Higher: 100 Years of Boeing (2015)

2 The Age of Aviation

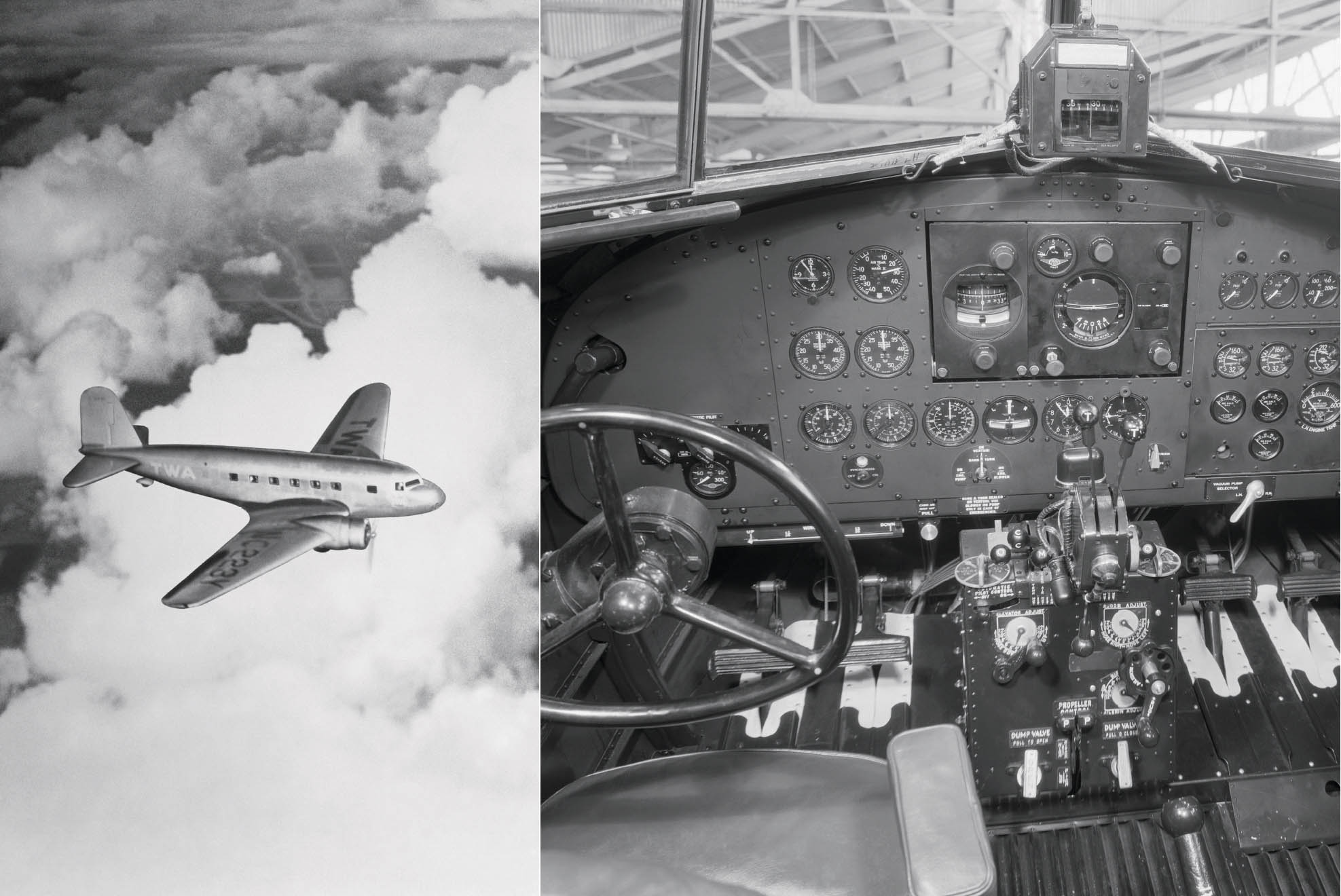

The luxurious Douglas DC-3 is recognized as the greatest airliner of its time.

Although the country was in the depths of the worst economic conditions in its history, the prospects for aircraft manufacturing actually increased during the Great Depression. Aviation heroes such as Charles Lindbergh and Amelia Earhart, along with Wiley Post, made headlines by shattering records for altitude, speed, and distance. By the end of the 1930s, air travel was an accepted means of transportation for many people.

The age of aviation had begun, with a fantastic future predicted. Popular Mechanics wrote about a “non-stop air express,” a massive plane dropping smaller planes from cables for departing passengers. Popular Science predicted that huge “islands of ice” would soon dot the oceans as airport hubs. Even Henry Ford, whose Model T car had made automobiles affordable for the masses, forecast an airplane in every garage—“air flivvers,” he called them.

Despite the continuing economic crisis, United Aircraft and Transport invested in this future by adding marquee names to its roster of airframe manufacturers, engine makers, and airlines, including Sikorsky, Stout Airlines, and National Air Transport. The company grouped the airlines under one name: United Air Lines, the precursor of today’s United Airlines. “What [Bill Boeing] was imagining very early on was the modern corporation,” author Clive Irving said. “He saw that you had to put all those bits together.” This combined control of supply, production, and distribution—what is known today as vertical integration—was increasingly part of the company’s success.

By 1933, United Aircraft and Transport was a vast enterprise. It transported roughly half of all the passengers and airmail in the United States. It manufactured aircraft and components. It even managed airports, including the United Airport in Burbank, California, which touted the world’s “first million-dollar terminal.” It also founded the Boeing School of Aeronautics in Oakland, California, to train the pilots needed to fly its planes and the mechanics to maintain their reliable operation.

The company was the industry’s frontrunner, but there was growing competition from other pioneering aviation concerns led by men who were determined to build market share.

Among them was Jack Northrop, who began his career as a draftsman-engineer for Loughead (later changed to Lockheed) Aircraft Manufacturing Company but left to work at Douglas Aircraft in 1923. Four years later, he assisted Jack Ryan of Ryan Aircraft in designing the larger wing of Lindbergh’s Spirit of St. Louis plane. In 1932, Northrop, with financial backing from Donald Douglas, incorporated a new enterprise called Northrop Corporation in El Segundo, California. The company manufactured several successful monoplanes, planes with a single set of wings instead of the biplane’s two. There was a distinct advantage to a single wing set: the external struts and cables needed to support the weight of earlier aircraft could be eliminated, and the surface area could be reduced by half. Both the weight and the drag produced by the aircraft declined considerably, enabling greater speed and distance. Northrop’s Gamma monoplane broke world speed records and recorded the first flight across the Antarctic.

Dutch Kindelberger left his position as vice president of engineering at Douglas Aircraft to become the president of North American Aviation in 1934. Founded six years earlier, North American initially was a holding company like United Aircraft and Transport Corp., comprising multiple airlines and aircraft-manufacturing businesses. Two former designers from Douglas, Lee Atwood and Stan Smithson, joined Kindelberger at his request. North American’s first government contract was for 161 sets of pontoons for Navy observation planes. An order for 42 NA-16 trainers soon followed. Later, Kindelberger was put in charge of the manufacturing business at the company’s new Los Angeles headquarters.

Like Bill Boeing, James Smith McDonnell, who founded J.S. McDonnell & Associates in 1928, was a pilot. His first aircraft, the Doodlebug, a tandem-seat monoplane, crashed in a 1929 flight competition, nearly killing him. As the Great Depression took hold, he was forced to dissolve the company and found work first as a consulting engineer and test pilot and later at Martin Aircraft. After raising $165,000, he again entered the manufacturing business, incorporating McDonnell Aircraft Corp. in 1939. He rented office space at the Park Plaza Hotel in St. Louis, Missouri, and recruited a small engineering team. The first year of business produced a loss, and the company struggled until World War II put it on firmer footing.

The celebrated pilot and social gadabout Howard Hughes inherited his father’s thriving Hughes Tool Company at a young age and successfully expanded and diversified his holdings to amass great wealth. The brash Hughes produced aviator movies including Hell’s Angels, dated well-known actresses including Katharine Hepburn, and created a few spectacular airplanes. In 1932, he founded Hughes Aircraft Company in Glendale, California. It manufactured the H-1 racer, a wood- and-metal single-seat monoplane. Hughes was at the controls of the H-1 when it earned a world landplane speed record of 352 miles per hour in 1935.

Like Dutch Kindelberger and Bill Boeing, Hughes vertically integrated his aviation enterprises. In addition to building airplane prototypes, in 1939, he acquired 77 percent of Transcontinental & Western Air. TWA was one of the Big Four American airlines that also included Eastern Air Lines, United Air Lines, and American Airlines. The airline operated a major transcontinental route from New York to Los Angeles.

As the new companies fought to gain a foothold in the burgeoning industry, their heated battles for airline and government orders led to an extraordinary array of aviation innovations. Chief among these were the transition from wooden components to metal parts and the migration from biplanes to monoplanes. Each product introduced was quickly outdone by a competitor’s product.

At Boeing, the all-metal Monomail, a monoplane that carried airmail, featured the industry’s first practical retractable landing gear. Designed by Claire Egtvedt and Boeing chief engineer Monty Monteith, its single metal wing was set lower on the fuselage than on Douglas Aircraft’s planes. Also featuring a streamlined fuselage and an engine enclosed in an anti-drag cowling, the Monomail was the most advanced, aerodynamic, and cost-efficient commercial airplane in the industry in 1930—until another Boeing plane bested it.

No sooner had the Monomail gone into service than its successor, the Model 247 airliner, was ready for production. Aviation experts consider the Model 247 to be the first truly modern commercial airliner. The aircraft incorporated multiple firsts, including variable pitch propellers, wing deicers, trim tabs, and an autopilot. Boeing also unveiled a bevy of new passenger comforts, including a heated cabin, individual reading lights, toilets, and a galley. The innovative plane leapfrogged competitors’ planes with these modern developments. So advanced was the Model 247 that it was a star of the Chicago World’s Fair in 1933, which was named “The Century of Progress.” The plane regularly took off and landed at the fair, to the delight of spectators.

The Boeing Model 200 Monomail helped make biplanes a thing of the past.

Unfortunately, on a transcontinental flight the same year, a 247 was destroyed by an explosive device that had been planted on the plane. All aboard died, including three crew members and four passengers. A subsequent federal investigation was unable to pinpoint a suspect, and the case remains unsolved.

But it was not this disaster that spelled doom for the 247. It was Boeing’s refusal to provide planes to other airlines until the first 60 were delivered to Boeing’s United Air Lines. TWA wanted to purchase several 247s, but Boeing’s board of directors declined to squeeze it into the queue ahead of United Air Lines. So TWA sent out a request for bids to competing manufacturers, and Douglas won the business with its twin-engine DC-1.

Douglas’s success demonstrated the value of a second-to-market strategy—patiently waiting for a competitor’s plane to make its debut and then quickly incorporating and improving upon its new features. This continuous process of adaptation fostered many technological advancements that otherwise might have taken more years to materialize.

The DC-1’s success cost Boeing dearly. In subsequent years, the aircraft was refined into the legendary DC-3, a plane significantly larger and faster than the Model 247. Introduced in 1936, the DC-3 had what airlines wanted: a cabin that accommodated 21 passengers (compared to 10 on the 247), a 1,500-mile range, and two reliable 1,200-hp Twin Wasp Pratt & Whitney engines.

Donald Douglas knew he had a winner. Although remembered as a quiet, introspective, and reflective leader, he promoted the plane skillfully. When Inter-Island Airways (the modern Hawaiian Airlines) ordered three DC-3s, he agreed to a bold idea offered by Inter-Island’s founder, Stanley Kennedy Sr.—to have the planes fly 2,500 miles across the Pacific Ocean from Oakland, California, to Honolulu for delivery. To accommodate the additional 1,000-mile distance, the seats inside the planes were removed and replaced with spare fuel tanks and oil drums. Thousands of spectators were in attendance as the DC-3s arrived over Waikiki Beach.

More than 15,000 DC-3 airliners in civilian and military versions were ultimately manufactured through 1946. By comparison, Boeing built 74 Model 247s. So revolutionary was the DC-3 that in 2014, 78 years after its debut, it is still safely flying passengers and freight with airlines across the globe. The legendary aircraft took the wind out of Boeing’s sails. Boeing Airplane Company’s head start making passenger planes lost all momentum.

The bruising competition from the Douglas DC series was not the worst news for Boeing in the mid-1930s. Even in the collapsed economy, the airmail business was a gold mine for the aviation industry. Newspapers caught wind of the airlines’ profits and soon alleged that the industry had engaged in collusion to reap higher government subsidies. A controversial Congressional investigation was launched, in which Boeing and his peers were accused of getting rich off the backs of taxpayers. When the investigation concluded, the federal government acted swiftly. It passed the Air Mail Act of 1934, which forced holding companies to separate aircraft manufacturing from their airline operations. In effect, aircraft manufacturers could no longer own mail-carrying airlines. The industry’s vertical integration strategy came to an abrupt halt.

United Aircraft and Transport was split into three independent entities: United Air Lines (responsible for air transportation), Boeing Airplane Co. (responsible for manufacturing operations), and United Aircraft (responsible for manufacturing operations in the eastern United States and later renamed United Technologies). United Aircraft comprised several previous acquisitions such as Sikorsky and Pratt & Whitney.

A Boeing Model 247D flies over New York. The all-metal, twin-engine aircraft is considered the first modern passenger plane.

Douglas Aircraft developed the DC-1 in response to Boeing’s 247. Only one was built, but the company quickly followed up with the DC-2. The DC-3 would go on to become one of the best-selling planes in history, and still flies today.

For Bill Boeing, the breakup of his company was an insult to his integrity and vision. He had long contended that the capital influx from airmail contracts served the public because it was reinvested in aviation advancements. In later years, he would say that the government’s hasty decision had curtailed the industry’s progress by half.

The industry’s former airmail contracts were turned over to the U.S. Army Air Corps, which was unprepared for the responsibility. The Air Corps suffered numerous crashes and fatalities by pilots untrained for bad weather conditions. With the public in an uproar, President Franklin Roosevelt had no choice but to return service to the commercial airlines. In 1941, the U.S. Court of Claims would rule that there had been no fraud or collusion in the awarding of airmail contracts. Boeing and the other pioneers of commercial aviation were absolved of any misconduct.

Bill Boeing had founded a company that was in the process of changing the world, and the government broke it up—as it turned out, based on false suppositions. But the vindication came too late for him. In 1934, following the industry’s breakup, Boeing resigned as chairman. His vision of the company suppressed by the government’s decision, Boeing sold his stock and for the rest of his life observed the company that bore his name from the sidelines. He pursued a quiet retirement in the Pacific Northwest, raising Thoroughbred horses, sailing the Taconite, and keeping his pilot’s license active.

The loss of Bill Boeing was an unexpected setback, made worse by the fact that business prospects had again fallen off. Claire Egtvedt assumed the chairman’s position and continued in his duties as president, a post he had filled since 1933. The gifted former mechanical engineer had been in charge of all aircraft engineering since 1917 and had been responsible for numerous technological enhancements through the years. His steady hand was needed as even more turbulent times lay ahead.

War was again brewing in Europe. Adolf Hitler had assumed power in Germany and rearmed the military. Hitler’s aggressive actions indicated a growing need for modern military equipment in Europe and the United States. In particular focus was the manufacture of large aircraft able to transport weaponry and personnel—the aerial equivalent of battleships.

Egtvedt believed the company’s best prospects were to design and make extremely large bombers. Such giant planes represented a major departure for Boeing, as the company was known primarily as a manufacturer of small fighter planes. In retrospect, had Egtvedt not redirected the company toward large bombers, the future could have turned out much differently for Boeing. Its expertise in these airplanes would play an important role in its later development of passenger jetliners.

Egtvedt wanted the bomber’s design to share features with a large airliner—a two-for-one market strategy. Boeing engineers led by Jack Klystra responded with the experimental XB-15, the largest and heaviest plane ever built at the time. The XB-15 boasted a wingspan of 149 feet—so immense that the crew could venture through passageways in the wings to make minor repairs while the plane was in the air.

The XB-15 was designed to achieve the Army Air Corps’ plans for a heavy bomber that could achieve a range of 5,000 miles. For a company that had previously manufactured small airplanes, this was a completely new Boeing.

The experimental plane, the very first of the “big Boeings,” set the foundation for larger, more powerful, and much faster aircraft in the years ahead. The first of these planes was the Model 299, later known as the B-17 bomber, which boasted an almost 74-foot length and a wingspan of more than 103 feet. Looking at the 22-ton plane armed with an array of machine guns and a 4,000-pound bomb load, a newsman remarked, “It’s a flying fortress.” The name stuck.

The Army Air Corps was looking to purchase 200 long-range bombers. In competition with Douglas and Martin, Boeing submitted the prototype for the B-17 but failed to win the contract when the plane crashed, killing two of the five crewmen on board. Its vast size also was a concern to a few high-ranking military officers who feared it would be a bull’s-eye in the sky. Nevertheless, the Air Corps was impressed by the plane’s design and ordered 13 B-17s for further evaluation. To build them, Boeing constructed a second plant, Plant 2, on 28 acres two miles south of its first plant and doubled the total workforce to 1,500 employees by 1939. “It is a considerable source of pride that we are producing the most advanced type of defensive aircraft ever offered our country,” Boeing News reported.

As Egtvedt had planned, the XB-15 also gave birth to a commercial airliner, the Model 314 Clipper seaplane. Like its sibling, the B-17, the Model 314 was gigantic. It weighed 82,000 pounds, was 106 feet long from nose to tail, and could transport 74 passengers over a distance of 3,500 miles—far enough to cross the Atlantic or parts of the Pacific. It was the jumbo jet of its day.

The Clipper was built specifically for Pan American Airways, founded by Juan Trippe. When he was a boy, Trippe witnessed Wilbur Wright’s 1909 flight around the Statue of Liberty; after getting his pilot’s license and graduating from Yale University, he incorporated an airline, Aviation Corporation of the Americas, which evolved into Pan American Airways in 1927.

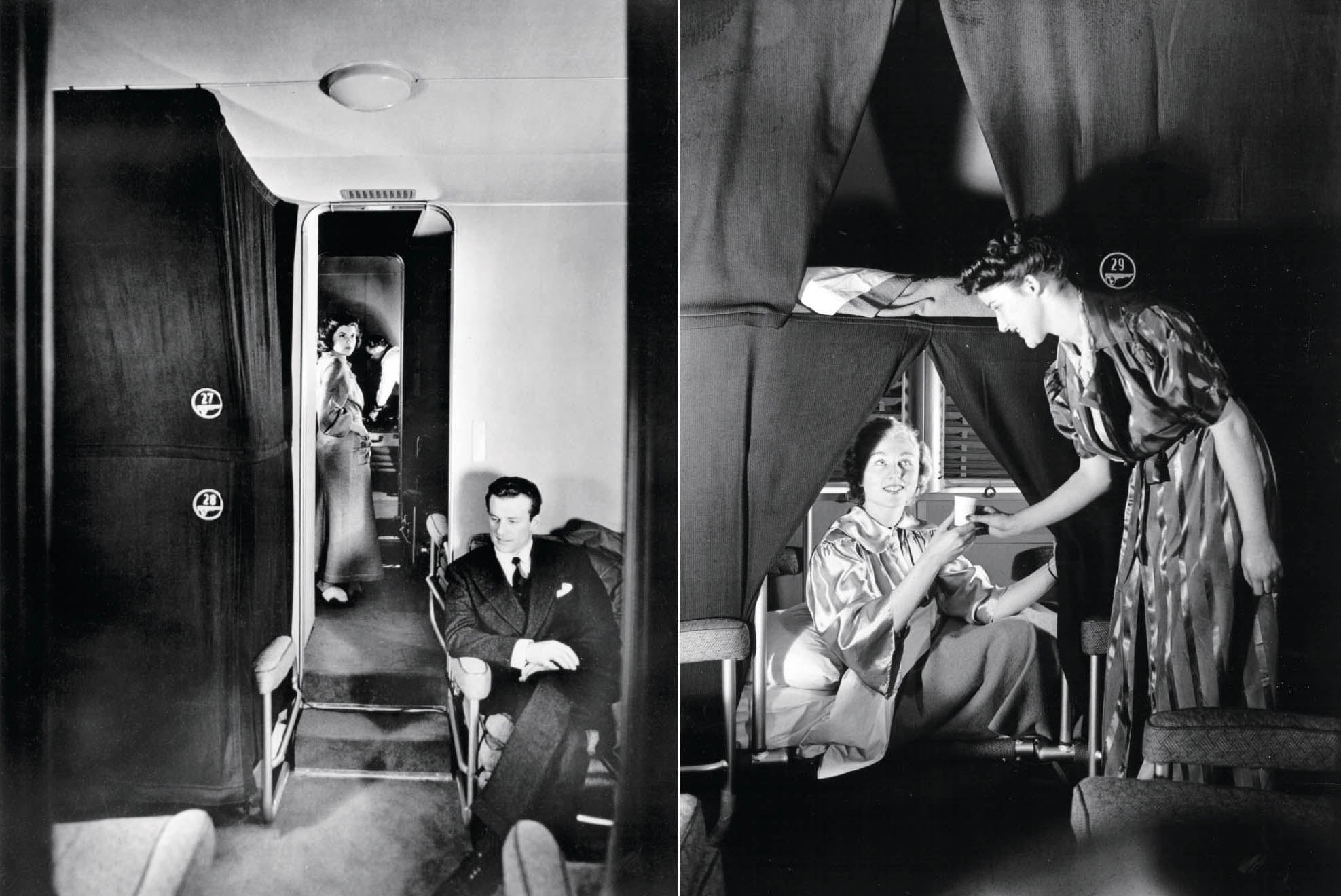

Trippe wanted a first-class aircraft that could speed passengers to exotic destinations in unheard-of luxury. Boeing’s Model 314 Clipper—named for the fast sailing ships of the 19th century because it took off from and landed on water—fit the bill. It boasted an elegant dining room and bar, dressing rooms for men and women, seats that faced each other so passengers could converse or play cards, and even a bridal suite for newlyweds. “[The Clipper was] beautiful, silver-hulled, and very majestic, all this glamor happening during the midst of the Great Depression,” said Yale University history professor Jenifer Van Vleck.

Service from San Francisco to Singapore commenced in March 1939, and transatlantic runs were inaugurated with the Atlantic Clipper that June, allowing regular air service between the United States and Britain.

The same year, Boeing’s four-engine Model 307 Stratoliner made its debut. Once again, Boeing moved the industry forward, continuing to develop innovative designs inspired by the success of existing aircraft. In the aviation industry, this process is referred to today as “adaptive architecture.” Boeing learned from its success with the XB-15 to create both the Clipper and the B-17. Now the B-17 would inform the development of the Model 307, combining the former plane’s wings, tail, rudder, landing gear, and engines with a revolutionary fuselage that could be pressurized.

The Boeing Model 314 Clipper was renowned for its luxury. The plane featured dressing rooms, sleeping berths, lounges, and even a honeymoon suite.

The largest passenger plane of its time, the Model 314 seaplane was called the Clipper, a nod to the fast, long-distance sailing ships of the previous century.

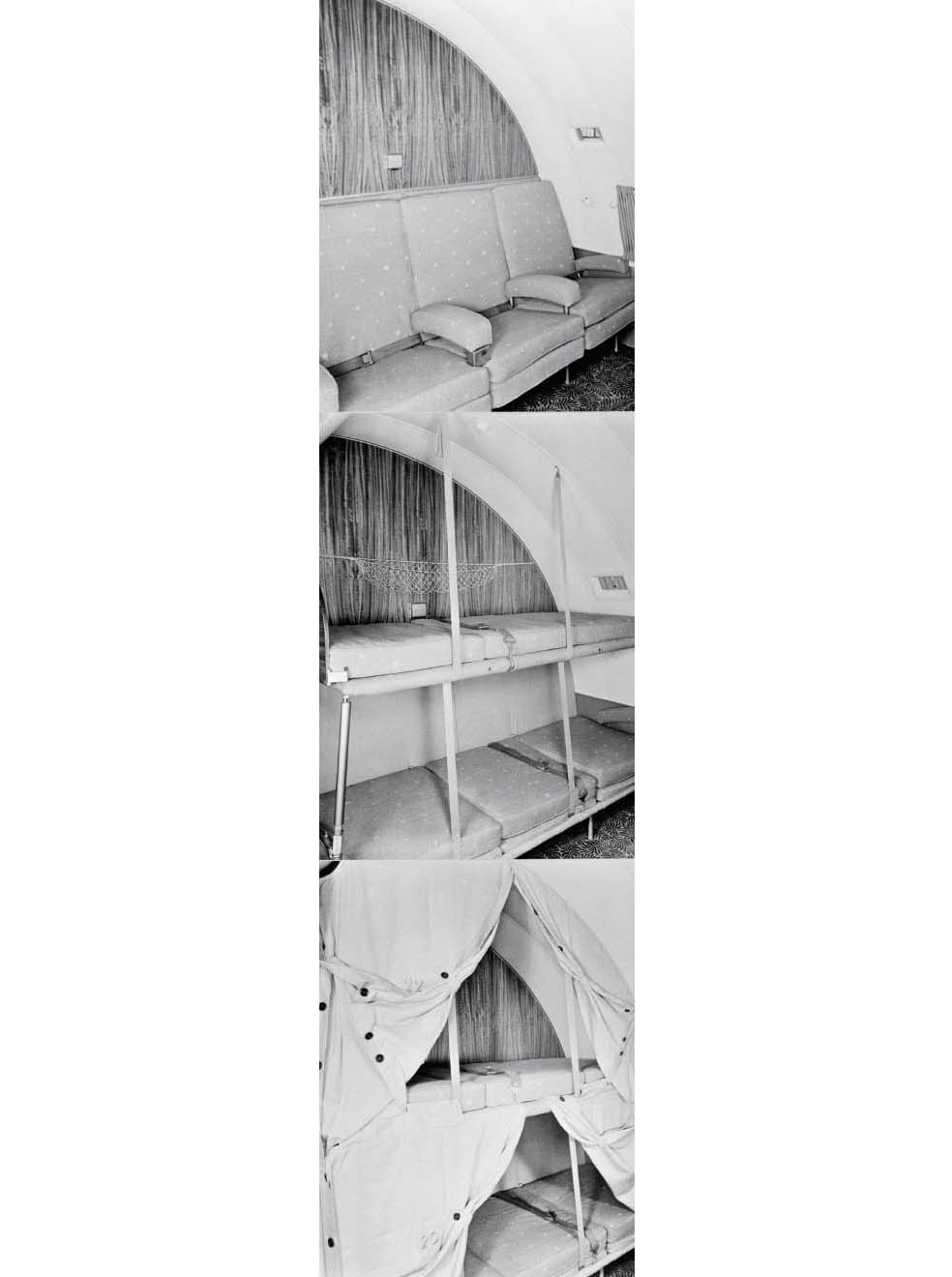

The Stratoliner thus became the first commercial airliner to enter service with a pressurized cabin. This allowed the plane to soar above storm-induced turbulence at altitudes of 20,000 feet, approximately two-thirds the height of Mount Everest. Before this historic achievement, flying above 12,500 feet caused passenger discomfort and oxygen deprivation due to the low outside air pressure. Flight attendants, all of them registered nurses, conveyed oxygen bottles attached to masks to give the beleaguered passengers a breath of air.

It is hard to fathom just how uncomfortable air travel was in the 1930s. Boeing flight attendants frequently spent their time treating travelers experiencing motion sickness from the aircraft’s constant jostling and turbulence at lower altitudes. If the pilot flew the plane higher, passengers had trouble breathing in the thinner air.

Both Boeing and Douglas had experimented with air pressurization, pumping conditioned air into the cabin at high altitudes to maintain the air pressure of a lower altitude. Thanks to ventilation expert Nate Price, Boeing broke the tape first. Price’s patent called for the Model 307 Stratoliner to ascend, unpressurized, to 8,000 feet, a level where passengers could breathe normally. Above this level, a supercharger on each of the inboard engines pumped air in from outside the plane to maintain air pressure in the cabin. Above 16,000 feet, where the air was even thinner, cabin pressure diminished slightly. But at 20,000 feet, the plane was above the worst of the weather, allowing normal breathing, reducing motion sickness, and enabling the plane to fly a more direct route. Although Boeing sold only 74 Stratoliners (and produced just 10, as Boeing turned all of its resources to building B-17s for the war effort), its technological ingenuity contributed immensely to the future comfort of all passenger aircraft.

In the space of a decade, air travel had transformed from a sole human being flying across the Atlantic to the cheers of an astonished public to anyone with the price of a ticket regularly and comfortably doing the same. Companies in the growing industry outdid each other with advanced design and manufacturing concepts, producing ever faster, larger, and more sophisticated aircraft. This continuous improvement process soon became the norm.

For Boeing—shaken by the Air Mail Act of 1934 and the abrupt resignation of its founder—new president Claire Egtvedt’s reimagining of the company as a maker of large, long-range airplanes came just in time. With the fuse ignited by Germany’s continuing aggression, another world war would soon explode in Europe. Egtvedt’s belief in the value of big bombers would prove crucial to the future of the industry and the fate of the free world.

Although only 10 Model 307 Stratoliners were built (above), the passenger plane ushered in a new era of passenger comfort, with a pressurization system that enabled it to fly above bad weather, and plush seats that converted to sleeping berths (next).

The name of the 787 Dreamliner (next) was chosen in a worldwide vote and echoes the name of another game-changing Boeing passenger plane—the 307 Stratoliner (above).