank to achieve parity in battle.” One of these studies tried to compare the PzKpfw IV Ausf. H against several common British tanks. In the evaluation, the PzKpfw IV was given a rating of “1” and the British tanks were rated against this baseline.1 The results are shown in more detail in Chapter 8.

Soviet tank experts also made a similar evaluation in the 1970s as a means to employ computer simulation to model the modern battlefield. The main Soviet tank research center, VNII Transmash (Scientific Research Institute of the Transportation Industry), created a computer model of a factor they called “combat potential.” As in the British case, one tank was established as the baseline vehicle and assigned the value of “1.” The other tanks were then evaluated against the baseline tank based on armor, firepower, and mobility, and given a value based on this assessment. Some of their evaluations were extended back to take a look at the World War II battlefield. Unlike the British assessment, the calculations behind the Soviet method have not been published. Some examples will be found in subsequent chapters.

This book will not use such a strict numerical assessment, but will provide the data to make an informed judgment about the Tanker’s Choice for a given period.

BATTLEFIELD DYNAMICS

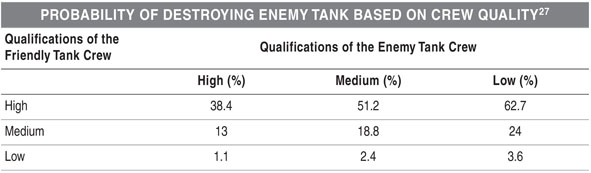

Battlefield Dynamics are one of the most critical aspects of the success or failure of a tank in battle. The two most important criteria are crew quality and battlefield circumstances. History has shown time and time again that a mediocre tank in the hands of a good crew will usually triumph against a better tank with a poor crew. Some obvious examples are the performance of German tanks in 1941 against the Red Army. The Red Army had superior tanks, such as the T-34 and KV, and massively outnumbered the Wehrmacht.2 Yet the Red Army suffered massive defeats in tank combat. Another example, outside of the time period for this book, has been the performance of Israeli tank crews against Arab tank crews.

It is very difficult to place a quantitative value on crew quality. I recently wrote a book on tank fighting in Normandy pitting the M4 Sherman tanks of the 2nd Armored Division against the PzKpfw IV tanks of the Panzer-Lehr Division during Operation Cobra in July 1944.3 The crews of the 2nd Armored Division had excellent, prolonged training and had seen a moderate amount of combat, including North Africa in November 1942 and Sicily in 1943. The Panzer-Lehr Division had only been formed at the end of 1943. Its officer cadre came from Wehrmacht tank training schools and were mostly combat-hardened veterans who had fought in Poland, France, and Russia. Its rank-and-file crewmen were mostly new recruits but they had already seen more than a month of fighting in Normandy against the British before their encounters with U.S. tanks at the end of July 1944. Both sides had training and experience advantages in different areas. It is no simple matter to quantify the capabilities of such opponents.

Battlefield circumstances are extremely important in the outcome of any tank-versus-tank fighting. The popular view of tank warfare is an armored joust. Two armored opponents are positioned opposite one another on the field of battle, with the more valiant or better-armed opponent the eventual victor. This has been cemented in the public mind by the scene in the movie Patton where George C. Scott muses that the battle could be decided at a lesser cost in blood if he and Rommel faced each other, man to man, in a tank. This is, of course, romantic nonsense.

Tank-versus-tank fighting was more often than not an opportunistic clash fought from ambush with one tank knocking out the other before the opposing tank even identified the presence of the enemy. The great “tank aces” of World War II were mostly bushwhackers, usually having a decided advantage in firepower or armor, and often having both. The hero of all Nazi fanboys is the Waffen-SS Tiger ace Michael Wittmann. Yet Wittmann fought from a Tiger heavy tank in 1943-44 when the Tiger could kill its opponents long before they were close enough to inflict damage on his tank. Most of the “tank aces” of World War II were simply the crews lucky enough to have an invulnerable tank with a powerful gun. How many “tank aces” operated the ordinary tanks—the PzKpfw III, PzKpfw IV, or Sherman?4

Aside from the clash between grossly unequal tank types, most tank skirmishes were won depending on battlefield advantages, not technical advantages. Let’s create an example. A stationary, well-camouflaged tank is sitting in ambush; its opponent is a tank moving forward along a road with no knowledge that the enemy tank is waiting for it. Clearly the tank in ambush position has a much greater chance of success than the other tank crew that is oblivious to the position of the other tank. In the 1950s, the Operation Research Organization (ORO) of Johns Hopkins University conducted a number of studies on tank warfare, especially in the Korean War, to determine what factors lead to success in tank-versus-tank fighting.5 This strongly indicated the side that spotted the enemy force and engaged first had up to a six-fold advantage. The simplest condensation of the rule of tank fighting is “See first, engage first, hit first.” Tanks in a stationary defensive position had an obvious advantage against tanks moving to contact, since the stationary tanks were more likely to spot the approaching enemy first and engage first. The ORO research from tank battles in the Korean War suggested that tanks in well-prepared defensive positions enjoy a 3 to 1 advantage against attacking tanks. The other important element of the equation here is crew quality. It is not enough to see first and engage first. It is also necessary to hit first, meaning a crew that is well trained enough to have a high probability of getting a hit on the first shot. This is not as easy as it seems.

Even though these Battlefield Dynamics are absolutely critical to tank combat, they are almost impossible to quantify. Situational factors of the battlefield are unique to every single engagement; crew quality is difficult to measure. As a result, these factors will be mentioned in the ensuing chapters, but in most cases they will not be used to pick the Top Tanks.

COMMANDER’S CHOICE

Tank crews obviously want the best possible tank in terms of technical virtues since their survival depends upon it. But this is not necessarily the criteria of senior commanders. A tank such as the Tiger in 1943 would be the obvious Tanker’s Choice. But the Tiger was a horribly expensive tank. The German army could have bought ten StuG III assault guns or three Tiger tanks. It can certainly be argued that ten assault guns give more combat power than three tanks. So cost is an important factor in assessing the combat power available to an army.

The other issue is reliability. Many of the heavy tanks of World War II, such as the Tiger, had poor reliability. They were at the “bleeding edge of technology” and existing power-train technology was at its outer limits when dealing with tanks of this weight. As will be described in more detail below, the ordinary vehicles such as the StuG III and PzKpfw IV had much better reliability than the Tiger and Panther. Factoring in reliability, the Wehrmacht could have had seven operational StuG III or one operational Tiger tank. From a general’s perspective, seven assault guns offer far more combat power than one heavy tank, no matter how powerful. The Commander’s Choice is therefore capabilities-driven. How much combat power can a given tank type contribute to the battle? These factors will be used in assessing the Commander’s Choice for Top Tank.

A TANK PRIMER

Many readers of this book will already be familiar with World War II tank technology, but some will not be. This section will provide a thumbnail sketch of some of the basic criteria used in judging the Top Tanks.

Armor Protection

The survivability of the tank on the battlefield depends largely on its armor. Since World War I, armor has usually been provided either in the form of rolled armor plate or cast armor, with plate armor the most common. Until the 1930s, most armor plate was assembled using rivets. This traditional fabrication method has some problems, notably the possibility that if the rivet is hit by a projectile, the impact could shear off the inner head, sending it careening inside the tank. The solution to this problem was to seal-weld the rivet heads, a process sometimes used in the early 1940s. However, by 1945 welded armor was the preferred solution.

The protective value of armor depends largely on its thickness. World War I tanks typically had armor from about ¼ inch thick (6mm) to 1 inch thick (25mm), more often on the lower end of this scale. The initial intention was to provide protection against rifle and machine-gun bullets. It usually took about 15mm of armor to protect against light machine guns in the .30-cal (7.62mm) range, or about 25mm to protect against heavy machine guns in the .50-cal (12.7mm) range.

Armor protection did not increase very dramatically after World War I, and most tank designs of the period focused on the traditional threat posed by machine guns and field guns. A typical tank of the mid-1930s, the Soviet T-26 light infantry tank, had 15mm on the front surfaces, except for the turret front which had 20mm. With the advent of the dedicated antitank gun during this period, epitomized by the German Rheinmetall 37mm gun, tanks began to face a new threat. This gun could penetrate contemporary tank armor at nearly any practical combat range. As a result, some armies began to increase the thickness of their tank armor to provide it with “shell-proof” capabilities. A good example of this was the French Renault R35 infantry tank that entered production in 1936 after the advent of the German 37mm gun. This tank used cast armor that was 40mm thick to defeat the threat of the 37mm antitank gun. World War II saw a continued race between guns and armor, with tank armor steadily increasing to resist more and more powerful guns.

The 40mm cast armor of the Hotchkiss H39 was very effective in protecting the tank against German weapons up to the 37mm gun. This H39 from the 3rd Light Mechanized Division was knocked out during the tank melee at Hannut on 13 May 1940 by two 37mm hits at close range from PzKpfw III tanks. There are numerous gouges in the armor from hits by 7.92mm and 20mm fire from the PzKpfw I and PzKpfw II tanks that did not penetrate.

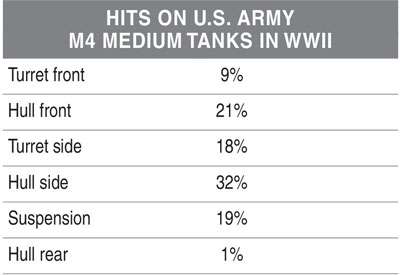

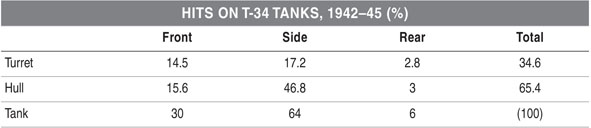

It has never proved practical to use thick armor on all surfaces of the tank—otherwise the tank would simply become too heavy. Armor thickness generally varies due to the probability of a surface being hit, so the front of the turret and glacis plate on the front of the hull usually have the thickest armor, the hull and turret sides less armor, and the tank roof and belly the least armor. Armor can be compared to a shield of an ancient warrior: the shield is used to protect the areas most likely to be struck in combat.

The formidable frontal armor of the Panther led the Allies to conduct a series of tests using various types of ammunition against captured tanks at Isigny, France, in July and August 1944. This photo from the report shows the results against one of the targets, with penetrations from the new 17-pounder APDS (armor-piercing, discarding sabot) projectiles, a plate failure around the machine-gun position, and numerous gouges from rounds that failed to penetrate.

The U.S. Ninth Army conducted their own trials against a Panther on 10 January 1945, using an M4A3 (105mm) assault gun firing HEAT (high-explosive antitank) and an M4A3 firing 75mm armor-piercing and high-explosive. While it may not be apparent in this view, several of the HEAT rounds made clean penetrations of the glacis plate and would have killed the crew.

Tank designers tried to determine which surfaces were the most likely to be hit and to allot the armor accordingly. Historical data provides some idea of the probability of hits on the tank. This data stems from investigations of 107 M4 Sherman tanks of the U.S. Army in 1944-45.6

The Red Army carried out a far more exhaustive study of where tanks were hit in combat, examining 7,639 T-34 tanks from the time of the Stalingrad battles in 1942 to the end of the war in 1945. The data is summarized on page 8.

A destroyed M4A3 medium tank in Luxembourg in September 1944. Judging from the missing center bogie, this tank probably ran over a mine that set off the wet stowage ammunition racks in the hull floor. The off-kilter turret is a sure sign of a catastrophic ammunition fire.

While the Sherman has developed a reputation for its vulnerability to fire, German tanks were not exempt. This PzKpfw IV Ausf. H suffered a catastrophic ammunition fire during the fighting with the Canadians on the road between Caen and Vaucelles in Normandy in the summer of 1944.

A GI looks down in amazement at the gouges from no fewer than seven rounds that ricocheted off the glacis armor of this King Tiger near Moinet, Belgium, in January 1945. The tank was eventually penetrated on the left side, striking ammunition which set off a catastrophic fire that blew off the turret.

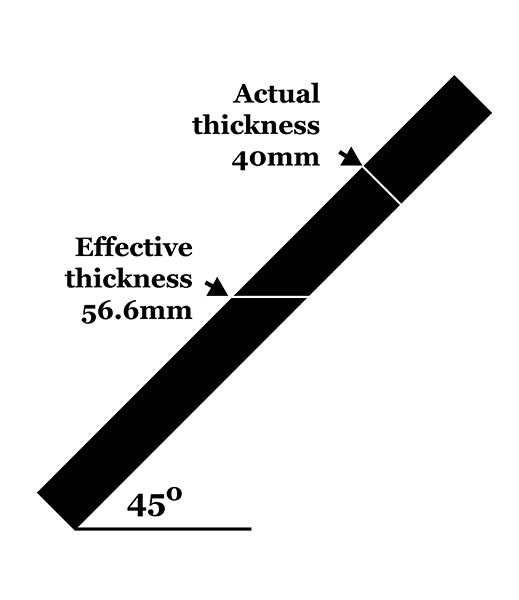

Although thickness is the primary determinant in the protective quality of armor, it is not the only one. By angling the armor relative to the enemy weapon, the effective thickness of the armor can be increased. So for example, in the case of a tank with 20mm armor, the vertical plate has an effective thickness of 20mm. When angled 30 degrees, the effective thickness increases to 22mm, and when angled to 45 degrees its effective thickness is 28mm. Armor at extremely inclined angles can also increase the chances that the enemy projectile will deflect off the surface. So the comparative charts in the following chapter will list the actual thickness of the tank armor as well as its effective thickness to give a more complete picture of its protective value.

The protective qualities of tank armor can also be affected by production techniques. German tanks in the early war years, notably the PzKpfw III and PzKpfw IV, used face-hardened armor that offered better protective qualities than homogeneous armor when hit by standard armor-piercing projectiles. However, the introduction of improved antitank projectiles such as APC (armor-piercing, capped) undermined the advantages. Not all steel armor plate has the same protective quality due to variations in hardness and the use of different alloys.7 Different countries preferred different armor qualities. For example, the Soviet Union favored very hard armor, but the U.S. Army favored medium hardness armor that was more ductile.8

The angle of an armor plate to attack improves its protective values since its effective thickness relative to the ballistic path increases.

Nor was armor quality constant through the war. Evidence would suggest that German tank quality began to decrease by the autumn of 1944 due to shortages of critical alloys. There was a severe decline in the quality of cast armor for T-34 turrets in 1942 when Soviet tank plants were hastily shipped east, but it later improved in 1944-45. This book does not have the length to discuss armor manufacturing technology in great depth, but readers should be aware of the complexities of armor protection.

Early tank and antitank guns used solid armor-piercing shot that was often not very destructive. Here a crewman of this PzKpfw IV Ausf. D from Panzer-Regiment.1 in Belgium inspects the penetration by a single 25mm antitank gun hit on the lower bow plate; the hit disabled the tank’s transmission.

Tank Vulnerability

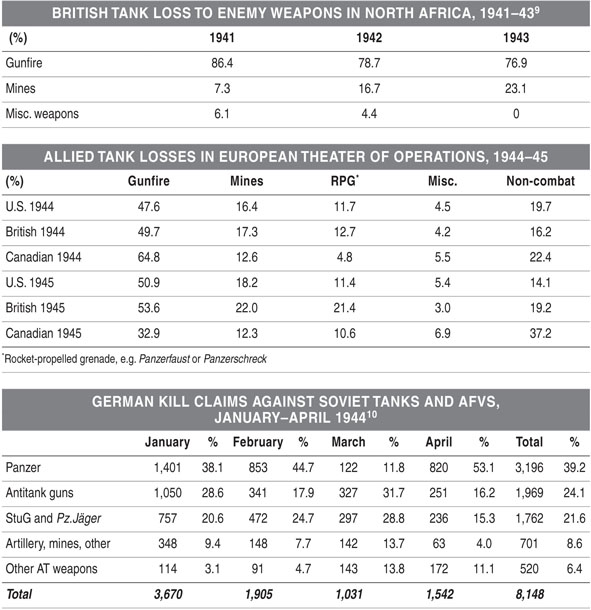

What killed the most tanks on the World War II battlefield? The simple answer is that enemy guns were the primary killer. However, the percentage varied by time and theater, and the data seldom distinguished between enemy tanks versus antitank guns. Here are a few samples of historical data to give a sense of the source of casualties.

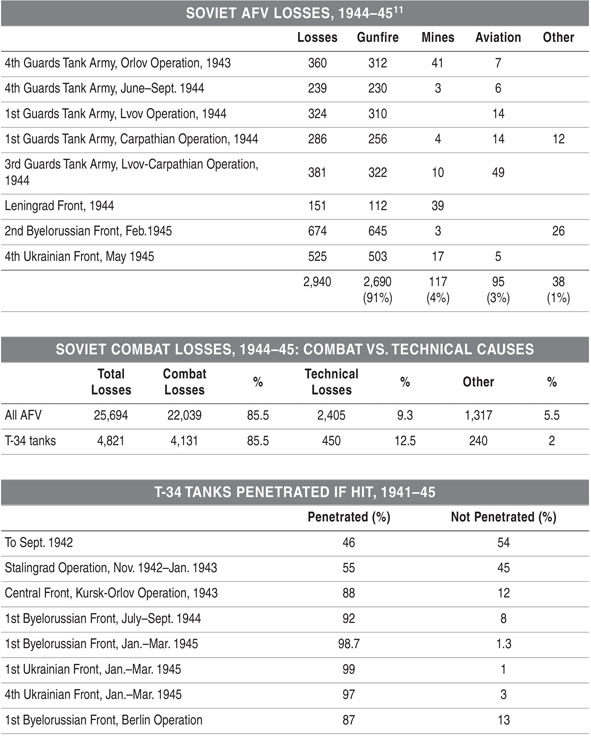

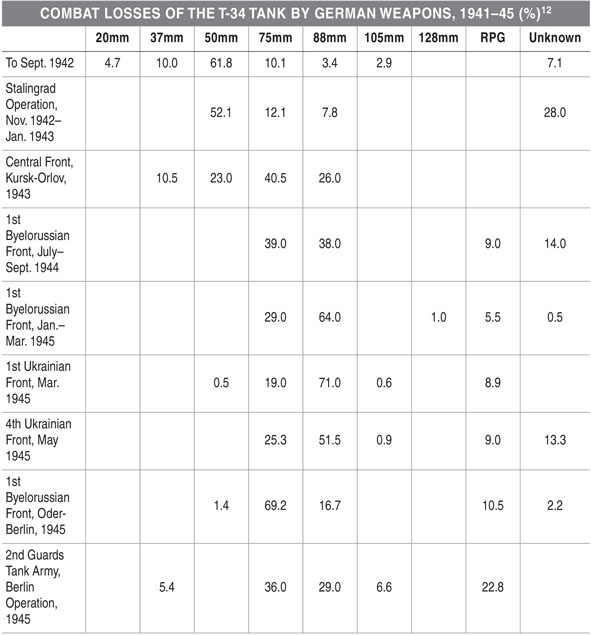

The effectiveness of tank armor also varied through time due to improvements in tank and antitank guns. A Soviet study examined the combat losses of the T-34 tank in 1941-45 and the statistics show the shift toward heavier firepower on the Russian Front.

This was also reflected in the growing vulnerability of tanks from 1941 to 1945. A Soviet study examined the probability of a T-34 tank being penetrated if hit throughout the war, based on various reports. As can be seen, through 1942 the T-34 had about an even chance of being penetrated if hit up to the time of the Stalingrad battles. By the final 1945 battles, the T-34 almost always was penetrated if hit.

This is an example of the penetration of a German Panzerschreck or Panzerfaust-shaped charge warhead detonating against the left hull side of a French Army M4A2 in November 1944. Shaped-charge warheads usually leave a distinct pattern of spall away from the point of penetration, as can be seen here.

An ordnance lieutenant from the 6th Armored Division looks at the damage to an M4A3 Sherman tank in November 1944. A German 75mm gun hit the turret at least five times from the rear left quadrant. Two rounds penetrated while three ricocheted off.

Thin armor hit with high-explosive projectiles tends to suffer catastrophic failure. This Jagdpanzer 38 (Hetzer) was hit on the side by a couple of 76mm rounds from a Soviet SU-76M in the January 1945 fighting; they completely collapsed the left side armor. This vehicle was fished out of the Czarna Nida River in Poland in the 1990s when a summer drought lowered the water level.

Firepower

Tanks of World War I were usually armed with machine guns and small cannon since their main mission was to fight enemy infantry and machine-gun nests. Tank-versus-tank fighting was a rarity. The French army conducted over 4,350 tank missions in 1917-18, yet never encountered a single German tank; the British army only had one encounter with a German tank.

Not surprisingly, tanks in the interwar period tended to carry much the same sort of weaponry. Light tanks often used one or more machine guns as their basic armament; short, low-velocity 37-47mm guns were common on medium tanks. The Red Army was the first to widely use a dual-purpose tank gun, a 45mm gun derived from the German Rheinmetall 37mm antitank gun. In contrast to its 37mm ancestor, the 45mm gun was designed to fire both an antitank projectile and a high-explosive projectile. This gun became the predominant Red Army tank armament, equipping both infantry tanks such as the T-26 and cavalry tanks such as the BT. The versatility of this weapon became evident in 1937 during the Spanish Civil War, which saw the first widespread tank-versus-tank encounters. The T-26 dominated these skirmishes against machine-gun-armed opponents such as the German PzKpfw I and Italian L-3 tankette. By this stage, European armies began to realize that reliance on machine-gun armament was shortsighted, and most tanks designed after this point, except for reconnaissance light tanks, carried some form of gun armament. This did not mean the end of machine-gun armament on tanks. Machine guns remained an important secondary weapon for use against infantry. Rather, they were no longer the principal weapon of most new tank designs, but instead supplemented guns.

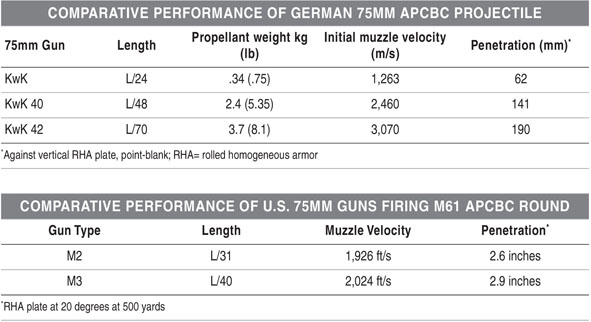

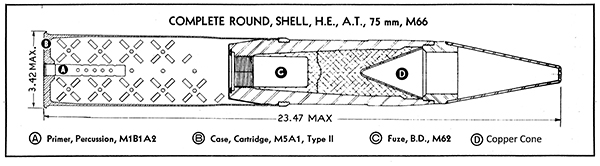

One of the most common misconceptions about tank guns is that their antiarmor performance is largely dependent on their caliber. The presumption is that a 76mm gun is more powerful than a 75mm gun. This is entirely false. Armor penetration is largely a factor of the velocity of the projectile. A rough measure of the energy of a tank projectile is mass x velocity (squared). In other words, increases in projectile velocity are far more important than increases in weight of the projectile. Projectile velocity can be accelerated in several ways. The most important source of velocity is the amount and type of propellant. So for example, in the case of German 75mm tank guns, the early war short 75mm gun used a round with only 12 ounces of propellant, which increased to 5.35 pounds in the mid-war “long” 75mm KwK 40 on the PzKpfw IV Ausf. G, and finally to 8.1 pounds in the Panther’s very long 75mm KwK 42. As can be seen from the chart below, this resulted in substantially higher muzzle velocity and armor penetration even though the projectile was essentially unchanged.

Tank ammunition, even if the same caliber, is not interchangeable. These three 37mm armor-piercing rounds from the author’s collection are (from left to right) American, German, and Czechoslovak.

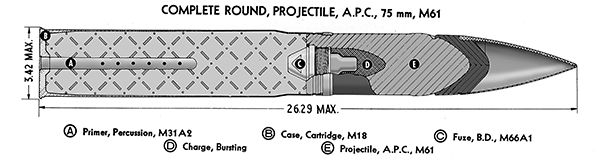

The APCBC (armor-piercing capped, ballistic cap) ammunition was one of the most common types in use in the later years of the war. The basic steel core (E) has a blunt soft metal cap welded to the front, followed by a thin steel windshield for better ballistic performance.

The other important factor in armor penetration of tank guns is barrel length. A tank gun firing the same type of projectile with the same propellant load will get more muzzle velocity with a longer barrel than a shorter barrel since the longer barrel provides more time for the detonation of the propellant to impart its energy to the projectile. Good examples of this are the American 75mm tank guns. On a technical note, gun barrel length is usually expressed as “caliber” (L/), which is the length of the gun tube divided by the bore diameter. So the M3 gun had a length of 3,010mm divided by its 75mm bore diameter, which equals L/40.

Another factor affecting armor penetration is the design of the projectile. Armor-piercing (AP) projectiles early in the war were simple steel bullets, often with an aerodynamically sleek design for better flight characteristics. As the speed of these projectiles increased, there was a tendency for the steel to shatter on impact with sloped armor, especially face-hardened armor. One solution was to cement a soft metal cap, typically iron, to the nose of the projectile. The cap cushioned the forces on the projectile on impact, helping to make it more resistant to shattering. In its simplest form, these were called APC (armor-piercing capped). These gave way to a more sophisticated version that added a thin metal “windshield” in front of the cap for better aerodynamic performance. These were called APCBC (armor-piercing capped, ballistic cap) and became the common antiarmor projectile in the later war years.

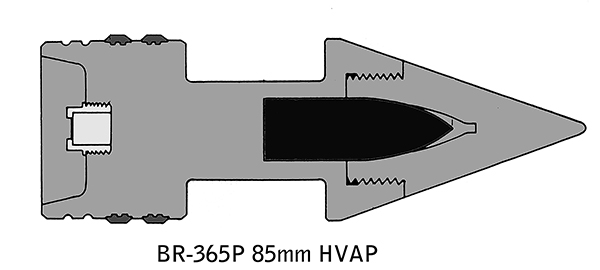

To squeeze more performance out of antitank projectiles, a variety of more novel projectiles were developed. One innovation was to encase a very dense and hard sub-caliber penetrator within a larger, light metal projectile. During World War II, the penetrator was usually a very hard and heavy material such as tungsten carbide, which is denser and harder than steel (13 vs. 7.8 grams per cubic centimeter). It was usually encased in a light, soft metal such as duraluminum. The main advantage of this type of projectile was that its lighter weight gave it greater speed. In addition, on impact the soft outer shell peeled away, and the projectile’s energy was concentrated on a smaller impact point of the hard metal penetrator. This type of projectile was called APCR (armor-piercing composite rigid) by the British, but was known as HVAP (high-velocity armor-piercing) by the U.S. Army; HVAP is used in this book. By way of comparison, the HVAP round for the 88mm gun on the King Tiger tank had a penetration of about 260mm at 500 meters compared to about 210mm for the more conventional APCBC round. The German army began to use this type of ammunition in 1941 to improve the performance of the 50mm tank gun on the PzKpfw III in 1941 against the threat of the T-34 tank. The Red Army began using it in 1942-43 and the U.S. Army in the late summer of 1944.

There were two main disadvantages to this type of ammunition. First, the HVAP round had the same frontal area as an APCBC round while only about 70 percent of the weight. As a result, its ballistic performance fell off faster at longer ranges, or in technical jargon, it had a lower ballistic coefficient. The second problem with HVAP was that the penetrator was made of tungsten carbide, a precious commodity in World War II and one badly needed by defense industries for machine tools. As a result, HVAP production was severely constrained by most armies. In the case of the U.S. Army, the goal in late 1944 was to equip each tank with one round of HVAP. The Red Army, due to more ample supplies of tungsten, was able to equip its tanks in 1944-45 with more of these rounds, often five to six per tank. The German army made extensive use of HVAP in 1941-43, but due to dwindling supplies it became scarce in 1944-45.

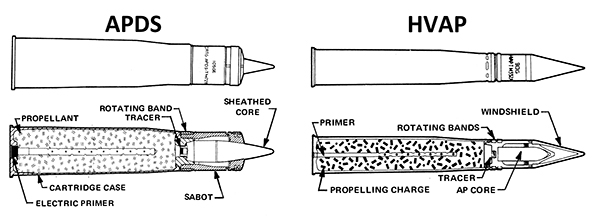

Another approach to launch a high-velocity, sub-caliber penetrator was the APDS (armor-piercing, discarding sabot), also called SVDS (super-velocity discarding sabot). Instead of encasing the penetrator in soft metal, it was placed in a light metal sabot, usually made of aluminum. When the projectile left the gun barrel, the separate “petals” of the sabot peeled off, leaving the penetrator to fly to its target at very high speed. In the case of the British 17-pounder, the APDS round offered about a 1,000 ft/s increase in speed over the conventional APC round, a sizzling 3,950 ft/s initial muzzle velocity. The main problem with the APDS rounds in 1944-45 were the mechanics of the sabot separation.13 Unless all the petals fell away neatly and simultaneously, the penetrator suffered slight deviations in its ballistic trajectory, which translated into dispersion and decreased accuracy at longer ranges. These problems were gradually worked out after the war. Generally speaking, HVAP offered better accuracy, but APDS offered better penetration in the 1944-45 time frame.

The shape of HVAP projectiles varied from army to army. Soviet HVAP projectiles such as this 85mm BR-365P were called “arrow-head” due to their shape. The tungsten-carbide core was surrounded by an aluminum ballistic body.

The two principal types of hyper-velocity armor-piercing ammunition in World War II were APDS (armor-piercing, discarding sabot) and HVAP (high-velocity armor-piercing). When the APDS projectile leaves the gun, the sabot and other parts separate from the core, and only the armor-piercing core impacts the target. When the HVAP projectile leaves the gun, the lightweight structure around the tungsten-carbide core remains with the core until impact.

HEAT (high-explosive antitank) was not widely used for tank guns in World War II since the impact fuzes did not work quickly enough for the shaped charge to detonate properly. In a shaped-charge warhead, the explosive behind the copper cone detonates and explosively compresses the copper liner into a hypersonic stream of metallic particles that penetrate the armor.

The projectile with the best armor penetration during World War II was the HEAT (high-explosive antitank). However, this seldom proved practical for tank-versus-tank fighting in 1939-45. The HEAT projectile used a shaped-charge warhead consisting of a hollow copper cone backed by a layer of explosive. On impact, the detonation of the explosive collapsed the copper into a hypersonic jet of metal particles that could bore through a substantial amount of steel armor. This type of warhead was first used on antitank rockets such as the U.S. Army 2.36 Bazooka antitank launcher. Other armies adapted it to various types of guns, mainly low-velocity guns and howitzers. It was not used by high-velocity tank guns in World War II for two reasons. Rifled tank guns spun the projectile and decreased the penetration of its jet by 30-50 percent. There were also problems detonating the high-explosive warhead quickly enough after impact. When impacting at high velocity, the copper cone at the front of the projectile was crushed or deformed before the base-detonating impact fuze could trigger the explosives. This was not as great an issue with handheld rocket weapons or howitzer rounds that were so slow that the fuze could work in time. This problem was not solved until after World War II with the invention of piezo-electric fuzes that could detonate the high-explosive warhead in microseconds before the copper cone was damaged. These became the predominant form and antitank ammunition in NATO through most of the 1950s and 1960s.

How much ammunition was needed on board a tank? Contrary to popular computer games, it took a lot of ammunition to hit another tank in typical World War II combat. For example, the Tiger tanks of Panzer-Abteilung 502 during 24-30 June 1944 claimed the destruction of 27 Soviet tanks and AFVs, expending 1,079 88mm armor-piercing rounds. This equals 40 rounds for each Soviet vehicle destroyed. In the next engagements during 4-27 July, 85 Soviet tanks and AFVs were destroyed, for an expenditure of 555 rounds or about 6.5 rounds per target destroyed. The difference between the two engagements were battlefield circumstances. The first set of engagements took place at very long ranges, often 2 kilometers; the second set were meeting engagements at closer ranges.

These high rates of ammunition expenditure per kill claim were not unusual. From 1 December 1943 to 31 May 1944, 23 StuG III brigades on the Russian Front fired a total 51,595 armor-piercing rounds against Soviet tanks and other armored targets. This resulted in claims for 1,899 Soviet AFVs destroyed as well as 132 disabled.14 This indicates that it took more than 25 rounds of ammunition for every Soviet tank destroyed or disabled. German 88mm Flak guns used in an antitank role in the Western Desert in 1942 might seem the ideal tank-killing weapon since they were on stable, stationary mounts with an excellent telescopic sight, firing in open desert, using a very powerful, high-velocity projectile. Yet unit records over the course of several days showed that on average, it took 11 rounds for every tank claimed.15

Another factor worth considering here is the issue of kill claims. When an airplane is shot down in combat, it is almost invariably a total loss. This is not the case in tank combat. In many cases, tanks are temporarily put out of action by a less-than-fatal hit. For example, a track is hit by an antitank gun, stopping the tank. Or an antitank projectile penetrates the tank, killing or injuring several crewmen but leaving the rest of the tank unharmed. In these cases, the tank can be recovered and put back into action. Tanks are usually not written off as total losses unless they suffer a catastrophic fire intense enough to damage the armor. Most often this resulted from an ammunition fire. As in the case of aircraft kill claims, tank kill claims by the various armies tended to be exaggerated. Sometimes this was done due to the usual chaos and confusion of battle. Several tanks simultaneously would engage an enemy tank, and when it was finally hit all would claim it as their victim. Sometimes, exaggerated kill claims also served propaganda purposes.16

Although most attention is paid to the antitank performance of tank guns, high-explosive throwing power remained a more critical ingredient for most tank combat. Tank buffs tend to focus on tank-versus-tank fighting. Large-scale tank-versus-tank battles such as the Battle of Kursk in the summer of 1943 are viewed as the norm rather than as the exception. This tendency has been further reinforced by video games such as the popular “World of Tanks” that focus entirely on tank-versus-tank fighting. Many military buffs grow up reading about fighter plane combat and see tank fighting as an analog to air combat. They were not.

Yet in terms of day-to-day tank combat, the vast majority of engagements were between tanks and infantry and their supporting arms such as antitank guns. For example, in the European Theater of Operations (ETO), 71 percent of 75mm tank gun expenditure and 73 percent of 76mm gun expenditure by the U.S. Army was high-explosive; the remainder was smoke and armor-piercing. Less than 20 percent of the targets were other tanks or armored vehicles. In the case of the German army, the 23 StuG III assault gun brigades on the Russian Front fired a total of 315,280 rounds, of which 263,685 (83.7 percent) were fired against unarmored targets such as infantry, buildings, and vehicles, while 51,595 (16.3 percent) were fired against tanks and other armored targets from 1 December 1943 to 31 May 1944.

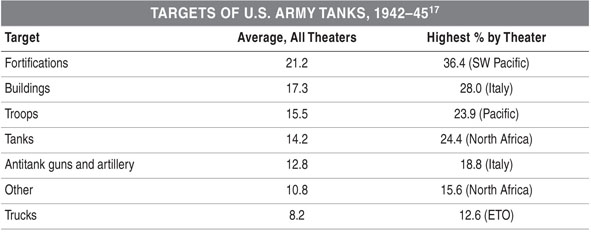

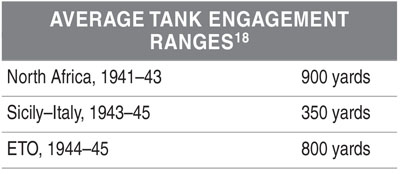

A U.S. study of targets engaged by tanks found that enemy tanks represented only about 15 percent of the targets engaged by U.S. tanks during the war. The target set varied by theater, with tank-versus-tank fighting more common in North Africa and least common in the Pacific; correspondingly, non-tank targets were more common in the Pacific.

Most armies in World War II eventually discovered that the ideal tank gun was a dual-purpose weapon able to fire both a lethal antitank projectile and a high-explosive round with a large content of high-explosive. In reality, the balance between both characteristics was elusive. This was especially the case in the early war years of 1939-42 when common tank guns such as the German 37mm gun and the British 2-pounder had good antitank performance but poor high-explosive throwing power due to the small size of the projectile. For example, the German 37mm high-explosive round had only 25 grams (1 ounce) of high explosive. This problem became less acute in the mid-war years with the advent of larger caliber tank guns in the 75mm range, which had projectiles large enough to accommodate high-explosive charges of 1.5 pounds or more.

Combat Ranges

The effectiveness of World War II tank guns was highly dependent on the engagement range. Performance quickly fell off at long ranges as the projectile lost speed and accuracy decreased due to ballistic drop. Tank gun sights did not offer accurate range determination; this is dealt with in more detail below in the Command and Control section. Studies after the war found that typical combat ranges varied through time. In the blitzkrieg era, ranges were limited by the guns such as the typical 37mm tank and antitank guns. Later in the war, combat ranges were often limited by terrain factors. Open desert terrain or the Ukrainian steppes permitted longer ranges than mountainous terrain such as in Italy or built-up terrain such as northwest Europe. One U.S. study summarized typical engagement ranges as follows:

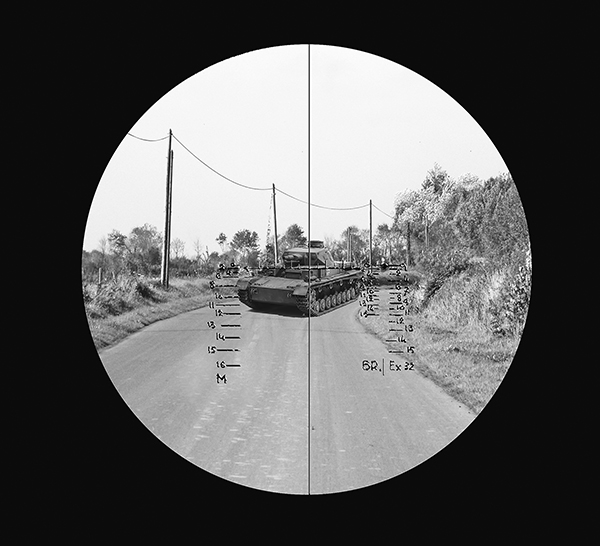

The French tank commander in the Char B1 bis or Somua S35 had a 4-power L.762 monocular telescopic sight to aim the 47mm SA35 gun. This is a simulated view through that sight at a range of 200 meters. The “stairs” on the left were for the MAC 31 machine gun (M= mitrailleuse) while the “stairs” on the right side had two separate gradations: the one on the left marked BR (R = rupture, armor-piercing) and the one on the right marked Ex (explosif, high-explosive). The commander rotated the reticle dial on the telescope to match the cross hair with the appropriate range gradation, moving the cross hair to provide the necessary super elevation, and then elevated the gun to align the realigned cross hair with the point where he wished to aim.

The German gunner on the PzKpfw IV Ausf. D tank had a 2.5-power Leitz TZF5b (Turmzielfernrohr) monocular telescopic gun sight to aim the 75mm KwK 37 gun. This simulated sight shows the appearance of a French Char B1 bis 200 meters away. The difference is noticeable when compared to the higher magnification of the French 47mm gun sight shown here.

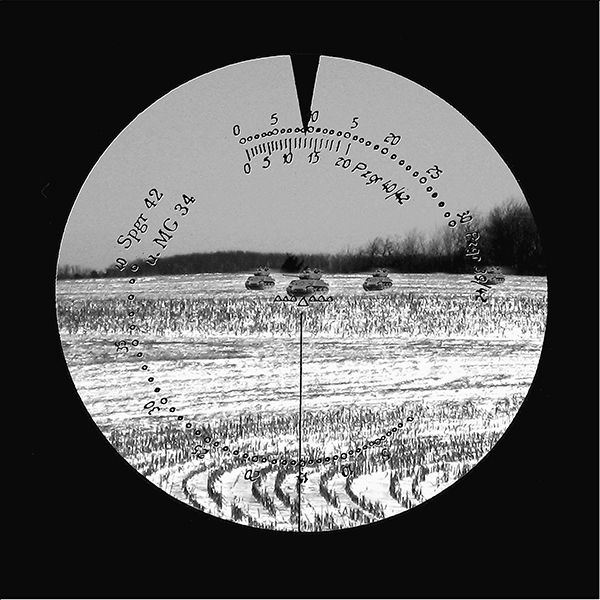

The German gunner in a Panther Ausf. G tank aimed the 75mm KwK 42 gun through a TFZ 12a monocular telescope. The telescope operated at two magnifications, 2.5 and 5 power, with the lower magnification used for general observation, at which point the gunner switched to the higher magnification for precision aiming. The view shown here depicts what a gunner would see at the typical engagement range of 900 meters at 5 power. The sight’s engraved reticle provided a limited stadiametric ranging capability, which allowed a well-trained gunner to estimate the range based on the size of the target compared to the large triangle. The small gradations around the periphery of the reticle were to help adjust the weapon depending on the weapon and type of ammunition being used. The gunner would dial in either the machine-gun or main gun gradations, seen here set at 900 meters for the Pz.Gr.39/42 armor-piercing projectile.

The gunner in an M4A3 (76mm) Sherman would aim the 76mm M1A2 gun with a 5-power M71D monocular telescopic sight. The reticle had range gradations for the standard M62 armor-piercing projectile; the performance of the M62 HE projectile was essentially similar at ranges under 1,000 yards. The reticle pattern was graduated in yards, so the commander estimated the range to target, including this in his firing commands, and the gunner adjusted the sight on the target accordingly.

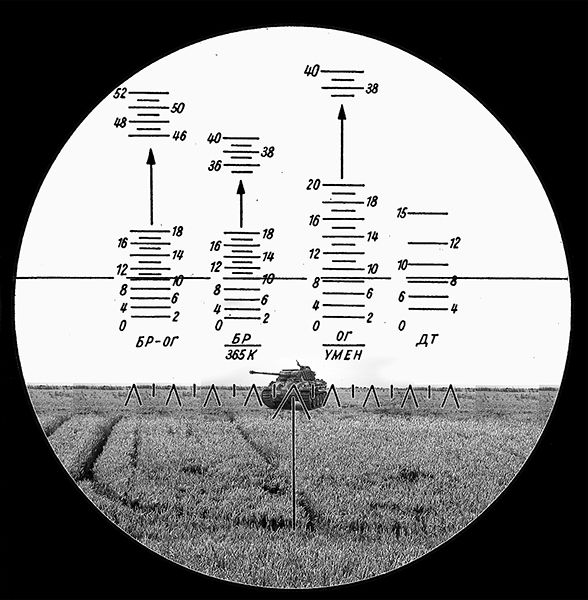

The Soviet gunner in a T-34-85 used a 4-power TSh-16 sight for aiming the ZIS-S-53 gun. The illustration here simulates the engagement of a Panther tank at 1,000 meters. The stadiametric rangefinder etched into the reticle has four vertical “stairs” for providing ballistic corrections for the four main types of the ammunition (from left to right): armor-piercing, armor-piercing hyper-velocity, high-explosive, and DT machine-gun. The lower lines consisting of upside-down Vs and dashes provide a simple stadiametric scale, with the width of the center V roughly equivalent to the length of a tank when viewed at 1,000 meters.

Mobility

The distinction between infantry and cavalry tanks early in the war led to strong variations in tank mobility. Infantry tanks tended to place the accent on armor protection over speed, while cavalry tanks tended to place the emphasis on speed. By mid-war, these distinctions had begun to erode and most tanks were expected to have a road speed in the range of 25-30 miles per hour and a cross-country speed around 15 miles per hour.

Tank mobility begins with engine power. Gasoline engines were the predominant type during the war, though some major tank forces such as the Red Army had shifted in favor of diesel for their medium and heavy tanks. One of the more popular canards was that gasoline engines made tanks more prone to fires. There is very little statistical evidence to support this, and more wartime research indicated that ammunition fires were the primary cause of catastrophic tank fires.

The prevalence of gasoline engines in tanks was in part due to the origins of the engines. Most countries adopted existing engines for tanks rather than developing dedicated tank engines. The U.S. Army in the early war years favored aircraft radial engines, though later adopted a variety of other types when the aircraft industry received priority for engine production. A popular tank engine in the 1930s was the World War I Liberty in-line aircraft engine, which formed the basis for the Soviet BT tanks of the 1930s and many early British tanks. The French army used a variety of engine sources, although bus and truck engines were widely adopted on the common infantry tanks. Some armies developed engines specifically for tanks and these were often diesels. The Japanese were the first to widely use diesel engines on tanks; the Soviets followed with the development of the V-2 diesel engine for the T-34 and KV in 1939-40.

A critical but often overlooked element in tank mobility was the transmission and power-train. Tank transmissions were frequently derived from tractor or automotive transmissions, but the peculiarities of tank propulsion often required substantial redesign of components such as the final drives. Power-trains were a frequent source of reliability problems, and some World War II tank designs were seriously undermined by inadequate power-trains.

Tank suspensions in World War II started with a range of leaf spring-based types which offered a good balance between light weight and adequate cross-country performance. At the extreme was the Christie spring suspension, intended for high-speed tanks, which offered considerable wheel travel in terrain but at the expense of stealing considerable internal hull volume. The U.S. Army favored volute springs over leaf springs, and this system proved robust enough for tanks into the 30-ton class. Torsion bar suspensions began to appear in the late 1930s, first widely used on the PzKpfw III Ausf. F. This was gradually adopted by most tank manufacturers by the end of the war since it offered good road-wheel travel while not taking up much internal hull volume.

Track design has a considerable impact on mobility, both in terms of rolling resistance and ground pressure. Most armies relied on simple, narrow-pitch cast metal track with simple pins. (Pitch is the measure of the length between two links of track.) The U.S. Army preferred a family of track including rubber-padded track blocks as one option for better road performance, albeit at a higher unit cost. Track width was a critical ingredient in establishing the ground pressure of a tank. Almost any form of track is useful on roads or in dry terrain conditions, but soft ground in the form of mud or snow requires the better flotation made possible with wider tracks. Track widths on western European and American tanks tended to be narrow through 1941 when the German army encountered the mud and snow of the Russian Front. The short-term expedient was to introduce wider winter track or added track extensions. German tank designs after 1941 took the lead offered by the Soviet T-34 tank and moved toward wider tracks. The U.S. Army stuck with relatively narrow track through 1944 due to its reduced rolling resistance, but the mud and snow of the European Theater in the autumn of 1944 led to a hasty adoption of extended end connectors, and eventually new suspensions with wider tracks in early 1945.

The Christie spring suspension as used on tanks such as the T-34 and Cromwell provided a smoother ride and offered greater wheel travel. On the downside, the spring towers consumed considerable internal hull volume and could be difficult to service.

Narrow tracks are good for low rolling resistance on roads and dry ground but they suffer in mud and snow. One solution was to use extended end connectors in the wet autumn and winter months, the approach preferred by the U.S. Army in 1944-45. Germany called their type of extended track Ostketten (“eastern track”) since they were intended for use on the Russian Front.

Command and Control

Most armies had tactical doctrines that expected tanks to operate in formations no smaller than a platoon in size, roughly four to five tanks. Unlike infantry that can rely on voice communications for small formations, tanks require some other means to coordinate their battlefield actions. In World War I, this usually involved some form of visual signaling, sometimes a semaphore or arm signals but most often some form of flags. Flags remained a standard form of tank communication in the early years of World War II, but this method was never satisfactory. Flags were difficult to see if the tanks were more than a short distance away, and the visibility of flag commands was further undermined by smoke on the battlefield and the difficulty of seeing small detail through typical tank vision devices. Finally, flag signaling often involved the tank commander exposing himself outside the tank to conduct the signaling, a risky operation on the battlefield.

Radio was a possible technical solution, but radios were on the “bleeding edge of technology” in the early war years. Early tactical AM radios relied on tube technology and were fragile. The first tank radios relied on Morse code, which required a skilled operator. Voice radio became available in the late 1930s, but the sets required a dedicated operator. Due to cost and other factors, the best approach in the 1939-41 period was to issue a full transmitter-receiver to the platoon commander and simple receivers to the other tanks. Very few armies made radios standard in the early war years. Germany was one of the pioneers in this regard because senior commanders appreciated the need for real-time communication in high-speed warfare.19 Britain was another of the pioneers, especially for use in cruiser tanks and reconnaissance tanks.20 France intended to deploy radios in all cavalry tanks and in the battle tanks such as the Char B1 bis, but largely refrained from using it in infantry tanks due to cost and training issues.21 The Red Army intended to make widespread use of radios, but cost and poor radio technology limited it; for example, in the case of the Soviet T-26 tank, the most widely produced tank of the 1930s, about half the tanks were fitted with radios. After the start of the war in 1941, the Soviet use of radios decreased in 1942-43 due to shortages, rising again in 1944-45 as production capacity improved.

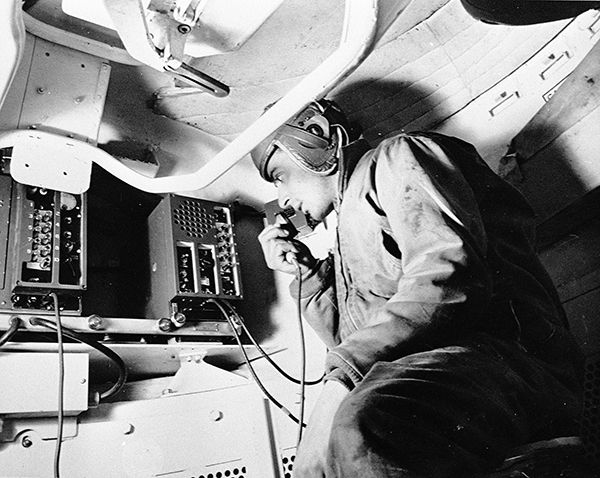

One of the more common methods for communication within the tank was an intercom system, with each crewman receiving a throat mike as in the case of the U.S. system seen here. The crewman pressed a button on the small switchbox to activate the mike.

Throat mikes were not entirely popular, and some later systems such as this American example in 1944 used a handheld mike that offered better sound properties.

Radio technology improved dramatically during the war. One important innovation was the adoption of preset channels which made it easier for crews with limited training to use. The early German tank radios had two preset channels. The U.S. Army made a major leap forward in 1941 by switching to FM (frequency modulation) radios. These had a significant advantage over AM (amplitude modulation) radios since they could be filtered to reduce signal noise. AM radios were very vulnerable to signal noise induced by the tank itself, including the tank’s electrical ignition system and metal-on-metal contact of the tracks and running gear.

Besides their use for communication between tanks, radios also proved useful in communicating with the infantry units that the tanks were supporting. In most armies, the pattern was for the platoon or company commander to communicate with the headquarters of the infantry unit being supported, usually no lower than company or battalion level. This was a cumbersome and time-consuming procedure, since the tanks were often assigned to support smaller infantry formations at company level. So for example, if an infantry platoon spotted an enemy antitank gun that threatened the accompanying tanks, the platoon had to inform the company headquarters, which used its radio to inform the tank platoon commander. The delays imposed by this poor network could be fatal in combat.

The slow evolution of tank-infantry radio communications was due to the fact that radio distribution in small infantry units was quite limited until late in the war. For example, the German infantry battalions were not regularly issued radios until 1943, with the potential to deploy some of these in the infantry companies. The U.S. and British armies were the most lavish in equipping small units with radio; the U.S. Army began issuing small radios at platoon level starting in 1941. However, it was not until the fighting in France in 1944 that the issue of tank-infantry communication at the platoon or company level arose. The U.S. Army pioneered this tactic by equipping some tanks in each company with a SCR-300 radio and, starting in September 1944, with a dedicated tank-infantry radio, the VRC-3. These radios could communicate between the tank formation and the associated infantry company’s SCR-300 radio. For communication with smaller infantry formations, many U.S. tanks were fitted with field telephones in boxes at the rear to permit neighboring infantry to talk to the tank crews and pass on vital instructions.22 The German army began steps to link its panzer regiments to its associated panzergrenadier regiments in early 1944 at company level, a process complicated by shortages of equipment.23 However, tank-infantry radio communication was at a very immature stage of development at the end of World War II.

The advent of tank radios was usually accompanied by improvements in internal crew communications. Tanks in the early war period as often as not depended on simply voice communication or voice tubes between the commander and crew. In some tanks, the tank commander communicated to the driver by foot signals against his right or left shoulder to indicate the direction he wanted him to drive. Once radio use became more common, crew intercommunication systems began to appear, with each crewman receiving headphones.24 This significantly improved crew coordination under noisy and chaotic battlefield conditions.

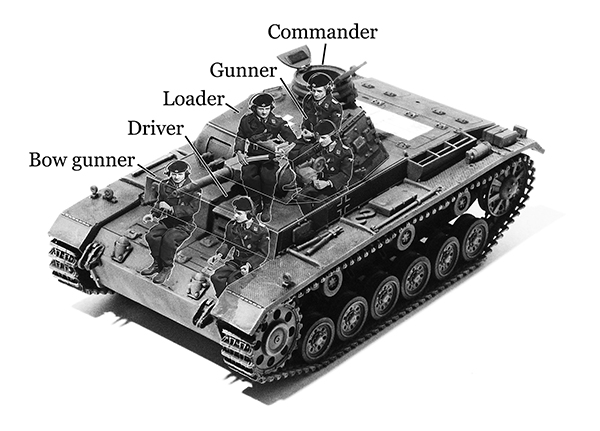

One of the most critical ingredients in tank command and control was crew size. Many early tanks, starting with the Renault FT in 1917, had a two-man crew consisting of a driver and a commander/gunner. This was adequate for slow-moving tanks in the infantry support role. Once tactics became more complex and tank mobility improved, larger crews were needed. Crew size gradually increased to three, consisting of a driver and two men in the turret. This was better but not ideal, since the commander had to double up either as loader or gunner. The most important innovation came in the early 1930s as a result of German tactical trials when it was discovered that two-man turrets were not efficient on the battlefield. As a result, when the next generation tanks were designed in the mid-1930s, the new Krupp turrets had three men: the commander, gunner, and loader. This design had two critical advantages: It freed the commander of any responsibilities as loader or gunner and allowed him to concentrate his attention to coordinating his own tank crew as well as the actions of his tank within the tank platoon. This was absolutely vital in the maturation of modern tank small-unit tactics.

By 1944, the trend was to equip all tanks with at least a radio receiver, and preferably both a transmitter and receiver. The American and British practice was to mount the radio in a bustle in the turret for easier access by the tank commander. As shown in this M4 Sherman, the U.S. practice was to cross-train the loader to assist the commander with the radio.

The importance of three-man turret crews became very evident in the blitzkrieg era of 1939-41 when the Germans found that their French and Russian tank opponents behaved in a sluggish and uncoordinated fashion due the poor ergonomic factors of their one- or two-man turrets. The other innovation of the Krupp turrets on the PzKpfw III and PzKpfw IV was the provision of a special commander’s cupola that provided all-around vision. This gave the commander far better situational awareness than typical tank turrets of the period which offered very limited views through periscopes or episcopes. The independent commander feature became the hallmark of most successful tank designs in the mid-war years of 1942-43.

The Renault R35 was typical of many tanks of the 1930s with a simple two-man crew. This burdened the commander with additional chores including the loading and aiming of the main gun and co-axial machine gun.

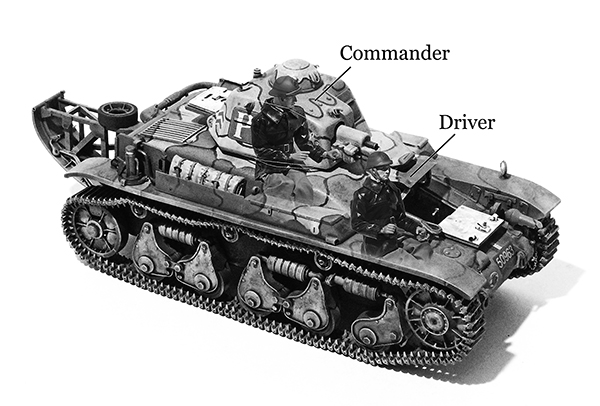

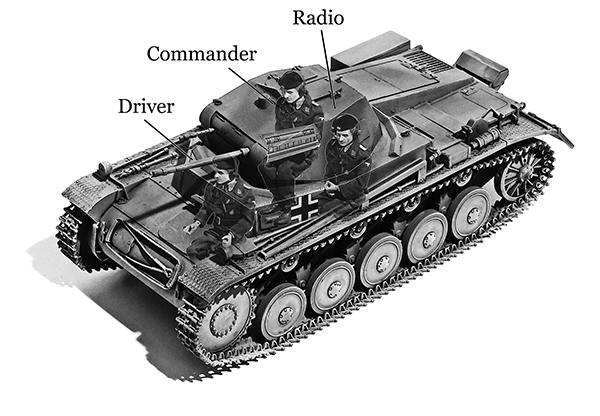

The PzKpfw II added an additional crewman to deal with the radio. Early radios required careful tuning and telegraphic skills.

The other important element of tank command and control was the tank’s vision systems. This fell into two main categories: general purpose vision devices and tank gun aiming devices. Early tank vision systems were often limited to simple view slits, which were vulnerable even to small-arms fire. By the 1920s, these were gradually replaced with episcopes consisting of armored glass mirrors, with the operator indirectly viewing outside the tank through the episcope lenses. This made the crew less vulnerable to injury from small-arms fire against the view slit, and in the event that the upper episcope glass was damaged, it could be replaced by spares. Episcopes gradually fell out of favor since they still required a slit in the armor, which was vulnerable if hit by an antitank round. Instead, periscopic sights became favored since they exited through the roof armor, which was far less vulnerable to enemy fire. These were first introduced on the Polish 7TP light tank and later copied on British, Soviet, and American tanks. Periscopes also could be rotated, giving the crew better situational awareness.

The Krupp turrets on the PzKpfw III and PzKpfw IV pioneered the classic three-man turret configuration. This freed the commander to concentrate on leading the tank in combat, a vital tactical innovation in tank warfare.

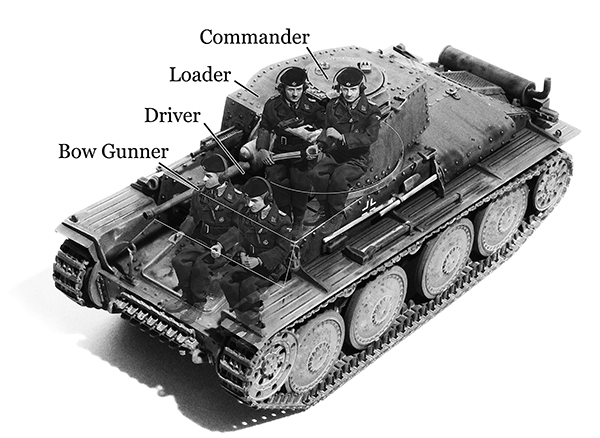

The Czech LT-38, better known in German service as the PzKpfw 38(t), was typical of tanks of the late 1930s and early 1940s with a four-man crew. The commander still had to double as gunner, but a loader was added to simplify his tasks. In the hull, the bow gunner also served to operate the radio.

As mentioned above, by 1944-45 most of the major armies adopted special commander cupolas to provide him with all-around exterior vision. The Germans had been doing this since the PzKpfw III medium tank, but later designs such as the U.S. Army’s 1944 all-vision cupola offered a simpler design that did not require each periscope or view device to be opened separately every time it was used. In reality, tank vision devices during World War II were never entirely satisfactory, and many armies encouraged tank commanders to operate with their head outside the hatch to maintain better situational awareness.

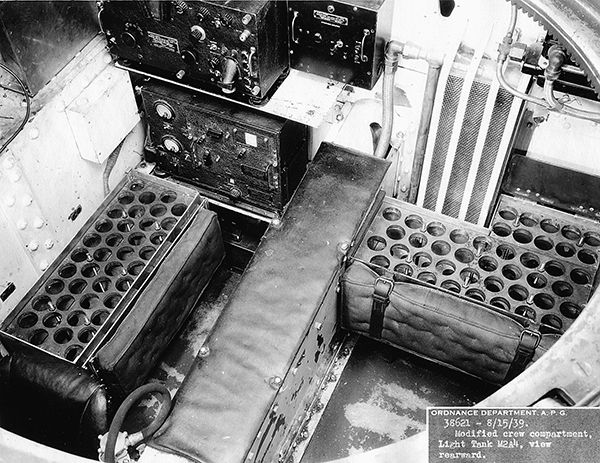

Crew performance in the chaos of combat was frequently impeded by cluttered fighting compartments. This photo is of the interior of an M2A4 light tank and shows the typical amount of obstruction in the fighting compartments of many tanks of the late 1930s and early 1940s. These tanks usually had a simple folding seat for the turret crew, attached to the turret ring.

A step forward in the fightability of turrets was a simple turret basket. This example is found in an M22 Locust light tank and is fairly typical of tank designs in the 1942-43 period.

Tank gun fire controls usually relied on telescopic sights for aiming the weapon. There were some alternatives to this; the U.S. Army used a periscopic sight on the early M4 Sherman tanks to avoid the need for a hole in the turret front for the telescope. However, the linkage between the periscopic gun sight and the gun was prone to being jarred and it was more difficult to boresight the weapon. The British, who were operating the M4 Sherman by 1942, encouraged the U.S. Army to switch back to telescopic sights, which became standard again in late 1942 with the M55 telescope in the M34A1 gun mount.

One way to avoid the turmoil in the turret was to provide the crew with a turret basket. This is an example on an early M4 of the 5th Armored Division during training in December 1942. Sherman baskets grew progressively less extensive in 1943-44 to provide faster access to ammunition.

Tank gun mounts also had an important role in gun accuracy. In the late 1930s, some armies still used gun mounts that were free in elevation and elevated using a simple shoulder pad on the gun mount. This was adequate for very short-range engagements; however, for longer range engagements, a geared elevation system was essential so that corrections could be made after the first shot. In the U.S. Army, the transition occurred between the M3 and M3A1 light tanks. The British army still used a free-elevation system in the Matilda infantry tank and early Crusader Cruiser tanks of the 1940-41 period. The geared elevation feature became standard in most armies by 1942.

Gun accuracy at longer ranges was largely dependent on accurate range determination to the target so that the gunner could super-elevate the gun to compensate for the ballistic drop of the projectile. In the German army, the preference was to use reticles in the gun telescope which a well-trained gunner could use to estimate range to target. In the U.S. Army, tank commanders were issued binoculars with reticles and it was the role of the commander to call out range instructions to the gunner. These types of systems were not especially accurate in long-range engagements, but until the advent of long 75-90mm guns in 1944-45, it was not a major concern. During the final years of the war, armies began to experiment with coincidence rangefinders for tanks, similar to the type widely used by antiaircraft and battleship guns. These did not reach service in World War II, but became commonplace in the 1950s. Soviet studies concluded that the World War II reticle-based rangefinders had an error rate of 15 percent compared to about 2.6 percent for coincidence rangefinders.

One reason for the amount of clutter inside tanks was the sheer amount of gear that had to be stowed. This is an example of the equipment stowed outside and inside the M3 light tank.

Another fire-control innovation that emerged in 1944-45 was night-fighting equipment. Britain developed the Canal Defense Light concept using a powerful searchlight mounted on Matilda or Grant tanks. Although this was built in significant numbers for both the U.S. and British armies, the high level of secrecy attached to the project doomed any attempts to use the system as intended in the summer and autumn of 1944. It was eventually abandoned without any extensive use. Germany, Britain, and the United States worked on infrared night vision systems. The British and American systems were primarily oriented toward night driving rather than combat. The German Uhu system involved IR searchlights on a supporting half-track vehicle and metascopes on the tanks. A small number of Uhu sets were issued in 1945, but the system was technologically immature to the point of being useless. There are rumors that the Uhu sets were used in combat in 1945, though evidence is not especially clear.

Aside from tank gun optics, one of the innovations in tank fire controls in World War II were early attempts at gun stabilization. The only army to pursue this on a large scale was the U.S. Army, which used a one-axis stabilization system on the M4 Sherman tank. The aim of this system was to permit firing while on the move at slow speeds or to keep the gun on target before halting and making final fine adjustments. This device was controversial due to the maintenance and training burden it imposed. Some of the better-trained gunners favored the system, but heavy attrition of trained gunners after the summer of 1944 led to an influx of less well-trained gunners who did not find the system as valuable.

The Crew

The quality of the tank crew greatly affects the performance of the tank. Probably the clearest example of this was the ineffectiveness of the T-34 tank in the battles of the summer of 1941 at the start of the Russo-German war. The T-34 tank was clearly superior to its German opponents from nearly every technical standpoint, but its battlefield performance was unexceptional. Unit after-action reports were full of complaints about the poor preparation and training of the tank units prior to the start of the campaign due to the lack of familiarity with this new tank type and a general deficit of training.25

The U.S. Army experience provides another perspective on this issue. U.S. tank units deployed to France in 1944 had in many cases been training for two years or more prior to the combat debut, and so had excellent preparation in tank operation. Yet these tank battalions frequently suffered half of all wartime tank casualties in their first month of combat.26 No matter how good the technical training, combat experience was a critical ingredient in successful tank employment.

The Soviet army conducted studies of the effect of tank crew quality during an engagement between equivalent tanks. The criteria was based on the probability of locating and identifying the opposing tank, being the first to fire, and actually hitting the enemy tank. In the case of a well-trained crew facing an equally well-trained opponent, the friendly tank had only a 38 percent chance of knocking out the enemy tank. On the other hand, in the case of a well-trained crew facing a poorly trained enemy, the probability increased to almost 63 percent. Correspondingly, two poorly trained crews facing one another had a very low probability of knocking out the enemy tank.

Durability/Reliability

One of the most important but overlooked aspects of tank effectiveness was their durability. Tanks had emerged from the First World War as an important but fragile innovation. The early tanks were a reincarnation of medieval siege engines, powerful weapons capable of cracking open a fortified trench line but mechanically very delicate. A big question in the interwar years was whether tanks were durable enough to sustain offensive missions. The principal cause of casualties in the early tanks was simple mechanical breakdown. For example, the German A7V tank of World War I could seldom operate for more than a day without requiring depot-level rebuilding. French and British tank reliability was somewhat better, but few tanks would still be functioning after operations involving more than 10-20 miles of travel.

Tank reliability can be enhanced by careful design. The Sherman had a modular transmission that could easily be unbolted and replaced. In contrast, German tanks such as the Panther and Tiger had the transmission encased in armor, making repairs difficult.

During the 1930s, tank reliability began to improve. The most common tank of the 1930s was the Vickers 6-Ton tank, most notably its license-built Soviet derivative, the T-26. The T-26 light tank required medium overhaul at district workshops after 150 engine hours and factory rebuilding or replacement after 600 hours. Tracks and track pins began to wear out after 500 miles of travel; side clutches became worn out and the power-train was gradually knocked out of alignment from hard cross-country travel.

When the T-26 saw its combat debut in the Spanish Civil War in October 1936, the first group of about 50 tanks were all largely worn out after 2 months of operations. During the Teruel campaign in December 1937-February 1938, the 104 T-26 tanks that participated were repaired 586 times over 65 days of fighting, or roughly once every 11 days. Most of these were ordinary field repairs involving tracks and minor engine repairs. However, there were 63 medium and capital repairs requiring 58 engine replacements, 6 transmissions, 15 main clutches, and 22 side clutches. In other words, every other tank had its engine replaced after only about 2 months of combat use.

To help minimize wear on the tanks, the Spanish army turned to the use of transport trucks to move the tanks between battles, a tactic first developed by the French army in World War I to extend the effective combat life of their tanks.28 During the Soviet invasion of Poland in September 1939, the Red Army deployed 1,675 T-26 tanks on what was essentially an uncontested road march into eastern Poland. Of these, 302 tanks, or roughly one-fifth of the force, broke down for mechanical reasons; in contrast there were only 15 combat casualties.29 Throughout the 1930s and the early years of World War II, tanks crews were obliged to keep detailed logbooks charting their engine and track usage.

Another key factor in tank durability was the provision of spare parts. The M4 Sherman series had excellent reliability in U.S. Army service in no small measure due to an ample supply of spare parts and a robust infrastructure for maintenance, including wrecker trucks and armored recovery vehicles. This is an M4 of the 2nd Armored Division being repaired in Normandy in the summer of 1944.

The Soviet examples given here were not especially unusual. During the Battle of France in 1940, the British Army estimated that about 75 percent of its tank casualties were due to mechanical breakdowns. In the case of the French Char B1 bis, the evidence suggests that about half of the tank casualties were the result of mechanical breakdowns, particularly its delicate transmission.30

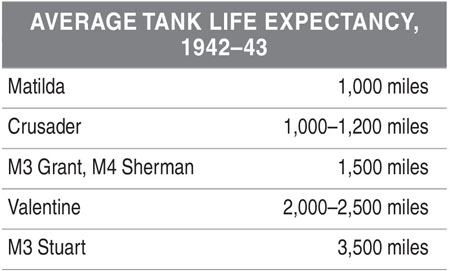

Tank durability remained a nagging problem throughout the war, even though on average the mechanical life expectancy of most tank types increased. The South African army, which operated a variety of British and American tank types, estimated their average life expectancy.31 The figures on page 35 underestimate U.S. tank durability; later studies give the Sherman at least a 2,000-mile life expectancy.

The T-34 had an unusual layout with the transmission at the rear of the tank. This provided easier access for repair and more direct connection to the engine but required lengthy connecting rods to the clutch, which made operations more strenuous for the driver.

Aside from inherent manufacturing features, dependability was also strongly affected by availability of spare parts. The British army suffered from low rates of tank availability in the early desert campaign in 1941-42 due to spare parts shortages, and as a result made a determined effort to increase spare parts production through the mid years of the war. Spare part production for tanks in Britain as a percentage of tank production contracts went from 4 percent in 1939 to 12 percent by 1940, 22 percent by 1942, 37 percent by 1943, and 45 percent by 1944.32

As in the British army’s case, the German army continued to increase its spares production in the early war years, based on the growing recognition that this was essential to keep the tanks rolling. For example, in October 1940 spares deliveries for tanks were only 352 metric tons, but this steadily increased to 1,190 metric tons by March 1942.33 The German objective was about 30 percent of the contract devoted to spares and repair parts in 1941.34

The German army generally enjoyed better tank reliability than many of its opponents in the early years of the war, but still faced constant problems with the mechanical attrition of its tank force. During the month-long Battle of France in June-July 1940, the 3. and 4.Panzer-Divisions deployed 674 tanks at the start of the campaign and at the conclusion had about half (55 percent) still operational, about a quarter destroyed in combat (24 percent), and about a fifth (22 percent) broken down or battle damaged and inoperable.35 During the campaign in Russia in the late summer of 1941, long road marches led to an especially high level of mechanical problems. Many panzer divisions could barely keep half of their tanks operational at any given time. The mechanical state of the panzer force was even worse in the winter of 1941-42 due to the advent of harsh winter conditions.36 This issue is covered in more detail in subsequent chapters.

Cost

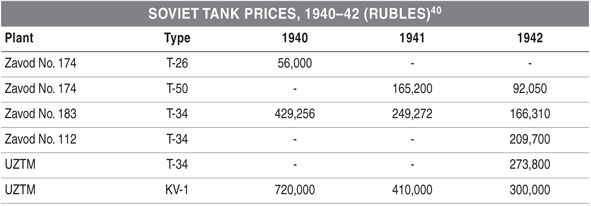

Josef Stalin is reported to have quipped, “Quantity has a quality all its own.” One of the dilemmas facing all armies is whether to field a tank force with large quantities of inexpensive and mediocre tanks, or a small number of more effective but expensive tanks. Usually, armies try to come up with some sort of balance. While the German army might have desired to field panzer divisions completely equipped with the superb Tiger I tank in 1943, in reality, there were not the resources to do so since the Tiger cost almost three times as much as the standard medium tanks. Germany also continued to build armored vehicles on the light PzKpfw 38(t) chassis until the end of the war since the Czech factories where they were built could not manufacture larger and heavier tanks due to a lack of suitable machine tools. Likewise, the Red Army continued to manufacture the dreadful little T-60 and T-70 tanks through 1942 and 1943 since the automotive plants manufacturing them were not well enough equipped with the proper machine tools and armor plate facilities to build the larger T-34 tank.

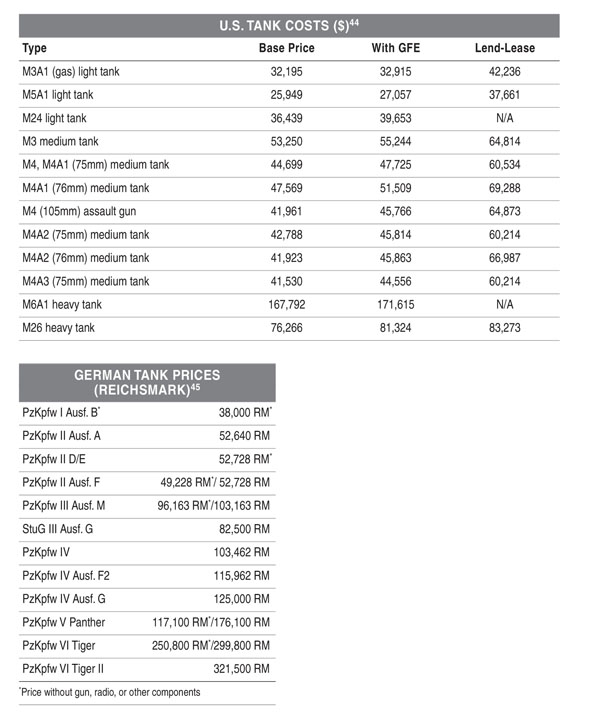

The charts presented here show some typical price data for tanks during World War II. It is very difficult to compare prices between two countries since the accounting methods were so different and the exchange rates likely to be artificial. For example, many German weapons prices reflected the payment to the manufacturer for the “tin box” even though some major components such as the gun and power-train were provided to the assembly plant as government-furnished equipment (GFE). So for example in the case of the Panther tank, the basic price was listed as 117,100 RM (Reichsmark), but the gun cost an additional 12,000 RM.37

The price of tanks also varied from factory to factory due to the availability of machine tools and other equipment. For example, for one of the Panther production batches, the additional state investment in machine tools and facilities at some plants such as Daimler-Benz in Berlin and MNH in Hannover was about 25,000 RM per tank, about 82,000 RM per tank at the new Nibelungen Werk in St. Valentin, and some 190,000 RM at Demag in Falkensee.38In addition, there was wide variation in prices at the various plants due to different rates of taxation depending on whether the plant was private or state-owned.39 Other problems with assessing German prices were the politicization of the process resulting from the 1943 “Adolf Hitler Panzer Program” and the temptation of Albert Speer’s armaments ministry to claim enormous cost efficiencies on new tank types such as the Panther and to hide or disguise capital investments needed for production. It’s worth noting that the price for a Tiger I tank for the German army was about 300,000 RM, but the example sold to Japan was priced at 645,000 RM, an amount more likely to reflect the actual cost including industrial infrastructure investment.

The chart below on U.S. Army tank prices covers the basic vehicle, the vehicle plus the GFE including tank guns and sights, and finally the cost for Lend-Lease export which presumably adds spares, technical documents, and shipping costs.

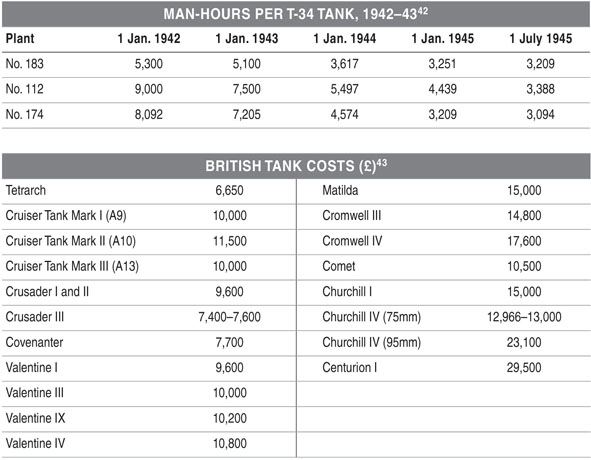

A further complication is that costs were not constant. The price of a given tank, for example the T-34, varied depending on the contract batch, the plant, and the specific production series. As the chart below demonstrates, the amount of work needed to manufacture a T-34 tank declined through the war due to efficiencies and automation, but varied considerably from plant to plant.