Edison and the Electric Chair: A Story of Light and Death - Mark Essig (2005)

Chapter 9. George Westinghouse and the Rise of Alternating Current

IN THE LATE summer of 1882, about the time the Pearl Street station began delivering light to lower Manhattan, Edison took a lease—at an exorbitant $400 a month—on a home on Gramercy Park. The move to New York had been proposed by his wife, Mary, who was anxious to escape the isolation of Menlo Park. At first she thrived on city life, hosting receptions and teas in her home. A year later, though, her health deteriorated so much that she had to give up housekeeping, and the family moved into a hotel.

Mary's health improved somewhat after a Florida vacation in the spring of 1884, but something was still not right. "I am so awfully sick," she wrote in April. "My head is nearly splitting and my throat is very sore." In the summer the couple once again left the city for the comfort and familiarity of Menlo Park, but Mary's condition worsened, and she unexpectedly died early in the morning of August 9. Dot awoke that day and found her father "shaking with grief, weeping and sobbing so he could hardly tell me that mother had died in the night." Mary Stilwell Edison was twenty-nine years old. The doctor attributed her death to "congestion of the brain."1

Mary's death so upset Edison that it brought about (at least temporarily) a realignment of his concerns. A thirty-seven-year-old widower, for the first time he began paying attention to his children: eleven-year-old Marion, eight-year-old Tom, and five-year-old Will. After her mother's death, Marion became her father's chief companion. He took her to the theater and afterward to Delmonico's, where he smuggled her into the men's dining room and kept her there with him until past midnight. He also bought his daughter a horse and a parrot. The bird never learned to speak, and the inventor complained that it had "the taciturnity of a statue, and the dirt producing capacity of a drove of buffalo." The horse was more useful. At least once a week they hitched it to a carriage and took a drive in the country, with Marion at the reins (her father could never be trusted to control a horse). "It seems wonderful... that Father had so much time for me," Marion later recalled. "He was interested in my clothes, diary, the novel I was going to write." As the ultimate mark of approval, he allowed her to assist at the laboratory. Her entry into this all-male preserve demanded a new nickname, so he took to calling her "George." In a lab notebook he left a doodled love note: "Dot Edison angel Miss Marion Edison Sweetest of all."2

WHILE DISCOVERING his sentimental side at home, Edison grew more aggressive in his business dealings, because he was dissatisfied with the progress of the industry. The Edison lighting empire was organized as a three-tiered system. The Edison Electric Light Company held the patents and licensed them to the independent Edison manufacturing companies (the Lamp, Tube, and Machine Works). The manufacturing companies sold the equipment they produced either to individuals who installed isolated lighting systems for private use in one office building or factory, or to local electrical utilities that funded the construction of central stations and then sold electricity to customers in their areas. The directors of the parent company, Edison Electric, hoped that the Pearl Street station in New York would prove the reliability and economy of electric light and lead investors in other cities to organize and capitalize local utilities.3

Because the New York station was long delayed and over budget, however, cities that had been contemplating central stations shied away. The Edison Electric directors were content to bide their time and make money from the sale of isolated lighting plants. Edison, however, did not want his lights to dot the night landscape in a factory here and a hotel there; he wanted to light whole cities, to make the entire nation glow with the radiance of his lamp. He believed that the parent company should invest in more central stations to demonstrate the system's viability. The problem, as he saw it, lay not with his system but with Edison Electric's failure to promote it—yet another example, he thought, of "the characteristic timidity of capital."4

"If the business is to be made a success it must be by our personal efforts and not by depending upon the officials of our companies," Edison declared. "I am going to take a long vacation in the matter of inventions. I won't go near a laboratory."5

He became, as he put it, "a regular contractor for electric light plants." He did not have the resources to take on something as big as the New York station, so he concentrated his efforts on smaller towns. He plowed his own money into a new company called the Thomas A. Edison Construction Department. The company's agents recruited local investors, who then formed utility companies and paid Edison—in cash and stock—to install central stations. In the next year Edison installed central stations in nearly twenty towns. But local investors were slow with their payments, and the Construction Department's up-front costs were high. Most of the money was coming directly out of Edison's pocket, and he soon ran low on funds. In the fall of 1884 he disbanded the Construction Department and allowed the parent company to take over its assets and operations.6

Edison decided that if the officers of Edison Electric would not promote the business, he would change the officers. When Edison Electric was founded, he owned five-sixths of its stock, but he had sold most of his stake in order to finance the manufacturing firms. Edison, though, had more influence than the average minority stockholder. In a proxy battle at the stockholders' meeting in October 1884, he gained enough support from other investors to oust the board of directors and install a new one that included several of his closest friends, men who saw the business as he did. Francis Upton and Charles Batchelor won positions on the board, and the new president was Edward Johnson, Edison's longtime friend and formerly the vice president of the company.7

"I have given a perfect system, and I want to see it sold," he told a newspaper reporter. "I have worked eighteen and twenty hours a day for five years, and I don't want to see my work killed for want of proper pushing."8

Now that his friends ran the company, Edison pursued strategies that the previous board had avoided. Edison Electric filed patent suits against infringing rivals and gave Edison's lighting system the promotion it deserved. The results were striking. Edward Johnson pushed the expansion of the central stations in New York and Boston, but most of the growth came in smaller towns. This "village business," as Edison called it, relied on one of his latest patents. Because the high cost of copper remained the greatest stumbling block to his light's success, Edison deployed the "three-wire system," a new circuit arrangement that required 60 percent less copper than the feeder-and-main arrangement used in New York. He installed the first three-wire central station in Sunbury, Pennsylvania, in the summer of 1883, and in the next few years the system spread across the country.9

Before Edison installed the new board of directors, there had been 103 only eighteen Edison central stations in the United States. A year later there were thirty-one, and by August of 1886 there were fifty-eight. During the same period the number of isolated lighting plants nearly doubled. As the companies prospered, Edison recovered his investments and became a wealthy man. Just as important, his dream of seeing his light spread across the country was beginning to come true.10

EDISON'S LIGHTING SYSTEM inspired an electrical craze. A New York bartender mixed an "electric cocktail" by caramelizing sugar with an electric light wire, then adding alcohol. The Electrical Journal reported in 1882 that a Richmond man "cooked the first four eggs boiled in water by electricity, the first piece of beefsteak, and probably the first bacon" (the rival claimant for the bacon prize was not identified). A physician used the Edison current for the "eradication of a mustache from a woman's lip." J. P. Morgan's daughter appeared at a ball with tiny glowing bulbs in her hair, and the Electric Girl Illuminating Company, incorporated in 1884, adorned servants with incandescent lamps and hired them out, promising "girls of fifty-candle power each in quantities to suit householders."11

Although Edison's light had captured the nation's imagination, in 1886 it remained a luxury service, available only to the relatively few people who had purchased isolated lighting plants or who lived in the central districts of some cities. Arc lamps, because they were placed on public streets, had a more immediate impact.

Brush Electric remained the leading arc lighting firm, but a strong competitor had entered the field. In the late 1870s Elihu Thomson and Edwin J. Houston, two science teachers at Philadelphia's Central High School, designed an arc lamp system, located investors in Connecticut, and founded a manufacturing company there. Originally known as the American Electric Company, in 1883 the firm was reorganized as the Thomson-Houston Electric Company. Brush's supremacy in arc lighting was challenged not only by Thomson-Houston but also by the United States Electric Lighting Company, Fort Wayne Electric, and about twenty smaller firms.12

Because competition was so intense, arc lighting manufacturers marketed their systems aggressively, with salesmen for the companies essentially acting as promoters. In each city, they located investors, helped them organize a local lighting utility, secured a franchise from the local government, arranged for the purchase of equipment, and assisted with setup. Installing an arc lighting system, like installing an Edison incandescent system, involved creating a central station with one or more dynamos, then running conducting wires to carry electricity to individual street lamps, but the similarities ended there. An incandescent lighting system reached into the interior rooms of houses and offices and required the wiring of thousands of individual lamps. An arc lamp central station, by contrast, served just a few dozen street lamps. Even more important, most arc lamp companies avoided the most laborious part of Edison's system installation: digging up the streets to lay conductors underground. Arc lighting firms, like operators of telegraph services, strung their wires on poles over city streets.13

Because they were relatively easy—and therefore inexpensive—to install, arc lighting systems spread more quickly than incandescent. The number of arc lamps in service in the United States jumped from 6,000 in 1881 to 140,000 in 1886. New York City followed the national trend during that period, with the number of arc street lights rising from S5 t o 7°°> illuminating more than thirty miles of the city's avenues and major cross streets.14

Whereas the arc lighting industry was crowded with competitors, Edison enjoyed a virtual monopoly in incandescent lighting. Through the end of 1886, he controlled four times the market share of his closest competitor, the United States Electric Lighting Company. The mistake of U.S. Electric and Edison's other early rivals was in trying to compete with him directly. They could try to copy his system, but they did not have the Edison brand name and could not match the years of experience of Edison and his men. The competitors offered pale imitations of the Edison system, and most customers were wise enough 105 to choose the original article. Late in 1886, however, a formidable new challenger arrived.15

GEORGE WESTINGHOUSE was born in 1846 (ayear before Edison) in the upstate New York town of Central Bridge. When he was nine, his father opened a shop in Schenectady for making farm machinery and steam engines. The boy found his father's shop much more interesting than school, so he cut class and spent his days designing model powerboats, waterwheels, and other bits of "trumpery," as his father called them. Aside from his deft mechanical touch, young George was known for a volcanic temper and a sometimes misguided devotion to efficiency. A story was told about the day his father whipped George for misbehavior. After the wooden switch broke twice, George choked back his sobs long enough to point out a leather whip that would do the job more competently.16

In 1863, at the age of seventeen, Westinghouse enlisted as a cavalryman in the Union army. Early the next year he transferred to the navy and put his mechanical skills to use on steam-powered gunboats. After the war he enrolled at Union College in Schenectady but did not last long. "He was my despair," one of his teachers recalled. "While the other boys were struggling with German syntax or French pronunciation, he would amuse himself making pencil drawings on his wristbands. His sketches were always of locomotives, stationary engines, or something of that sort." The school dismissed Westinghouse after three months, which was just as well with him, for he could then work on machines rather than draw them on his cuffs. Soon after leaving school, he invented a device for putting derailed trains back on track, as well as a new type of "frog," the mechanism that allowed trains to move from one track to another. Westinghouse persuaded two local investors to finance the manufacture of the devices, and before long he was a partner in a thriving industrial operation.17

While returning home from a business trip one day, Westinghouse was delayed by an earlier head-on collision between two freight trains. He wandered up to inspect the damage and fell into conversation with the chief of the wrecking crew. It was a straight stretch of track, the man explained, and the engineers saw each other, but they could not halt in time. "You can't stop a train in a minute," the man said.18

George Westinghouse

When an engineer needed to halt his train, he used a whistle to signal to the brakeman, who climbed to the roof of a car and twisted a wheel that tightened a chain that pressed the car's brake shoe against the rail. Then he jumped to the next car and repeated the maneuver. It was a slow process even in routine circumstances, and trains often overshot stations and had to back up to the platform. In an emergency, such as when two trains were hurtling toward each other on the same track, they were usually stopped not by brakes but by impact.19

Westinghouse decided to build a better brake. He first tried using steam lines running the length of the train: The steam pressure drove pistons that instantaneously would press all the brake shoes against the rails. The invention failed miserably, however, because the steam condensed before it could do its work. After reading a magazine article about mining drills driven by compressed air, Westinghouse adapted his steam brake to use compressed air and patented the design.

Like Edison with the electric lamp, Westinghouse was attacking a problem that many had attempted before. There were already more 107 than two dozen patents covering automatic braking systems, including one using compressed air. But Westinghouse was the first inventor to build a practical system and the first to organize for its manufacture. After trials proved the worth of his system, a few wealthy railroad men formed the Westinghouse Air Brake Corporation in 1869. They built a factory in Pittsburgh, capitalized the company at $500,000, and named George Westinghouse president. He was twenty-two years old. In the decade after its invention, the Westinghouse air brake became standard equipment on passenger trains around the world.20

In the early 1880s both Westinghouse and Edison were wealthy industrialists in their early thirties, but the two men played the role very differently. Unlike the smooth-cheeked Edison, Westinghouse cultivated the extravagant facial hair common at the time: bushy side whiskers and a handlebar mustache. Whereas Edison was boyish and playful, Westinghouse, over six feet tall and barrel-chested, was an imposing, stern figure. Most strikingly, Westinghouse avoided granting interviews or being photographed. "When I want newspaper advertising, I will order it and pay cash," he once said. "If my face becomes too familiar to the public, every bore or crazy schemer I meet in the street will insist on buttonholing me." Although the company bore his name, Westinghouse did not attempt to sell himself along with his products. An engineer who worked in the Pittsburgh factory said Westinghouse never struck him "as being a wizard, but he seemed to be a plain human being with lots of initiative, with nerve to attempt difficult things."21

Having conquered the railroad brake industry, Westinghouse went looking for new challenges. According to Thomas Edison's secretary, a fit of pique drove Westinghouse into the lighting business. When Westinghouse tried to interest Edison in a steam engine he had invented, Edison supposedly replied, "Tell Westinghouse to stick to air brakes. He knows all about them. He doesn't know anything about engines." Westinghouse, so the story goes, decided to avenge the insult by competing with Edison.22

108 The true story is more mundane. Westinghouse first met Edison when he visited Menlo Park while looking for an isolated lighting plant for his Pittsburgh house. Edison showed him around the lab, and West inghouse later recalled the visit warmly. He entered the light business not out of spite but for the same reason so many others did: He saw profit and glory in it. Early in 1884 he met a young electrical expert named William Stanley, who had worked for U.S. Electric and other electric lighting companies, and brought him to Pittsburgh to develop an incandescent lighting system. In 1885 and 1886 Westinghouse and Stanley installed isolated lighting plants in hotels in New York and Pittsburgh and built a central station in Trenton, New Jersey. But Westinghouse ran into the same problem that stymied U.S. Electric: His system was too similar to Edison's to be competitive with it.23

DESPITE ITS SUCCESS, Edison's light suffered from a serious weakness. The feeder-and-main and three-wire distribution systems lowered copper costs somewhat, but Edison still could not serve areas more than a mile or so away from the generating plant. There was, though, an inexpensive way to cut copper usage and broaden the service area of a central station: by boosting the voltage.

The behavior of electricity can be thought of in terms of water flowing through pipes. A pump (voltage) drives the flow, the diameter of the pipe determines resistance, and the rate of flow (amperage) is determined by voltage as limited by resistance. If there are two pipes, one with double the capacity of the other, both will carry the same amount of water if the pressure in the smaller is twice that in the larger.

Similarly, to deliver a given amount of energy, engineers could either couple a thick (lower-resistance) conductor with a low-voltage current or couple a thin (higher-resistance) conductor with a high-voltage current capable of overcoming the resistance. Given the high cost of copper, the choice was clear: A high-voltage system with thin wires was much more economical.

Because domestic lighting required low pressures of about 100 volts, an ideal system would allow a company to transmit through slender wires at high voltages (over 1,000 volts), then lower the pressure to 100 volts for use in the home. Charles Brush, the arc lighting pioneer, was the first American to exploit the economies of high-voltage transmission. In 1882 he built an incandescent lighting system in which electricity was transmitted over longer distances at over 1000 volts, then fed into batteries near the site of consumption. Charged at high voltage, the batteries then discharged electricity at much lower voltages to operate lamps. Brush's battery system, though, was clumsy and inefficient, and it never caught on.24

In 1885 Stanley and Westinghouse began to work on a lighting plan that, like Brush's storage battery system, involved transmitting at high voltages, then lowering the voltage and distributing into homes and offices at low voltages. Their system, though, had one significant difference: Rejecting direct current, which flowed continuously in one direction, they chose to use alternating current, which changed direction back and forth many times a second.

It was a radical step. Rotating a coil of conducting wire between the poles of a magnet naturally produced alternating current, because the relationship between the coil and the north and south poles of the magnet reversed with each half turn (see figure 1). The earliest generators in the 1830s produced alternating current, but, because this current had no apparent uses at the time, instrument makers added switching devices that converted alternating-current generators into direct. From the 1830s through the 1870s, electroplating and electrochemistry—both of which required direct current—were the primary commercial use of electrical generators, and as a result most available dynamos were direct-current machines. When inventors took up electric lighting in the 1870s, they patterned their generators on the direct-current models common at the time. Charles Brush's arc lights used direct current of 1,000 or more volts, and early incandescent light systems, like Edison's, used direct current of 100 volts or so.25

In the early 1880s a few inventors realized that alternating current had one distinct advantage over direct, an advantage related to the principle of induction, discovered independently by Michael Faraday and the American scientist Joseph Henry in the 1830s. The principle stated that a variation—starting, stopping, or reversing—of the current in one coil of conducting wire will induce a current in a second coil placed in close proximity to (but not touching) the first. Direct current, which flowed continuously, without variation, produced no induction effect. But alternating current did, because it reversed direction many times a second. An alternating current in one coil of wire (the primary circuit) caused a current to flow in another coil (the secondary circuit) placed close by.26

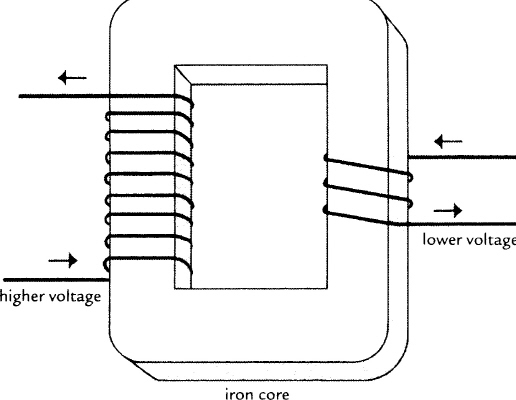

Figure 3: A transformer consists of two distinct coils of wire wound around an iron core. The input current enters the primary coil, producing a magnetic field in the iron core that repeatedly switches on and off. The core transfers this field to the secondary coil, where it induces an output current. The degree of change in the voltage depends upon the ratio of the number of windings of the coils: This transformer steps the current up or down three times.

Induction allowed the conversion of low voltage to high or high voltage to low. The degree of change depended on the ratio of the number of coils of conductor in the primary circuit to the number in the secondary circuit. Given nine coils of wire in the primary circuit and three coils in the secondary circuit, a current of 300 volts in the primary would induce a current of 100 volts in the secondary. Operated in reverse, the arrangement raised voltage instead of lowering it. One of Edison's favorite toys, the induction coil, operated on this principle: Low voltage from a battery in the primary circuit induced a higher voltage in the secondary, which was then used to administer shocks.

In the early 1880s the French inventor Lucien Gaulard applied the principle of induction to the problem of transmitting electrical energy. He would transmit alternating current cheaply at high voltages, then use induction coils to reduce the voltage to levels safe for use in homes and offices. Used in this way, the induction coils became known as converters or transformers. Together with his British business partner John Gibbs, Gaulard designed transformers for use in the long-distance transmission of alternating current. In 1884 they transmitted along a fifty-mile circuit between Lanzo and Turin, Italy.

Gaulard and Gibbs displayed their system at the 1885 London Inventions Exhibition, where it came to the attention of George Westinghouse, who purchased on option on the patent. He also ordered several Gaulard-Gibbs transformers and an alternating-current generator made by Werner Siemens, the German pioneer in electric lighting.27

The engineers on Westinghouse's staff opposed these moves. Like most experts, they believed alternating current could never compete with direct because transformers wasted too much energy. An editorial in a leading electrical journal explained that the best minds in electrical science had tested and abandoned alternating current, and that these men would never "have allowed this subject to dwindle away to mere nothingness had there been a chance of bringing the matter to a successful issue."28

Westinghouse disagreed, and his enthusiasm for alternating current was shared by William Stanley. Starting early in 1886, Stanley redesigned the Gaulard-Gibbs transformer and tested it in a new system. He installed an alternating generator and transformer in an old mill in Great Barrington, Massachusetts, strung a mile of thin copper wire into the center of town, installed another transformer in the basement of a store, and ran wire from that basement to lamps in a hotel and several stores. Stanley used the first transformer to step up a generator's voltage from 500 to 3,000 volts, transmitted the current to the center of town, then used the other transformer to step it back down to 500 volts.29

"All the converters are under lock and key, so that no one knows anything about them," Stanley wrote to Westinghouse after a successful test in March. "I might say a great deal about the system, but briefly, it is all right."30

Despite the continued objections of his other engineers, Westinghouse moved ahead with alternating current. He developed a system that transmitted current at 1,000 or 2,000 volts, then stepped it down to 50 volts for distribution within homes and offices. After further refinement of the system in Pittsburgh, Westinghouse Electric installed its first commercial alternating-current plant in November 1886 in Buffalo, New York, where, at the same time in the same city, Alfred Southwick was in the midst of his research on killing with electricity. Orders for twenty-five more plants arrived within a few months, and Westinghouse Electric moved into bigger quarters in Pittsburgh to handle the business.31

THE TRANSFORMER ALLOWED high-voltage transmission of alternating current over long distances and low-voltage distribution near the point of consumption. Since Edison's low-voltage system required such thick copper conductors, he had to build several different direct-current generating plants to serve an area of a few square miles. But the same area could be served by a single large alternating-current central station, which allowed lower initial capital costs. Changes in the international copper market also helped Westinghouse. In 1886 copper sold for about ten cents a pound, but the following year a French syndicate cornered the world's copper supply and doubled the price. This made the alternating system, with its thinner conductors, even more attractive.32

Direct current had a few points in its favor. Most important, its dynamos converted mechanical energy into electrical energy with a loss of only about 10 percent, whereas alternating generators had losses closer to 25 percent. Direct current also offered the versatility of supplying power as well as light. A lightbulb had no preferences as to current type—its filament heated to incandescence whether the current flowed in one direction or alternated back and forth. But electrical companies needed a way to earn income from their plants during the day, when there was little demand for light. Direct current could run electric motors, allowing Edison to sell electricity to users of sewing machines, elevators, and other machines. There was no motor for alternating current, so Westinghouse's plants would sit idle during the day. There was also no way of measuring usage. The only electric meter—Edison's—worked on the principle of electroplating, strictly a direct-current phenomenon. Without a meter, Westinghouse would have to charge a flat rate, and this would lead to inefficient use of his power.33

EDISON FOLLOWED Westinghouse's work with great interest. Late in 1886—around the time Westinghouse's Buffalo plant went on-line-he wrote a thirteen-page memo to Edison Electric president Edward Johnson about alternating current, professing to be not a bit worried. The inventor pointed out that the generators and transformers wasted energy, and that the lack of meter and motor was a problem. Edison also worried about the dangers of sending high voltages through wires over city streets and into people's homes. Whereas direct-current lighting used just 100 volts, the Westinghouse system, Edison explained, "uses 2000 volts alternate—This gives a difference of 4000 volts (!) (HOLY MOSES)… . Suppose Wfestinghouse] uses 2000 and one leg gets crossed, the first man that touches a wire in a wet place is a dead man." The inventor then made a prediction: "Just as certain as death Westinghouse will kill a customer within 6 months after he puts in a system of any size."34

Edison's evaluation of alternating current was accurate, given the state of the industry in 1886. But Westinghouse was placing a bet that the efficiency would improve, that meters and motors would be invented, that the dangers of high voltage could be controlled. Just as Edison had done in his work on the incandescent lamp, Westinghouse chose to gamble that he and his engineers could do what most experts said was impossible.

THROUGH HIS FLAIR for promotion, Edison had created a demand for electric light that he could not meet. Most Americans still lived in sparsely populated areas, and the limited range of the Edison system left them in the dark. Westinghouse filled the gap. His high-voltage system delivered affordable electricity to homes and businesses outside the reach of the Edison system.35

When Edison wrote his memo to Edward Johnson, he admitted, "One thing that disturbs me is the fact that Westinghouse is a great man for flooding the country with agents and travellers." It was an astute assessment. Unlike Edison, Westinghouse shunned publicity and built his business not through the power of personality but through aggressive marketing. Although at first Westinghouse was content to promote his system in rural areas Edison could not reach, before long he was competing head-to-head with Edison for customers.36

In April 1887 Westinghouse moved into New Orleans, selling light at a loss in order to undercut Edison's operation. "They are robbing our business pretty badly," Edison's local representative complained. The numbers bore out the complaint, in New Orleans and across the country. Westinghouse sales, less than $200,000 in 1886, jumped to $800,000 the following year. By the fall of 1887, just a year after the first alternating central station went on-line in Buffalo, there were 68 Westinghouse central stations in operation or under contract. Edison, who had been in the business several years longer, had only 121. 37

At the end of 1887, Edison agents from across the country sent panicked letters to the head office in New York, begging for a way to compete with Westinghouse in smaller towns and the outlying districts of cities. "There is an enormous pressure everywhere for a system to cover distances," one agent explained. An agent in Tacoma was more blunt: "Are we going to sit still and be called cold fashioned,' 'fossils,' &c, and let the other fellows get a lot of the very best paying business?"38

Edward Johnson told Edison in December that he was going to Chicago to talk to the agents there and "stiffen them up a bit—they have been completely demoralized by Westinghouse." Johnson also warned Edison that until they came up with a new system to compete with Westinghouse's, they would have to accept the fact that they would "do no small town business, or even much headway in cities of minor size."39

IN NOVEMBER 1887, at the height of the panic over the Westinghouse competition, Edison received a letter from Alfred Southwick concerning the work of the death penalty commission. Southwick asked Edison to name "the necessary strength of current to produce death with certainty in all cases," and also to specify the best equipment for the task.

In reply, Edison told Southwick that he was opposed to capital punishment and refused to offer any advice.

On December 5, Southwick wrote again. "The question does not arise do we as individuals believe in capital punishment," Southwick told Edison, because the practice "has existed by law in all ages and in all nations and perhaps will for all time to come." This being the case, Southwick continued, "it appears to me that science and civilization demands [sic] some more humane method than the rope. The rope is a relic of barbarism and should be relegated to the past." The dentist also admitted that he was seeking more than technical advice from Edison. "The reputation you have as an electrician," Southwick wrote, would be invaluable in persuading the legislature to abolish the gallows and substitute electricity. Southwick closed by begging Edison, "Change your mind on the subject and give us the benefit of your knowledge."

The plea worked. Edison wrote a letter to Southwick on December 19,1887.

Your points are well taken, and though I would join heartily in an effort to totally abolish capital punishment, I at the same time realize that while the system is recognized by the State, it is the duty of the latter to adopt the most humane method available for the purpose of disposing of criminals under sentence of death.

The best appliance in this connection is to my mind the one which will perform its work in the shortest space of time, and inflict the least amount of suffering upon its victim. This I believe can be accomplished by the use of electricity and the most suitable apparatus for the purpose is that class of dynamo-electric machine which employs intermittent currents.

The most effective of these are known as "alternating machines," manufactured principally in this country by Mr. Geo. Westinghouse, Pittsburgh.40