Fukushima: The Story of a Nuclear Disaster (2015)

3

MARCH 12 THROUGH 14, 2011: “WHAT THE HELL IS GOING ON?”

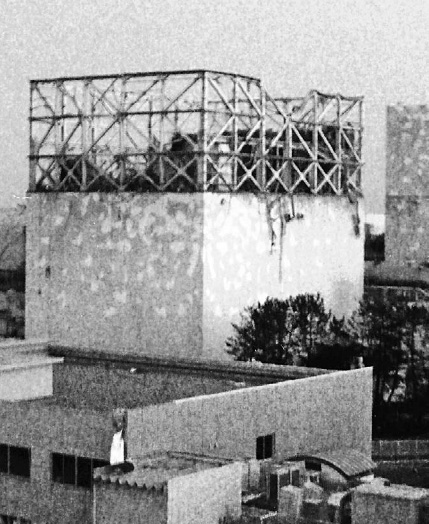

At first, plant boss Masao Yoshida thought the violent motion beneath his feet at 3:36 p.m. March 12 was another earthquake. Then came potentially worse news: the top of the Unit 1 reactor building had blown off; only the steel framework remained.

Four minutes later, the harried team in the plant’s emergency response center joined the rest of the world watching the explosion replayed on TV screens. A huge billow of white smoke and debris expanded skyward, drifting away on the prevailing winds.

A check of the jury-rigged gauge showed that the water level inside the Unit 1 reactor had not changed: 5.5 feet below the top of the fuel, or about 21.5 feet below normal. The fuel had started melting about twenty-one hours earlier. Also, the pressure within the reactor vessel had not dropped, suggesting that the worst-case scenario—that the explosion had damaged the reactor vessel itself—had not occurred.

This looked to personnel at the plant and at TEPCO’s emergency operations center like a hydrogen explosion. But from what source? Prime Minister Kan had asked the Nuclear Safety Commission chief, Haruki Madarame, that morning about the likelihood of hydrogen igniting, and had been assured that this was unlikely.

During normal reactor operations, nitrogen gas is added to the drywell—part of the primary containment structure—to preclude an explosion of hydrogen should any accident occur. Hydrogen cannot ignite unless oxygen is present, so substituting nitrogen for oxygen—a process called “inerting”—eliminates the possibility of a volatile mix forming inside the drywell. The atmosphere in the reactor building itself was not inerted because regulators never thought it would be necessary; protecting the containment from rupture would be sufficient to prevent radiation leaks. Now, somehow, hydrogen gas had apparently migrated to an area where no one had expected it to be.

The initial reaction among the startled workers was denial that the hydrogen was generated from damaged nuclear fuel. Yoshida first thought the explosion might involve the turbine generators, which use hydrogen gas as a cooling medium in their operation. However, this was ruled out when reports indicated that the Unit 1 turbine building had not been damaged in the blast.

Unit 1 after a hydrogen explosion blew off the top of the reactor building. Tokyo Electric Power Company

Another theory suggested that the spent fuel pool in the “attic” of the reactor building was boiling and the fuel there was no longer completely immersed. If so, the overheated cladding of the fuel rods could have reacted with steam to generate the hydrogen gas that ignited. Without working instruments, there was no way to check the water level or temperature of the pool. But it was not clear how so much of it could have boiled away in such a short time, given what the operators knew about the amount of heat generated by the relatively small quantity of fuel in the pool: only 292 spent fuel assemblies and 100 new assemblies. (The new assemblies were there to await the next refueling.)

Then another hypothesis was put forward: the extreme pressure and heat that had built up before venting had loosened bolts and seals in the reactor’s drywell, allowing radioactive steam and hydrogen to leak into the reactor building, where a spark or static electricity triggered the blast. Or perhaps when the containment was vented, hydrogen under enormous pressure had leaked out of the vent pipe into the reactor building before it could be expelled through the tall exhaust stack shared with Unit 2. Normally, ventilation fans within the reactor building might have helped to draw any hydrogen up and out of the building, but the fans couldn’t work without electricity. Instead, the gas would have accumulated until it became concentrated enough to explode. No matter what the hypothesis, though, one thing was clear: if the containment had been vented sooner to reduce its pressure, this might have prevented hydrogen—and fission products—from leaking into the reactor building.

For the hapless crew in the plant’s emergency response center, there was more bad news: falling debris had damaged the electric cable that workers had spent hours laying and were within minutes of energizing to restore power to Units 1 and 2. The explosion had also damaged the fire hoses that workers had carefully arranged to inject seawater into Unit 1. Although radioactive litter was now scattered around the Unit 1 reactor building, Yoshida ordered his employees to get the hoses working. The fire engines injecting freshwater into Unit 1 had used up their supply nearly an hour earlier. The need to get water into the core was still imperative, and the workers had been very close to being able to supply it. The explosion set them back by several hours, but despite the hazardous conditions they repaired the damage by 7:00 p.m.

Meanwhile, just beyond the six-mile (ten-kilometer) evacuation zone, residents of the coastal town of Namie thought they had finally reached safety. Earlier that morning they had been rousted from the evacuation centers to which they had fled to escape the tsunami; now those centers were too close to a new danger: Fukushima Daiichi. Their next haven was a school. Children played in the schoolyard. Adults, dressed in heavy winter coats, sat together on the gymnasium floor or cooked a meal outside. While the world watched images of the giant cloud billowing from Unit 1, those closest to it were unaware because of the loss of cell phone and television service.

As the Namie evacuees would later learn, merely being farther from the damaged reactors would not necessarily protect them. Luck was on their side that night, however, because the emissions from Unit 1 were relatively small, and the prevailing winds blew them primarily northward along the coast and then out to sea.

Almost from the beginning of the accident, an early-warning system had been making ominous predictions about the danger that the Namie evacuees and other people near Fukushima Daiichi could face should conditions worsen at the plant. The System for Prediction of Environmental Emergency Dose Information, or SPEEDI, was developed by the Japanese after the Three Mile Island accident. It went into operation in 1986. If radiation is released in an accident, SPEEDI uses real-time measurements from the nuclear plant together with meteorological data to predict where the radioactivity will spread and how intense it will be. When actual radiation release data are available, the system is far more useful in assessing risks and defining evacuation areas than the concentric zones arbitrarily drawn around a plant. The system is continually updated and monitored from an office in the capital.

The day before, when TEPCO declared a nuclear emergency, SPEEDI had switched to emergency mode, ready to track any releases from Fukushima Daiichi and guide decisions about evacuations based on the location of radiation plumes. There was one problem: Fukushima Daiichi had no power. As a result, when radiation was released, the plant’s on-site measuring devices were unable to gather and transmit data about it to SPEEDI. Without such data, all SPEEDI could do was indicate the direction in which the radiation would travel.1

Those projections were duly passed from the Education Ministry, where SPEEDI is housed, to NISA, which forwarded them to the prime minister’s office. But they came with a caveat: their reliability could not be guaranteed because no one knew how much radiation was actually being released. As a result, the readouts were never shown to the prime minister.

Four days into the accident, the news media began asking for the SPEEDI data. That prompted a meeting of top Education Ministry officials who worried that “a release of the predictions could cause people unnecessary confusion.” With that, responsibility for SPEEDI data was handed off to the NSC, whose chief, Madarame, dismissed the calculations as no better than “a mere weather report.”

The Namie evacuees at the school had no inkling they were at risk until a TEPCO employee showed up late on the afternoon of March 12 in protective clothing, carrying a dosimeter. Less than an hour after the Unit 1 explosion, radiation readings at the plant boundary had soared. But the employee reassured the worried families that they were safe because they were outside the official evacuation zone—and then he jumped in his car and left. About 6:30 p.m., military trucks arrived at the school. With little official explanation, the occupants were made to pack up their few belongings and head out into the night, once again in search of safety. Other evacuees weren’t as lucky; some remained in areas that were in the path of radiation plumes until March 16 before being told to leave.

In Tokyo the evening of March 12, officials gathered in the prime minister’s office, struggling to figure out what was happening at Fukushima Daiichi. Just before 6:30 p.m., a decision was made to double the evacuation zone to a 12.4-mile (twenty-kilometer) radius around the plant. Kan announced the decision on national television, telling his audience that Japan was facing an “unprecedented crisis.” Joining him was Cabinet Secretary Edano, who reassured the public that although an explosion had occurred in the Unit 1 reactor building, the primary containment remained intact and there would be no major escape of radioactive material. “Please remain calm,” Edano told viewers. It was advice the government repeated often.

Absent from this briefing was Koichiro Nakamura, deputy director general at NISA, who had been handling regular updates for the media. Nakamura’s candor at press conferences earlier that day apparently had gotten him in hot water with Kan’s office. In a morning session with reporters, Nakamura, who had a degree in nuclear engineering, was asked if the fuel had started to melt. He replied: “We cannot deny the possibility.” Four hours later, at another briefing, Nakamura said: “It looks like a core meltdown is occurring.” A short time later, NISA was notified that the prime minister’s office had to clear all statements about the situation, and that NISA also needed to obtain permission from Kan’s office before holding further briefings. Nakamura asked to be replaced.

When reporters gathered for another briefing shortly after 9:00 p.m., a new NISA spokesman was in charge. Asked about media accounts of a meltdown, the spokesman backpedaled, saying: “The condition of the core has not been clearly identified yet.” The word meltdown was not mentioned. The next morning, another NISA briefer was asked about the likelihood of a meltdown. The answer: “The likelihood cannot be denied because such a material [cesium] has already been detected and we must keep that in mind.”

In short, if reporters were looking for definitive answers from the government’s nuclear safety officials, NISA wasn’t providing them. In its steadfast effort to avoid the word meltdown, NISA ultimately came up with its own terminology: fuel pellet melt. (TEPCO also eschewed meltdown, preferring core damage.) Although NISA’s classification made technical sense, the agency had little basis to avoid concluding that a full-scale meltdown had occurred. In the minds of many listeners, its careful parsing of words was a distinction without a difference.

During the afternoon of March 12, after the explosion in Unit 1, Kan was meeting in his office with Madarame and several others when the discussion turned to the question of injecting seawater into the Unit 1 reactor as a last-ditch attempt to cool the damaged core.

TEPCO officials, realizing that the injection of seawater offered perhaps the last hope of cooling the reactor, had already given the go-ahead. That information was passed along to members of the Emergency Operations Team working in the basement of the prime minister’s office building. But the news never made it upstairs to Kan’s office.

The decision to use seawater is the death knell for a reactor, and in this case it would send an unequivocal signal that Unit 1 had now been written off by its owners as a piece of radioactive scrap. Seawater is highly corrosive to the internal parts of a nuclear reactor; even the freshwater used in a reactor is filtered to protect components from impurities. The Pacific might cool the core, but it would finish the job of destroying the reactor.

Kan asked Madarame about the possibility that the seawater could trigger recriticality—an uncontrolled chain reaction—in the damaged fuel.2 Madarame reassured the prime minister that this was unlikely. Participating in the conversation was TEPCO’s liaison, Ichiro Takekuro, who interpreted the discussion to mean that the government might not approve of injecting seawater.

Shortly after 7:00 p.m., Takekuro called plant superintendent Yoshida to tell him about the conversation. Yoshida said that the seawater injection had already begun. Takekuro told him to stop it because the prime minister’s office was still weighing that option. An angry Yoshida called TEPCO headquarters and was told he had no choice but to suspend the injection pending a decision by Kan.

Yoshida knew that if he stopped the injection, he might not get the jury-rigged pumping system to work again. And he knew that continuing to get water into the core was the highest priority, regardless of the government’s apparent dithering. In a moment of bare-knuckled defiance, Yoshida summoned the person in charge of the injection work and whispered instructions: “I’m going to direct you to stop the seawater injection, but do not stop it.” Then, in a loud voice, heard in the plant’s emergency response center—and, via video feed, in Tokyo—Yoshida ordered that the pumping be halted. Finally, at 8:20 p.m., Takekuro delivered word that the prime minister had given the okay and the injection could resume. By then, however, Yoshida had a new spate of emergencies.

On Saturday morning, March 12, NRC chairman Gregory Jaczko was en route to an 11:00 a.m. meeting at the White House to discuss the situation in Japan when he received an update. Information was still in short supply at the NRC, with most coming via media outlets. The NRC wasn’t alone; the Departments of State, Defense, and Energy, the U.S. Agency for International Development, and especially the U.S. Embassy in Tokyo were also laboring to learn more.

Martin Virgilio, the NRC’s deputy executive director for reactor and preparedness programs, was manning the Operations Center at White Flint and had just gotten off the phone with nuclear industry officials. They had provided new information that Virgilio, a level-headed thirty-four-year veteran of the NRC, wanted to pass along to Jaczko by phone.

Virgilio’s information had come from the Institute of Nuclear Power Operations (INPO), an industry group created after the Three Mile Island accident to bolster nuclear safety initiatives and enhance the industry’s tattered public image. INPO, and its international counterpart, the World Association of Nuclear Operators (WANO), had been working sources to learn as much as possible. (One valuable source for the industry and the NRC was Chicago-based Exelon Corporation, which operates more boiling water reactors than any other U.S. utility.) The call provided the NRC with important details, including information gleaned by industry people directly from their contacts at TEPCO. Not all of the information, however, was accurate.

INPO and WANO representatives told Virgilio that a hydrogen explosion had occurred in the Unit 1 reactor building, confirming the assessment of NRC staff members who had watched the explosion on television. It was a significant detail. If the explosion was in the turbine building, the hydrogen could easily have come from sources other than damaged fuel in the reactor core and/or spent fuel pool. But if the reactor building exploded, it was a far more likely indicator of extensive fuel damage somewhere.

As the industry representatives and the NRC shared what they knew, they pieced together this picture of the situation at Fukushima Daiichi: after the explosion, radiation levels at the plant boundary had jumped to one hundred millirem (one millisievert) per hour—about ten thousand times background—but then dropped to fifty millirem per hour. The primary containment at Unit 1 was believed to be still intact. Iodine and cesium isotopes had been detected, indicating some melting of fuel. About eight inches (twenty centimeters) of the fuel in Unit 1 had been partially exposed, and maintaining water levels in that reactor vessel was problematic. There was an unconfirmed report that the Unit 1 containment was being filled with borated seawater using fire trucks. Unit 3 appeared to be in cold shutdown. Unit 2’s RCIC cooling system seemed to be doing its job of transferring heat from the core to the torus, but there was no electrical power to run the pumps that cooled the torus water and transferred heat to the sea. If heat could not be removed from the torus water, the containment temperature and pressure would continue to rise.

Although trouble seemed to be brewing at Unit 2, the Unit 1 situation topped everyone’s list of concerns. And in hindsight, they were not wrong—Unit 1’s damage was actually far more extensive at that point than the briefing had indicated. However, the worsening conditions at the other two units, as well as Unit 4, would soon vie for the NRC’s attention.

For the NRC, the fragmentary information spilling out of Japan posed a combination of challenges the staff had never encountered during emergency drills; nobody had trained for an event this severe. The experts at White Flint and elsewhere within the agency were largely forced to rely on secondhand information and computer analyses that might not have accurately reflected what was actually happening. At the same time, the NRC, as home to the U.S. government’s resident experts in nuclear power, was being counted on to provide guidance to ensure the safety of Americans scattered all over Japan, including 38,000 U.S. troops, 43,000 dependents, and 5,000 civilian defense employees, plus embassy personnel, businesspeople, students, and tourists.

One of Jaczko’s main concerns, even at that early stage, was the potential radiological impact of the accident and how far away from the site significant radiation exposure could occur. The NRC’s Protective Measures Team had already begun to run computer simulations, using a code called RASCAL (the Radiological Assessment System for Consequence Analysis) to address this question. However, as was the case with SPEEDI, the RASCAL simulations were of limited value without data on how much radiation was actually being released. Virgilio told Jaczko that, based on crude assumptions, including a total failure of the Unit 1 reactor containment and severe core damage, the exposure levels that would trigger evacuation by U.S. standards would be exceeded at fifty miles from Fukushima.3 Jaczko asked if there could be danger even farther away and Virgilio said the NRC hadn’t modeled past that point. He didn’t mention to Jaczko that the RASCAL code was only good out to fifty miles.

In addition to monitoring what was happening in Japan, the staff at the Operations Center was beginning to focus on a different kind of crisis: a potential public relations nightmare at home. The NRC oversees twenty-three reactors of the same design as the units in trouble at Fukushima Daiichi. The agency had been dragging its feet for years on addressing a host of difficult issues, including revising seismic safety rules. And now the NRC faced the unpleasant task of having to defend its oversight before a newly skeptical public.

Although early news releases offered general assurances about U.S. reactor safety—“Nuclear power plants are built to withstand environmental hazards, including earthquakes and tsunamis”—the NRC didn’t know enough about the Japanese plants to say with certainty that the safety situation was any better in the United States. For instance, the NRC did not know at the time whether Japan had installed hardened vents at its Mark I boiling water reactors back when most U.S. plants did so, at the urging of the NRC, in 1989.4 And even if NRC officials could legitimately claim U.S. plants were safer, they had to tread carefully or risk embarrassing a major U.S. ally. One NRC staffer called this a “slippery slope.”

While the NRC was trying to pry more information from Japan, it also faced pressure to be more forthcoming. Some of the push was coming from its own staff. As Jaczko was heading home after the White House meeting, Virgilio asked his boss if the NRC might step ahead of the other federal agencies, “sanitize our Qs and As [about the accident] and post them on the website.” Jaczko said no. “At this point, all of the public communication needs to be coordinated,” he said. “[L]et’s continue to keep it within the federal family.”

At that moment, the federal family was engaging in a little sibling rivalry, with the NRC butting heads with the Department of Energy (DOE), which fields its own team of nuclear experts, many of whom work in the national laboratories around the country. Those experts were “chomping at the bit” to get involved, which didn’t sit well at the NRC. “[S]omebody might want to call DOE and tell them to tell their labs to cool it,” said the NRC’s Brian Sheron on March 12, “because the last thing we want is the labs going off, talking to the press, talking about consequences and all sorts of other stuff.”

State officials were beginning to press NRC officials for an assessment of radiation risks to their residents.5 “I think we need to do more with the states,” Virgilio told Jaczko. That’s where most requests for information were coming from, he said. So far, anyway. The U.S. news media, already plying the NRC for information about events in Japan, were also looking for a local angle.

Eventually, Jaczko and his team knew, the NRC would have to answer the question: could Fukushima Daiichi happen here? For the NRC, that was the ultimate “slippery slope.”

“I think … it’s inevitable that we’re going to get those questions and calls for comparisons of U.S. facilities to [those in] Japan,” the NRC’s Brian McDermott, joining Virgilio on the call, told Jaczko. Jaczko agreed and told his crew to start working on some talking points.

Later that day, the conversation in the NRC’s Operations Center turned to crafting acceptable answers, first for the states and then, ultimately, for the media and the public. Staying on top of the message could be difficult, the NRC team agreed.

“[I]f we’re trying to restrict the information, or at least control the information, that we’re getting outside, anything that you give a state or a governor, you’re not going to be able to control what they do with it, even if you ask them to keep it close,” said Dr. Charles L. Miller, an NRC veteran who oversaw state programs. Officials in western states, in particular, wanted to know what the NRC knew, especially the likelihood of a meltdown in Unit 1 and the possibility of radiation reaching the United States. So far the NRC had refused to make any public statements about exactly what was happening at Fukushima.

Together, a handful of staff members drafted the talking points. The gist of the message, they agreed, should be this: The NRC will not speculate. Don’t believe everything reported in the media “by the so-called experts.” Be cautious. “And avoid answering questions on whether it could happen here,” Miller warned. “I mean, I don’t think we’re ready to do that yet.”

As the crisis continued, the NRC exerted considerable discipline, refraining from appearing to second-guess the plant operators or to make pessimistic assessments ahead of the Japanese. The press releases it issued, while seeking to reassure Americans, flatly stated that “the NRC will not comment on hour-to-hour developments at the Japanese reactors.” As for speculating, Bill Borchardt, the NRC’s director of operations, had his own advice for his impatient colleagues: “Don’t … scratch the itch.”

Within minutes of getting the official go-ahead from Tokyo to “resume” injecting seawater into Unit 1, Yoshida found the next problem landing in his lap. At 8:36 p.m. on March 12, the gauge monitoring water levels in Unit 3 ran out of battery power. In fact, problems in Unit 3 had been quietly multiplying. They, too, involved cooling the core.

Aware early on that battery life was an issue, the Unit 3 shift team had cut off all nonessential power loads, fearful that if the RCIC stopped for some reason there might not be adequate power to restart it. With battery power alone, operators were able to keep the cooling system running by continuously monitoring the water level and controlling the flow rate.

Because Unit 3 appeared to be stable with the RCIC limping along, Yoshida and his workers had focused on restoring power to Units 1 and 2. But at 11:36 a.m. on March 12, the RCIC in Unit 3 stopped and could not be restarted. Now Unit 3 needed water and needed it quickly. All available fire engines were being used to pump water into Unit 1. Obtaining another off-site truck was not immediately possible because roads were treacherous.

Fortunately, Unit 3 had an emergency cooling system that was still functional: the “high-pressure coolant injection” system or HPCI (pronounced hip-sea). When water levels dropped in the core, the HPCI automatically kicked in about an hour later, also drawing on battery power. Under normal circumstances, the RCIC was used to deliver makeup water to replace coolant boiled away by decay heat. The HPCI system, with about ten times the flow rate, is designed for much larger water losses, such as could occur from a ruptured pipe or stuck-open relief valve. But these weren’t normal circumstances, and the operators worked to control HPCI flow as they had been doing with the now dormant RCIC.

The water level rose and pressure inside the reactor decreased. Yoshida ordered preparations to vent the containment, knowing it was only a matter of time before that became a necessity. He hoped to vent while radiation levels in the reactor building were low.

The last reading of the Unit 3 water gauge, before the batteries died, indicated that the fuel might be covered by a mere sixteen inches of water. Supervisors doled out thirteen two-volt batteries from the stockpile of fifty batteries that had been delivered overnight from another power station, and the gauge was reactivated. Stabilizing Unit 3 became the priority now that Unit 1 was being cooled by seawater injection.

However, the HPCI pressure started to drop and the shift team at Unit 3 began to worry that it could not depend on the HPCI much longer. The team decided to switch to external injection, using a diesel-driven fire pump, which team members thought would be more reliable. But to do this, they would first have to depressurize the reactor vessel by remotely opening a safety relief valve (SRV). (The reactor vessel’s pressure had to stay low enough for the low-pressure fire pump to be able to inject water.) The shift team thought opening the SRV was possible because the valve’s indicator light was on in the control room, signaling that the SRV could still be operated from the control panel. Yoshida was notified, but he didn’t think dealing with the issue was a priority in light of other, more pressing crises.

Shortly before 3:00 a.m. on March 13, the Unit 3 operators decided to shut down the HPCI. However, when they tried to open the SRV, the switch didn’t seem to work and the SRV indicator didn’t change from green to red to show it was open. The workers attempted to use the fire pump anyway and persuaded themselves from a sound they interpreted as flowing water that it was working. None of this was reported to Yoshida until nearly 4:00 a.m. If he had known in advance of the plan, Yoshida probably would not have approved it: he knew the fire pump would not have worked well even if the SRV had been successfully opened.

After Yoshida discovered what had happened, he decided that the team should try to depressurize the reactor vessel manually, using scavenged car batteries to power the valve controls, and then inject water using a higher-pressure fire engine that had become available from elsewhere on the plant site when a road was cleared. But the reactor had already been without cooling for an hour, and it had entered a critical phase. After a final attempt to restart the HPCI and RCIC failed around 6:00 a.m., Yoshida had no choice but to report to Tokyo that operators had lost the ability to provide emergency cooling to Unit 3.

Although there is some uncertainty about the timing, by approximately 9:00 a.m. on the morning of March 13, the fuel rods became uncovered, triggering the same sequence of events that had occurred at Unit 1 some thirty-six hours earlier: overheating of the fuel, oxidation of the fuel cladding, hydrogen formation, and release of fission products. The Unit 3 core was melting down, and the vessel pressure was rising fast. As though in a nuclear version of Groundhog Day, workers once again faced the urgent need to vent the containment to reduce pressure so they could inject makeup water to try to halt damage to the reactor core.

Racing against time, the operators attempted to open the valves in the piping between the containment and an exhaust stack in order to discharge gas, but they couldn’t outpace the increase in pressure within the intensely hot reactor. Another reactor now appeared doomed.

Three hours passed before venting got under way and the containment pressure dropped. Because core damage had already begun, high levels of radioactive materials were vented and radiation levels at the plant boundary spiked. But soon afterward, a safety relief valve opened, perhaps automatically, and depressurized the reactor, allowing injection of a newly uncovered supply of freshwater in fire cisterns to the core. Freshwater supplies were running low, however, and Yoshida ordered workers to prepare to switch to seawater. Just after noon, the freshwater reservoir had been depleted and workers scrambled to hook up the seawater line. Seawater began flowing in an hour. But once again it was too little, too late; measurements indicated that the core remained exposed, a sign that not enough water was getting into the reactor vessel to re-cover the fuel. Radiation levels were continuing to rise, hitting 1.2 rem (twelve millisieverts) per hour on the Unit 3 side of the shared control room.

Across Japan, concern was growing about this disaster that seemed to worsen by the hour. Late Sunday evening, TEPCO officials held a news conference. President Shimizu, dressed in a blue company uniform, apologized to the Japanese people and said that the tsunami had “exceeded our expectations.” With that, he dropped out of public view for about two weeks, prompting much speculation in the Japanese and foreign media. (TEPCO officials later explained that Shimizu had fallen ill because of overwork.) Shimizu apparently remained involved in decision making, however. He and Prime Minister Kan would soon tangle over a highly publicized misunderstanding.

TEPCO corporate management likely wasn’t winning fans inside the frenzied command center at Fukushima Daiichi, either. Tapes of conversations between Tokyo and the center reveal a certain disconnect.

Earlier Sunday, headquarters had ordered one thousand spare car batteries, but delivery to the plant was held up for hours by delays in obtaining the government permits necessary to use the expressways. By Sunday night, with the shipment still en route and batteries in employees’ cars and trucks already appropriated, the need for the additional batteries had grown critical. About 7:15 p.m., an announcement blared over the public address system at Fukushima Daiichi: “We are going out to buy some batteries, but we are short of cash. If anyone could lend us money, we would really appreciate it.”

And despite his responsibilities managing the deepening crisis, Yoshida’s bosses expected him to keep up with the paperwork. The previous night TEPCO headquarters had called the exhausted superintendent asking him to submit his night shift schedules. Yoshida, who at that moment was struggling to get vital water into the Unit 1 reactor, responded: “I’m a bit too beat to prepare them now.” Headquarters persisted and Yoshida eventually replied, “[N]one of our workers can go home anyway. It’s just a question of whether they are awake or asleep.” Whether that satisfied the timekeepers at headquarters is unknown; by the time Yoshida responded to them, they had all gone home for the night.

Back in the United States, it was early Sunday morning when the NRC’s emergency operations center received a call from Admiral Kirkland Donald, director of naval reactors at the National Nuclear Security Administration, a semiautonomous division of the DOE. Donald wanted to notify the NRC and the DOE, which joined the call, that the U.S.S. Ronald Reagan, a nuclear-powered aircraft carrier off the coast of Japan, had “picked up some activity out at sea that we think you need to be aware of and probably need to be addressing with the Japanese government.” The “activity” was radiation.

The Ronald Reagan and six other navy vessels from the Seventh Fleet had been en route to South Korea to participate in joint naval activities there when they were diverted to Japan after the earthquake to help in relief efforts. The ships had taken up position about one hundred nautical miles off Fukushima Daiichi, with the officers thinking they would be outside any radiation plume. Then radiation detectors in the Ronald Reagan’s engine room picked up readings two and a half times normal.

Radiation was also detected on crew members and helicopters that had landed on a Japanese ship fifty miles offshore from the plant. Although the levels were low, the admiral was worried. The measurements were higher than the navy had expected, based on the scant information available. The prospect that U.S. personnel might be at risk became real. (There were more than 3,400 sailors and aviators on the Ronald Reagan alone.) The crew and equipment were decontaminated and the navy ships headed for safer water about 130 nautical miles offshore. En route, the Ronald Reagan continued to detect contamination.

For the navy vessels, getting out of harm’s way was a matter of weighing anchor and moving farther out to sea. It would not be as simple for the tens of thousands of Americans living in Japan. They no doubt were beginning to wonder whether they were safe and where they could go if they weren’t.

Approximately 160,000 U.S. citizens were living in Japan in March 2011. Responsibility for their well-being rested with the U.S. Embassy in Tokyo. U.S. ambassador John V. Roos had put out a call to Washington for guidance almost immediately after the earthquake and tsunami; soon the embassy was also caught up in responding to a nuclear accident. The Japanese were not providing information and relations were growing strained.

The NRC scrambled to get one of its experts aboard a military flight about to depart for Japan late on the evening of March 11. It was such a hasty departure that Anthony Ulses, the chief of the NRC’s reactor systems branch, had no time to pack. By March 14, a total of eleven NRC experts had been dispatched to Japan.

It was that same day, March 14, that the Japanese relented and accepted the U.S. offer of assistance, and as a result more systematic data collection began. The National Nuclear Security Administration sent thirty-three people and eight tons of equipment that are part of its Aerial Monitoring System (AMS). The AMS uses specially equipped aircraft to identify and measure radiation in an emergency. Eventually, a U.S. Global Hawk drone went aloft over the reactors to begin gathering data and images that were shared with the Japanese government.

On the morning of March 14, radiation levels at monitoring posts around Fukushima Daiichi were high, and the drywell pressure in Unit 3 was again starting to rise. Workers had successfully vented the containment three times the day before—or at least thought they had—and now needed to do so again. Although they managed to get power and compressed air to the necessary valves by using a portable generator, the drywell pressure continued to increase. The crew was aware that there had been a gap of more than five hours between the time it shut down the HPCI and the time it managed to set up the fire engine to inject water into the core: more than enough time for significant core damage to occur.

Even worse, although water was being pumped into the reactor, the level inside did not appear to be rising. No one had known for quite some time just how much water had been getting into the reactor vessel, because of the intermittent operating histories of RCIC, HPCI, and the fire engine. Workers feared that Unit 3 might now be following a trajectory similar to that of Unit 1. Meanwhile, another crisis was about to emerge in an unexpected place.

While plant personnel focused on cooling the three reactors that had been operating when the earthquake struck, trouble was slowly brewing in one of those that had been shut down on March 11. In the spent fuel pool of Unit 4, the water temperature was steadily rising, inching toward the boiling point. At the time of the earthquake, Unit 4 had been out of service for maintenance, and the entire reactor core was sitting in the spent fuel pool, high above the reactor vessel. Consequently, the fuel pool was loaded with more than 1,500 fuel assemblies. More than one-third of the spent fuel assemblies had been removed from the core just three months earlier, meaning they were still relatively “hot” in terms of both temperature and radiation levels. Of the seven spent fuel pools at Fukushima Daiichi—one for each reactor plus a common pool for extra storage—the Unit 4 pool had the highest heat load by far.

The spent fuel pools are big tanks of water, forty-five feet (fourteen meters) deep, with walls and floor made of reinforced concrete and lined with steel. Spent fuel assemblies are stored in racks in the lower third of the pools. The large volume of water above the racks provides radiation shielding. Without the water to provide shielding, the radiation level even at the rim of the pool would be quickly lethal to workers. Because spent fuel generates heat and high levels of radioactivity for many decades after discharge from a reactor, active cooling systems are critical. During normal operation, pumps circulate water to maintain a pool temperature of about 100°F (40°C). Once cooling is interrupted, the water in the pool will begin to heat up, and if it should reach the boiling point losses can mount rapidly.

The spent fuel pools at Units 1 through 4 had been without power to circulate cooling water for almost three days. Yet until now operators had paid little attention to them. For decades, engineers believed that spent fuel pools posed much less safety risk than operating reactors and hence required far less protection. Compared to fuel assemblies in an operating reactor core, most assemblies stored in spent fuel pools are cooler and less radioactive, because they have been out of a reactor for years and their shorter-lived fission products have decayed away. If a spent fuel pool were to lose cooling, operators typically would have days to respond before the massive volume of water in the pool could heat up enough to boil and eventually uncover the fuel. More severe scenarios—such as a massive earthquake that might damage the integrity of the pool structure itself—were regarded as too improbable to worry about.

This lackadaisical attitude informed the way spent fuel pools were designed and built. Regulators in the United States and elsewhere who reviewed boiling water reactor designs did not require that the spent fuel cooling systems be as robust as those for the reactor core. Nor did they require that the pools be surrounded by leak-tight, pressure-resistant containment structures such as those mandated for the cores. And, in approving GE’s Mark I and II reactor designs, the regulators saw no problem in having the spent fuel pool perched on the fifth floor of the reactor building and topped only by a steel frame structure, despite the obvious dangers such an arrangement might pose in a serious accident.6

The safety of these pool designs was predicated on the ability of operators to restore cooling within a few days. Apparently little thought was given to the question of what would happen if they couldn’t respond promptly—say, if they were occupied with a prolonged loss of power and three reactor meltdowns simultaneously. Neither did the designers or regulators worry much about what would happen if the operators didn’t have as much time to act as everyone assumed—for instance, if a large earthquake caused the pool to lose water by sloshing it over the sides or cracking the liner and causing it to leak.

What could happen is this: if the water level did decrease and uncover the fuel rods, they could overheat and melt, much like those inside the reactor—but with one critical difference. The spent fuel is not enclosed by the robust primary containment.

Even though the amount of heat in a spent fuel pool is far lower than that in a reactor, the zirconium alloy cladding encasing the hottest rods can catch fire if it reaches a temperature of 800°-900°C, generating its own heat source. This in turn could rapidly damage the fuel pellets themselves and allow the release of gaseous isotopes, like the long-lived cesium-137. Under certain circumstances, such a fire could spread to other assemblies in the pool. And because typical spent fuel pools hold more fuel than a single reactor core, a fire that involved the entire pool could release more cesium-137 than a reactor meltdown. (Iodine-131, another major isotope of concern in a reactor accident, poses much less risk in a spent fuel pool. It would not be present in significant amounts unless the fuel in the pool was less than three months old; after that time, the iodine-131 would largely have decayed.) And finally, reaction of the zirconium with steam would produce explosive hydrogen gas, just as it did in the damaged reactor cores at Fukushima Daiichi.

At that point, the only barrier between these isotopes and the environment would be the leaky, flimsy top of the reactor building. Such a structure had already proven to be no match for the hydrogen explosion that occurred at Unit 1. When that happened, radiation levels did not increase very much because the primary containment inside the building remained intact. But a hydrogen explosion resulting from a spent fuel fire at Unit 4’s spent fuel pool, occurring in a largely uncontained environment, would release a catastrophic amount of radiation.

By the time operators began to focus on ways to cope with the rising temperature in the Unit 4 pool, the radiation level there was already so high that it precluded any human intervention to get water into the pool using temporary pumps. As they began to explore other approaches, the operators knew time was against them.

But on this Monday morning, March 14, the next explosion to hit Fukushima Daiichi came not from Unit 4, but from Unit 3. At 11:00 a.m., a huge blast blew out not just the upper sections of the reactor building, as had happened at Unit 1, but also large sections of the walls, injuring a number of people nearby. Debris fell into the Unit 3 spent fuel pool and onto the ground, where it damaged the fire engine and hoses positioned to inject seawater into the reactor. Once again, hours of painstaking work were undone in an instant.

Smoke pours from Unit 3 following a blast at 11 a.m. on March 14. Falling debris injured workers on the ground and damaged firefighting equipment that was being readied to inject vital cooling water into the reactor. Tokyo Electric Power Company

By early afternoon, radiation levels above thirty rem (three hundred millisieverts) per hour were detected just north of Unit 3, raising concerns that the core had already undergone significant damage and that the explosion had dispersed radioactive material around the site. The rising radiation also rendered part of the Units 3 and 4 control room unsafe, further hampering operators’ ability to gauge the condition of the reactor.

Compared to the seriously damaged Units 1 and 3, Unit 2 had seemed like a success story. In contrast to Unit 3, the RCIC at Unit 2 had apparently continued to operate on its own for nearly three days, keeping the water level from dropping and exposing the core. This was remarkable, because ordinarily the RCIC should not have been able to operate for that long without battery power. But operators knew it couldn’t keep running indefinitely.

The RCIC transferred heat from the reactor vessel to the torus, but that heat remained within the containment, which itself was already overheated. Without any means of external cooling, pressure and temperature in the containment continued to increase. The RCIC had not been designed to function under such punishing conditions. And at around 1:30 p.m. on March 14, it looked like it had finally quit. The Unit 2 water level started to drop. Now it was clear that, without prompt action, Unit 2 would suffer the same fate as Units 1 and 3.

For exhausted shift operators, some of whom had been on duty for three days without sleep, the crises seemed to have no end. The operators needed to inject water into the Unit 2 reactor vessel as soon as possible to keep the core from being exposed. But just as at Units 1 and 3, they first needed to vent the containment. Otherwise, they would not be able to depressurize the reactor vessel adequately to force water into it with the fire engines. Yoshida had anticipated this eventuality right after the Unit 1 explosion and had ordered workers to prepare the means both to vent the Unit 2 containment and to inject water into it when needed.

But Yoshida had not anticipated the Unit 3 explosion, which disrupted both the Unit 2 containment vent line and the alternate water injection line that workers had established. This setback marked the third strike against the doomed plant. Working amid rubble, aftershocks from the earthquake, and high radiation levels, a crew raced against time to repair the damage to the Unit 2 vent line and to construct a new water injection line. Workers tried to vent the containment at 4:00 p.m. but failed. Meanwhile, the water level inside the reactor vessel kept dropping. By 4:30, the top of the core was exposed.

TEPCO president Shimizu ordered Yoshida to try to inject water into the reactor vessel without waiting for venting to succeed. But to make the attempt, workers needed to open a safety relief valve that would move steam from the reactor vessel into the torus. Efforts to open the valve were complicated by a lack of battery power. (This relief valve is different from the containment vent valves that workers struggled with on Units 1 and 3.)7

Once again, a search was mounted for batteries to energize the safety relief valve. These were carried to the control room and connected, but they lacked enough voltage. The water level continued to drop. Finally, at about 6:00 p.m., additional batteries allowed the valve to be opened. But the water was now so low it didn’t even register on the gauge, meaning that the core might be completely uncovered. Also worrisome was the fact that, although hydrogen and radioactive gases were flowing into the containment, pressure there was not rising, as it had in the other units. The containment possibly had sprung a leak, allowing gases to escape into the reactor building and out through the hole blown in the side of the building when Unit 1 had exploded.

By 7:00 p.m., pressure inside the Unit 2 reactor had dropped far enough for the fire engine pump to force water into the core. But a passing worker discovered that the fire engine, which had been idling while awaiting the injection operation, had run out of fuel. The engine was restarted shortly before 8:00 p.m., but water levels in the core remained too low to measure. Soon pressure inside the reactor rose again, thwarting the fire engine pump. The intense heat from the exposed fuel was quickly vaporizing the water being injected. As steam refilled the reactor vessel, the pressure increased. To enable the pump to inject water again, the operators managed to open a second relief valve. That appeared to do the trick; water inched up to cover part of the fuel. But the progress came at a cost: steam pressure inside the reactor was on the rise too. For the next several hours, the operators played cat and mouse with water level and pressure. The steam pressure periodically spiked above the water pressure of the fire engine hoses, and the operators could not be certain how much water was getting into the reactor vessel.

At the same time, operators were trying without success to vent the Unit 2 containment. According to the gauge readings, by now the containment pressure should have forced the vent open by blowing through a rupture disk, but it had not. The pressure in the drywell suddenly began to rise rapidly, and Yoshida was afraid it would burst. He decided it was necessary to try to vent the drywell directly—an action that was considered a last resort because it would allow radioactive gases to escape into the environment without first being filtered through the water in the torus. However, for better or worse, operators were not able to vent the drywell either.

The operators continued to struggle through the early hours of March 15 to find a way to vent the containment. At 6:00 a.m., just as a shift change in the Units 3 and 4 control room was taking place, a noise that sounded like an explosion was heard in the area around the torus beneath the Unit 2 reactor vessel. Pressure in the torus dropped, suggesting that the explosion had damaged the torus and allowed its contents to escape into the reactor building. If the containment had actually been breached, vast amounts of radiation could soon spill out into the environment.

Then, around the same time, a hydrogen explosion ripped through the Unit 4 reactor building, collapsing the top two stories of the five-story structure. The incoming and outgoing control room crews fled to the safety of the Seismic Isolation Building, retracing their route on foot this time because the concrete and rubble covering the ground near the reactor made car travel impossible. In their cumbersome radiation suits and breathing equipment, it took them nearly two hours to make their way to the building and alert Yoshida of the damage to Unit 4.

At about 6:20 a.m. on March 15, a huge explosion rips apart the top two stories of Unit 4, exposing the spent fuel pool. Until then, Unit 4 had seemed to pose the least threat in the first days of the accident. Tokyo Electric Power Company

The workers at Fukushima had experienced many surprises in the past few days, but the explosion at Unit 4 must have come as a particular shock. Although they were aware that the temperature was rising in the spent fuel pool, they believed that Unit 4 was the least of their problems. Now it appeared that the pool had heated up much faster than they had expected, so rapidly in fact that the spent fuel might have become uncovered, sustained damage, and generated explosive hydrogen. But even more worrisome was the realization that the other spent fuel pools at the site might also be in jeopardy—a particular concern given that the pools at Units 1 and 3 were now directly exposed to the environment. In an instant, the spent fuel pools went from being a low priority to an immediate threat.

In response to the deteriorating situation, at 11:00 a.m. Prime Minister Kan ordered residents between about twelve and eighteen miles (twenty to thirty kilometers) of the reactor to remain indoors. Those who hadn’t already fled now became housebound, relying on their small frame homes to protect them from whatever might happen next, and not knowing when they might be allowed out again. No one had ever warned them to prepare for a situation like this.

With the catastrophic events at Fukushima Daiichi showing no sign of slowing, the radiation exposure levels of the workers grappling with the disaster had begun to worry government and utility officials in Tokyo. The government came up with a solution: increase the allowable limits of exposure.

On March 14, the government agreed to raise the maximum allowable radiation dose for workers in an emergency from ten rem (100 millisieverts) per year to twenty-five rem (250 millisieverts) per year. The decision, announced the following day, was based, in part, on fear that soon everyone at Fukushima Daiichi might exceed the existing exposure limit and thus be required to leave. Already workers had to perform tasks in short bursts to stay within cumulative dose limits.8

That evening, TEPCO president Shimizu was told that, because of the worsening conditions, Yoshida was considering evacuating about 650 nonessential personnel from the plant. Shimizu telephoned the head of NISA before dawn on March 15 to apprise him of the grave conditions at Unit 2 and noted that if things continued to worsen, the company might pull out some personnel. In another instance of bungled communication, Shimizu apparently did not make it clear that essential workers would remain.

Officials in the prime minister’s office feared a total abandonment of the plant, in which case the dangers would grow exponentially. At around 4:00 a.m., an angry Kan summoned Shimizu to his office, where the utility chief told him there was no plan to abandon the plant. (The media reported that Kan, irate that he was not informed of events at the plant, shouted at Shimizu, “What the hell is going on?”) The encounter apparently convinced both Kan and Shimizu that the lines of communication—and cooperation—needed to improve quickly. The two men agreed to establish a government-TEPCO integrated response center at the utility headquarters.

About ninety minutes later, Kan visited TEPCO headquarters to make it clear that the government was asserting a stronger role in the accident response. En route, he said later, he considered a worst-case scenario in which evacuations could extend as far as metropolitan Tokyo, population 13 million. (Indeed, mass evacuations might have been necessary, according to a worst-case assessment prepared at Kan’s request by the chairman of the Japan Atomic Energy Commission and presented to the prime minister on March 25.)

The TEPCO showdown coincided with the arrival of the latest bad news from Fukushima Daiichi: the possible containment rupture at Unit 2, followed by the blast in the Unit 4 spent fuel pool.

When the Japanese finally did ask for help from the United States on March 14, they were looking for heavy-duty pumping equipment that could deliver seawater to pits from which it could then be injected into the reactor cores via fire engines. U.S. military forces in Japan had firefighting equipment that would fit the bill, and discussions already were under way with TEPCO.

Over the course of that day, NRC staffers began arriving in Tokyo, including Tony Ulses and Jim Trapp, both experts in boiling water reactors. Finally, the NRC’s emergency operations center at White Flint had eyes and ears on the ground. The NRC team joined experts arriving from other government agencies, most of them based at the U.S. Embassy.

Later on Monday, Jack Grobe, the NRC’s deputy director for engineering, was manning the White Flint Operations Center when Chairman Jaczko telephoned for an update. Grobe had worrisome news: the prevailing winds in Japan, which had been carrying radiation out to sea, were about to shift to the southwest—toward Tokyo. With three reactors and the Unit 4 spent fuel pool in trouble, “that changes the dynamic of the protective measures aspects of this,” Grobe told his boss. Vast numbers of people could now be downwind. As a result, the Operations Center had summoned additional staff experts on radiation dose assessments and meteorology. But so far, Grobe told Jaczko, Japan’s 12.4-mile (twenty-kilometer) evacuation zone around Fukushima Daiichi was “consistent with what we would recommend.”

Marty Virgilio then called Grobe to tell him U.S. nuclear industry officials now speculated that there was a crack in the torus at Unit 2. If true, this could dramatically change the team’s assessment of the situation. The torus was part of the primary containment. Up to that time, as bad as things had gotten, the NRC was not aware of evidence that the primary containments at any of the reactors had experienced a major rupture. Such a breach could release dozens of times as much radioactive material as the minor leakage that had previously occurred. Given the projected wind shift inland, a Unit 2 containment failure could have catastrophic consequences for a large segment of the Japanese population.

“I mean, this is beginning to feel like an emergency drill where everything goes wrong and you can’t, you know, you can’t imagine how these things, all of them, can go wrong,” said Grobe. No drill had ever come close to this.

But the bad news hadn’t stopped arriving. Jim Trapp called to say that an admiral at the U.S. naval base at Yokosuka, south of Tokyo and 188 miles from Fukushima Daiichi, was reporting radiation measurements of 1.5 millirem (0.015 millisievert) per hour, apparently because of the wind shift. The NRC team was astonished that such a high dose rate would be detected at such a great distance from the plant.

Trapp added one more ominous bit of information from Japanese officials about the blast inside Unit 2: “[T]hey do believe they breached the primary containment.” Tony Ulses, also on the phone, raised an even more frightening prospect: the loud noise heard in Unit 2 “was probably when the core went X-up”—meaning when it had melted through the bottom of the reactor vessel. “Landing in the water under the vessel, it would have caused a little steam explosion,” said Ulses.

“Believe it or not, Jack, we’re telling you the good news,” Trapp told Grobe. Then he launched another dire litany, based on information gleaned from NISA officials in Tokyo. No one was certain of the water level in the spent fuel pool at Unit 3; as a result of the explosion, the reactor building “really collapsed into the fuel pool.” Radiation of ten rem (one hundred millisieverts) per hour was being measured near Unit 4, which could prove lethal after a day or two of exposure. (For context, workers at U.S. nuclear reactors are limited to five rem per year and generally receive far less than that.)

In an attempt to find some good news to pass along to his exhausted colleagues in Tokyo, Grobe told Trapp and Ulses that additional NRC staff members were en route. But that prompted a word of warning from Trapp: “[W]e’ve got to think about … whether we want them to come.”

“I mean,” added Ulses,” we’re getting to the point where this is just more bodies to have to get back out of here possibly.”