Higher: 100 Years of Boeing (2015)

7 To the Moon and Beyond

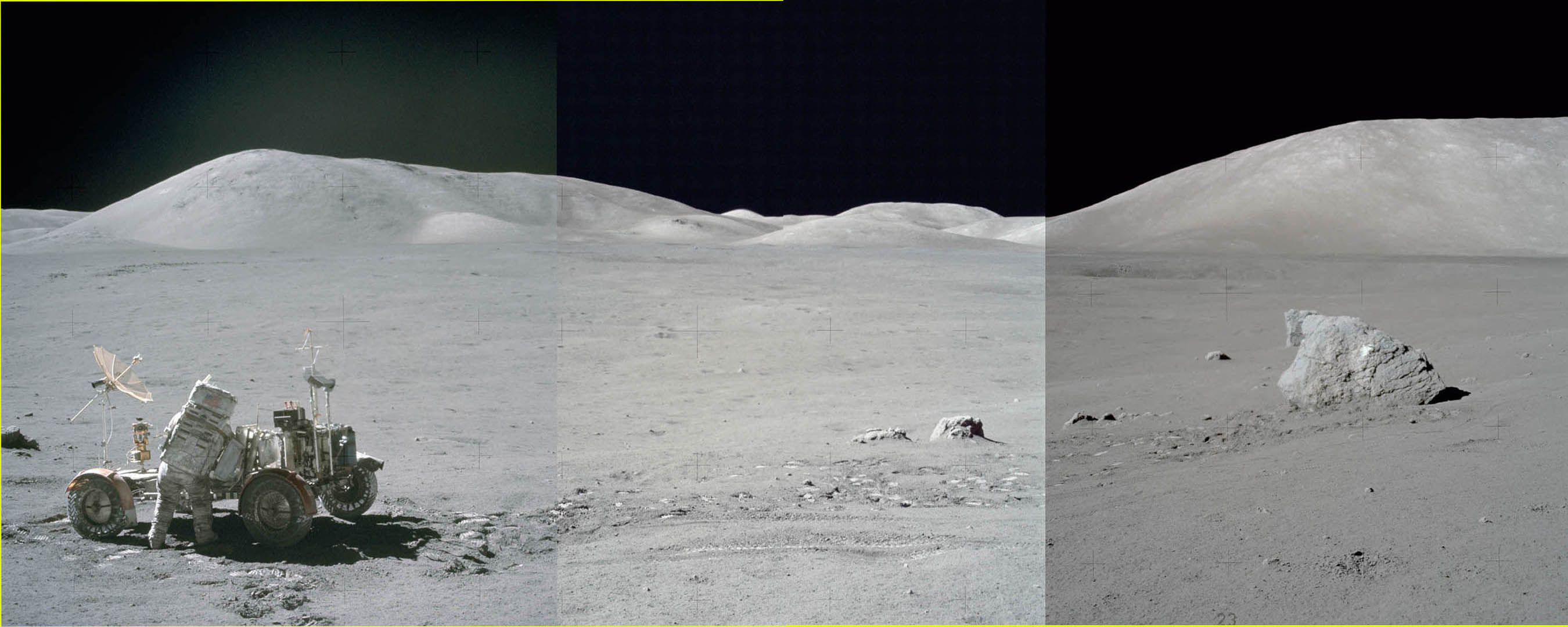

An astronaut uses the Boeing-built Lunar Roving Vehicle to explore the terrain of the moon.

The Cold War between the United States and the Soviet Union was as much a battle of ideas as it was a series of regional conflicts. Each of the superpowers jockeyed to be the technological leader of the world. Throughout the 1960s, the United States lagged behind the USSR, which had put the first satellite and first human being in space. President John F. Kennedy had tasked NASA with the goal of landing astronauts on the moon by the end of the decade in part because he was aware of the importance of global scientific leadership. This was one “first” the United States did not want to lose.

The bulk of this extraordinary effort would fall on the shoulders of the American aerospace industry. Much as they did during World War II—when Boeing, McDonnell Aircraft, North American Aviation, and Douglas Aircraft augmented each other’s skill and expertise and collaborated to win the war in the skies—aerospace companies allied to win the race to the moon.

“They wanted to participate in what they saw as a national enterprise, something that would be worthy of national glory,” said science historian Asif Siddiqi. “They were proud to do it. And their cooperation was very crucial to the success of Apollo.”

Project Apollo was NASA’s third (after the Mercury and Gemini projects) and most ambitious spaceflight program, conceived with an audacious purpose: ferrying astronauts to and from the moon. Nowhere was the industry’s shared legacy more profound than in Project Apollo’s nine manned and unmanned expeditions to the moon between 1969 and 1972. Virtually all of Project Apollo’s spacecraft and launch vehicles, including the Saturn V rocket, Apollo command and service modules, and Lunar Roving Vehicle, were designed, developed, and built by Boeing and the aerospace manufacturers that would later become part of it.

Each manufacturer possessed a wide array of scientific, technological, and engineering skill sets. Their combined efforts represented a mobilization of American industry that had not been seen since the end of the war—the arsenal of democracy was again collaborating toward a shared national purpose, tackling the most complex project in history at the time.

“There were 400,000 Americans who worked on [Project Apollo],” said former NASA astronaut Frank Borman. “They were all dedicated and they all wanted to win. That was the key. We win. They lose.”

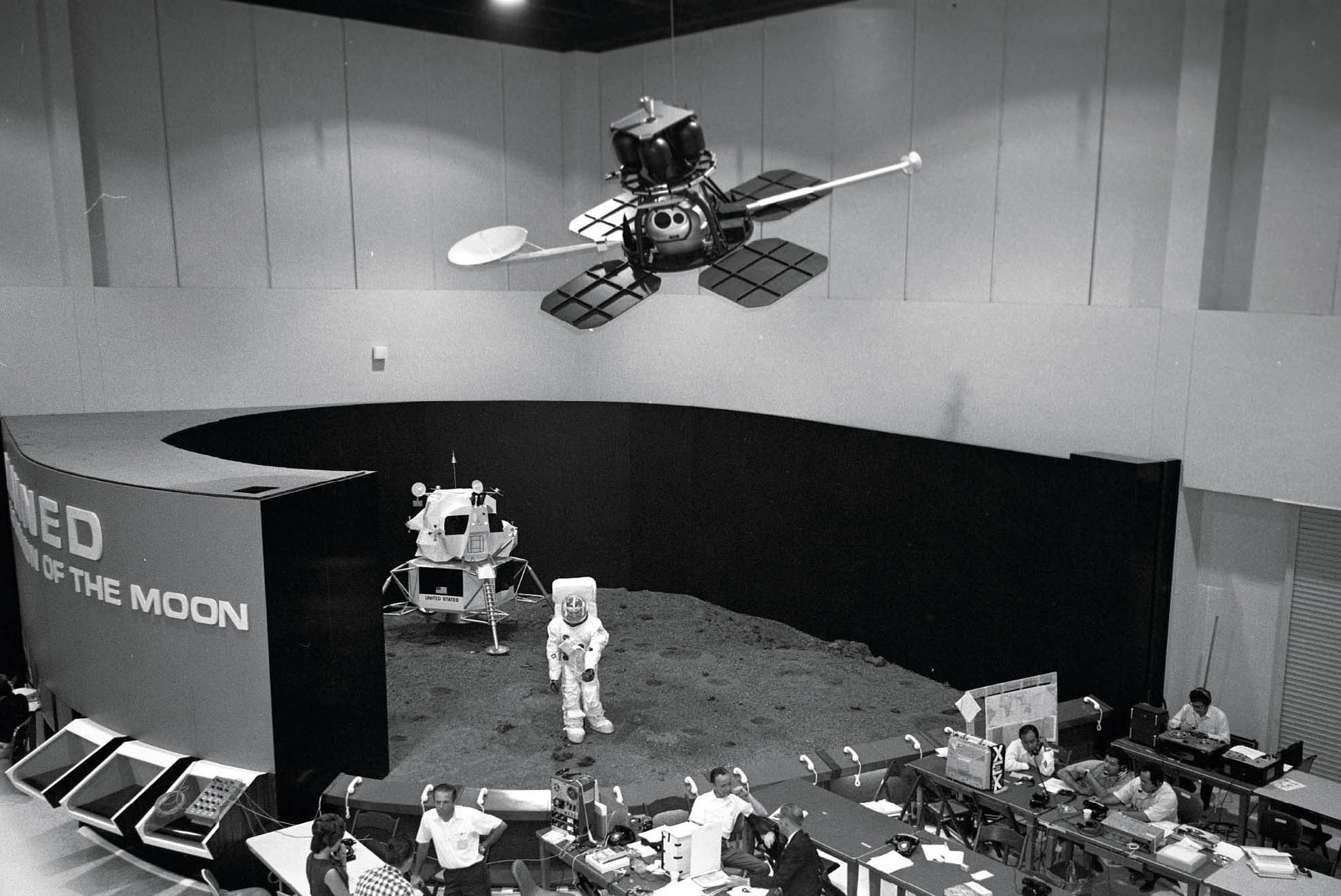

Winning meant the program would need to carefully design, develop, test, and take a series of challenging technological steps leading to the eventual landing of astronauts on the moon. To assure safe landing sites for the manned Apollo command module, for instance, Boeing built crewless Lunar Orbiters to circle and photograph the moon’s surface. The five orbiters had to operate precisely because photos could only be taken under the proper light and temperature conditions.

The first picture of Earth rising above the moon’s cratered surface in 1966, taken by Lunar Orbiter 1, was hailed by many as one of the greatest photographs of the 20th century. People were awed seeing the planet from such a perspective.

Tellingly, the photograph was snapped at roughly the halfway point of Boeing’s 100-year history. In just 50 years, the company had gone from making an open-cockpit biplane out of wood and cloth to creating an unmanned metal craft that could circle the moon and take pictures of Earth.

A mock-up of the Boeing-built Lunar Orbiter is displayed above a model of the moon’s surface.

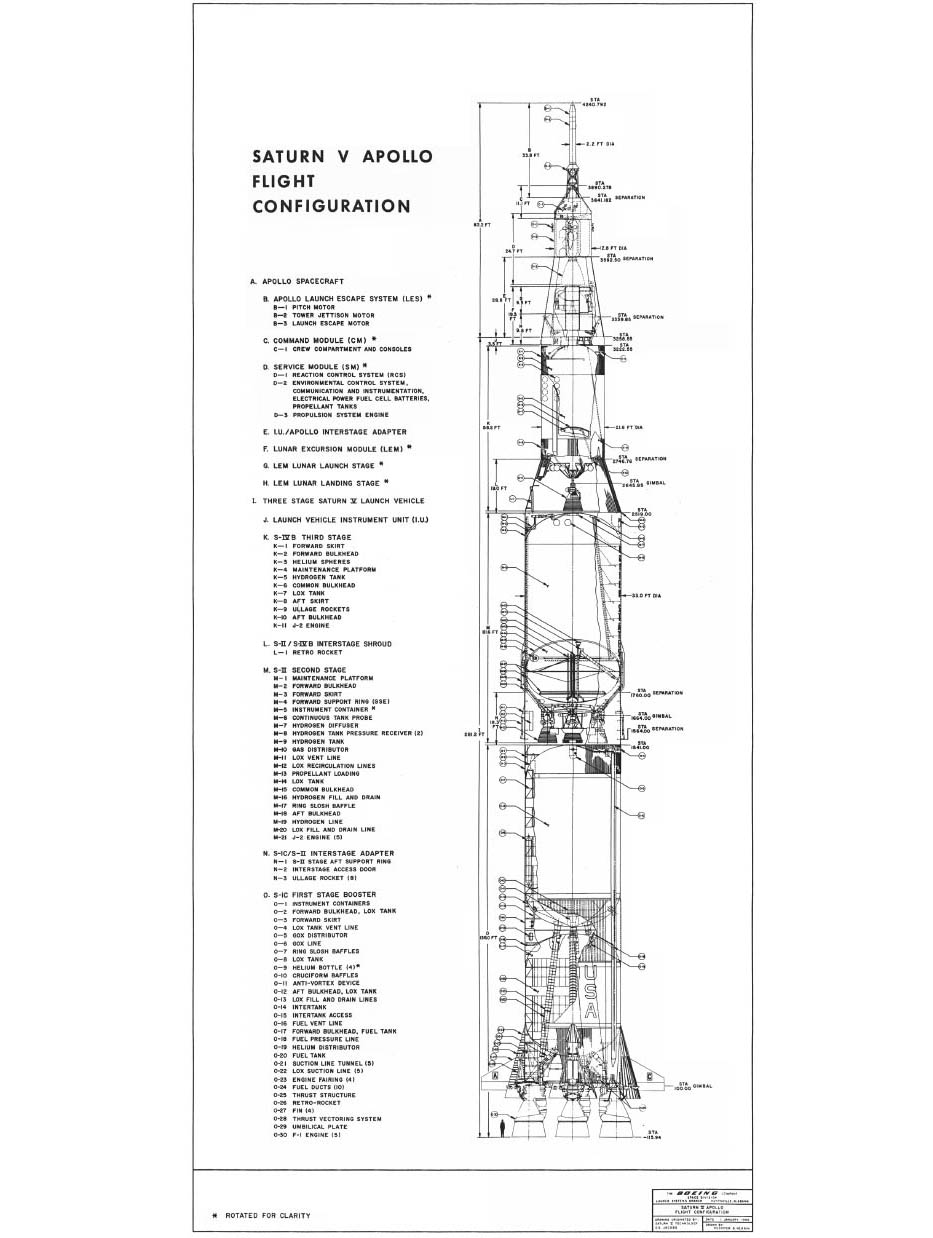

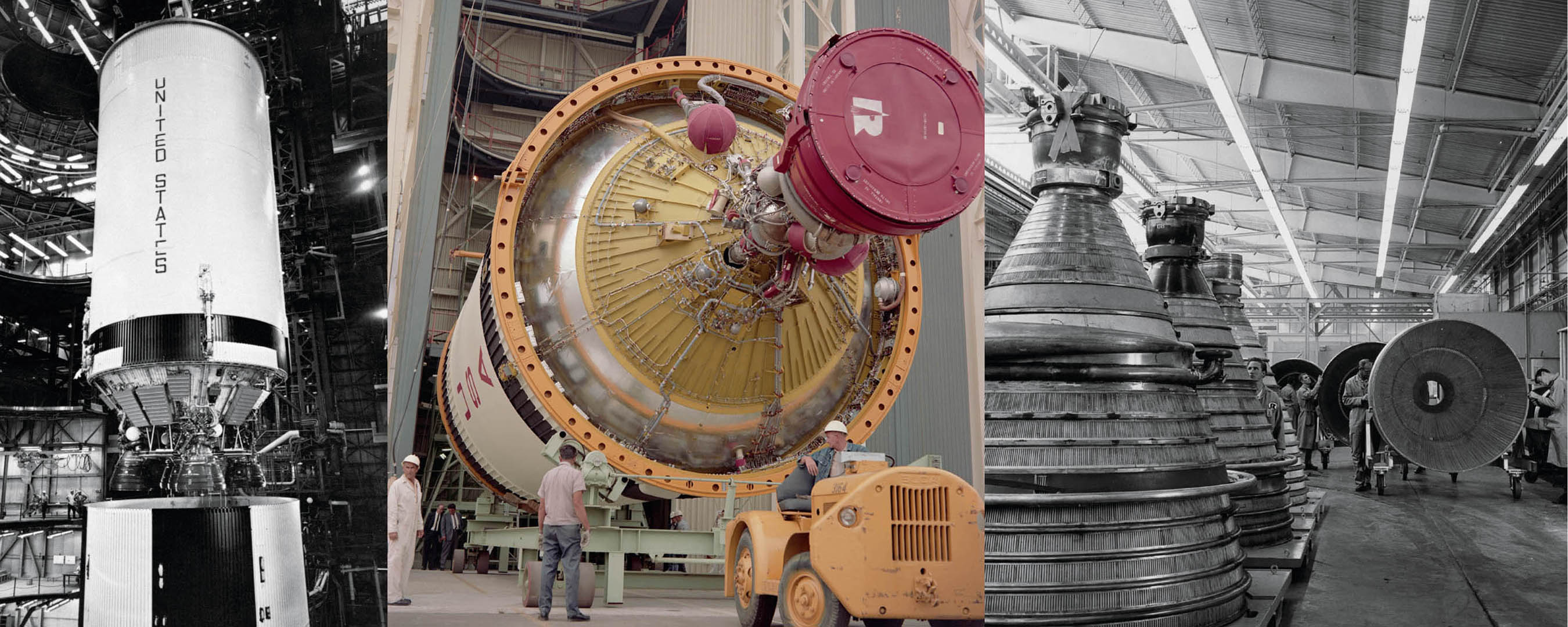

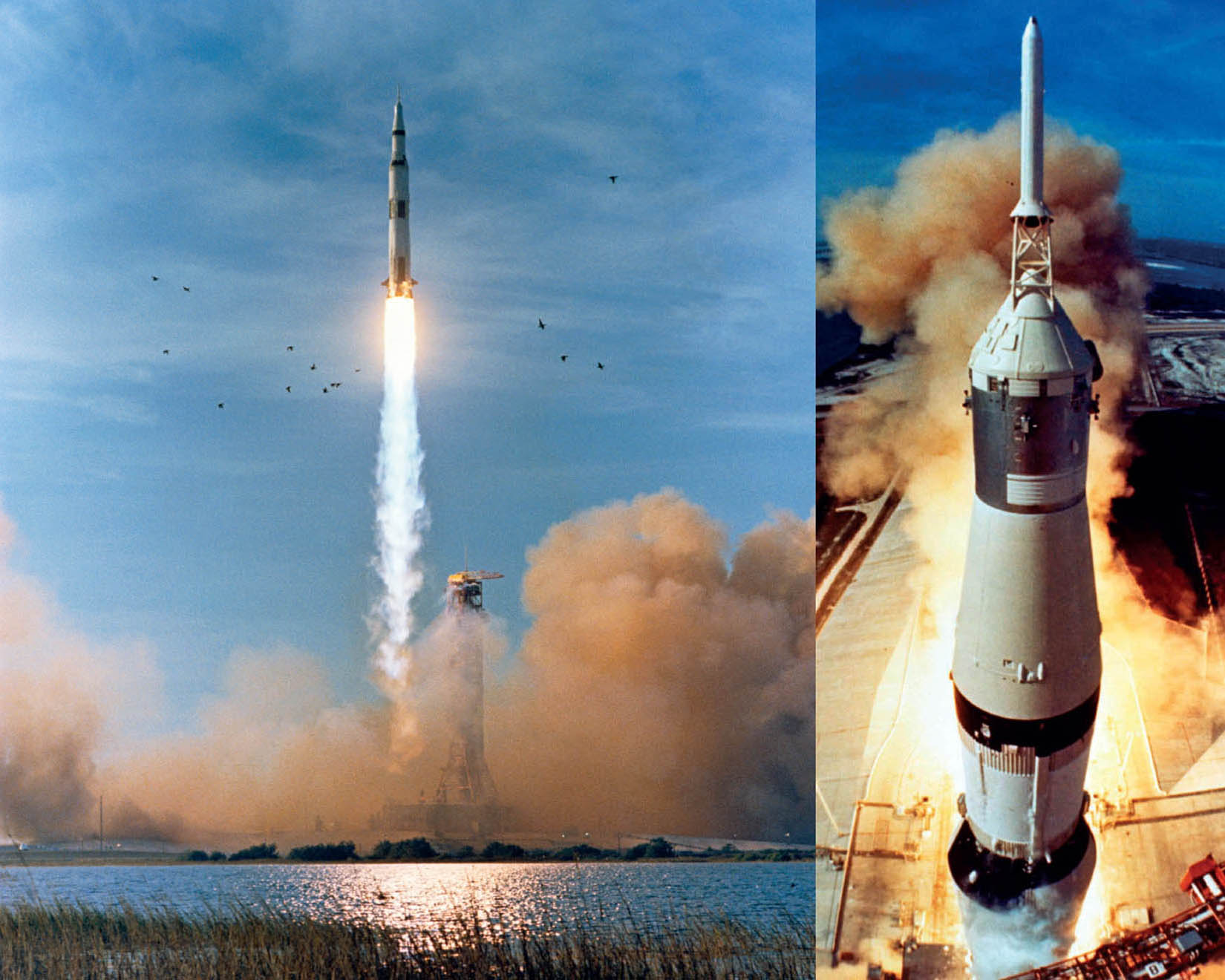

The Saturn moon rocket was an example of collaboration among aerospace companies. Boeing was in charge of the rocket’s first stage

North American, the second stage; and McDonnell Douglas, the third stage. North American’s Rocketdyne built the engines for all three stages.

As planning for the Apollo missions progressed, NASA and the aerospace industry relied heavily on Wernher von Braun and the hundreds of other German engineers and technicians brought to the United States after the end of the war.

Von Braun was put in charge of developing the Saturn V rocket, the powerful multistage liquid-fueled rocket that would serve as the launch vehicle for the Apollo lunar craft. Saturn V involved three propulsion stages. Boeing was in charge of building stage one, North American Aviation was responsible for stage two, and Douglas Aircraft for stage three. North American’s Rocketdyne division made all the engines. The rocket was composed of more than three million parts and 700,000 components, and much of this technology was original.

“Each one of those parts has to meet thousands of individual specifications and requirements to make sure it does its job, that one part,” said Boeing chief technology officer John Tracy of the challenge. “And then all those parts have to come together … and work together without fail.”

All three stages of the rocket were critical and required unparalleled collaboration among the three aerospace manufacturers. For liftoff, more than 203,400 gallons of kerosene fuel and 318,000 gallons of liquid oxygen were needed. Once ignited, the first stage’s five F-1 rocket engines produced more than 7.5 million pounds of thrust, creating more power than 85 Hoover Dams. At an altitude of 42 miles, the second stage ignited as the first stage disengaged from the launch vehicle. Then, at nine minutes and nine seconds into the launch, the third stage’s engines fired and the second stage was discarded.

The Saturn V multistage liquid-fueled rocket was the launch vehicle for the Apollo missions. The Saturn V second stage is shown at far left; third stage at left; and Rocketdyne J-2 engines at right.

To provide the heavy lift needed to launch the lunar craft to the moon, Saturn V had to be not only complex but gargantuan. Fully fueled, the rocket weighed 6.2 million pounds and was taller than a 36-story building.

Boeing became the technical integrator and coordinator of the Apollo project following a devastating fire in the command module during preparations for the first crewed Apollo flight in 1967. Three astronauts—Gus Grissom, Roger Chafee, and Ed White—perished in the disaster, compelling NASA to reach out to Boeing for help. Boeing President Bill Allen responded, “We’ll help the nation in any way that NASA wants.”

NASA and Boeing entered into a historic Technical Integration and Evaluation (TIE) contract to support Apollo by strengthening the program’s management to avoid another safety setback in the quest to reach the moon by decade’s end. Allen assigned more than 2,000 Boeing managers to assist NASA, while dozens of others worked on the overall systems integration.

Management of the integration effort was entrusted to George Stoner, vice president and general manager of the Boeing Space Division. Stoner was responsible for ensuring that the millions of pieces of hardware making up the spacecraft’s myriad components were in perfect working order. He was also in charge of the space project’s schedule.

Because reliable, secure communications were crucial, Boeing worked with a number of major U.S. companies including Xerox, AT&T, and Western Union to establish the Blue Network, a dedicated system connecting key managers at NASA facilities with Boeing personnel.

The first Saturn V was launched, unmanned, as Apollo 4 in 1967. The first successful manned mission was Apollo 7 in October 1968; it used the Saturn 1B rocket. The first manned mission involving the Saturn V launch vehicle was Apollo 8, which orbited, but did not land on, the moon. Piloted by Frank Borman, Apollo 8 reached the moon on December 24, 1968. “A machine of that size, of that scope, working perfectly—unbelievable,” Borman said.

The importance of the historic flight cannot be overstated. Borman and fellow crewmates Jim Lovell and Bill Anders were the first human beings to see Earth as a bright-blue planet, the first to reach the moon, and the first to orbit the moon—10 times over the course of 20 hours. They had traveled farther than anyone had gone before, and without a lunar module to take them back if something went wrong. As they circled the moon that Christmas Eve, they read verses from the Book of Genesis as millions listened and watched from their television sets at home. They snapped another iconic photograph of the planet and broadcast it to the world, this one in full color—Mother Earth as a vividly alive world spinning in the vastness of space.

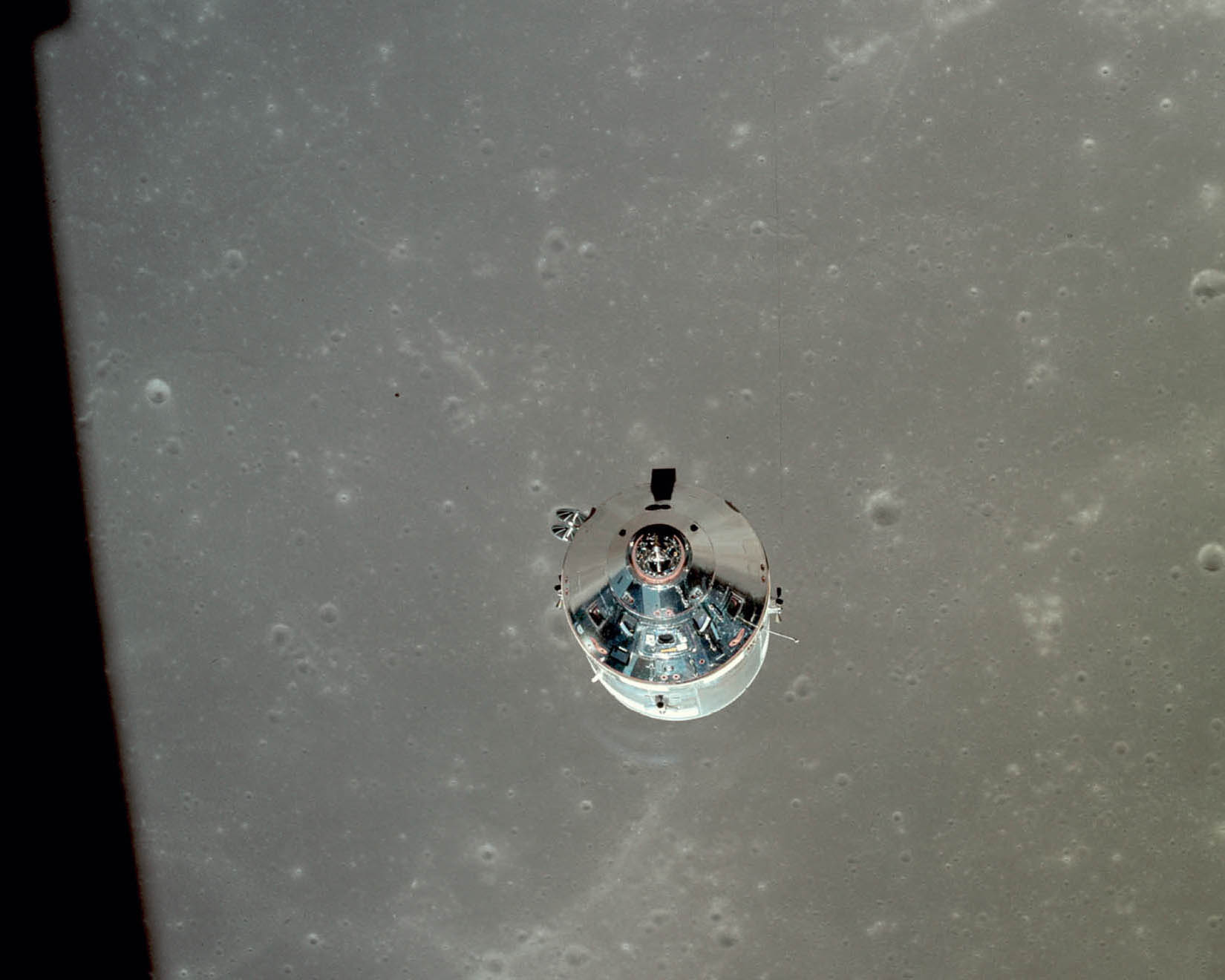

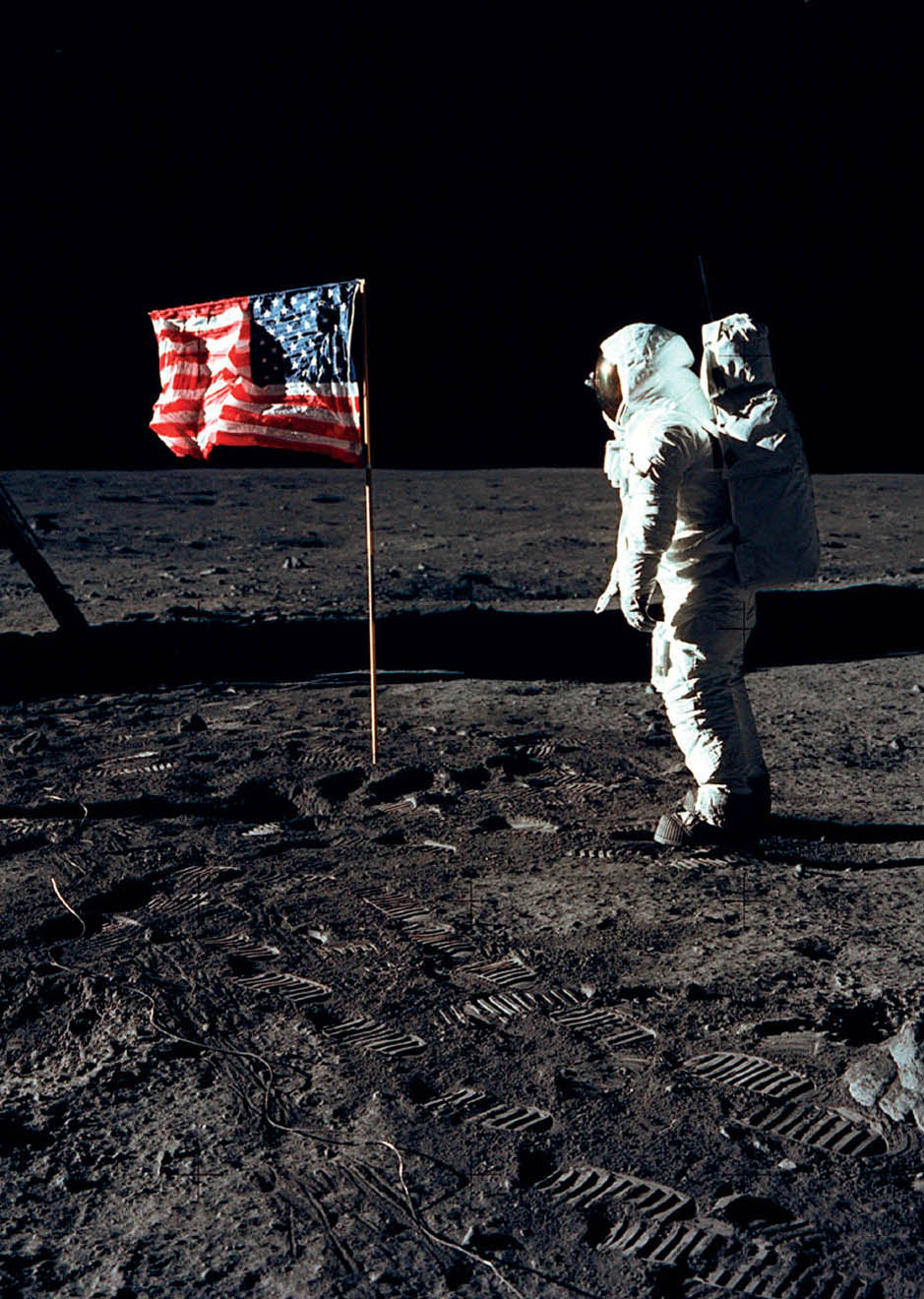

The launch of Apollo 11 in 1969 finally achieved President Kennedy’s vision. Astronaut Neil Armstrong became the first human being to walk on the surface of the moon. The Apollo 11 command module that transported Armstrong and fellow astronauts Edwin “Buzz” Aldrin and Michael Collins to Earth’s only natural orbiting satellite was designed and built by North American Rockwell, which along with Boeing was the industry’s primary architect of the Apollo program.

For U.S. aerospace manufacturers, their ability to work together effectively and successfully on the most daunting project in history was meaningful beyond compare. “They all knew they were involved in an immensely satisfying effort, and they really worked together in ways that probably never could have happened in any other program,” said former NASA deputy administrator Dale Myers, who had been in charge of the Apollo Command/Service Module at North American at the time of Apollo 11. But it was not the first time they had pulled together for an important project, nor would it be the last.

Apollo 11 lifts off the launch pad on July 16, 1969.

The North American Rockwell-built Apollo Command/Service Module is shown in orbit above the moon.

Although Boeing’s contribution to the Apollo program was not a moneymaker and its costs would contribute to the company’s financial stress during the 1970s, the work nonetheless provided a wealth of newfound knowledge that would contribute both to its future space endeavors and to more traditional enterprises. Chief among these lessons was how to make aerospace vehicles of greater reliability.

When NASA began preparing for the Space Shuttle program in the 1970s, North American Rockwell was selected as the prime contractor. Unlike previous once-and-done spacecraft, NASA wanted the shuttle to be a reusable transport system—a freight truck in the sky hauling modules and components into space to build the planned International Space Station, deploy satellites, and someday serve as a launch pad for trips to Mars. To meet NASA’s objectives, North American’s Rocketdyne division developed the first reusable liquid fuel engines for the vehicle.

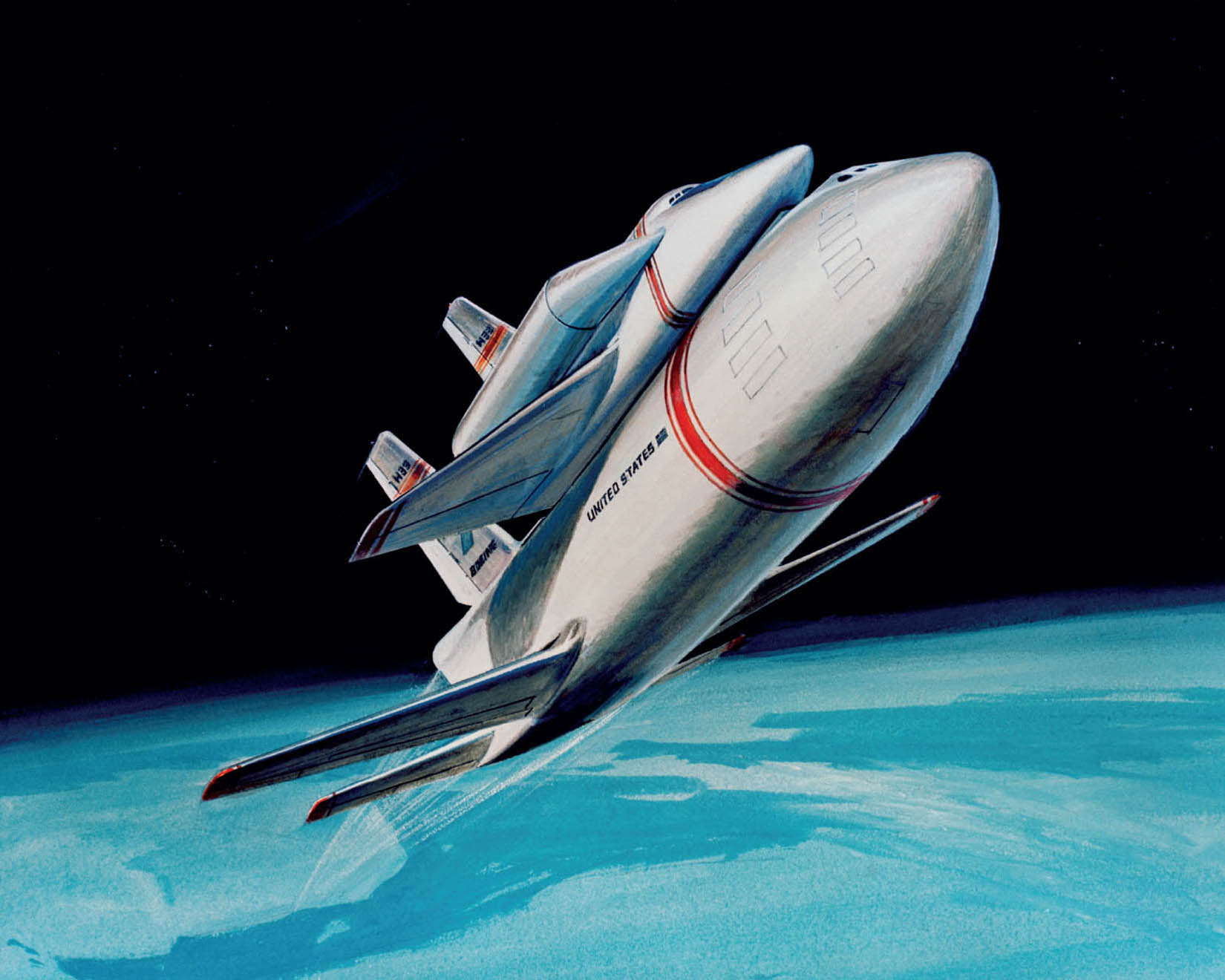

Although creation of the Space Shuttle orbiter fell largely to North American Rockwell, Boeing’s Dyna-Soar, an earlier 1960s project to develop a crewed, reusable space vehicle, played an instrumental role. Later designated the X-20, the futuristic space vehicle featured sharply swept wings, a graphite-and-zirconia composite nose cap, and three retractable struts for landing. Eleven manned flights of the X-20 were scheduled, but the government canceled the program in 1963 because it had no applicable military mission.

It took the cooperative efforts of many cutting-edge companies to put humans on the moon.

Artists’ renderings depict the Dyna-Soar space vehicle (above) and an early Space Shuttle concept (next). Dyna-Soar was canceled before a prototype was made, but it shared similarities with the Space Shuttle as it ultimately evolved.

North American Rockwell’s first orbiter for NASA was named Enterprise after a write-in campaign by fans of the Star Trek television series, which featured a spaceship of that name. Although NASA’s Enterprise was an approach-and-landing test vehicle that had no capability to fly into space, it helped guide the development of the next shuttle orbiter, the Columbia, the first space shuttle to fly into actual orbit. The Columbia’s many triumphs include the first launch of a satellite from a space shuttle and the first flight of the European-built scientific workshop, Spacelab. It made 27 successful round trips. Near the end of its 28th mission in 2003, the Columbia disintegrated upon reentry, resulting in the deaths of all seven crew members aboard. It was the second such disaster after the loss of the shuttle Challenger in 1986.

Over the course of 135 missions through the end of the Space Shuttle program in 2011, the fleet of five shuttles deployed an astonishing array of satellites, stargazing telescopes, and astrophysical instruments. The many components of the International Space Station relied on this space transportation system, as did the deployment of the Hubble Space Telescope. When either needed repair, parts and technicians flew on board a shuttle to service them. The shuttle also had the capability to recover malfunctioning satellites in orbit and return them to Earth for repair and possible relaunch.

The people of North American Rockwell (later Rockwell International) and Boeing played a huge part in making the program possible, but the effort was not their sole focus. Simultaneously, these companies and others in the aerospace industry were putting their respective skills toward manufacturing and launching satellites. Leading the effort this time was Hughes Aircraft.

Following the launch of Sputnik in 1957, Hughes engineers and scientists were intrigued by the communications possibilities that could be afforded by satellites circling the planet. Sputnik was a basic satellite that merely beeped out its location. Harold A. Rosen, an engineer at Hughes, envisioned an array of advanced satellites connecting with television, telephone, and other broadcast signals on Earth and beaming them back across the world. This system would be far more effective and cost-efficient than the physical wires and undersea cables providing global communications at the time.

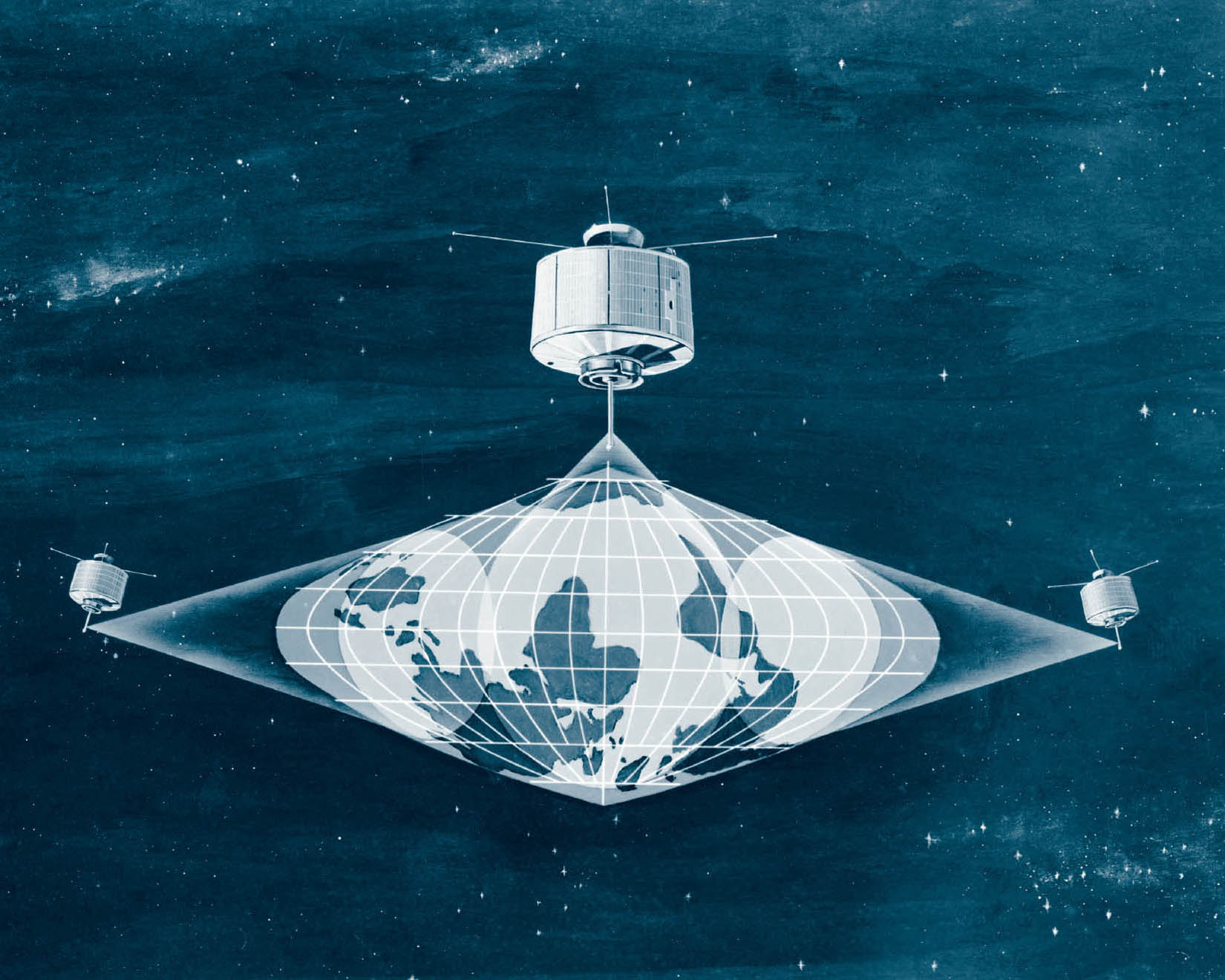

Rosen drew up his concept for an unmanned geostationary satellite that would circle the globe at exactly the same rotational speed as the planet. In effect, the robotic satellite would be stationary above a fixed point on the planet and would synchronously rotate with Earth. From a distance of 22,300 miles, the satellite could receive and transmit communications signals from approximately one-third of the planet’s surface. Radio and television antennas on the ground would be directed precisely toward the satellite. Three satellites could connect the entire globe. It was a mind-blowing idea.

“Most of the people I talked to thought it was pretty wild,” said Rosen. “And it was.”

Hughes Aircraft was initially reluctant to invest in the concept, as it did not fit the company’s traditional military and commercial manufacturing focus. Other problems loomed: while many engineers were impressed by the science behind Rosen’s idea, the practicality of transporting a heavy satellite by rocket to its geostationary resting place that far from Earth was questionable, as was the mechanism by which the satellite would stay in place.

These misgivings soon gave way, in large part because of the promise of this vast communications network and the ingenuity of Rosen and the engineers at Hughes. For instance, they developed lightweight satellites that were made of small-scale components and used thin antennae. The small, cylindrical craft, which measured just 28 inches in diameter by 15.35 inches high, could be put into orbit by the elementary rockets then available. They also developed the idea of spinning the satellite like a gyroscope to help it remain fixed in place. Two tiny jets, one powered by nitrogen and the other by hydrogen peroxide, would keep the satellite from drifting off course.

On behalf of NASA’s Syncom (synchronous communication satellite) program, the first experimental satellite, Syncom 1, was launched in 1961, but the satellite’s electronics system failed. Two years later, Syncom 2 was successfully placed in orbit. A few weeks later, President John F. Kennedy phoned the prime minister of Nigeria from the White House. It was the first live two-way conversation between heads of state involving a satellite. Syncom 3 ushered in the first international television broadcast, transmitting signals from the 1964 Olympic Games in Tokyo to the United States.

“I remember to this day the young man running down with the torch and lighting the flame,” said Rosen. “It just felt great.”

In succeeding years, Hughes Aircraft would manufacture satellites for countries including Malaysia, for commercial enterprises such as XM Satellite Radio, and for military applications such as the Milstar F-6 satellites operated by the U.S. Air Force to provide secure and jam-resistant worldwide communications. The company opened vistas of an interconnected world that was previously the province of science fiction. A half century later, people across the planet would send texts, photos, email, and videos to each other on mobile devices—messages instantaneously beamed back and forth by a constellation of satellites.

A conceptual illustration portrays the operation of Syncom, the first geosynchronous communications satellite.

A Boeing technician prepares a 702 communications satellite for service.

An artist’s rendering depicts the 601 Tracking Data and Relay Satellite in operation.

Once Hughes had proven the practicality of satellites, the rest of the aerospace industry entered the market. In October 1972, Boeing launched its 72-1 Scientific Satellite, which circled Earth a total of 26,375 times during its first five years of sun-synchronous circular orbit, ultimately logging more than 637 million miles. More important to future satellite development, Boeing applied its technological ingenuity to developing additional satellite applications. Company engineers studied the possibilities of solar-powered satellites affixed with enough silicon solar cells to generate electric energy from sunlight and beam it down to power U.S. cities. The idea was feasible—an early prototype indicated a very large satellite could produce 10,000 megawatts of usable power, enough electricity for one million homes—but not economically viable.

Numerous satellites were launched in subsequent years, among them the 601 satellite, one of the best-selling models in the world today. Introduced by Hughes Space and Communications in 1987, the 601 addressed industry needs for high-power, multiple-payload satellites used for such applications as direct television broadcasting. A more powerful version, the 601HP, made its debut in 1995, featuring up to 60 transponders. Building on the 601HP’s success, Hughes unveiled the 702HP satellite in 1999. It carried more than 100 high-power transponders to deliver the broadest range of communications frequencies to commercial customers.

Other manufacturers made their contributions as well. In February 1989, a McDonnell Douglas Delta II rocket launched the first fully operational Global Positioning System (GPS II) satellite into orbit. The prime contractor for the satellite was Rockwell International. Today, a network of GPS satellites provides accurate location information to millions of military and civilian users all over the world on devices as small as a watch or cell phone.

Just as the original aviation industry pushed physical boundaries to allow humans to leave the ground, the new aerospace industry put humans and human technology beyond our atmosphere. The giants of aviation had once again defied the odds.

In 1929, Bill Boeing said, “Science and hard work can lick what appear to be insurmountable difficulties.” His statement proved true—even for such fantastic notions as space-traveling human beings and instantaneous global communication.