Mastering Basic Cheesemaking: The Fun and Fundamentals of Making Cheese at Home - Gianaclis Caldwell (2015)

Part 1. THE FUNDAMENTALS OF MAKING CHEESE

Chapter 2. UNDERSTANDING INGREDIENTS

CHEESE IS ONE OF THE SIMPLEST FOODS ever created by humans. All you really need to make cheese is a bowl of fresh unpasteurized milk and patience. After a number of hours, natural fermentation will create a primitive curd that can be rescued from the whey with a basket or even your hands. While rather bland without the addition of salt, it is still cheese. Much like the tale of stone soup in which a clever vagabond crafts an extravagant feast from water and stones, delicious and complex cheeses can arise from the humble combination of milk and time. To learn to make cheese is to learn to love what milk can become. Let’s take a look at all of the necessary ingredients, plus a few optional ones, that go into making cheese in the order that we’ll be using them in the recipes.

A QUICK LOOK

Milk: Cheese starts with fresh, raw, or pasteurized whole or partly skimmed milk (never ultra-pasteurized [UP] or ultra-high-temperature [UHT]), most often from dairy cows, goats, and sheep.

Acid: Many quick cheeses are made using food acids such as vinegar, lemon juice, citric acid, and tartaric acid.

Culture: Most cheeses rely upon acid that is created by starter culture bacteria.

Calcium Chloride: (optional) A mineral solution often added to help coagulate the milk.

Lipase: (optional) An animal-source ingredient that creates the sharp, piquant flavor desired in some cheeses. (None of the recipes in this book call for lipase.)

Rennet: An enzyme that helps coagulate the milk. Rennet, as a liquid or tablet, can derive from several sources: plants, microbes, and animals.

Salt: Salt is added to cheese for flavor and preservation. Pure salt, without any added in - gre dients, is the best choice for cheesemaking.

Flavorings: (optional) Herbs, spices, beer, smoke, and a variety of other ingredients can be added to most cheeses for additional flavor.

MILK

From the killer whale to the kangaroo, the guinea pig to humans, all mammals owe their start in life to milk. The first food of this large, diverse group of creatures, nutrient-packed milk is designed to meet all of the needs of their helpless offspring. These nutrients are also what make it possible to convert milk into cheese. Understanding the nuances of milk is the greatest task of every cheesemaker, whether novice or pro.

All great cheese starts with great milk. Here a Jersey cow is being milked into a hooded pail at By George Farm, Applegate, Oregon.

The majority of the world’s modern cheeses are made from the milk of domesticated cows, goats, sheep, and water buffalo. At some points around the globe, milk for drinking and fermenting is collected from more exotic beasts such as donkeys, horses, camels, yaks, and even reindeer. As you may imagine, this great variety of milk offers a diverse assortment of cheesemaking possibilities. What you may not know is that even the milk from a single animal will change throughout the year and throughout her life. Unlike the seasonal production of the small farm, the modern, large-scale milk supply is managed in a fashion so as to limit these variations and provide the most consistent milk possible (see sidebar Milk’s Journey from the Farm to the Grocery Store). While this might be a desirable quality for the shopper expecting a glass of milk to taste the same all year long, it comes at a price for those hoping to transform the milk into cheese.

MILK’S JOURNEY FROM THE FARM TO THE GROCERY

Most grocery store milk goes through several steps of processing before it reaches your local market. Milk is collected at the farm in a large cooling container called a bulk tank. It is usually picked up from the bulk tank approximately every other day by a milk tanker truck. In the truck’s large holding tank, it is combined with milk from several other farms and then transported to the processing and bottling facility. While most facilities bottle daily, milk can sit in an even larger holding tank called a milk silo for several more days before being processed. Samples of milk are tested for safety issues, such as disease-causing bacteria, and other factors such as how much fat it contains. From the silo, milk moves through a series of machines. In one it might have the cream removed, such as in the case of skim or low-fat milk. Then it is pumped through a pasteurizer that heats and cools the milk to temperatures stipulated by the Pasteurized Milk Ordinance (PMO), the U.S. Food and Drug Administration’s regulatory document on pasteurized milk production. Following pasteurization, most milk is homogenized by pushing it through a series of screens that resize the large fat globules into tinier pieces that will not float to the top. Before bottling, milk is standardized to the desired fat content — for example, 1% or 2% — and vitamins, destroyed by pasteurization or deemed nutritionally or economically advantageous, are added. Some milk is treated to other processes too, such as microfiltration and ultra-high-temperature pasteurization, which greatly extend its shelf life. (Sadly, most of the organic cow’s milk and commercially available goat’s milk are ultra-pasteurized.) Once packaged, the milk is crated and transported to the grocery store.

The Components of Milk

Milk is mostly water, and indeed making cheese is in large part just the separation of the watery element of milk from its solid constituents: fat, protein, and minerals. Because of the way that these components behave in the presence of acid and rennet, it is possible to consolidate the nutritious solids as curd, leaving the water and a few other components behind as a translucent liquid called whey. Let’s take a look at each of the components in milk — sugar, fat, protein, minerals, and vitamins — and see what role they play in the creation of cheese.

Milk sugar, or lactose, serves as food for cheesemaking bacteria, either those naturally in raw milk or those added as a starter. (As we learned in chapter 1, fermenting bacteria metabolize the sugar and produce acid.) The lactose content of milk changes throughout the year, but it does not vary that much between most milking species. Fresh cheeses made from all milks will still have quite a bit of lactose in them, but varieties that age for longer than a month are virtually lactose-free, making them digestible for those who cannot fully digest lactose.

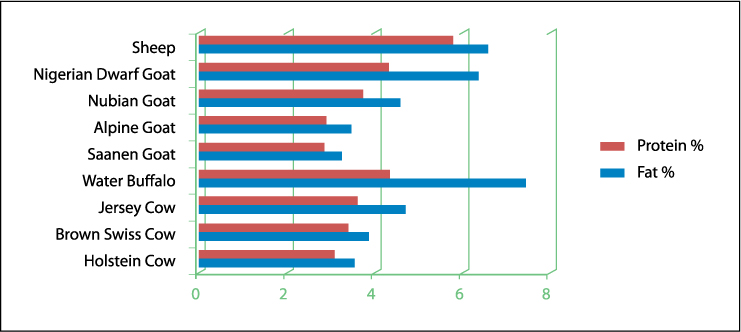

The Average Fat and Protein Content of Several Milk Producing Species and Breeds

Milk fat is mostly captured in the cheese-making process and lends flavor and texture to the final product. Some cheeses are made using milk that has had some of the fat, as cream, removed. Removing the fat changes the texture of the cheese, but mostly it changes the flavors that develop during aging. Other cheeses have extra cream added, such as cream cheese and triple-cream Brie. The fat in milk varies greatly depending upon the species of the animal, what it eats, and the time of year. For example, goat’s milk typically has more types of fat that are known for lending strong, musky flavors and smells under certain conditions. (This is contrary to the old farmer’s tale of goat’s milk being tainted by the proximity of the buck.) Homogenization, over-agitation (from milk pumps used in processing plants), and unwanted microbes all damage milk fat and can lead to unwanted flavors in cheese. Goat’s milk, with its smaller, more fragile milk fat globules, is the easiest to damage.

Milk protein comes in several varieties; some are better at making cheese than others, thanks to their structure. It is the proteins in milk that knit together to form a network that becomes the cheese curd. During aging, the proteins in cheese are broken down to smaller segments that provide flavor and aroma and are easier to digest. The amount of high-quality cheese protein in milk can vary by breed and species. For example, many goat breeds have far less of the most desirable cheese proteins, making their milk more suitable for fluid use and certain types of cheese. Milk proteins like fat globules can be damaged and altered by pasteurization, homogenization, cold storage, and unwanted enzymes from bacteria.

Milk contains several minerals, but the most important one for the cheesemaker to understand is calcium phosphate, which we’ll call simply “calcium.” This mineral is responsible for creating a strong protein network during coagulation. It is also takes credit for much of the final texture of a cheese. Once fresh milk has been refrigerated, the calcium begins to behave differently and becomes less available for helping with coagulation. Even high-quality raw milk that has been refrigerated for 24 hours will experience a change in mineral balance that will affect coagulation. For this reason, a mineral solution of calcium chloride is often added to the milk before coagulating. In general, the more calcium that is left in the curd, the more pliable, sliceable, and supple the cheese, while the less calcium that remains, the more crumbly and breakable the texture.

WHY THE FAT OF GOAT’S MILK DOESN’T FLOAT

Fat globules in milk are larger and more buoyant compared to the other components. When cow’s milk is allowed to sit, the fat rises to the top as cream. The fat in the milk of goats, sheep, and water buffalo does not separate as rapidly because the globules are much smaller and because these milks lack a protein that causes the globules to clump together like a bunch of balloons and rise even faster. The cream in these milks can be separated using a piece of equipment called a cream separator. Varieties from breeds that produce high fat will form a nice natural cream layer after a few days sitting in the refrigerator. In addition, the placing of cooled goat milk in the freezer for a few hours, but not long enough to actually freeze, will speed the rise of cream to the top. Remember these types of milks cannot truly be called “naturally homogenized,” rather they simply do not naturally separate quickly.

Milk also contains vitamins, but they don’t play a major role in cheesemaking. The presence or absence of vitamin A relates to the color of the milk and the resulting cheese. The more yellow color of cow’s milk compared to that of goats, sheep, and water buffalo is due to the presence of an organic compound called beta-carotene that exists in plants, particularly orange-colored fruits and vegetables. Our bodies convert beta-carotene into vitamin A. Animals that make milk that does not contain beta-carotene have already converted the beta-carotene they have eaten into vitamin A, thus their milk is whiter.

Choosing and Storing Milk

For the recipes in this book, you can use cow, goat, or sheep milk for any recipe, but be sure to follow the tips below for choosing your milk. Most cheeses are best made with whole, unskimmed milk. Grocery store cow’s milk, with the exception of non-homogenized or cream top milk, is neither, as even the highest fat content product has been standardized to a regulated percentage of 3.2-3.5%. If you are using farm-fresh raw milk, the fat percentage will be closer to what is natural for the animal. This percentage depends not just on the type of animal, but also on the breed as different breeds within the same species may have milk with a very different fat content. (At this stage in the cheesemaking game, you really don’t need to think too much about the differing fat contents, but it is useful to know.) You can make cheese from skim milk, but it will have a rubbery and unpleasant texture in addition to lacking some of the vitamins present in milk fat. Dried, powdered milk can also be used to make cheese, but with similar textural and aesthetic differences. Even if you are limited to only grocery store milk, you can still make some pretty great cheese at home.

TIPS FOR CHOOSING AND STORING COMMERCIALLY AVAILABLE MILK

Don’t use ultra-pasteurized (UP) or ultra-high-temperature (UHT) pasteurized milk; the proteins in these types of milk are too damaged and will not form a strong network in the curd. High-temperature pasteurized milk is labeled as such, while lower temperature pasteurized milk will simply say “pasteurized.”

When available and affordable, use non-homogenized milk, often called cream-top or cream-line milk, thanks to the layer of cream that forms as the milk sits. The cream in this type of milk is somewhat changed by pasteurization and is difficult to mix back into the milk once it has separated. But the flavor and texture of cheeses made using cream-top milk will be superior.

Choose the freshest milk possible, and use it as soon as possible. Don’t be shy about asking the dairy department manager about when they receive new milk deliveries.

Experiment with different brands and at different times of the year; you might find some work a bit better than others.

TIPS FOR CHOOSING AND STORING UNPROCESSED, UNPASTEURIZED MILK

1.Educate yourself about the standards of production for high-quality milk (see the appendix for more).

2.Follow handling guidelines for raw milk (see appendix).

3.Choose the freshest milk possible, and use the milk as soon as possible. Milk should be no older than four days and ideally less than 24 hours old.

4.When in doubt, milk can be gently heat treated at home (see next sidebar).

5.The U.S. Food and Drug Administration (FDA) currently recommends that raw-milk cheeses be aged for a minimum of 60 days.

HEAT TREATING MILK

There are many occasions when heat treating, or pasteurizing, raw milk is a good idea. Every consumer and user must find their own level of comfort with raw milk on their own, hopefully after researching the topic. Should you decide to heat treat, it can be done simply using the same pot and water-bath setup that you will learn about in chapter 3. There are three levels of heat treatment that are good options for the home cheesemaker:

✵155oF (68oC) for 15 seconds: a gentle heat treatment that is not complete pasteurization, but greatly reduces the number of bacteria in the milk without significantly changing proteins or enzymes (as long as it reaches this temperature fairly quickly and then is cooled quickly. This type of treatment is called thermization.

✵145oF (63oC) for 30 minutes: also called low-temperature long-time (LTLT) pasteurization

✵161oF (72oC) for 15 seconds: also called high-temperature short-time (HTST) pasteurization

With any of these methods, you can cool the milk (by setting the pot in a sink of cold water)to the temperature needed at the start of the recipe and then begin making cheese. In our first lessons, in chapter 4, the milk temperatures are all beyond what is needed to pasteurize the milk, so you don’t need to perform any of these heat treatments first.

Raw cow’s milk with a beautiful cream top, from Runnymeade Farm, Rogue River, Oregon.

In some states, the sale of unpasteurized (raw) milk is allowed, either directly from the farm or in retail stores. If raw milk is of high quality, it can make a superior cheese as compared to its processed peer. But raw milk that has not been collected properly from healthy animals and processed safely can contain disease-causing microbes (pathogens) that can cause severe illness, miscarriage, and even death. If you choose to use raw milk, as we do at our farm from our own animals, then you MUST be confident of its quality.

Determining the quality of raw milk, especially from unregulated sources, might be difficult or even impossible for the home cheesemaker. You will have to make up your own mind about your comfort level working with unpasteurized milk, but the tips below will assist you. (See my book The Small-Scale Dairy [Chelsea Green Publishing, 2014] for information on producing the best-quality raw milk.)

ACID

In the most basic cheeses, such as those we’ll cover in chapter 4, cheese curd is quickly made by adding a food acid, such as lemon juice or vinegar to heated milk.

Choosing and Storing Acid

Any edible acid can be used to coagulate milk. Since the human palate prefers foods that are a bit on the acidic side, there are many options readily available for the cheesemaker. Vinegars, citrus juice, and even wine can be used to coagulate milk — each lending its own characteristics and color. Powdered food acids such as citric, tartaric, and ascorbic can be used when minimal flavor is desired. These granulated dry acids are also quite convenient to keep on hand due to their indefinite shelf life. Remember, the weaker the acid, the more you will have to use: for example, in order to coagulate a gallon of milk with wine, you might need a bottle or more of wine but only ½ cup (237 ml) of vinegar. Of course, if the wine is no longer palatable and has begun to turn to vinegar, you will need less! Also remember that commercially made vinegars vary in acid content. It is always a good idea to have a little extra on hand when starting a recipe in case more is needed to get the right results.

A BIT ABOUT pH

The pH scale is a way to indicate the presence or lack of acid in a substance. Something that is pH neutral, like pure water, has a pH of 7. As the number drops from neutral, the substance is more acidic. Fresh healthy milk is just slightly acidic, with a pH of about 6.6. (Goat milk on average has a pH that starts a bit lower than cow’s milk.) Fresh soft cheeses are usually about pH 4.5, or about as acidic as a glass of wine. Cheeses that are coagulated with rennet and pressed are a bit less acidic at about 5.2, similar to the tartness of a fresh tomato. You don’t have to know how to measure pH to get started in cheesemaking, but the concept of acid and how it creates and preserves cheese is important to understand.

Adding vinegar to acidify and coagulate milk.

CULTURES

Cheese starter cultures contain bacteria and other microorganisms that change the sugar in milk into acid and other by-products. When acid is produced by cheese starter bacteria, the resulting cheese will have a much more complex flavor and a potential for developing even more nuanced aroma and character during aging. It is the amount of acid in a cheese, combined with the salt and lack of moisture, that allows it to have a long shelf life — even for years, as is the case for some of the world’s greatest cheeses, which can age for a decade.

Fortunately, the cheesemaker today has a tremendous variety of cultures available for purchase (but don’t worry, you only need a couple). The home cheesemaker has the additional benefit of several companies that have made the selection process very easy and reliable thanks to the use of premeasured, single-dose packets. While cheese starter cultures are manufactured in several forms, including fresh bulk starter and frozen pellets, the hobbyist will get the best results using freeze-dried culture, often called direct-set, direct-vat set, or direct-inoculation culture.

RAW MILK AND CHEESEMAKING THEN AND NOW

In the best possible world, milk would be collected from pasture-grazing and housed cows and sheep, and from free-ranging, shrub-browsing goats. During the milking process, the udders would be clean, but not sanitized, and bacteria collected during milking would be mostly harmless, and also helpful to the cheesemaking process. The milk would never be chilled, but would instead be fermented immediately and made into cheese. This idealistic situation is what occurred traditionally when farms were small, multigenerational (meaning plenty of uncomplicated labor), and refrigeration was rare. All of these qualities meant that animals could be managed differently and milk had to be processed immediately — leaving no chance for the growth of unwanted, disease-causing microbes and the best-quality milk — with no change due to refrigeration.

The modern world brings us not only refrigeration, but expanding labor costs, lack of land, and different market pressures that all combine to make the above cheesemaking utopia almost impossible. Most of us seek to find a balance between acknowledging the different realities facing dairy farmers and our desire to make great cheese. For that reason, even the farmer-cheesemaker who collects their own superb quality raw milk is most likely to refrigerate it, add calcium chloride, and use added starter cutlures in addition to appreciating the bacteria and qualities that still raw milk will most certainly bring to the process. Indeed, science and critics all agree that properly-made, raw milk cheeses are more complex and interesting than their pastuerized counterparts.

In the recipes in part 2, I will give measurements for cultures in teaspoons as well as weight in grams. You may notice that the weights of cultures are different than that of the same teaspoon amount for things like salt and citric acid — and sometimes they are even different for two types of culture. Cultures have different densities than things like salt, so the same one half teaspoon of each will have a different weight. For this reason, it is always more accurate to weigh cultures than to measure with a teaspoon, but either way is just fine at this level of study.

Choosing and Storing Cultures

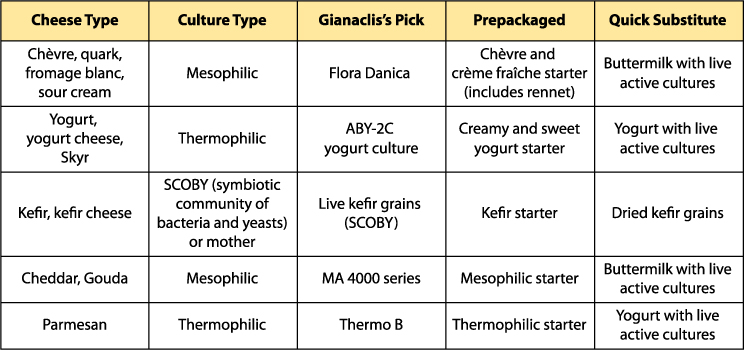

When you first start shopping for cheese cultures, don’t be discouraged by the large number of choices (In fact, you can make almost every recipe in this book with only one or two types of culture). Cultures are packaged and labeled for specific cheese types, but there is a great deal of overlap and room for successful experimentation. Most cultures include several strains of bacteria that are intended to produce the right amount of acid as well as provide flavor to the cheese. The many types of starter can be divided into two main groups: mesophilic and thermophilic. Mesophilic blends grow best in moderate temperatures and are used when making cheeses in which the temperature never exceeds 102oF (39oC). Thermophilic blends prefer high temperatures. As long as you choose a culture from the right group, your cheese-making will be reasonably successful.

Freeze-dried cultures can be stored in a home freezer for extended periods, even years. When packaged for use with small batches of about two gallons of milk, they are protected from moisture and contamination. Large packets that contain enough culture for hundreds of gallons of milk can be used in smaller doses, but they can be difficult to protect from problems with humidity and contaminates. My best recommendation for storing larger packets is the use of reusable zipper-lock vacuum-sealable bags. By placing the open culture packet in one of these and removing the air with a vacuum pump, humidity is also removed and the culture will stay very dry.

Culture Chart

CALCIUM CHLORIDE

Calcium chloride is a mineral solution that is useful for cheesemakers to have on hand. It is added to the milk to help it to coagulate better and to improve the odds of getting the best cheese yield possible. It is also used when making a saltwater solution, or brine, in which to soak or store some cheeses, such as feta. Using calcium chloride is always optional, but can be very helpful when using grocery store milk, farm-fresh milk that is over two days old, and often goat milk that is experiencing seasonal variations that affect the coagulation quality.

Choosing and Storing Calcium Chloride

Calcium chloride is usually sold as a dry crystal or diluted liquid. I recommend buying and using the pre-diluted liquid form, as it saves the step of properly measuring and mixing the dry form. Either form can be stored at room temperature for an indefinite period of time; both are harsh in flavor and can cause problems with coagulation if not measured properly. In chapter 6, I’ll tell you how to figure out how much to use and how to add it to the milk.

LIPASE

Lipases are enzymes that break down fats. The breakdown of fat in cheese releases additional flavors and aromas. Lipase is naturally present in raw milk, but is not as strong as the type that is added in cheesemaking. This optional ingredient is added when a piquant (spicy, hotness) flavor profile is desired. An example of a cheese with a strong lipase presence is Pecorino Romano.

Choosing and Storing Lipase

The lipase used in cheesemaking is harvested from the digestive tract of a young calf, kid, or lamb — as is traditional rennet. Depending on the animal it comes from, lipase has a different potential for developing flavor, with calf lipase lending the mildest and lamb the strongest flavor. Lipase should be stored in the freezer in the same manner as starter cultures: protected from humidity and other contamination. While I don’t call for lipase in any of the recipes in this book, as you progress with your cheesemaking, you may want to try adding very small amounts to recipes such as feta and Parmesan, following the suggestions on the container for how much to add. The resulting products will be distinctively different than those without lipase.

RENNET

The word rennet today refers to several solutions that are added to milk in order to cause it to coagulate, or curdle. Rennet contains an enzyme that causes milk to coagulate by changing the way that the proteins in it behave: instead of staying separate, as they do in a glass of milk, the coagulant changes the proteins so that they will stick together. No matter the source of the rennet, whether animal, vegetable, or microbe (see sidebar More about Rennet), they all have a similar effect on milk proteins. The better the coagulation, the stronger the protein network. A strong network helps retain fat in the curd and increase the amount of curd and, therefore, cheese.

MORE ABOUT RENNET

Animal rennet, often called “traditional” rennet, is harvested from the abomasum, or true stomach, of a young calf, kid, or lamb that has not yet ruminated (chewed cud). Before that time, usually when it is less than a week or two old, the baby’s stomach contains a high percentage of an enzyme, chymosin, which coagulates the milk it drinks from its mother. This allows time for the milk, now a curd, to be absorbed. If the milk moves too quickly through the young animal’s system, the nutrients cannot be utilized. Superior animal rennet should be at least 90% chymosin. Many cheesemakers swear that traditional rennet is superior to all others. I have used both traditional and microbial, and even when used side-by-side on the same aged hard cheese made from the same milk and culture, the differences are extremely subtle, and in blind tastings at our farm, there is an almost equal split in preference, with the slight majority choosing the microbial version.

Junket rennet, found in some grocery stores, is a product made from the fourth stomach of an adult cow and is not a good choice for making cheese as it has very little of the desired enzyme chymosin, but instead contains mostly pepsin, which will coagulate milk, but can also create bitterness.

Vegetarian rennets include those made by microbes (both natural and genetically engineered) and true vegetable rennets. Microbial rennet contains an enzyme that is produced naturally by the microbe mucor miehei. It has an undeserved reputation for producing bitterness in cheese, especially hard aged cheeses. It is true that some of the first attempts at the production of this type of coagulant resulted in a product that imparted that unwanted quality to aged cheeses, but brands available now do not when measured accurately. It is my preferred rennet for use in our creamery.

Fermented chymosin is another vegetarian rennet produced by microbes. Unlike the coagulant made naturally by the microbe mucor miehei, fermented chymosin is produced by genetically engineered microbes that have had the gene for producing calf chymosin added to their genes.

True vegetable-source coagulants such as those made from cardoon thistle can also cause bitterness. They also are much weaker coagulators and work best with a milk that is high in fat and protein such as sheep’s milk. I include instructions for making cardoon thistle rennet in Mastering Artisan Cheesemaking.

Choosing and Storing Rennet

Rennet comes in either liquid or tablet form. Some types are also available in single- and double-strength versions. The liquid form must be stored in the refrigerator and not exposed to light for long. When stored properly, rennet can last up to a year, but may start losing strength earlier. Deciding upon the rennet source — animal or vegetarian — can be a matter of ethics or dietary desires. Most cheesemakers develop their own preference over time. I encourage some experimentation with different types while you perfect your craft. The differences the rennets produce in the cheese will be most evident with aged varieties due to the influence the enzymes have during aging. In our recipes we will be using double-strength liquid vegetarian rennet, which, by the way, can be purchased in an organic version from larger cheesemaking suppliers.

SALT

Salt plays an essential role in cheesemaking, contributing to both the flavor and preservation of the cheese. It accents flavors and prevents a bland, flat taste; it can help prevent cheese from becoming too sour by stopping bacteria from producing more acid; and in aged cheeses, it helps protect them from spoilage by making water unavailable for the activity of spoilage microbes. The right choice for cheese is a simple, pure salt that doesn’t contain any added minerals, flavors, or anti-caking agents (to prevent clumping). For cheeses that are salted and eaten immediately, the choice of salt isn’t as critical. But, for cheeses that will be aged or saved, it is more important to use only pure salt, or sodium chloride.

You will find a rather confusing variety of salt available at the grocery store. There is salt with and without iodine (one of those minerals we don’t want in our cheese); canning and canning salt (no additives); kosher salt (may have additives); rock salt (for chilling ice to make ice cream); and sea salt, to name a few. Some are named based on the shape of the salt crystals; for example, kosher salt is formed in small flakes to prevent them from rolling off the surface of meat. Kosher salt works great for dry salting cheeses, but many brands contain additives. (Diamond Kosher is one that doesn’t.) Sea salt, which does not contain additives, comes in different crystal sizes, from fine to coarse. Choose the fine version, as the coarse will not dissolve into the cheese quickly enough. The bottom line is look for a fine or flaked salt without any additives.

We’ll be adding salt to cheese both by sprinkling it into the curd, onto the wheel, and by immersing pressed wheels into a salty brine solution. Each method brings different positive qualities to the cheese. Sometimes you can choose the method, but in the beginning it is best to stick to what is recommended.

FLAVORING, COLORING, AND OTHER ADDITIONS

Many things can be added to cheese to add and enhance flavor or to change the visual appeal of the final product. Purists — both those that eat cheese and those that make cheese — might cringe at some of these additions, but many people love them, myself included. When handled correctly, an added flavor should not mask the taste of the cheese, but complement it and add a layer of interest. Similarly, added color, whether on the outside of the cheese, throughout, or in an interior layer, should not be overwhelming or distracting. That said, some very famous traditional cheeses, such as the bright orange French Mimolette, are a bit over the top when it comes to added color.

Annatto is a natural coloring obtained from the seeds of the achiote tree. If you want to experiment with adding a bit of orange color to the inside, or outside, of your cheeses, this is the ingredient you will need. Annatto comes in a liquid form that has a very long shelf life. Follow the instructions on the bottle and remember that very little is needed.

Herbs and spices can be added directly to the cheese curd after it has drained and before it is pressed. Infusions — liquid teas made by simmering herbs, spices, or other additions — are added to the milk before it is coagulated or to the curd after it is drained. Successful combinations with cheese include cumin, hot pepper flakes, fenugreek, fennel seed, caraway, and lavender. Let your creativity be your guide, but be sure to use superior quality seasonings from reputable sources, as contaminants can be introduced.

Ales and other types of beer are also a popular addition to cheese. They are added after the curd is drained, but before it is pressed. The amount is usually no more than about one-tenth of the total volume of milk used in the cheese. Interestingly, beers and ales often pair fantastically with cheeses — often more readily than does wine.

Smoke is an age-old complementary flavor for cheese. While liquid smoke is sometimes added to the milk before coagulation, real smoke provides a far superior taste. Cheeses are smoked either when fresh or after they are aged. Any type of wood chip used to smoke other foods will work, but the smoker must not be too hot, or the cheeses will get oily or even melt.

After simmering hot pepper flakes in water, the liquid is added to the milk just before adding the rennet. The softened pepper flakes are combined with the curd after it is drained.